Each saw is powered by a reliable 2-stroke gasoline engine equipped with a forced air supply system. The motors used by the manufacturer are distinguished by their reliability and ability to operate properly under variable and constantly high loads. A solid reserve of torque makes it possible to use saws to perform various household and industrial tasks.

To start the engine, each chainsaw is equipped with a manual starter with an easy start function. This makes it possible to easily start the tool at very low temperatures. The fuel mixture is ignited using a proprietary spark plug and electronic ignition. A durable clutch is responsible for transmitting torque from the internal combustion engine to the tire.

All parts and mechanisms of each saw are placed in a reliable plastic case. It is made of multi-layer polymers, which gives it the ability to withstand accidental impacts and falls from low heights. The manufacturer has provided free access to filters and other frequently replaced elements. This greatly simplifies the DIY repair of the Partner chainsaw.

The Partner is responsible for sawing wood in each chainsaw using a proprietary bar and chain. The saw set operates under the control of an oil pump, which automatically supplies oil as the chain moves along the bar. When the headset hits a nail or any other hard object, the inertial brake is activated, which makes the tool completely safe for the operator.

Each Partner model stands out for its ease of use. The front and rear handles of the tool are covered with high-quality rubberized material, which prevents the operator’s hands from slipping during operation. The tool's effective anti-vibration system dampens strong engine vibrations. This makes it possible to use a chainsaw both on the ground and at height without feeling tired during its operation.

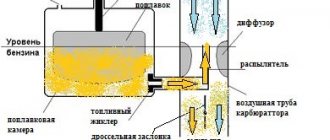

Carburetor design

The carburetor body of the Partner 340 chainsaw is made of aluminum alloy. It contains technological channels through which a mixture of fuel and oil and a diffuser move. The latter's task is to mix air with gasoline, thereby forming a combustible mixture.

The main elements of a carburetor include:

- fuel pump;

- main chamber with membrane;

- throttle and air dampers;

- screws (adjusting quality, quantity, idle speed);

- needle valve;

- fuel jets.

The chain is an important element of this type of equipment

The chain plays a very important role in a chainsaw, because it is the one that cuts wood. It is made from special steel. Chains come in different sizes and pitches. Although the chain is made of special metal alloys, sooner or later it becomes dull. How can we understand when the chain has become dull? Most often, a chainsaw user notices that the chain has become dull at the wrong time. This leads to poor performance and shortens the life of the chainsaw. The first signs of dullness are excessive vibration. Next, you can pay attention to cutting too slowly. In fact, you can even just look at the teeth of the saw and from them you can easily determine that it is dull.

To resume the operation of our chain, it must be sharpened. Sharpening can be done using a file ; there are also special machines that make sharpening better and easier. After the sharpening process, you should blow the chain with air and put it in oil. This is not a very simple process, because sharpening needs to be done at the right angle. The biggest mistake that inexperienced operators make is that they sharpen the chainsaw too deep. This sharpening too deep is the root cause due to which the strength of the link deteriorates.

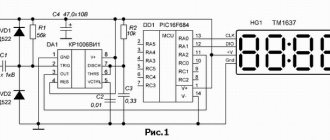

Do-it-yourself adjustment of the Partner 340 chainsaw carburetor

Initially, the carburetor on the Partner 340 chainsaw was adjusted by the manufacturer to operate in maximum power and efficiency mode. Additional adjustment may be necessary if traction characteristics deteriorate, which is possible due to sudden changes in air temperature or when filling the tank with other fuel.

Before adjusting, it is necessary to clean the chainsaw carburetor from dust and dirt (it is better to use a compressor with an air nozzle for these purposes).

The carburetor adjustment algorithm itself is performed as follows:

- To access the quality (marked H) and quantity (L) screws, the chainsaw has special holes on the left side. For convenience, you need to remove the protective cover.

- Tighten both screws all the way, and then unscrew each 1/5 turn.

- We start the chainsaw and warm up the engine for 5-10 minutes.

- Adjusting idle speed. To do this, tighten the screw T counterclockwise until the engine starts to operate as stably as possible. At the same time, make sure that the chain does not rotate (if it rotates, smoothly tighten the screw until it stops). If the engine stalls at idle, screw T needs to be unscrewed a little again.

- We adjust the engine power and mixture quality. Smoothly pressing the gas, we wait for the engine speed to increase to the maximum. According to the manufacturer, the maximum speed occurs at 11.5 thousand rpm (use a portable electronic tachometer for an accurate determination). If the speed does not increase, you need to turn screw L counterclockwise 1/8 of a turn. The maximum speed should not be allowed to exceed the recommended speed, because this can lead to ignition problems. In this case, turn screw H counterclockwise, thereby reducing the maximum speed

If you don’t have a tachometer at hand, you can determine if the carburetor is adjusted correctly visually. When the engine smokes heavily during operation (the mixture is rich), screw L must be tightened a little. When the engine warms up and picks up speed, screw H must be unscrewed counterclockwise by approximately ¼ turn.

Sometimes it happens that adjustment does not help. The engine does not develop speed or stalls. The cause may be a clogged filter or air intake. It is enough to clean and re-adjust the carburetor if necessary.

Model specifications

The Partner chainsaw has higher factory parameters compared to other amateur tools.

These include:

- engine power – 1.96 liters. s./1.44 kW;

- cylinder working volume – 35 cm3;

- engine speed at idle/maximum speed – 3300/13500 rpm;

- recommended tire length – 35 cm;

- the pitch of the cutting chain used is 3/8 “;

- chain rotation speed – 22 m/s;

- sound impact – 105 dB.

The Partner P340S chainsaw stands out for its modest weight, which, with fully filled tanks and installed accessories, is 4.8 kg.

Chainsaw carburetor repair Partner 340

A frequent malfunction of the carburetor of the Partner 340 chainsaw is associated with a fuel leak (loss of tightness). First you need to check the integrity of the gasket between the carburetor and the engine crankcase. If everything is fine with it, then the problem is the carburetor is tight.

To check the tightness you will need a pressure gauge. The inlet of the measuring device is placed on the fuel supply hose. Then, using a bulb, a certain amount of air is pumped into the carburetor. The device readings must be at least 0.4 bar. After some time, the pressure is measured again. If it falls, the carburetor needs repair. This may be due to the following reasons:

- malfunction of the control membrane (in the main chamber) or the fuel pump membrane. The tightness here is broken due to the loss of the shape of the membranes or the appearance of holes in them. This problem occurs due to prolonged operation or overheating of the carburetor;

- the needle does not completely close the valve, because Low-quality fuel contributes to its clogging. In addition, over time, the geometry of the needle cone changes due to wear. Let’s also add here the insufficient mobility of the needle valve lever on its axis when it is worn out or bent. And its spring lost its elasticity.

- the plane of the petal valves in the fuel pump is disrupted. As a result, they are poorly pressed against the supporting plane and, as a result, the seal of the carburetor is broken (the pump loses performance).

A membrane chamber cover is installed on the side of the carburetor of the Partner 340 chainsaw. Through the hole in it, dirt gets inside the carburetor. When it accumulates, the membrane rises and presses on the needle valve lever. As a result, the lever does not completely close the fuel channel, which leads to over-enrichment of the mixture.

It is necessary to remove and clean this cover from accumulated dirt more often. Fortunately, its design allows this to be done easily and quickly (you need to unscrew the four screws on the side of the carburetor).

All of the above malfunctions, as a rule, have 2 main causes: engine overheating (lean mixture) and carburetor clogging (insufficient fuel cleaning). Both problems can be solved by correct adjustment and timely cleaning of the carburetor and air filter. Don’t forget about a high-quality gasoline filter element.

When cleaning, special attention should be paid to the mesh; the slightest clogging of it leads to unstable operation of the chainsaw.

Failed parts can be replaced by purchasing the appropriate repair kit.

Disadvantages of the saw

On the Russian market you can find low-quality fakes of the Partner 350 chainsaw, which is not only additional evidence of its popularity, but also harms the brand as a whole. And other models of this brand are popular with summer residents and farmers.

If you are ready to consider the Partner 350 as your home tool for sawing thin trees, trimming branches and other not very voluminous work, then you should also know the disadvantages, most often mentioned by their owners:

1. The vibration damping system is not of very high quality, as a result of which the hands get tired quite quickly. But, considering that this is a household tool that requires 15–20 minutes of rest every 20–25 minutes of work, you can put up with this drawback.

Price range and workshop repair guarantee

If you have a chainsaw, then you should always have spare parts with you so that you can carry out repairs on the spot if necessary. Amateurs should never try to repair a chainsaw themselves. Improper repairs can lead to more complex damage. There are many services for repairs - try going there. Repairs are carried out within a certain time frame. In good companies, minor repairs are carried out in just two or three days, but if the breakdown is serious, you will have to wait about a week. When choosing such a service, always pay attention to the warranty. It should be both for the spare parts themselves and for the work!

The price for repairs varies depending on the complexity of the repair. Some places can offer you repairs at fairly cheap prices. Low prices don't mean bad quality sometimes. And you may come across an “office” that will offer to repair your gas-consuming equipment for only four hundred rubles (or around that).

Don't be immediately scared. Study the reviews and perhaps you will come across a really good workshop where you will get high-quality repairs at quite attractive and beautiful prices. Good luck in creating any of your tasks using chainsaws and take care of yourself when working with the tool. Follow safety precautions and everything will be fine.

Partner chainsaws are an excellent example of truly high-quality tools at a low price. The range of chainsaws from the Partner company is truly huge, which allows every buyer to choose a model with suitable characteristics.

Basic faults

The following types of faults are typical for the Partner chainsaw:

- engine malfunctions, such as problems with ignition, fuel supply, or exhaust and piston-cylinder systems;

- failure of carburetor components, such as the clutch assembly, chain brake or lubrication system.

The causes of failures can be different, but most often it is improper operation, insufficient amount of oil or poor-quality fuel mixture.

How to remove and disassemble

Correcting malfunctions of a chainsaw carburetor is possible only after this part has been removed. And to do this you need to disassemble the chainsaw itself. This work will have to be done in the following sequence:

- Remove all components in strict order. First the chain brake cover and saw set, then the top cover, saw handle and starter.

- After these parts are removed, you need to clean the saw using a compressor with an attachment.

- After this, you need to plug the inlet window, since there is a risk of dirt and foreign objects getting inside.

Cleaning

You can clean the carburetor in different ways, most often it is done with air. The sequence of work is as follows:

- Unscrew the top bolt of the part cover.

- Remove the valve gasket. After this, you need to blow the mesh with compressed air. In this case, you should not blow closely, but at a short distance.

- There is no need to remove other parts of the carburetor. You can use a special liquid to clean the surface.

- Now the carburetor needs to be assembled, attaching the parts in the reverse order.

Other renovations

For the Partner chainsaw to operate efficiently, other repairs may be required. It is not difficult to carry out repairs with your own hands.

The most common problem is the lack of:

- sparks in the spark plug (you need to either clean the gap on the spark plug, or replace the coil or flywheel with similar parts);

- fuel supply (the cause may be a clogged hose or fuel filter);

- air supply (air filter needs to be washed).

Diagnosis of problems

Before you begin repairing the device, it is necessary to conduct a high-quality diagnosis of the saw. To determine the cause of the breakdown, you need to familiarize yourself in detail with the design of the Partner 350 chainsaw. Failure of the saw can be caused by damage to any of its parts, but the most common reasons are the following:

Main components of chainsaws Partner

- ignition element failure;

- damage to the fuel system;

- failure of the support shaft.

Each of these defects is accompanied by certain “symptoms” that will help accurately diagnose the problem.

Candle testing

Checking the spark in the Partner 350 chainsaw is carried out by removing this element from the saw and then connecting it to a high voltage wire. Correct operation of the spark plug is always accompanied by the release of a spark, so this parameter will be easy to track.

Miscellaneous spark plug failures

Problems in this area can be caused by the following damage:

- malfunction of the spark plug itself;

- weakening of contact in the wired network;

- broken ignition button;

- lack of ventilated passages between parts in the ignition system.

Adjusting the mixture and spark plugs of the Partner 350 chainsaw

Fuel system testing

Fuel is the main source of energy for the operation of the saw, so problems in the area of fuel processing can cause breakdowns. Checking the fuel in the Partner 350 chainsaw is the first stage of diagnosis. If the tank is full enough, you should carefully inspect the spark plugs. If the spark plug is dry, fuel is not passing through it. After discovering this fact, you need to check all elements of the system, starting with the carburetor.

Adjusting the carburetor of the Partner 350 chainsaw

The cause of the malfunction is as follows:

- failure of the engine cylinder-piston group;

- overheating of the piston and cylinder;

- foreign particles entering the engine.

If after a test fuel supply the Partner 350 chainsaw turns on, then the problem lies in other elements of the saw.

Chainsaw carburetor Partner 350

Bearing check

The support shaft of the saw should be checked for stability through the crankshaft bearings. The piston rod and bearings must be firmly attached to the frame. If, when the piston moves, gaps are observed between individual parts of the mechanism, then these elements must be replaced.