Motor malfunctions

Motor problems can be indicated by spontaneous stopping, lack of power levels and interruptions:

- If the unit is equipped with a gasoline engine, then in the process of searching for problems you need to check whether there is fuel in the tank, what is the condition of the special damper of the device, how the ignition is started, whether fuel flows into the carburetor.

- To check the final condition, you need to fill a special chamber using one button. In this case, fuel should pour out of the hole in the lid of this chamber. If gasoline flows in a small stream or is not visible at all, this may be a problem with a dirty fuel filter or a clogged valve in the device. The recommendation for repairing this walk-behind tractor in this case advises cleaning the valve or filter.

Why won't the walk-behind tractor start?

Malfunctions with this problem can be very different and affect different walk-behind tractor systems. First of all, you need to check the availability of all necessary spare parts and accessories, especially if the walk-behind tractor is new or, conversely, has not been used for a long time. Before starting work, carefully check all fasteners, connections and cables and their movement. Make sure there is oil in the crankcase and enough fuel in the tank. Do not start the walk-behind tractor if the cable is difficult to pass through - this may indicate twisting of the harness threads.

After the winter holidays, the most common reasons for the inability to start a walk-behind tractor are oxidized contacts, broken electrical wiring insulation, wear and tear of fuel and oil during inactivity.

In addition, the common reasons that the walk-behind tractor starts to turn on poorly are the following:

- Breakdown and/or clogging of the carburetor and its components;

- Malfunctions in the ignition system (the most common malfunction);

- Low level of lubricant or its complete absence in the gearbox;

- Problems with the cylinder.

Problems with fuel flow

The condition of the spark plug may indicate that fuel is entering the engine cylinder. It must be checked by unscrewing it from the cylinder cover, having previously connected the wire. If the spark plug is dry , this means that fuel is not entering the cylinder. If you manage to find out that it passes into the carburetor, then the main reason for the engine failure to start may be a clogged filter mesh of the device.

Sometimes clogged jets lead to serious problems. If all conditions are met, the instructions for repairing the walk-behind tractor provide the possibility of removing the carburetor, disassembling and cleaning the part. These manipulations can be performed without visiting a specialist .

Checking the condition of the spark plug

The recommendation for repairing the unit, which you should study before carrying out work, will help you understand how to inspect the condition of the spark plug.

If it is wet, then gasoline passes into the cylinder. Failure to start may be due to an excess of the special mixture. If the surface of the spark plug is heavily covered with gasoline, you need to dry the cylinders, bleed the engine with the starter, leaving the spark plug in the inverted state.

Before this manipulation, the master must close the fuel supply. The spark plug may become clogged with carbon deposits, but it can be cleaned with small sandpaper and gasoline. The main thing is to analyze what size the gap between the electrodes will be. If necessary, it is worth making adjustments, following the rules presented by the manufacturer in the instructions. The gap size should be 0.8 mm.

How to check the ignition coil on a walk-behind tractor?

Most often, this important element of the ignition of a walk-behind tractor is checked using a known working test sample. If during testing it turned out that after installing the sample everything began to work as it should, then the standard ignition coil of the walk-behind tractor is faulty.

However, not everyone has a test sample at hand. If it is not there, then you need to try to check the built-in coil in other ways. Before this, you need to eliminate any damage that may occur in the start button and high-voltage wiring. In addition, the user must carefully study the electrical diagrams, which indicate the location of the ignition system elements.

Further verification methods include:

- measuring the resistance of the built-in ignition coil. It is worth noting that it is not always used by users of agricultural machinery. First, the operator must know the exact parameters of the resistance created by the standard coil. Secondly, in addition to the inductor coil, the design of the ignition system contains semiconductor components required to generate the required electrical impulse. Problems with all these elements can only be identified when they are heated. To properly check the ignition coil, you will need to disconnect the cap and the standard armored wire from it. Knowing the exact resistance parameters of the built-in element, the operator will be able to understand which part of the system is faulty;

- checking the spark being created using a special device - it must be connected to the point where the electrical circuit is broken between the high-voltage wires of the standard coil and the spark plug;

- testing the coil using a spark plug built into the design - to do this, you need to unscrew the built-in spark plug and carefully place its body against the cylinder. Then you need to pull the starter handle and pay attention to the spark that forms between the factory contacts of the spark plug. It should be noted that this method of checking an existing coil is approximate - in this case the spark plug is not under load, which is why there is no compression in the internal combustion engine cylinder. As a result, the standard engine flywheel will rotate faster.

Carburetor problems

The carburetor of the walk-behind tractor may be dirty, and in many cases it may not be adjusted correctly. If this happens, then such a unit is removed and cleaned, its adjustment is carried out, which should be provided for by the rules:

- Another problem may arise, which is expressed in the fact that air does not flow into the carburetor in full. This can happen due to a clogged air filter; ultimately, the fuel mixture comes out over-rich. During use, you should periodically clean the special filter to prevent such problems from occurring. However, if the equipment is used in very dusty conditions, more frequent cleaning may be necessary.

- You should consider the condition of your air filter. Depending on the material in the base, it is necessary to rid the part of dirt using one of the effective methods. If the carburetor of the device begins to receive air in small quantities, then it may be necessary to clean the paper filter, which is done by lightly tapping or blowing.

- If you have a foam filter, you can wash it and then dry it completely. The mesh filter can be cleaned with a vacuum cleaner. Such parts have their own expiration date; as soon as it is used up, the unit will need to be replaced.

So you have learned how to repair the Cascade walk-behind tractor.

Specifications

The technical characteristics of the Cascade MB-6 walk-behind tractor are as follows:

- Engine type: 1-cylinder, 4-stroke carburetor, air-cooled.

- Power - 6 hp

- Working volume - 317.4 cm³.

- Cylinder diameter - 76 mm.

- The volume of oil in the engine is 0.9 l.

- Crankshaft rotation speed - 2750-3250 1 rpm.

- The type of running system is wheeled in a 2x2 pattern.

- The clutch is a V-belt drive.

- Belt size for walk-behind tractor Cascade:

- forward belt - A-1180 internal IV GOST 1284.1-89;

- reverse belt - A-1400 IV GOST 1284.1-89.

- Gearbox - 2-speed.

- Gearbox seals:

- 941/20 GOST 4060-78 - 7 pcs.;

- 942/30 GOST 4060-78 - 2 pcs.;

- 306K GOST 8338-75 - 2 pcs.;

- 942/15 GOST 4060-78.

- Number of gears:

- forward travel - 2;

- reverse gear - 2.

- The working width with the KMB 1.002.000 cultivator is 930 mm.

- Processing depth - 100-200 mm.

- Operating temperature - -5... 35°C.

- Overall dimensions - 1500x600x1150 mm.

- Machine weight - 103 kg.

The Cascade MB-61 walk-behind tractor has the following design features:

- The MB61-102, 104 units are equipped with Vanguard 7.5 HP type 0035A1 engines from Briggs & Stratton (USA), designed for operation in extreme and difficult conditions. This engine has a displacement of 205 cm³.

- MB61-122, 124 units are equipped with Intek I/C 6.5 HP (Briggs&Stratton) general-purpose motors with high performance, reliability and endurance.

- MB61-142, 144 have Intek Pro 6.5 HP engines with dual Dura-Bore barrels for long lasting performance and a float carburetor for consistent easy starting.

- MB61-152 and 154 with Vanguard 7.5 HP engines type 0127E1.

The features of the Cascade MB61 distinguish it from the agricultural equipment Cascade MB6. Motorized vehicles are efficient, reliable and well-built, but the cost of units with American and Japanese engines is much more expensive. Therefore, walk-behind tractors with domestic engines are more popular among farmers.

MB-1 walk-behind tractor: operating instructions and do-it-yourself fault repair

Special equipment, such as a walk-behind tractor, is very useful in farming. Due to the fact that walk-behind tractors are maximally balanced in terms of price, cost and performance ratio, they benefit greatly from both tractors and other special equipment.

With its help, you can perform a large number of different operations that take a lot of time and require a lot of effort, using manpower and simple equipment. All areas where a walk-behind tractor can be used no longer evoke disgust and reluctance to work.

In fact, all the work comes down to management - you just need to be present as a driver.

This applies to both modern technology and older models of walk-behind tractors, because over the decades their design, in general, has changed little - weight has decreased, the variety of models has increased, and more advanced materials are used for manufacturing.

But the frame, engine placement and control method remained the same , the attachments, in fact, remained unchanged, the difference can only be external, in insignificant details.

Therefore, the good old walk-behind tractors, whose service life has already exceeded thirty years, are still in service, and do their job year after year. But every year they increasingly need repairs and replacement of parts and components.

After all, any equipment wears out and needs repair. And you should pay great attention to this if, for example, you make long trips with a loaded trailer. A seized hub won't be a big deal, but a malfunctioning part of a more complex part like the transmission will be frustrating, to say the least.

Therefore, you should familiarize yourself with all the “symptoms” of breakdowns in order to diagnose and prevent a malfunction in time.

Description

Motoblocks "Cascade" have proven themselves as reliable farmer's assistants.

These are productive, durable machines capable of working with a full range of mounted implements, performing the functions of a cultivator, plowing machine, mower, snow blower and many others. In order for the walk-behind tractor to work without failures for many years, you must follow the instructions during its operation.

Timely maintenance of the walk-behind tractor is also important. For the Cascade, the maintenance schedule is the same as for any other household walk-behind tractor:

- scheduled maintenance: once a season, at the end of seasonal work and before it begins (at the beginning and end of spring, at the beginning and end of summer, etc.);

- regular mini-inspection - every day upon completion of work and turning off the walk-behind tractor, as well as an external inspection in order to identify damage, chipped paint, etc.;

- winter storage - is allocated to a separate maintenance category, since it involves draining all fuels and lubricants and storing the walk-behind tractor in a room with a positive temperature; upon completion of the winter “preservation” the unit is refilled with fuel and lubricants;

- annual engine prevention (detecting faults, eliminating them, maximizing the service life of the motor and other key components of the unit).

Next, we will look at the basic rules and requirements for fuels and lubricants, the process of starting and running in the Cascade walk-behind tractor, as well as the most common malfunctions of these devices.

Repair instructions

In order to restore a faulty walk-behind tractor "Luch" MB 1, the repair instructions will definitely not be superfluous. By instruction we mean the same booklet that was supplied with all equipment produced in Russian factories.

But, as you know, without experience it’s quite difficult to figure out what’s broken, not to mention the design of the walk-behind tractor itself. But a person who is experienced in repeated repairs will be able to identify the problem without wasting time and also quickly fix it.

A good example of the level of knowledge and how well a person navigates a given walk-behind tractor is the reason why fire occurs from the exhaust pipe. The reason could be very simple - a defect associated with partitions in the muffler, which could burn out or simply fall off.

If the walk-behind tractors "Luch" MB 1, Cayman, Patriot, Texas, Foreman, Crosser, Viking, Forza do not start , then there may be more than enough reasons for the problem, starting from the presence of gasoline in the tank before it enters the carburetor, or if the belts are not in order or there are problems with their size...

In the first case, it is necessary to carry out simple manipulations: you need to fill the float chamber until the fuel begins to pour out from the hole in the lid. Or, check how gasoline flows by disconnecting the fuel hose from the carburetor.

A thin stream means that one of the filters is clogged - the fuel filter inside the tank, or the air filter in its lid. In this case, to restore operation it is enough to clean them, or, in extreme cases, replace them. But if you have any ignition problems, you should still check the spark plugs.

It needs to be unscrewed and inspected - if the spark plug is dry, it means the mixture is not getting into the cylinder. Otherwise, the problem is in the carburetor itself.

Ignition coil

The ignition coil of the Luch walk-behind tractor is an important part of the ignition system.

With its help, a low-voltage impulse, using the primary winding, is converted into a high-voltage one, which is supplied to the spark plug using a wire. Essentially, this is a sealed pulse step-up transformer, which, although manufactured using sophisticated technology, does not last forever.

there is no spark during the start , then there can only be one option - replacing the old coil with a new one, since it is not possible to repair it.

Carburetor

One of the vulnerable parts for which the Luch walk-behind tractor is known is the carburetor. It is best to repair a faulty carburetor after first familiarizing yourself with its diagram, since without disassembling the engine it will not be possible to even inspect it.

If you have already read all the necessary documentation and are ready to begin the actual repair, first you need to check whether everything is in order with it, as follows: after dismantling, you need to apply a stream of air through the fuel supply fitting when the part is in the working position.

A garden sprayer is an important and highly effective tool in the competent organization of work in the garden, allowing you to protect the plant, timely fertilize and carry out preventive maintenance. Here's how to make a sprayer with your own hands.

Snowmobiles are an indispensable form of personal transport in the northern regions. Yamaha snowmobiles - Japanese quality for harsh winters.

Those who sow lawn grass by hand know how difficult it is to achieve uniform seeding. By clicking on the link, you will become familiar with the different types of lawn seeders.

This operation must be repeated by turning the carburetor around and blowing into it from the other side. In the first case, the air should pass freely, in the second, it should not pass at all. If in both cases everything happens as described above, then the valve is working properly and fuel is flowing properly.

If air does not pass through, it means the carburetor is clogged and needs to be cleaned .

To do this, remove the cover over the fuel supply valve and pour cleaning agent into all channels. Having allowed it to cope with the contamination, the carburetor needs to be thoroughly cleared of dirt. Compressed air from a compressor is perfect for this.

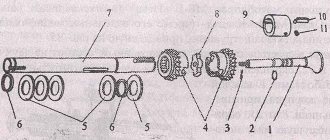

Gearbox

Another cause of malfunctions is the gearbox of the Luch walk-behind tractor. Although most often it is the consumables that wear out, such as the gearbox seal of the Luch walk-behind tractor. It is replaced if a leak appears.

Running the gearbox dry, without oil, can lead to consequences in the form of rapid wear of the components - the gearbox will very quickly fail. The oil seal is replaced quite simply with a screwdriver; you just need to remove the cap and boot; there is no need to drain the oil.

Engine

The engine is the main unit of the walk-behind tractor , which most often needs repair.

It is with it that all the main difficulties associated with operation and work arise.

Repairing the engine of a walk-behind tractor Luch, Sadko, Don, Huter, Profi, Plowman, Champion with your own hands is quite possible, but it is still better not to start without prior preparation in the form of reading the instructions, especially if you have not done this before. In order to successfully repair the MB 1 “Luch” walk-behind tractor by disassembling the engine, the video will be very useful.

There is no spark on a walking tractor.

This malfunction is directly related to a malfunction in the ignition system. Ignition system failures include faulty magnet, alternator, wiring, cap and spark plug. If the spark disappears or becomes weak, the only reason is the cap and spark plugs. First of all, remove the spark plug and assess its condition. If necessary, wipe the coal off it and fry it over the fire (if it is not possible to immediately replace it with a new one).

Install the spark plug and try to restart the walk-behind tractor. If there is still no spark, check the contact of the cap with the center electrode of the spark plug. The gap between the cover and the electrode is checked with a special sensor and should be 0.8 mm.

A few words about how to avoid such situations. First of all, always strictly follow the recommendations given in the instructions. If you follow them, your walk-behind tractor will last much longer.

In addition, in order to avoid problems with starting the walk-behind tractor, it is important to know which engine cycle is intended for this model (which is also indicated in the instructions). For example, walk-behind tractors Neva (MB-1 and MB-2, which are most often equipped with a Subaru engine), Bison, Salute, Agro, Cascade are equipped with a four-stroke engine. And Mole walk-behind tractors have a two-stroke engine. The value of this information to owners is that it indicates how to properly refuel the equipment. For models with a two-stroke engine, it is necessary to prepare a special fuel mixture, for which gasoline and oil are mixed in a certain proportion. For walk-behind tractors with a 4-stroke engine, oil and gasoline are poured separately. But don't forget to also monitor their quality!

You should also always remember the correct procedure for starting the walk-behind tractor. For example, for a Krot walk-behind tractor or any other gasoline-powered unit, startup is performed in the following sequence:

- Open the gas valve.

- Set the fuel suction lever to start mode (throttle).

- With the ignition off, the engine is checked several times with a kick starter.

- Start the walk-behind tractor and move the fuel suction lever to the “Work” position.

The situation is somewhat more complicated with diesel engines of Neva, Bison, Salute, Cascade or Agro walk-behind tractors. First you need to supply air from the fuel system. To do this, open the fuel supply valve, unscrew the fuel hose connection until fuel appears, tighten the connection and bleed the injectors. If after the manipulations the walk-behind tractor does not start or start, but thick white smoke leaves the muffler, it is necessary to urgently change the oil.

READ Motoblock Forza Or Bright Which Is Better

After a long period of inactivity, the diesel engine must be started according to the following algorithm:

- Open the gas valve.

- Check for fat.

- Turn on the ignition.

- Unscrew the throttle slightly, no more than halfway.

We also suggest watching a video on how to properly start a walk-behind tractor:

Source

With the arrival of spring, difficult times begin, when every farmer must take care of his plot, garden and vegetable garden. This is tedious digging, weeding, garbage removal, grass mowing. Until recently, everyone managed without the help of technology, but today you can maintain your health and use such universal and practical equipment as the Cascade walk-behind tractor.

In our country, farmers value the Cascade walk-behind tractor for its practicality, versatility and ease of use. However, this method requires careful handling and careful maintenance. If a breakdown occurs, you must, if you do not repair your device, at least determine the cause of the malfunction.

If the Cascade walk-behind tractor does not start, there may be many reasons for this. Damage may be caused by the engine, carburetor, or clogged spark plugs. We will try to figure out this problem, after which you can find out the cause of the failure and fix it.

Remember that timely repairs will allow your walk-behind tractor or walk-behind tractor to last much longer. Due to lack of time or desire to fix something, the result is that the device simply fails completely. Our recommendations will help solve the problem when the equipment cannot be started.

The unit does not work or is unstable

It’s logical to start analyzing possible breakdowns with the following situation: the “Cascade” walk-behind tractor starts up and immediately stalls. Or it stopped starting altogether. The most likely reasons are:

- excess gasoline (this is indicated by the humidity of the candle);

- in models with an electric starter, the problem often lies in the battery being discharged;

- the total engine power is insufficient;

- There was a problem with the muffler.

The solution to each of these problems is quite simple. So, if a lot of gasoline is poured into the gas tank, be sure to dry the cylinder. After this, start the walk-behind tractor using a manual starter. Important: before this, the candle must be unscrewed and also dried. If the manual starter works but the electric starter does not, then the battery needs to be charged or replaced.

If the engine does not have enough power to operate normally, it must be repaired. To reduce the likelihood of such a breakdown, you must use only impeccable quality gasoline. Sometimes the carburetor filter becomes clogged due to poor fuel. You can clean it, but it’s better - we repeat again - to perceive such an event correctly and stop saving on fuel.

Sometimes adjustment of the KMB-5 carburetor is required. Such devices are installed on lightweight walk-behind tractors. But this does not diminish the importance of their work. After repairing a failed carburetor, only suitable grades of gasoline should be used to flush individual parts. Attempts to remove contaminants using a solvent will result in deformation of the rubber parts and washers.

You need to assemble the device as carefully as possible. Then bending and damage to parts will be avoided. The smallest parts of carburetors are cleaned with a thin wire or steel needle. Be sure to check after assembly whether the connection between the float chamber and the main body is tight. You should also evaluate whether there are any problems with the air filters or whether there are fuel leaks.

The actual adjustment of the carburetors is carried out either in the spring, when the walk-behind tractor is rolled out for the first time after the “winter vacation,” or in the fall, when the device has already been working for a very long time. But sometimes this procedure is resorted to at other times, trying to eliminate the shortcomings that have arisen. The typical sequence of steps is:

- warming up the engine in 5 minutes;

- tightening the adjusting bolts of the smallest and largest gas to the limit;

- unscrewing them one and a half turns;

- setting the transmission levers to the smallest stroke;

- setting low speeds using the throttle;

- unscrewing (slightly) the throttle screw to set the idle speed - with the engine running continuously;

- stopping the engine;

- assessment of the quality of adjustment by a new start.

To eliminate errors in the process of setting up the carburetor, you must check each step with the operating instructions. When the work is done normally, there will be no extraneous noise in the motor. Moreover, failures in any of the operating modes will be excluded. Then you will need to observe the sounds that the walk-behind tractor makes. If they differ from the norm, a new adjustment is needed.

Useful information about the Neva MB-2k walk-behind tractor with the DM-1k engine

I decided to put in order the garden walk-behind tractor my parents bought about 7 years ago. The device began to stall and behave very badly. Well, it’s not surprising, during these 7 years no maintenance was done to it, only a year ago I rebuilt and lubricated the starter block, since the rope was no longer wound up at all.

I went online and realized that they sell walk-behind tractors on every second website, but it’s hard to find meaningful information on the content. Therefore, I am sharing what I managed to dig up, maybe it will be useful to someone.

To begin with, it turned out that my father had been pouring the wrong gasoline from the very beginning. The drygatel is designed for the A-76, and the lily is the A-95. But it could have burned out. On the walk-behind tractor itself there is no information about the type of gasoline, but there is a tag with the engine model and power. Here is a sign taken somewhere on the Internet, by which you can determine the brand of gasoline.

Next about the oil. The oil obviously needs to be changed sometimes. There is oil in the engine and gearbox.

The engine manual, which I did find, lists the oils: M10GI, M12GI, M53/10G1, M63/12G1. Horrified by the abbreviations, I rummaged through the forums. In principle, everyone uses ordinary modern automobile oil. Only traditionally there is debate about the type of oil - mineral or synthetic.

I took VAMP 10W-40, about 120 UAH for 4 liters at Epicenter (the amount of oil in the crankcase is 1.3 liters). Oil viscosity according to SAE is selected based on the air temperature at which the unit is operated.

The gearbox oil in the instructions is stated verbatim: gearbox oils according to GOST 23652-79. Read whatever you like. In the same Epicenter there was only one oil, the label of which clearly indicated gearboxes in the area of application - VAMP TAD-17i. Costs about 50 UAH for 3 liters. Crankcase volume – 2.2 liters.

By the way, during the process of overhauling the carburetor, it was discovered that a break-in plate was installed between the carburetor and the intake manifold, which does not allow the engine to be given full throttle (it reduces the intake diameter). The network recommends not removing the plate.

Almost all useful information and adjustment methods are indicated in the instructions for the walk-behind tractor and engine, which I highly recommend reading. But, firstly, you need to find them, and secondly, find the time to read them. It should be noted that in 7 years of living in a shed, nothing particularly critical has happened to the walk-behind tractor, so, in my opinion, it’s not worth worrying about all the service points indicated in the instructions - there’s too much of everything there.

The following is information from the instructions, which I noted as important for myself.

- When installing the cultivator, the sharp edges of all knives must be installed in the direction of movement of the walk-behind tractor.

- If the pneumatic wheels slip, it is recommended to attach additional weights to the walk-behind tractor, up to 80% of the weight of the walk-behind tractor.

- The permissible work time of one operator per working day should not exceed two hours.

- The service life of the walk-behind tractor is 5 years (I hope it will last 25).

- When selling a walk-behind tractor, there must be a spare spark plug (A-11, SI-12RT), belt, and gasket.

- One of the main conditions for successful engine operation is the quality and purity of the gasoline used. In the vast majority of cases, engine failures are associated with clogging of the carburetor metering jets (channels) with dirt and deposits of resins released from the fuel.

- To reduce noise and direct exhaust gases, a muffler is installed on the engine, the cover of which with the exhaust window has three fixed positions (why this is necessary is not explained, maybe this is a typo from the next paragraph about the fuel valve).

- To stop the engine, a STOP button is provided, which closes the electrical ignition circuit to ground (when the throttle is moved to the STOP position) and thus stops sparking on the spark plug.

- When starting a cold engine, close the choke completely. When starting a warm engine, do not close the air damper.

- When starting the engine, set the throttle to one-quarter to one-eighth of full travel. Fill the float chamber by pressing the plunger and hold it until fuel appears from the drainage hole.

- After starting, set the throttle to XX, warm up the engine at XX for two to three minutes. During warm-up, do not set the maximum speed, otherwise the engine may seize.

- Do not clean the carburetor calibrated holes with metal objects.

- Oil or fuel must not come into contact with the air filter.

When ordering spare parts, it is advisable to know their code. Many codes can be found in the instructions if you look at them carefully. For example, my fuel supply valve broke, it was not easy to find. Found at the VDNKh company, phone number: (094) 925-71-53.

Before this, a lot of time was spent searching in other offices, and you won’t be able to come and buy in this one either. You need to know the part number and make an advance payment. We also relied on the office’s experience in service and they gave us a liter of expensive synthetic motorcycle oil, which I, naturally, did not pour into the walk-behind tractor. Maybe it will be useful as a thread in a motorcycle. In general, everything is in the best traditions of domestic service