By reading the numbers on the product, a specialist can determine the size of the pipe, its type, steel grade, strength, manufacturer and some other parameters of the product.

The marking of special purpose steel pipes contains additional markings.

Special purpose products include:

- Pipes made of alloy steel grades;

- Stainless;

- Drilling;

- Main gas pipelines;

- Boiler rooms, etc.

What can be used for marking?

For marking the following can be used:

- Indelible paint.

- Electrographs.

- Electric inkjet printing devices.

- Branding.

No data is applied to some types of pipe products, and for those that must have markings, the marking method is selected depending on the grade and main parameters of the pipe.

Mitral valve insufficiency - symptoms and treatment

Publication date August 24, 2020 Updated April 26, 2021

Mitral valve insufficiency is a defect in which, due to incomplete closure of the valve leaflets, reverse flow of blood (regurgitation) occurs from the left ventricle into the left atrium [8].

The pathology is manifested by weakness, dizziness, a feeling of lack of oxygen and fatigue, since the disease disrupts the blood supply to the brain. Without treatment, severe mitral valve regurgitation can cause heart failure and abnormal heart rhythms (arrhythmias).

Causes of mitral insufficiency:

Mitral insufficiency is in first place among all acquired valvular heart defects. The pathology rarely occurs in isolation; it is often combined with mitral stenosis and aortic valve defects. The prevalence of mitral valve insufficiency in combination with mitral valve prolapse in the population is 2–6% [15].

If you notice similar symptoms, consult your doctor. Do not self-medicate - it is dangerous for your health!

Symptoms of the disease:

- general weakness and dizziness;

- cardiopalmus;

- shortness of breath that occurs even with minor exertion;

- aching, pressing and stabbing pain in the heart, which can radiate to the left shoulder and arm;

- “dissatisfaction with inhalation” - the patient takes one breath after another, but feels a lack of air and panics;

- frequent colds;

- bleeding from the nose and gums, prolonged menstruation in women;

- memory impairment, panic attacks, anxiety, suspiciousness (this is due to a lack of oxygen supply to the brain, impaired metabolic processes and a slowdown in the transmission of impulses between neurons);

- trembling in the body;

- frequent appearance of bruises;

- discomfort when being in a closed and stuffy room, fainting is possible;

Constant anxiety often leads the patient to consult a psychiatrist or neurologist. It is very important to prevent such patients from participating in professional sports, since excessive stress can cause death during training and competitions.

In patients with mitral regurgitation during pregnancy, interruptions in the functioning of the heart are possible, especially undesirable during childbirth, but generally pregnancy proceeds without complications [3][4].

The human heart consists of four chambers: the right and left atria, the right and left ventricles. Between the atria and ventricles there are inlet valves - tricuspid and mitral. At the exit from the ventricles there are exit valves similar in structure - pulmonary and aortic.

Valves have flaps that open and close during heartbeats. Sometimes the valves do not open or close properly, preventing blood flow.

The mitral valve has two leaflets and opens to allow blood to flow into the left ventricle. The valve then closes to prevent blood from flowing back into the left atrium. In mitral regurgitation, this valve does not close tightly, causing blood to flow back into the left atrium.

Chronic deficiency of magnesium ions plays an important role in the pathogenesis of primary or congenital mitral valve insufficiency. A lack of magnesium leads to the fact that fibroblasts produce defective elastin, collagen and fibronectin, as well as to disruption of the properties of enzymes that regulate collagen metabolism. As a result, the structure and functions of the connective tissues of the heart are disrupted [14].

The secondary form of mitral regurgitation occurs as a result of previous diseases and injuries.

With pathology, there is expansion of the left ventricular cavity, flexion of the mitral valve leaflets, dysfunction of the muscle papillae and rupture of the chordae tendineae connecting the valves with the papillary muscles.

Sometimes the cause of secondary mitral valve insufficiency is calcification of the valvular fibrous ring. Mitral annulus calcification is a chronic degenerative process in which calcium deposits in the valve annulus.

When calcified, the mitral annulus becomes thicker and less flexible. Although mitral valve calcification was initially considered an age-related degenerative process, evidence is accumulating that its development is facilitated by atherosclerosis and genetically determined disorders of calcium-phosphorus metabolism [16].

There are three periods during the course of the disease:

- Compensation of the valve defect by increased work of the left atrium and left ventricle. This is a long period of good health, but already at this stage the first characteristic symptoms begin to appear: weakness, dizziness, frequent colds, a feeling of lack of air, interruptions in heart function, shortness of breath.

- Development of venous mitral insufficiency. Patients complain of shortness of breath and rapid heartbeat. With intense physical activity, attacks of severe shortness of breath and hemoptysis are observed.

- Shortness of breath decreases, but the patient feels heaviness in the right hypochondrium. Swelling appears, the amount of urine decreases, and the neck veins swell. Hemoptysis intensifies, pulmonary edema develops, cardiac arrhythmias (atrial fibrillation and supraventricular extrasystole) and thromboembolic complications occur.

Taking into account the severity of reverse blood flow, four degrees of mitral regurgitation are distinguished: with slight mitral regurgitation, with moderate, severe and severe.

Stages of mitral regurgitation:

- Mitral blood return is 20-25%. At this stage the patient is healthy.

- Mitral blood return is within 25-50% of systolic blood volume. Blood stasis in the lungs of the second degree develops. Cough, shortness of breath, and interruptions in heart function appear.

- Severe mitral valve insufficiency. The return of blood to the left atrium is 50-90%. Coughing, hemoptysis, attacks of suffocation occur, the liver enlarges, and edema appears [8].

Complications of the defect:

- Hemoptysis and pulmonary edema. Manifested by shortness of breath, difficulty breathing, and wet cough. Blood appears in the sputum. Body temperature rises to subfebrile (37–38 °C) and febrile (38–39 °C) values. Urgent hospitalization in the intensive care unit is required.

- Heart rhythm disturbances in the form of atrial fibrillation and supraventricular extrasystole. Manifested by interruptions in heart function, dizziness, weakness, fainting. Requires hospitalization in the cardiology department.

- Thromboembolic complications (thrombosis of the left atrium, intestinal vessels, kidneys, brain). The consequences will depend on the location of the blood clot. With thrombosis of cerebral vessels, a stroke is possible. If the blood clot is located in the kidneys and intestinal vessels, the patient experiences acute abdominal pain. Hospitalization in the intensive care unit is required [8][9].

When collecting anamnesis, the cardiologist clarifies:

- whether the patient feels short of air when inhaling;

- Are there any disturbances in the heart's function?

- does shortness of breath occur with minor physical exertion;

- whether you suffer from anxiety, fear of death, or panic attacks.

Auscultation (“listening” to the heart) reveals a systolic murmur at the apex and above the base of the heart. Phonocardiography (PCG) is important for the diagnosis of mitral insufficiency . PCG is a method for studying the work of the heart muscle, which is based on the registration and subsequent analysis of sounds that occur during heart function.

Another important instrumental diagnostic method is echocardiography (Echo-CG) . Echo-CG is a painless ultrasound examination that allows you to examine the work of the heart in real time.

Echocardiography will show decreased valve elasticity, valve damage, the size of the mitral valve opening and the distance between its leaflets.

Also, during the study, you can see a rupture of the papillary muscle and sagging of the valve leaflets into the cavity of the left atrium [4][8][9].

Standard marking of steel pipes

All necessary data is applied to the pipes according to a certain standard.

Location of symbols

Manual marking of a steel pipe is printed at a certain distance from the end of the product: no less than 2 cm and no further than 50 cm. With mechanized marking, this value increases and is 0.1 m and 1.5 m.

Symbol size

The letter and numerical designations of the pipe must have a certain size, which is also regulated by a certain regulatory document. Signs must have a height of no less than 0.5 cm and no more than 3 cm, and a width from 0.3 cm to 1.2 cm. The size of the signs is determined in accordance with the parameters of the pipe.

Properties of polypropylene

Although polypropylene is the least dense of all plastics, it is more resistant to abrasion, tolerates heat better, begins to soften only at 140°C, is chemically resistant, and almost does not crack as a result of corrosion. The material is plastic. Under loads not exceeding the maximum, it stretches and then returns to its previous shape without any changes in properties and characteristics. So it's a really good and safe option. Pipelines in food factories are made from polypropylene pipes.

An additional plus is that polypropylene pipes are easy to connect - they are welded. In general, not only water pipes and heating are made from polypropylene. This material can be used as a frame for greenhouses, country furniture and a bunch of other useful things.

As you can see, the diameters of polypropylene pipes are different. And that's not all. There is also up to 1600 mm

Polypropylene has two disadvantages: high thermal expansion and reaction to oxygen and ultraviolet radiation. We learned to deal with both. In order for polypropylene to tolerate UV rays and light, stabilizers are added. To reduce thermal expansion, reinforced pipes are made. But even with reinforcement, the increase remains large and compensators must be installed in pipelines.

Another disadvantage of polypropylene pipes is that they become brittle at low temperatures. Some types begin to crumble at -5°C, others at -15°C. So external pipelines made of polypropylene require UV protection and insulation. That's why they probably prefer to bury them.

Division into classes

Conventionally, pipe products are divided into the following classes:

- Class 1 pipes can be used for gaseous and liquid media in irrigation systems. In addition, it is possible to manufacture fencing structures or supports from such products.

- Class 2 pipes can be used in pipelines operating at low and high pressure, transporting oil and petroleum products, gas or water.

- Class 3 pipes are suitable for work at high temperatures.

- Class 4 includes thick-walled drill pipes that can resist strong torsion.

- Class 5 pipes are used in the construction of carriages, cars, overhead cranes, drilling rigs and some furniture structures.

- Class 6 pipes are used in the engineering industry as blanks from which bearings, cylinders, pumps and receivers are produced.

Types of metal products

All pipe products are divided into 4 types. In descending order of quality and cost:

- new;

- lying down;

- restored;

- previously used.

New and used are self-explanatory. Let's consider the features and differences between old and restored metal products.

Lying down

A stale pipe, or in other words, a pipe from storage, is rolled metal that could not be sold or put into operation on time. Essentially, these are new products, but as a result of aggressive environmental influences, they have lost part of their original characteristics. As a rule, it is the appearance of the product that suffers the most, otherwise it is almost as good as new. The exception is storage in open space under conditions of low temperatures and exposure to precipitation.

The main differences between a stale pipe and a refurbished and used one:

– intact factory chamfer;

– no traces of installation/disassembly;

– no traces of exposure to an aggressive environment inside the rolled pipe, no deposits;

– preservation of the original geometry of the metal product.

At what point does a pipe become stale? There is no clear answer to this question, since different storage conditions have different effects on rolled products: the more aggressive the environment, the faster the metal will begin to lose its qualities. For example, outdoor storage with sudden temperature changes and increased exposure to humidity can cause metal products to become stale after just a couple of months. Other conditions, for example, storage in an equipped warehouse, will delay the onset of this moment to two to three years. Transportation conditions also play a role: if transported inaccurately, pipes may suffer mechanical damage to the protective layer, the integrity of the insulation will be compromised, which will accelerate corrosion processes.

Marking of a stale pipe

Restored

Metal products taken out of service, if there is a service life reserve, can be restored and given a second life. Often, a pipeline is dismantled long before its service life is completely exhausted in order to avoid emergency situations. This explains the good quality of the dismantled rolled products. After carrying out activities aimed at eliminating defects, such as removing old insulation and applying new ones, cleaning the internal and external surfaces, trimming and chamfering, etc., the metal product undergoes technical control: its geometry is checked and hydrotests are carried out. Upon completion of the inspection, an expert opinion is issued.

Thus, a restored pipe is a used product that has undergone restoration. This also includes illiquid products that were discontinued due to rejection due to deviations from the parameters of specifications or GOST. Reconditioned steel is prohibited from being used where increased strength requirements are imposed, as well as in pipelines for drinking water.

The cost of used metal products is higher than that of restored ones. This is due to higher quality due to the lack of exploitation.

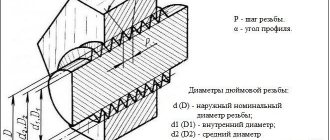

Classification by diameter

It is necessary to understand what diameters of steel pipes there are in order to know what you will have to choose from. Depending on the diameter, special-purpose pipes are also divided into several types:

- Small diameter pipes have a cross-section of no more than 114 mm.

- Medium diameter products - over 114 mm, but not more than 480 mm.

- Large diameter pipes have a cross section greater than 480 mm.

Small diameter pipes

Products of this type are not marked; they are transported in special packaging with an accompanying label. In a similar way, data is applied to pipes obtained in the process of cold deformation with a diameter of no more than 450 mm.

Products must be accompanied by the following information:

- Manufacturer information and order number.

- Date of manufacture and changeover information.

- Package number.

- Batch number.

- Dimensions, including designation of pipe wall thickness.

- Regulatory document.

- Melt number.

- Number of units in one package.

- Theoretical weight (indicated in meters when ordering).

- Actual weight.

- Total footage.

- Recipient code.

Medium diameter pipes

Products whose wall thickness exceeds 3.5 mm and whose diameter exceeds 159 mm are individually marked. Cold-formed pipes with a diameter of more than 159 mm and less than 450 mm are designated on three units of the entire package, and are also accompanied by a special label.

Large diameter pipes

Products with a diameter exceeding 530 mm may have markings inside the pipe.

If the wall thickness is more than 10 mm, then markings can be applied to the end of the products. Depending on the grade of steel used in the production of pipes, the color of the marking is selected. Most often, the pipe symbol is brightly colored to make it easier to find.

Pipes for boiler rooms, in accordance with the steel grade, are designated in the following colors:

- Green markings are applied to grade 20 steel.

- Blue markings are for steel grade 20PV.

- Brown letters and numbers correspond to 15GS steel.

- Yellow markings can be seen on steel grade 15ХМ.

- Orange markings are applied to steel 12Х1МФ-ПВ.

- The data on the pipe, printed in white, corresponds to steel 15Х1М1Ф.

- Blue letters and numbers are applied to 12Х2МФСФ pipes.

International standard GOST R ISO 3183-1-2007

Pipes with a diameter of up to 48.3 mm inclusive are transported in bags, and the marking is applied with a stamp on a bandage or an attached metal label. The total length is indicated in meters and centimeters.

Requirements for pipes for pipelines according to GOST R ISO 3183-1-2007

Next, with a diameter of up to 406.4 mm, each pipe is marked with paint using a stencil on the outer surface. The length is indicated anywhere at the discretion of the manufacturer.

With a diameter of 406.4 mm inclusive and more, by default they are marked from the inside, unless the customer has specified another option. Apply using a stencil at a distance of 152.4 mm or more from the end of the pipe.

Marking of thick steel pipes at the end of the product

The stamp is not used to mark pipes closer than 25.4 mm from the weld:

- Steel strength groups above L175 without subsequent hardening;

- With a wall thickness of less than 4 mm.

Marking contains

- Manufacturer's trademark or name;

- Designation of the GOST R ISO 3183-1 standard (applied if the product fully complies);

- If it meets several standards, then all may be indicated;

- Designation of mass per linear meter;

- Steel class and strength group;

- Pipe forming method (S, W, F);

- Performed heat treatment;

- Test pressure (if tested above the standard pressure, this number is indicated in Pascals, after the word TESTED);

- There may be additional requirements.

Water supply systems made from steel pipes are used quite often, so you need to know about their properties and classification. Steel water supply pipes - sizes, diameters, materials, quality classes. You will learn about the technical characteristics of polyethylene pipes in this article.

Steel strength group

L320 and higher, with niobium content the letter C is indicated, vanadium - V, titanium - T.

Mechanical properties of materials for the manufacture of pipes - steel strength groups

The formation method or production process is indicated by:

S – seamless pipe; W – welded, except those made with a continuous seam; F – pipe made with a continuous weld.

Heat treatment is indicated by the following signs:

- Tempered and/or normalized pipe – N;

- Subcritical stress relief – HS;

- Subcritically cured – HA;

- Quenched and Tempered – Q.

The supplement includes

A paint spot with a diameter of 50 mm can be applied, which corresponds to the steel strength group, this applies to pipes over 114.3 mm in diameter, strength group L320 and higher.

Used color combinations for pipeline markings

Table of correspondence:

Pipes L415

- L320 - Black color;

- L360 - Green;

- L390 - Blue;

- L415 - Red;

- L450 - White;

- L485 - Violet;

- L555 - Yellow.

Reading example

"X GOST R ISO 3183-1-2007 14 54 57 L245 S"

Let's decipher:

- “X” – trademark;

- "GOST R ISO 3183-1-2007" - GOST;

- "14" - size;

- “54, 57” - mass;

- “L245” - steel strength group;

- "S" - seamless.

If the pipes have been subjected to treatment, such as heat treatment, then any markings that no longer correspond to the condition must be removed.

Couplings for products are also marked in accordance with standards and contain:

- Manufacturer's name;

- Steel strength group;

- Standard designation.

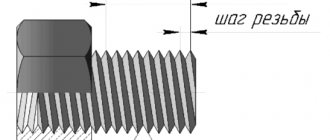

The threads on pipes are marked with a stamp or paint next to the thread; if the manufacturer of the pipe and thread are the same, then the trademark may be omitted.

Example of pipe marking with explanation

Thread marking according to GOST is carried out separately and does not give the right to claim that the entire product meets the same standard.

It can be quite difficult to understand all the intricacies of marking, but once you have mastered this “literacy”, one look at a steel pipe will be enough for you to learn everything, or almost everything, about it!

Mitral insufficiency treatment: mitral valve insufficiency - price in St. Petersburg

Mitral regurgitation

– valve failure, in which there is a reverse movement of blood from the left ventricle into the left atrium during contraction of the ventricles of the heart due to incomplete closure of the valve leaflets.

- Congenital pathology: cleft valve, prolapse, etc.

- Ischemic mitral valve dysfunction in ischemic heart disease.

- Degenerative processes: myxomatous degeneration, Marfan and Ehlers-Danlos syndromes, mitral annulus calcification.

- Inflammatory lesions: rheumatism, systemic lupus erythematosus, systemic scleroderma, aortoarteritis.

- Infection: infective endocarditis.

- Injury.

The development of acute mitral regurgitation, refractory to drug therapy, is an indication for emergency surgery.

The manifestation of clinical symptoms of mitral regurgitation is determined by the severity of mitral valve insufficiency and the functional state of the left ventricle.

Symptoms

The most typical complaint is shortness of breath, which occurs with moderate and severe chronic mitral regurgitation and the clinic of acute left ventricular failure with acute mitral regurgitation. The presence of atrial fibrillation before surgery is an independent predictor of reduced long-term survival after mitral valve surgery for chronic mitral regurgitation.

Diagnosis of mitral insufficiency

Echocardiography (ECHOCG)

occupies a leading place in the diagnosis of mitral valve insufficiency and determination of indications for patient management tactics. If transthoracic echocardiography is insufficiently informative and the possibility of reconstructive surgery on the mitral valve is clarified, transesophageal echocardiography should be performed.

Echocardiography allows you to determine the etiology of mitral regurgitation, its severity - the compensatory capabilities of the left ventricle, the presence of complications (left ventricular failure, pulmonary hypertension, right ventricular failure), and identify other heart defects.

An echocardiogram allows one to assess the degree of mitral valve insufficiency based on the ratio of the area of regurgitation flow to the area of the left atrium:

- Minor mitral valve insufficiency less than 20%

- Moderate deficiency 20-40%

- Severe deficiency 40%

- If ischemic heart disease is not the cause of mitral regurgitation and there is no evidence of concomitant ischemic heart disease, indications for surgery can be determined without cardiac catheterization.

- The use of invasive examination methods is indicated for patients with ischemic mitral valve dysfunction:

- Coronary angiography makes it possible to clarify the presence of stenotic lesions of the coronary arteries and determine indications for myocardial revascularization in combination with surgical correction of mitral regurgitation.

- Indications for surgical treatment of mitral insufficiency

Classification of recommendations and levels of evidence in ACC/AAC format:

- Class I: Conditions for which there is evidence and/or general agreement that a procedure or treatment is beneficial, useful and effective.

- Class II: Conditions for which there is conflicting evidence and/or differences of opinion about the usefulness/efficacy of a procedure or treatment.

- Class IIA: Weight credibility/opinion in favor of usefulness/effectiveness.

- Class IIB: Benefit/effectiveness less well established by evidence/opinion.

- Class III: Conditions for which there is evidence and/or general consensus that the procedure/treatment is not beneficial, not effective, and in some cases may be harmful.

In addition, the levels of evidence to support the recommendations are outlined as follows:

- Level of Evidence A: Data are from multiple randomized clinical trials.

- Level of Evidence B: Data are from single randomized trials or non-randomized trials.

- Level of Evidence C: Expert consensus only, individual case studies and standards of care.

Surgical treatment of mitral valve insufficiency

CLASS I

- 1. Patients with acute severe mitral regurgitation (Level of Evidence: B)

- 2. Patients with chronic severe mitral valve insufficiency and NYHA class II, III, IV heart failure, in the absence of severe LV dysfunction (severe LV dysfunction is defined as an ejection fraction less than 30%) and/or ESR greater than 55 mm. (Confidence level: B)

- 3. Asymptomatic patients with chronic severe mitral regurgitation and mild to moderate LV dysfunction, ejection fraction 30-60% and/or ESR greater than or equal to 40 mm. (Confidence level: B)

- 4. Mitral valve repair is preferred over mitral valve replacement in most patients with severe chronic mitral regurgitation who require surgery, and patients should be referred to surgical centers with extensive experience in MV repair. (Confidence level: C)

Class IIA

- 1. MV repair is indicated in asymptomatic patients with severe chronic mitral regurgitation and normal LV function (ejection fraction greater than 60% and ejection fraction less than 40 mm), in whom the probability of good results of valve repair is greater than 90%. (Confidence level: B)

- 2. Intervention on MV is indicated in asymptomatic patients with severe chronic mitral regurgitation with normal LV function and paroxysmal atrial fibrillation. (Confidence level: C)

- 3. Intervention on MV is indicated in asymptomatic patients with severe chronic mitral regurgitation with preserved LV function and pulmonary hypertension (systolic PA pressure more than 50 mm Hg at rest or more than 60 mm Hg during exercise). (Confidence level: C)

- 4. Intervention on MV is indicated in patients with severe chronic MR*, which developed as a result of primary pathology of the mitral structures, symptoms of NYHA class III-IV and severe LV dysfunction (ejection fraction less than 30% or ESR more than 55 mm), for whom restoration is more suitable MK. (Confidence level: C)

Class iib

- Mitral valve repair is possible in patients with chronic severe mitral valve regurgitation due to severe LV dysfunction (ejection fraction less than 30%), who, despite optimal HF therapy, including a biventricular pacemaker, have symptoms of NYHA class III-IV. (Confidence level: C)