Main malfunctions of walk-behind tractors

Diesel and gasoline engines have different motor resources.

For the former, the normal figure is 4000 m/h, but the latter are capable of providing only 1500 m/h. Despite this, diesel models of walk-behind tractors are not in high demand. After all, both when purchased and during operation they are much more expensive. Therefore, most likely, you are working with a walk-behind tractor equipped with a gasoline (carburetor) engine. All breakdowns that may occur during the operation of agricultural mini-equipment can be divided into two categories:

- Engine faults:

- startup problems;

- malfunctions.

- Malfunctions of other components and mechanisms:

In many ways, the success of repairing a suddenly broken machine depends on the correctness of the diagnosis. As for maintenance, it is carried out precisely in order to identify small faults that will later lead to serious ones.

If you do not have the necessary knowledge, premises, tools and materials necessary to service and repair the motor, entrust the work to a specialist!

Specifications

The Master walk-behind tractor with the American Quantum engine has the following technical characteristics:

- engine power - 5.5 hp;

- tank capacity - 3.6 l;

- fuel consumption - 1.2 l/h;

- tillage depth - 25 cm;

- cutting width - 60 cm;

- weight without additional options - 45 kg;

- length with handle in working position - 130 cm;

- width - 70 cm;

- height - 98 cm;

- Dimensions in transport condition - 78x57x75 cm.

You can buy a new walk-behind tractor in Moscow for 23,000-25,000 rubles; a full set of Russian-made options will cost another 9,000-11,000 rubles.

Analogs

The following models are similar in size and technical characteristics to the Master MK-265 walk-behind tractor:

- Champion BC 6712;

- Farmer;

- Centaur;

- AL-KO MH 4005;

- Gardena EH 600;

- Daewoo Dat4555;

- Lux 1400;

- GMC-1.8;

- Bison NT 105.

The price of the product depends on the type of power plant, country of manufacture and configuration.

Replacement and adjustment

Quite often, unfortunately, there is a need to completely change the motor on a walk-behind tractor. When choosing a replacement device, it is recommended to give preference to products from well-known companies. Traditional prejudices about products from Chinese factories have long become irrelevant. To avoid overpaying, you need to carefully analyze how productive the power plant should be. Buying a unit that is too powerful is simply irrational.

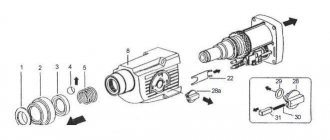

Even if there is no talk of a complete replacement, it is important to know how to adjust the engine of agricultural machinery. It is advisable to begin disassembly only after flushing the engine and removing oil from it. Lubricant is poured only when the engine is warmed up after a short run. Next it's time to remove the fuel tank. Sequentially remove:

- fuel supply hose;

- air filter;

- screen covering the cylinder.

Then remove the crankshaft pulley. Following the pulley, it is necessary to remove the fan, reflectors, and insulating flywheel casings. Unscrew the cover, removing the rings and coupling bodies. When the washer is removed, you can press out the flywheel using a wooden block.

Now, having dealt with the flywheel, remove the cylinder cover, camshaft and pusher. Once access to the connecting rod is gained, remove the oil sprayer and locknut. After repairing and replacing damaged parts, reassemble the engine in the reverse order. You should familiarize yourself with the diagram in advance, then there will be no errors.

Replacing damaged valves for a gasoline walk-behind tractor occurs after removing:

- gasoline tank;

- the head of the cylinder block;

- carburetor;

- muffler;

- boxes.

Often there is a need to replace rings. But this should only be done in the process of more serious repairs. An isolated change of rings in itself is irrational both economically and technically. Additionally, a high quality ring group will usually have the same lifespan as a cylinder. They are changed at the same time.

Installation with an elastic band is advisable if a Chinese motor is installed on domestic walk-behind tractors. Rubber cushions are often used as a platform. They can be used as parts of the front shock absorber from a classic car. Along with the need to rearrange individual parts of the walk-behind tractor engine, many people have a need to install an electric starter themselves. This starter will have to be properly connected to the battery.

The crown is attached only to the removed flywheels. First remove all interfering parts of the motor. To remove the flywheel, in many cases you cannot do without a special key. A generator and its magnets are installed in the flywheel assembly. When the terminals and contacts of the battery are aligned, you should conduct a test run of the walk-behind tractor.

Description

Motoblocks Bison, Cayman, Patriot, Texas, Foreman, Crosser, Viking, Forza are quite popular among buyers who value the optimal combination of price and quality provided.

Their use is advisable for a variety of agricultural work, which this equipment copes well with. Here is just an incomplete list of what these walk-behind tractors are used for:

plowing soil of varying densities;

- soil cultivation;

- mowing grass for hay;

- harvesting (beets, potatoes, etc.);

- tillage between beds, etc.

As we can see, the Bison does almost all the work typical of rural areas. This is a real helper for any farmer who spends his time usefully, i.e. cultivates the land, plants potatoes and other root crops, cares for livestock, etc.

This popularity is fully justified, because in the production of Zubr walk-behind tractors, only high-quality components that have passed special testing are used. In general, the Bison model range is quite extensive, ranging from small capacities to heavy units with power plants.

Today we are presented with Zubr diesel walk-behind tractors with a 6 hp engine, which use diesel as fuel. This circumstance allows them to show higher performance indicators than engines of similar power but running on gasoline.

In addition, diesel fuel is more economical, which is an additional plus for these walk-behind tractors. In the category of diesel walk-behind tractors with a power of 6 hp, the Zubr company represents the NT 105 model, which can cope with even the most difficult areas of land, i.e. virgin soil.

This became possible thanks to the use of a worm gearbox and a multi-disc clutch included in the design of the unit.

If you have a full-fledged plot of land with a vegetable garden and livestock, then it makes sense for you to purchase additional attachments for this walk-behind tractor, which will significantly expand the scope of its application:

- transportation of various goods;

- thanks to the use of a potato planter, you can plant potatoes in your garden quite quickly and efficiently;

- snow removal, etc.

As standard, the Zubr diesel walk-behind tractor has a rotary cutter and pneumatic wheels. Even this minimum set is enough to compete with European manufacturers, differing from them also in a more reasonable price.

For our compatriots, this is the competitive advantage that creates increased demand for Zubr equipment.

Specifications and price

The Zubr NT 105 walk-behind tractor has a 4-stroke diesel engine of the KM178F brand.

NT 105

In addition, it has the following technical characteristics:

- type of fuel used – diesel;

- engine capacity – 296 cm3;

- maximum power – 6 hp;

- fuel tank volume – 3.5 l;

- the width of the processed strip is adjustable, from 75 cm to 105 cm;

- digging depth – adjustable, from 80 to 300 mm;

- clutch type – multi-disc, in an oil bath;

- speeds - two forward and one reverse;

- total weight – 120 kg;

- fuel consumption - 1.5 liters per hour of operation;

- start type – manual;

- load capacity – 350 kg;

- cooling type – air;

- overall dimensions – 174cm/150cm/98cm.

The price of this unit is about 35 thousand rubles. This price does not include attachments, which must be purchased separately.

How does it work?

To understand breakdowns and fix them, it is important to understand how everything works in a normal situation. For greater simplicity, we will focus only on models with internal combustion engines. Previously, there were two-stroke walk-behind tractors, but now they are increasingly being replaced by four-stroke analogues. Diesel devices are also gaining popularity. As for the transmission, it can be configured in three different options.

The traditional approach involves the use of a gear transmission. Despite a decent level of reliability, this device takes up a lot of space. The force is transmitted using either a cone or a cylinder. Light walk-behind tractors are mainly equipped with a worm-gear transmission. A typical operating principle of a walk-behind tractor controller contains:

- a device that monitors the number of revolutions;

- a rod connecting this device to the throttle valve;

- spring.

The control unit operates on the basis of pneumatic or mechanical connection. “Pneumatic” means the presence of a kind of wing that reacts to the speed of the air flow. Centrifugal options involve placing a special camshaft inside the crankcase. It is complemented by small weights and an easily moving rod. The rod is made of wire, and the sensitivity of the spring determines how accurately the speed values will be maintained.

The role of the valve timing mechanism is to supply a mixture of fuel and air into the cylinder. But the same device also ensures the removal of exhaust gases. To influence the compression ratio, a decompressor is used. Gasoline engines are necessarily equipped with carburetors, which are responsible for preparing the fuel-air mixture. Regardless of the type of fuel, the starting device plays an important role.

Malfunctions of the walk-behind tractor engine during operation

The units and components of motors that are installed on mini-agricultural equipment are subject to significant loads. They can also fail during operation of the unit, which will very quickly lead to serious failures.

If you detect suspicious noises, jerks and disturbances in the operation of the walk-behind tractor systems, it is very important to immediately turn off the engine and then let it cool down - only after that will it be possible to fix the problem.

If during operation the motor begins to gain speed on its own, i.e. is “peddling”, most likely this means that the fastening of the regulator and thrust levers has become loose. In this case, the user will have to readjust the motor control drive.

Sometimes, when the throttle is fully open, the engine does not accelerate when the throttle is pressed, but rather begins to lose power until it comes to a complete stop. This is a clear sign of overheating, so you need to turn off the walk-behind tractor and wait until its components have completely cooled down.

Under increased loads on the engine, it may seize. There may be several reasons for this:

- there is not enough oil in the crankcase;

- a nadir has formed on the lower head of the connecting rod;

- The connecting rod or oil sprayer has completely failed.

If the motor of a walk-behind tractor is jammed, you will have to disassemble it and check the condition of the main components and components: faulty, deformed, melted, etc. subject to replacement.

Other common engine starting problems

What to do if the walk-behind tractor engine operates intermittently and does not develop the required power? There may be several reasons for this behavior:

- Air filter clogged.

Air does not enter the carburetor, which means the fuel does not burn well - the filter will have to be cleaned or replaced.

- Muffler clogged.

Residues of fuel, as well as the products of its combustion, form a thick coating on the internal walls of the muffler, which must be removed.

- Carburetor clogged.

In this case, the assembly will have to be removed, disassembled and all its components properly cleaned. After this, the carburetor must be assembled and adjusted correctly.

- Wear of the cylinder-piston group.

Temperature and high loads take their toll, and even the strongest metal wears out and deforms over time. Such parts should be replaced immediately, otherwise you may pay for it with irreparable damage to the engine itself.

- Broken ratchet housing or ratchet

The presence of this problem is indicated by the absence of crankshaft movement when starting the engine. To replace the clutch housing and ratchet, you will have to completely disassemble the starting unit.

- Loosening the screws securing the starter housing to the engine housing.

If the starter cord does not return to its original position, the starter needs to be adjusted. To do this, the screws are loosened, and the position of the knot is set by hand so as to ensure normal return of the cord.

- Broken starter spring.

A fairly common reason for the starter cord not returning is the failure of the starter spring - it will have to be replaced.

Competent maintenance of its main units and components significantly increases the service life of any equipment. Efficiency of replacement of worn-out spare parts is also of great importance. Therefore, if the slightest failures or malfunctions occur, they should be addressed immediately - in the end, this will prevent much more serious and expensive problems.

How much to pour the mixture

The amount of liquid that is poured into the mechanism directly depends on a number of factors, namely:

- the volume that is set directly by the manufacturer;

- recommendations regarding the amount of oil;

- design features of the mechanism;

- the amount of liquid drained from the device.

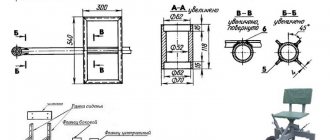

Taking into account all these nuances, you can choose the optimal value at which the device will work best. As a rule, about two liters of transmission fluid are poured into this part of the walk-behind tractor. To determine the reliable amount of this component, you can take a wire 70 centimeters long, and then bend it and insert it into the mechanism. As a result, at least 30 centimeters should be smeared on it (this is considered the norm). If the indicator is less, then you need to add fluid.

Important! If maintenance is performed, it is necessary to fill the liquid to the level, otherwise rapid wear of a part such as the gearbox will be observed.

Adviсe

In order to repair and adjust the walk-behind tractor less often, it is necessary to protect the motor from falling. This is especially true for products with four-stroke engines. Their maximum inclination during operation cannot exceed 25 degrees. The unit cannot be tilted more than 15 degrees for a long time. Otherwise, you may be afraid that part of the engine will be deprived of lubrication. It will soon fail.

For the same reason, prolonged operation of the walk-behind tractor in idle mode is not recommended. Before starting work, you should always check that there is enough fuel and lubricating oil. These fluids need to be changed and even added only when the engine is turned off.

You cannot start the walk-behind tractor when the levers associated with the wheel drive are locked. A cold engine is started only after the carburetor air dampers are set to the closed position; Always use strictly recommended fuel.

The valves are adjusted using:

- universal wrenches;

- probes of various sizes;

- screwdriver with a flat blade.

For the intricacies of repairing the Subaru ex21 engine for the Neva walk-behind tractor, see below.

Self-cleaning of the unit carburetor

Do-it-yourself repair of a motor cultivator often involves cleaning the carburetor. To do this, the unit must be completely disassembled and cleaned according to the manufacturer's recommendations. The work algorithm, as a rule, is described in detail in the cultivator operating instructions. All cleaning procedures performed are aimed at restoring the uniform immersion of the carburetor float. To do this, it is also necessary to eliminate the deformation of the bracket by which the float is attached to the piston system.

Immersion adjustment is performed with both the open and closed needle valve. A screwdriver should be used to align the bracket. All manipulations must be clear and accurate.

Along with eliminating the deformation, you will also need to adjust the valves of the cultivator.

To do this, check the tightness of each of them. Completing this procedure allows you to restore the functions of the carburetor and return the amount of fuel it consumes to normal.

Troubleshooting startup problems

Often, repair of a walk-behind tractor engine is needed because the engine will not start. If this problem occurs after winter storage, you can suspect:

- clogging of fuel or oil with water;

- oxidation of electrical contacts;

- insulation damage;

- the appearance of solid debris in the carburetor.

To prevent these problems, it is necessary to carefully inspect any connections before each start-up. If you notice the slightest tightening of the cable, especially if it is twisted, you cannot start the engine.

Even before the very first start, it is necessary to assess whether there is enough oil in the crankcase. If there is a deficiency, rapid destruction of the piston group is likely. In less than a second, the cylinders will be covered with burrs.

In this case, very serious repairs will be required, and sometimes even replacement of damaged parts. Sometimes instability in the functioning of the device is provoked by leaving the lubricant for the winter. If this is the case, in the first few moments after start-up, clouds of white smoke will pour out of the exhaust pipe. Immediately after this, the power plant will stall.

Diesel walk-behind tractors may also not start due to lack of oil. Only a few models are equipped with systems that protect against a drop in lubricant level. Most people will have to monitor the health of the walk-behind tractor themselves. It is also worth considering that failures occur due to the systematic use of unsuitable fuel. If the usual recommendations do not give much effect, you need to remove the candle and look for oil stains.

Oil, especially carbon deposits, should be carefully cleaned. Then the candle must be dried. The cylinder also needs to be dried. A very simple technique is used for “drying”: repeated sharp pulling of the starter cable. The question often arises: what to do if the walk-behind tractor does not start and smokes black smoke.

Typically, this manifestation indicates that the engine is overfilled with gasoline. You should also be wary of damage to the piston group. If both assumptions turn out to be incorrect, you need to contact the service center. Further attempts to troubleshoot problems on your own may lead to worsening damage.

When violations are associated with a lack of fuel in the working chamber, the spark plug will be dry.

You can deal with this problem if:

- pour out the old fuel;

- thoroughly clean the gasoline or diesel tank;

- clean the air filter;

- clean the fuel hose and nozzles with a jet of compressed air;

- add fresh fuel;

- After opening the fuel line, blow out the channel located in the gas tank cap.

In some cases, the failure is due to gasoline getting into the oil sump. It is necessary to check whether this problem exists after any adjustment or adjustment of the carburetor.

If the lubricant becomes clogged with fuel constantly, you need to look at the carburetor needle. It is likely that this particular node has become a weak point. It is worth noting that sometimes the walk-behind tractor engine shoots into the muffler, and perhaps even with a flame.

The most likely reason is incomplete combustion of fuel. It is provoked by:

- omissions in the ignition system;

- excessively saturated fuel mixture;

- unjustified heating of this mixture.

When the walk-behind tractor does not want to operate, interruptions in the ignition system must be looked for thoughtfully and consistently. Magneto, caps, spark plugs and high-voltage wires are examined.

Finding even minor contaminants is of paramount importance. If everything is clean, you need to inspect the ignition wire contacts. Next, check the stability of the electrodes and measure the distances between them using a special probe.

Functional failures

Quite often, among the malfunctions of a walk-behind tractor engine, its unstable operation appears. If the engine idles jerkily, and when you try to add gas it stops altogether, the reason is rooted in a lack of fuel. The screens of the fuel tank, carburetor and pipeline valve should be cleaned. And when problems occur even at idle, it is advisable to check the centrifugal regulator. Often the traction jams there.

Let's assume that the walk-behind tractor simply slows down without jerking. In many cases, this is due to the use of incorrectly tuned, unsuitable or simply badly worn motors. But replacing the power plant is not always wise. Installing a better quality spark plug may help. It is also worth assuming that malfunctions in the operation of the carburetor float in the high-voltage wire may occur.

If the walk-behind tractor engine knocks, you need to inspect the camshaft and crankshaft. This is where the sources of extraneous sounds are mainly located.

In all of the above situations, there is no particular need to carry out major repairs. High-quality diagnosis of problems is very important. It is pointless to try to increase the compression in all modern engines; anyway, the decompressor will not allow this to be done.

Why does the walk-behind tractor stretch under load?

The problem is quite common. The equipment stops after 5 minutes of operation. Fuel supply and ignition faults are often the cause.

If the equipment stops during operation, you need to check how well the fuel is being supplied:

- The candle is taken out and examined. It's overdried. This indicates a lack of fuel;

- There must be enough fuel in the gas tank for normal operation of the machine;

- The condition of the fuel valve is being examined. You can just block it. Sometimes it is enough to open it for further use of the device.

The outgoing tractor starts and stops in case of ignition failure. First you need to check the spark plugs. Wet objects indicate damage. The ignition system technology must be restored.

Reconfiguration is performed as follows:

- The cover that protects parts of the ignition system has been removed;

- The motor flywheel rotates until the contacts open in the magnet;

- A special probe measures the distance from the anvil to the mallow;

- The flywheel rotates to compress the piston. The latter must reach its peak;

- The flywheel rotates repeatedly until a characteristic knock appears, which indicates the operation of the free wheel;

- The flywheel rotates in the opposite direction until the mark of this element matches the mark on the unit body;

- Clearance from interruption contact to cam 0.3 mm;

- The cam is secured with a screw that is located above the element, and a protective cover is installed in the equipment body.

If the above steps are performed correctly, the walk-behind tractor does not stall under load. The tilter may stop if there is not enough fuel in the fuel tank. The device must be installed directly, disconnect the starter cable. If the engine starts, fill the tank with fuel.

READ What is the difference between Stihl 170 and 180