When choosing a walk-behind tractor for their household farming, users pay attention to the technological characteristics of its mechanism, for example, power and weight. Few people are interested in what wheels are installed on it, because the quality of work and duration of operation depend specifically on the mechanism.

The standard wheels sold as a set are good for working on soft soils. In difficult conditions they quickly fail, and new ones are quite expensive. Our article will tell you how to make wheels for a walk-behind tractor with your own hands.

Types of wheels

A unit such as a walk-behind tractor is used in a variety of types of work, so the wheels installed on it must also be different. Let's look at the modifications offered by manufacturers:

- Pneumatic type.

- Traction.

- Solid rubber products.

- Metal parts with couplings.

Pneumatic

Necessary for plowing the soil or plowing up beds. For high-quality work, the wheels must have a width of more than twenty centimeters with a diameter of 40 centimeters or more. A pronounced tread is welcome.

This unit is more stable, and all defects will be visible on the surface of the tires. As a rule, Neva walk-behind tractors are equipped with such parts.

Traction

In common parlance, these products are called herringbone - for the unique pattern on the tread. Their working width is universal. This option is used for transporting goods or hanging special equipment.

With traction wheels, your unit will be able to navigate off-road conditions and even loose snow. The rubber installed on it is highly durable and wear-resistant.

Solid cast

Such parts are characterized by increased tire power. They are usually used on diesel-type units, more similar to small tractors, such as MTZ.

Metal with lugs

These are heavy parts that provide the walk-behind tractor with additional power during operation. Special teeth allow the equipment to move even on very difficult and viscous soil. The heaviest load falls on the support wheel, so it is not its choice that you should pay the closest attention to.

When choosing a trailer, you need to ensure that the wheels in it have a similar structure. Then, when transporting a heavy load, the pressure on the walk-behind tractor and trailer will be compensated.

Types of wheels for farm walk-behind tractors

For home appliances for cultivating a summer cottage, different chassis configurations are provided. It depends on the type of work performed and the conditions of use of the minitrautor. Manufacturers install wheeled structures on walk-behind tractors, which are distinguished by shape, material, and weight.

Most factory motor cultivators quickly wear out rubber during operation, deform wheels, and are light in weight. Plowing the field, removing snow, mowing grass, planting and harvesting vegetables can be done with a low level of quality.

Traction wheels

The wheel elements that perform the function of moving the working farm mechanism are called traction. The standard factory equipment includes tires with a herringbone pattern on wheels of this type. The use of a walk-behind tractor with such protectors is advisable on loose soils, for transporting goods around the site, and for mowing grass.

If the result is unsatisfactory, the wheels may need to be replaced. Choose one of the options:

- install homemade, heavier and wider elements;

- replace tires on factory wheels;

- install car rims and tires;

- place weights;

- attach lugs that improve traction with the ground.

Narrow factory traction wheel designs make the use of a motor cultivator inconvenient, and the farming activities carried out are of poor quality.

Pneumatic wheels for walk-behind tractor

Wheel structures with pneumatic tires are metal disks on which rubber tubes with compressed air are attached inside. The elastic rim tape absorbs shaking when moving over uneven surfaces and transmits traction force. Working on a walk-behind tractor with a pneumatic chassis is characterized by convenience, high speed and decent quality.

The tires on the wheel system are made of a sealed rubber pipe, which is equipped with a valve and a check valve. Rubber, smaller in size than the diameter of the disc, is inflated with compressed air and ensures a tight seal. Throughout the entire circumference, the width of the tire rim has an equal size, no less than 20 cm. Elements with a radius of 20 cm and a pronounced tread pattern are installed on motor cultivators. Pneumatic wheels are characterized by:

- high wear resistance;

- good grip on the ground;

- service life of at least 5-7 seasons.

Important!

Install wheel tires with a rough, large pattern to prevent the cavities from becoming clogged with soil, slipping, and improve the maneuverability of the mini tractor.

With regular use of a motor cultivator with pneumatic wheels, the chassis wears out after 3-4 years. After the tires wear out, the element requires replacement - installing a new wheel structure or installing new rubber.

Metal wheels

For difficult terrain conditions and clayey soils, mini-equipment on a metal wheeled structure is used. Manufacturers offer different model options for plowing, hilling, and transporting goods:

- metal disc wheels;

- lugs are metal structures in the form of a rim and teeth.

Wheel elements made of steel or cast iron alloy make the equipment heavier, which ensures better performance of the unit. The lugs provide good traction with the ground, due to which the minitractor quickly moves along the ground, the soil does not clog the rim, and slipping is eliminated due to the deep immersion of the teeth in the soil.

Self-production

Of course, it is impossible to completely assemble these parts with your own hands. In any case, you will have to purchase an axle. All parts are hung on a ready-made base, which is purchased in the store.

You can use car or motorcycle pairs as a base. You can only make lug parts with your own hands, since weighting agents are used extremely rarely, and it makes no sense to buy products at a high cost.

To make a walk-behind tractor convenient for work, you need to properly debug all its parts, including making the wheel axle of the required length. For this, special extension cords are used. You can also assemble paired parts from iron, inside of which there is an internal cavity. It is in it that the weighting material is placed.

Naturally, they are not suitable for a trailer, but they can be used in the unit itself for mounting wheels from a car.

Advantages of paired parts:

- Reduced slippage time and increased product performance.

- Possibility to quickly remove and change products.

- Easy to assemble on your own.

- Excellent grip.

It is thanks to these properties that double wheels are becoming increasingly popular among farmers. You can also make them yourself. Of course, the parts turn out to be rough, but they work efficiently and for a long time, which is important for difficult agricultural conditions. The process is as follows:

- At the first stage, wheels and tires are selected.

- Next, the protectors are made more prominent by creating a pattern on them.

- Then a weight is inserted into the rim. To do this, the steel strip is cut into squares and the blanks are welded into a single structure.

- The second rim is secured to ensure the greatest strength of the mechanism.

- At the end, tires are put on and the structure is ready for work.

In general, it is not difficult to make such devices; you just need to choose the right parts and adjust them to size.

Recently, pneumatic wheels, which are perfect for walk-behind tractors, have been in great demand among buyers. They are made from medium-hard rubber, and they are quite expensive. Therefore, it is worth thinking about assembling the unit yourself.

Walk-behind tractors, so popular in our country, are very often independently redesigned and modernized by their owners. This is due, among other things, to the fact that owners want to significantly expand the capabilities of existing equipment, their requests for technical compliance of the unit may be greater, and the market may not always offer something. This article will discuss the installation and manufacture of wheels for a walk-behind tractor with your own hands.

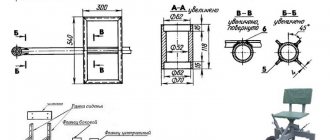

Options for wheel design drawings for a walk-behind tractor

Factory configurations of wheels for a motor cultivator are classified according to the number of axles, as well as the principle of traction. Manufacturers produce home mini tractors, the design of which involves the movement of the unit due to:

- two wheelsets;

- paired wheel structure on one axle;

- one drive wheel;

- on three wheels.

Single-wheel mechanisms are often equipped with additional devices on the axle, which also serve as support for the structure. Analyze the model of your home cultivator to improve its functionality. Choose a durable, reliable material or a suitable base for making homemade chassis elements.

Four wheel option

Small-sized agricultural tractors on four wheels are a miniature of a similar vehicle without a cabin. The configuration of the models allows the user to move on a walk-behind tractor.

To improve the factory configuration, you can replace only the drive pair or change all the disks. Choose one of the options to improve the performance of home agricultural equipment:

- equipping factory tires with additional protectors;

- putting new tires with a textured pattern on the wheels;

- installation of wheelsets of different radii on the axles - larger ones under the mechanisms, smaller ones under the driven part;

- installation of car wheels.

Important!

Designing wheels is an important stage in improving a walk-behind tractor, at which it is necessary to make accurate calculations of the optimal dimensions, arrangement of elements, and locations for drilling fasteners.

Four-wheeled walk-behind tractors are classified as heavy-duty models. A number of machines are configured with non-removable wheel elements. Before modifying a mini tractor, make a drawing according to which you plan to improve.

On one wheel set

Two-wheeled motor cultivators are equipped with one axle with a pair of wheel elements. The platform with the installed engine is controlled by the user using handles. Installing a passable wheelset will solve the problem with:

- slippage;

- slippage;

- filling the poorly expressed tread pattern with earth;

- poor handling;

- insufficient plowing depth, etc.

Draw a sketch of one element on paper yourself or make a drawing in a computer program. In the figure, indicate the diameter of the disk, the location of the holes for the axle, fastenings, and their dimensions.

With one driving wheel

Single-wheeled cultivators are devices in the form of a wheel element in a tire with a pronounced tread. The speed of work and efficiency when performing farming work depend on the permeability of the disk.

When preparing a drawing for replacing the drive wheel, use the following recommendations:

- select the diameter of the wheel element similar to the factory configuration;

- choose materials with greater weight when making a wheel yourself;

- replace the rubber with a more textured and wider one.

The walk-behind tractor on one wheel is controlled by manual manipulation. It will be easier for you to drive a design with a wide wheel and a powerful tread.

Three-wheeled models

On small-sized agricultural tractors for cultivating a summer cottage with three wheels, the front element performs the function of following a given trajectory. The rear wheel pair is supplied with torque from the unit engine. In most models, the chassis located at the front is made of a larger diameter.

To design the replacement of wheels on a single-axle small-sized tractor, use the following recommendations:

- calculate the same radius of the wheel and tire that is provided in the factory configuration. Installing a smaller or larger wheel in diameter will make the mechanisms work incorrectly;

- make identical wheel elements. Replacing wheels with different tread patterns or different weights will complicate the use of the mini tractor.

When making a drawing with your own hands, take as a basis the model designed by the manufacturer. Consider the full radius of the elements. You can design a disc with a smaller diameter, but install thick tires on it, and vice versa.

Do-it-yourself wheels for a walk-behind tractor

More and more gardeners who own walk-behind tractors are making changes to the chassis of their units with their own hands. This allows you to increase the cross-country ability of the cultivator, adapt it to a wide variety of soil types, successfully expand the track and much more, something that is not always included in the capabilities of the factory equipment.

Motor cultivator "Neva"

Wheels for walk-behind tractors come in the following types:

- pneumatic, used for plowing and removing roots from the soil, as well as for transporting the cultivator. Often, instead of factory narrow ones, they are installed from Zhiguli, Oka and Moskvich cars;

- metal or lugs are ideal for clay soils as they have steel teeth for excellent flotation in soft soil;

- solid rubber ones are also installed on mini-tractors; thanks to the aggressive tread pattern, they have increased cross-country ability;

- support - as a rule, this is one support wheel that takes on the entire load from the engine;

- paired, helping to increase maneuverability on difficult soils and significantly increase speed.

Criterias of choice

Any garden equipment is available in several variations. The chassis for the walk-behind tractor is no exception to this rule. If you look at the assortment of any store that sells spare parts for walk-behind tractors, you will see that there are three types of wheels:

- Pneumatic. Such products have a rubber tire and inner tube.

- Rubber. Monolithic design, which consists of a rim and durable rubber.

- Lugs. Metal elements aimed at increasing the cross-country ability of vehicles.

The difficulty of choice lies in determining the operating conditions of the equipment. For example, for processing clay areas or wet soil, it is recommended to use lugs.

A walk-behind tractor equipped with conventional rubber wheels will not show good performance in difficult conditions.

In addition, you should focus on the wheel radius and tread pattern

What wheels can be put on a walk-behind tractor? Here a lot depends on the intended use of the technology. If the unit is needed for planting and harvesting work, you can choose pneumatic wheels.

Such products are optimal for working on soft ground. The recommended radius is about 40 centimeters. At the same time, we recommend choosing wheels with deep tread, which will increase maneuverability and cross-country ability.

Cast wheel

For primary cultivation of virgin soil and soil with a high content of stones, it is better to use cast wheels. They receive virtually no mechanical damage due to the absence of an internal chamber.

However, such elements have increased weight, so they are installed on medium and heavy walk-behind tractors.

The lugs not only increase the maneuverability of the equipment, but also increase its productivity. The teeth enter the soil, which creates additional force to move the unit in a given direction.

Wheel lugs

Such elements are used mainly for arable work on large areas of land. It is not advisable to use lugs on a small plot of land.

Drawing with instructions for making wheels for a walk-behind tractor

Drawing of homemade wheels for a cultivator

You can make paired wheels, between which a weighting agent will be inserted.

Thanks to the paired type:

- slippage will be reduced, productivity levels will be higher;

- maximum contact with the surface will be achieved.

Homemade twin wheels for walk-behind tractors can be made in any variety of variations: mounting diameters, their weight, width, profile height - it all depends on the needs and capabilities of the owner of the unit.

How to make your own weights for the cultivator chassis

Weighting materials have been created to solve this problem. You can make them yourself. For this you will need:

- disc weights (from 5 kg);

- pancakes from a sports bar (10 kg each);

- clutch baskets for cars;

- hexagonal profile;

- Bulgarian;

- welding machine;

- electric drill.

The process occurs in the following sequence. Holes are drilled in two small sections from the profile, plate discs from the bar are attached to them, clutch baskets are welded to the plates and then weights are attached. The weighting material is ready, it can be attached to the cultivator.

How to choose tires for a walk-behind tractor

The correct choice of tires for walk-behind tractors is the key to its proper operation. To make a correct and correct choice, you need to know the width of the tire. It is indicated by the first numbers in the marking and, as a rule, is measured in inches, and you also need to know the mounting diameter of the rim.

Its characteristics

The main characteristics of rubber are its parameters - width, diameter, tire weight, maximum load weight that it can withstand.

Varieties

Tires for walk-behind tractors differ in size. The following are represented on the domestic market:

- 4,00-8;

- 4,00-10;

- 5,00-10;

- 5,00-12;

- 6,00-12;

- 6,00-16.

Rubber, which is most often installed on motor cultivators, is presented on the domestic market in the following versions:

- Kama-421 tires are capable of withstanding a possible load of 160 kg, width - 15.5 cm, weight of one tire - about 7 kg;

- “L-360” weighs 4.6 kg, diameter is 47.5 cm, can withstand loads of up to 180 kg;

- "L-355" has similar parameters;

- “L-365” can withstand up to 185 kilograms, diameter is 42.5 cm, weighs only 3.6 kg.

Selection of tires for wheels

If the factory tires wear out on the wheels of a small-sized tractor at the dacha, replace the tires. Before choosing tires, determine the tasks you will perform with the walk-behind tractor. For plowing and collecting tubers, choose wide tires with a radius of at least 20 cm and the same width.

For motor cultivators and trailers, 4-10 inch models with spikes are a universal option. Studded tires do not slip on clay and have good grip on the ground. Select tires based on the factory parameters of the vehicle. Do not exceed the diameter specified by the manufacturer. The aggressive tread pattern eliminates the problem of clogging the tire cavities. For domestic walk-behind tractors Zubr, Aurora, Centaur, Dobrynya, and foreign cultivators ZIRKA, it is possible to install chamber wheel structures of 5-12 inches.

DIY iron wheels on a walk-behind tractor

Essentially, these are metal wheels with welded spikes that cultivate the soil layer and provide traction. First of all, you need to decide on the diameter and size of the studs and draw up a drawing of the future wheels. In addition, you need to decide on the weight of the future wheels, taking into account that for traction with the soil it must be large, and a motor cultivator may simply not have enough of it.

Homemade lugs

You can use rims from car wheels as a basis. An axle shaft is welded to them, onto which the bearings are placed. Square-shaped metal plates are attached to the disks by welding. It is necessary that they touch the edges of the rim. Next, the plates are bolted to the rim. Then teeth are made - hooks that will go into the soil. They can be made from corners. They are welded to the wheel rim approximately 15 cm apart.

Pros and cons of car wheels on a walk-behind tractor

To begin with, we should provide a list of the advantages and disadvantages of such a modification.

- Reliability. Passenger tires are designed for more impressive loads than the original tires of a walk-behind tractor.

- Durability. Tires from a passenger car, even in used condition, will last much longer.

- Patency. Thanks to the increased ground clearance, as well as a more impressive tread pattern of car tires, the walk-behind tractor will be able to drive over obstacles more confidently.

- Good traction due to greater tire contact with the ground.

- Increased speed as a consequence of the increased diameter.

- The need to dismantle the arches or redo them.

- The controllability of the device is slightly deteriorated.

Wheels from a Zhiguli on a walk-behind tractor

You can also install Zhiguli wheels on walk-behind tractors with your own hands. The diameter of the Zhiguli wheels exactly matches the original wheels. Using Zhiguli wheels is more profitable, since original products, as a rule, are much more expensive. In addition, VAZ wheels are wider, heavier, have better cross-country ability and less slippage.

When replacing factory wheels with car wheels, the structure becomes heavier. An axle shaft is installed inside, onto which metal plates with holes are mounted, acting as weighting agents. Caps are installed on the outside to protect against external damage. The camera moves away. For greater traction between the wheels and the soil, it is possible to tighten a chain on them.

Zhiguli couple on the Neva

The installation process occurs in the following sequence:

- Installing the axle shaft.

- Removing a tire from a wheel.

- Installation of spikes.

- Attaching the structure to the rim with bolts.

- Replacing disks.

- The structure is screwed to the hubs installed on the walk-behind tractor.

A walk-behind tractor in operation.

You can make wheels for garden motorcycles yourself, improving the design to suit your needs, the tasks assigned to the equipment, and any desired type of soil and terrain. There are quite a lot of options for independent modifications; every gardener and farmer can easily make what he needs for comfortable work.

A walk-behind tractor is a technique that is familiar to most farmers. In fact, this is a mobile tractor that is used for plowing soil, planting plants or transporting goods. It is convenient in small summer cottages, where it is already difficult to do everything by hand, but a large tractor is not needed. If you are reading this article, then you either already have a walk-behind tractor or are planning to purchase one.

One of the most common questions from owners of this equipment is how to make wheels for a walk-behind tractor with your own hands? The thing is that in the standard configuration they wear out very quickly, and are also not suitable for all types of soils and terrain. Buying new ones is quite expensive, so you can resort to your own skills. In this article we will look at exactly how to do this.

What third-party wheels are suitable for the Neva walk-behind tractor?

Wheels from Muscovites and Lada are best suited for installation on the Neva walk-behind tractor. There is no need to change anything in them, since their diameter is ideal for installation on a walk-behind tractor. They only need to be slightly modernized by welding.

Zhiguli wheels on a Neva walk-behind tractor

Factory options will cost much more.

The main task when modernizing Zhiguli wheels is to make them heavier, since in the factory configuration they are very light.

Listed below are the main stages of manufacturing wheels for a walk-behind tractor from car tires:

- An axle shaft is installed inside the wheels;

- To make it easier to change wheels, square plates are installed on the axle and holes are made in them. And then the wheels from Zhiguei are attached to these plates;

- A cap is placed on the outside to protect against external factors;

- The tubes should be removed, and only the tires should be left (to improve the quality of traction, winter tires should be used).

Important Design of the ZIL-131 diesel engine

Using tires from other cars is problematic because they have a larger diameter or width, so they need to be additionally adjusted using an axle extension or some other method, and this is not always possible for everyone.

To improve the lug-holding properties, some people additionally cover the wheels with a chain. When driving, the chain digs into the ground and provides additional traction. The effect of it is especially noticeable when driving after rain or snow.

The video demonstrates how to install Zhiguli wheels on a Neva walk-behind tractor:

Types of wheels

First you need to figure out what types of wheels for walk-behind tractors exist. Since the equipment is used in many farming processes, the equipment varies. This also applies to pneumatic wheels, because good results and ease of use also depend on the right components. It is important to note that ordinary car wheels from Oka, Niva or Moskvich cannot be installed on the walk-behind tractor. All of the options below are larger and heavier. It would be more correct to compare them with ATV kits, although they do not always have the appropriate size.

- Pneumatic. This option can be used for arable work and for removing roots from the soil. These are large wheels in appearance, with a diameter of 40 cm and a width of 20 cm. The tread pattern must be rough for the walk-behind tractor to work well on the soil. Often this option comes as standard and is famous for its wear resistance. However, if they become unusable, you should immediately look for a replacement.

- Traction. The popular name for these wheels is herringbone. All because of the pronounced pattern on their tires. This type is also universal and suitable for lug or standard transport solutions. For example, they are often used by snow blowers. Traction tires for walk-behind tractors are also reliable in everyday use.

- Solid cast (most often made of rubber). Solid castings are ideal for rocky ground. They allow the walk-behind tractor to move faster on such terrain and do not deteriorate after the first use. The downside is that they are really very heavy, so carrying them is not so easy. Such tires are suitable for MTZ series walk-behind tractors and diesel vehicles.

- Metal. The last variation is suitable for clay soil. The thing is that, unlike previous wheels, these have steel teeth. This, of course, makes the equipment heavier, but in soft ground they do their job perfectly. In another way, metal teeth are also called lugs.

As for general recommendations, when choosing what to put on your walk-behind tractor, pay attention to the front wheel. It is supportive and during use it absorbs the entire mechanism. This helps to extend the service life and improve the quality of work.

In general, this classification of pneumatic wheels is used not only for walk-behind tractors, but also for trailers or other tools from the same category. So you can safely use it, because to maintain the wear resistance of all equipment, the farmer’s assortment must include both a trailer and a walk-behind tractor.

How to remake a walk-behind tractor

Many owners want to improve their walk-behind tractor to improve comfort during work. The most common modifications are the manufacture of adapters and trailers. This upgrade allows you to expand the functionality of the walk-behind tractor, because the adapter allows you not only to transport various loads, but also to use the walk-behind tractor as a vehicle.

Improving the walk-behind tractor will allow you to create a whole mini-tractor. Adapters and trailers can have their own steering, which is much more convenient than using a steering wheel from a walk-behind tractor. There are many step-by-step photo instructions and videos showing how to create a trailer. One of the most important elements of such a device is the frame, which is made of channel or pipes. Wheels can be taken from any car; the ideal option is wheels from an ATV. Bridges can be taken from VAZ 21-09, they need to be shortened. The steering column can be taken from the same car. The driver's seat will allow you to work with maximum comfort.

In addition, a mini-excavator can be made from a walk-behind tractor, the creation of which requires a hydraulic system. Such an excavator is very convenient for construction on a personal plot, because it is compact and can go where heavy equipment cannot.

How to make wheels with your own hands

Having understood the types of tires, you should learn how to make the same ones, but homemade ones. The first thing to consider is that in any case you will not be able to make wheels for a walk-behind tractor from scratch. You will need a base - old pneumatic wheels from a car, for example, from Oka or Niva. In this matter, everything depends on your choice or availability of suitable material. And by the way, farmers do not recommend buying a new set of tires for conversion, since they are not cheap and as a result, you will not be able to save a decent amount by doing the rest of the work yourself.

The second thing, without which nothing will work, is that before the process begins, you need to prepare drawings. This issue must be handled responsibly and the drawings must satisfy the requirements based on the materials available.

Often paired wheels are made, where additional weighting material can be placed inside. Let's start with this option. The twin option is a quick and effective wheel conversion that is affordable to many. You will need 4 wheels with a good stainless steel base (by the way, the masters have tires from Moskvich). It is also necessary to have iron plates with you. The process itself is carried out in several steps.

- The rubber tire is removed from the base.

- Several iron plates, up to 5 cm wide, must be welded to the rim on which the tire is placed. Usually, the plates are formed into a square, which is welded to one of the sides of the rim.

- Next, the rim from the second wheel is welded to this square. So you connect two rims together using plates and welding.

- At the last stage, the rubber is put back on the rims.

That's it, you have received the kit you need. As you can see, their main advantage is their large width. Thanks to this, they look less like wheels from a car, and more like an option for a walk-behind tractor.

The second option for strengthening pneumatic wheels is to increase their wear resistance using additional materials. In this way, you can remake the wheels of a vehicle such as a motorcycle or ATV. In general, you will need larger tires than for a regular car. And to increase rigidity, large chains may be suitable.

Let's move on to the process itself: chains need to be welded to the pneumatic wheels. You can try connecting them with rubber or an iron rim. Next, you need to make notches on them so that they imitate lugs. The result should look like store-bought metal wheels.

You will have to tinker with this method so that the chains hold tightly and do not fly off during work. Locking the chains with the rim will help here, which can be done using steel fasteners and hooks.

An additional element that is often missing for the convenience of working with a walk-behind tractor is an unlocker, sometimes called a differential. Since the instrument itself is heavy, it is often difficult to control it, namely, to turn it in different directions. In this case, an unlocker comes to the rescue - a special device that is attached to the wheels and increases their maneuverability in difficult areas.

The unlocking tool is installed to the output shafts of your walk-behind tractor using bolts. During operation, it reduces the turning radius of the entire machine and increases the track width. If you use a mini-tractor on a regular basis, then this thing is simply irreplaceable. You can make an unlocker yourself based on bearings, but in fact, the game is not worth the candle. You can find a wide variety of them on the market, and the unlockers are inexpensive. The most important thing is to find a specialist who can recommend a good product.

So, if you need new “shoes” for your walk-behind tractor and have the opportunity to use tires from a regular car or motorcycle, then why not give it a try. This article shows the simplest and most popular options, but it all depends on your experience and skills. In fact, the solution is very simple, you only need welding and a little skill. But for a good result, consult with experienced professionals before starting work.

To learn how to make wheels on a walk-behind tractor with your own hands, see the following video.

Very often in agriculture, serious problems arise when moving equipment. Wheels for the cultivator make it easy to deliver this unit to any part of the garden. Today the market offers a huge selection of wheels. However, it is possible to make them yourself without spending a lot of money.

Types of wheels

- rubber;

- metal.

It is worth noting that both options are excellent for plowing land. The only drawback may be the case when these wheels do not fit in size at the time of purchase or an attempt to change them when the old ones are already worn out, because they simply may not be sold separately.

The use of a motor cultivator is usually necessary to loosen the soil. A small unit is capable of plowing the land, planting crops, cultivating what was planted until a certain time and then collecting it, because a person buys a cultivator in order to exploit it to the maximum.

It is best to buy devices with a total diameter of more than 400 mm and a width of at least 200 mm. This will be justified, first of all, when planting potatoes or other types of vegetables.

It is very important that the exact distance between them is maintained. The optimal distance should be 70 cm. This is necessary so that there are no difficulties when moving the unit between rows.

Experts recommend buying universal pneumatic tires so as not to overpay in the future.

They are perfect for all types of walk-behind tractors and cultivators.

Making homemade lugs

Sometimes pneumatic tires can slip (soft ground, slush after rain, ice) and your work can go down the drain. For better adhesion to the soil, reliable devices are needed. These are ordinary lugs.

You can, of course, buy them in a store, but not everyone wants to spend money on something that is easy to make yourself, and from “waste” materials. Moreover, there are only two requirements for them, and both are necessary to ensure reliable grip:

- Weight 20-30 kg.

- Digging into the ground.

There are many options for DIY lug wheels. We will focus on two of them. For their manufacture, the main tools are:

- Bulgarian;

- welding machine.

To complete the first option, you will need metal strips (about 5 mm thick) and car rims. Their diameter depends on the size of the cultivator blades. Many people take Lada wheels as the best option. Picture 1.

Figure 2. Homemade lugs for the cultivator.

The method for making soil hooks is very simple:

- cut strips with a grinder so that their length is approximately one and a half times the width of the disks;

- they are bent in a vice at an angle so that they are inserted between the two sides of the disk;

- distribute the strips evenly and weld them into place;

- strengthen the resulting lugs on the axle.

The second option is more difficult. For it, they take a sheet of thick metal, mark it and cut out something like a large bicycle sprocket or a ratchet from a watch. Next, parts of the resulting beams are bent and metal plates are welded to them. Figure 2.

DIY walk-behind tractor wheels

In order to make wheels for a walk-behind tractor correctly, you will need to calculate all the dimensions, as well as establish the type of required elements. There are several options in terms of functionality:

- traction;

- solid rubber;

- metal with lugs;

- supporting;

- paired

Important! The support wheel for the walk-behind tractor takes on the main load from the structure. Almost any unit has such an element, since without it the cross-country ability will be less, and the load on all equipment will reduce functionality.

In this video we will look at how to make wheels for a walk-behind tractor with your own hands:

For full-scale agricultural work, additional weights can be installed on the wheels of the walk-behind tractor. Weighting is necessary for more complete immersion in the ground, as well as to increase the stability of the equipment.

The process of creating equipment for the unit depends on the selected type and all the features of the equipment. Preliminary plan:

- preparation of tools and materials;

- creating a basis on which the finished element is already reproduced;

- if the base is made up of the equipment of a motorcycle or car, then you will need to make extensions to widen the track;

- Tires are selected according to soil characteristics; the worse the soil characteristics, the more aggressive or studded the tread.

Important! Homemade elements must be large in size. If this point is not taken into account, the load will not allow the entire system to function normally during work. Small wheels have little maneuverability, so they are not used for agricultural work.

It is worth considering that for normal cross-country ability, homemade products must have a minimum disc diameter of 19 inches or 47 centimeters. If parts are purchased, then all technical characteristics of the unit must be reviewed individually.

An example of a homemade passable option:

- take 4 disks from the car;

- all burrs are cleaned off;

- both pairs are welded together with their convex sides facing each other;

- tires are put on the finished double devices;

- After pumping, everything is installed on the structure.

Thanks to this procedure, wide wheels with a large coverage area are obtained. This significantly increases the maneuverability of the equipment.

There are many independent solutions in the form of wheels for devices, but it is necessary to take into account the method of using the equipment, as well as all its technical conditions.

Pneumatic wheels for walk-behind tractor

Pneumatic wheels are used in various models of equipment. This is possible due to the presence of high permeability on any type of soil. Among the features of pneumatic tires are:

- Christmas tree protector;

- sufficient width;

- standard dimensions are 20 cm in width and 40 cm in diameter;

- Large size facilitates use over large areas.

Important! Pneumatic options may be different, but if available, it is better to use those with a more aggressive tread type.

When choosing sizes, you also need to pay attention to the technical characteristics of the walk-behind tractor itself.

Each type of model has its own characteristics that need to be taken into account. This is interesting: wheels on the Neva walk-behind tractor.

Independent creation of equipment for machinery depends on numerous factors, including the availability of parts and the required tools. If necessary, you can use old wheels from cars or motorcycles. The main condition is suitable dimensions for the walk-behind tractor class. The entire process is carried out in accordance with a sequential order of actions, that is, first the preparation of materials occurs, then drawing up a drawing, if necessary, and taking measurements. Only after this you need to start working independently.

Tags: manufacturing, rims, weight, factory, need, make, cultivator, clutch, task, automobile, ground, tires, chassis, holes, other, steel, heavy, most, pipes, make, quality, install, devices, configuration, follows, sections, bolts, pancakes, trailer, allows, excellent, read, drawing, possibility, teeth, complex, metal, landing, operation, take, maximum, rubber, wheeled, weights, processing, instructions, provide, very, pick up, terrain

On 4 wheels

The 4 wheels can be installed in different ways on the device. The first option is to transform the equipment into a mini-tractor and equip it with a seat. The second option is more common when making homemade equipment. In this case, and the use of unsuitable machine or motorcycle parts, two identical pairs are paired with each other.

Standard conversion of equipment into a mini-tractor is a common procedure if the unit has sufficient power. For this process, a free axis is created, which is installed on an elongated body. Paired equipment is placed on this axis.

When using the paired version, two sibling pairs are broken up and paired with the second wheel. It is also possible to install weighting agents between adjacent disks, but in homemade work, most often the disks are paired with a small gap using a small rectangular window, which then serves as a weighting agent.

Important! Paired options can be either solid rubber or pneumatic, but one pair must have an aggressive tread.

When fully created, each part will be a double element, which is created from equal parts. It turns out that the elements must be the same in shape and size.

Among the advantages of this design:

- higher level of productivity;

- quick removal of external parts;

- ease of creation;

- high level of contact with the surface.

The main advantages are increased maneuverability and increased speed.

A walk-behind tractor with 4 wheels is considered the most practical for creating at home.

Wheel extensions for walk-behind tractors - homemade

In order to expand the wheelbase of the walk-behind tractor and make it more stable on uneven terrain, it is best to install wheel extensions on the unit. These simple devices are quite easy to make at home, if you have certain tools and materials on hand. The algorithm for making extension cords is as follows:

- Take two metal pipes, the diameter of which should be 1–2 mm larger than the diameter of the walk-behind tractor axis;

- In the part where the products will be installed on the axle, it is necessary to make a thread that will allow the extension cords to be screwed onto the walk-behind tractor;

- The other side of the pipes should be 1–2 mm smaller than the holes in the wheel rims. If necessary, the pipes must be cut down to obtain products of the required size;

- To fix the wheels on the extensions, you need to make steel plates that will be attached to the disk with bolts.

Using all the tips listed above, you can make high-quality wheels for walk-behind tractors Agro, Neva, Krot and units of other domestic and imported brands.

Single wheel

A one-wheel motor cultivator is considered one of the simplest options for doing it yourself. One device can be both a pneumatic traction and a grouser. This type of equipment is used for carrying out simple agricultural work, for example, hilling or digging potatoes. One device is installed on the walk-behind tractor, which is also a support device.

During operation, significant pressure is exerted on the support area, which requires its large size. If the element on a one-wheel walk-behind tractor has a small diameter, then problems with maneuverability may arise, even in good soil conditions.

Why is this necessary?

At the moment, there are several types of mini-equipment for cultivating land:

- motor cultivators;

- walk-behind tractors;

- mini tractor.

At the same time, consumers often do not realize that each type of this equipment is designed to solve certain types of work. Therefore, buyers focus on price and purchase cultivators, as they consider them a cheap version of walk-behind tractors. Epiphany comes immediately after the owner of the cultivator realizes that his cultivator is only capable of loosening the soil with cutters, and it is impossible to use attachments while working on this unit for the following reasons:

- weak power;

- unreliable gearbox (reduction gear);

- no wheels.

However, the money for the purchase has already been spent. Therefore, the owner of a cultivator is faced with the question of whether it is possible to convert it into a walk-behind tractor.

How to install Zhiguli wheels

If you have old spare parts for Lada cars, then there are two options for using them. The first is the creation of lug elements based on discs. This procedure requires the following steps:

- remove and clean the disks;

- weld the plates in a certain order, which will act as lugs;

- install lugs using weights and extensions on the base.

If you use pneumatic tires from Zhiguli, then it is advisable to install winter tires on the walk-behind tractor, which are more aggressive and have greater cross-country ability. If the walk-behind tractor is used for large-area work, then it is necessary to use a paired version or lengthen the axle when installing parts from Zhiguli.