Small agricultural machinery of domestic production is widely popular among Russian farmers and owners of household plots. Cascade walk-behind tractors have many adherents. Many owners of these units successfully carry out independent maintenance of their equipment. However, in order to ensure its smooth operation and long service life, it is important to know how to properly maintain this equipment. Today we will study such an important part of the Cascade walk-behind tractor as the gearbox.

What types of walk-behind tractor gearboxes are there – types and purpose

Modern walk-behind tractors are equipped with gearboxes that differ in their design and purpose.

The mechanisms used to operate agricultural machines are divided into the following types: Angular gearbox for a walk-behind tractor - a mechanism of this type serves as a connector between the motor and the unit box. The good properties and low price of this unit make it one of the most popular among farmers. The design of the angular gear allows it to be modified, increasing it, thereby significantly increasing the performance of the mechanism;

Reducing gearbox for a walk-behind tractor - the task of this type of mechanism is to increase the power of the motor and reduce its speed. Such gearboxes are considered one of the more reliable and efficient devices, because they consist of strong iron parts that are virtually resistant to wear, and a standard air cooling system. Walk-behind tractors equipped with such gearboxes can easily handle any load and can solve a huge number of household problems;

Reverse gearbox - this reverse rotation mechanism is installed between bevel gears, which, in turn, are placed on the main shaft of the walk-behind tractor. This reversible circuit is quite simple, so disassembling it takes less than 10 minutes. The main advantage of a reversible gearbox is its ability to reverse. Among the shortcomings, one should highlight the low performance of the mechanism and the low speed when moving the walk-behind tractor in reverse;

Gear reducer for a walk-behind tractor - heavy walk-behind tractors are equipped with this type of mechanism. It is used to a greater extent to transmit the torque generated by the motor to the wheels of an agricultural machine. Among the main advantages of the gear reducer are the highest reliability and simplicity of design. The only disadvantage of this mechanism is the difficulty of maintenance. However, most manufacturers of walk-behind tractors equip their equipment with a gear reducer. If you are planning to make a homemade gearbox, then it is best to make a specifically gear-type mechanism;

Worm gearbox on a walk-behind tractor - the distinctive features of this mechanism include the presence of a special screw and a toothed worm wheel. For the production of each part of such a gearbox, materials with high strength are used. The gear ratios of worm gearboxes range from one to 4. The number of direct gears depends on the number of threaded channels on the mechanism screw. Among the main advantages of a worm gearbox, the highest efficiency of the mechanism should be highlighted. It is used in the production of equipment that requires low angular velocity and very high torque. The worm gearbox ensures smooth running and low noise levels when operating the walk-behind tractor.

Each of the listed device types has its own advantages and disadvantages. You should keep this in mind when choosing a walk-behind tractor equipped with one or another gearbox.

Carburetor of MB-1 walk-behind tractor

Let's look at the carburetor of the MB-1 walk-behind tractor. The device regulates the fuel supply to the engine and prepares the combustible mixture (mixing fuel with air). It is part of an internal combustion engine.

Why do you need to adjust the carburetor? A situation may arise when the walk-behind tractor begins to work unstably. This can happen if the unit has not been used for a long time or, on the contrary, has undergone heavy loads. In such a situation, you will need to adjust the carburetor, for which there are special instructions.

The carburetor must be adjusted in the following sequence:

- Tighten the full and low throttle screws all the way (without overdoing it), and then unscrew them one and a half turns.

- Start the engine and wait 10 minutes for it to warm up.

- Without turning off the engine, set the lever to minimum speed.

- Using the screw (throttle valve), which regulates the amount of fuel flowing, you need to achieve such a minimum idle speed at which the interruptions will stop.

- Adjust the throttle screw to maximum and then to minimum. This must be done until the motor starts working normally.

- Move the engine lever to gas.

- Set the throttle screw to a maximum of 2.5 turns.

Peculiarities

The design of the walk-behind tractor is equipped with a gear-chain unit, the main task of which is to transmit rotational motion, and therefore to change the rotation speed of the cutters. It is thanks to the gearbox that the driven pulley transmits the mechanical action to the wheels of the equipment, thereby changing the speed and direction.

Inside the housing there is oil, which is necessary to ensure the operation of the gearbox. The element is enclosed in a durable sealed housing. Its kinematic scheme consists of a chain and two stars located in opposite directions. The lower one is called the driven one, because it stands on the shaft and drives the entire walk-behind tractor system.

Walk-behind tractor Cascade: main technical characteristics

Any modification of Cascade walk-behind tractors is based on four main structural units - power, chassis, controls and transmission. The power plant includes the engine and its dependent systems. As mentioned earlier, all models of Cascade walk-behind tractors are equipped with motors of domestic and foreign production (more about them later).

The chassis consists of a reinforced frame, wheels (it is possible to install both pneumatic wheels and steel wheels with lugs) and connecting units. An undoubted advantage is the ability to adjust the track width. For ease of use and storage, a special support foot is installed in the front part of the walk-behind tractor.

The transmission of the unit includes a reinforced chain gearbox, clutch and gearbox. The gearbox is four-speed, has 2 forward and 2 reverse speeds. This has a positive effect on the maneuverability of the unit. The gearbox is reliable and resistant to vibration and mechanical damage thanks to the output shaft mounted on large diameter bearings.

First launch and run-in

Running in is necessary so that all parts can get used. Having worked for a short period of time at a minimum load level, the walk-behind tractor will be less likely to fail in the future.

- The break-in process must be no less than the time specified in the operating instructions.

- Loads should be small. For example, if the technical specifications indicate that the maximum tillage depth is 50 cm, then during the first start-up and run-in it is recommended to limit it to 30 cm.

- Before running in, it is necessary to fill the engine with oil.

- Fill the fuel tank.

- Start the unit at medium speed.

- Within 60 minutes it is necessary to check the operation of all gears.

- Perform a small amount of work on cultivating, plowing the soil and transporting small loads.

How to install a generator

In order to install an electric generator, you must do the following:

- The generator has 4 wires, 2 of which are blue. An energy converter must be connected to these 2 wires.

- The black wire should be connected to the motor.

- Connect the remaining red wire to the parts responsible for the external lighting and sound signal.

The generator generates electrical energy, which is supplied to the rectifier. When starting the engine, the adjusted belt transmits torque to the rotor part of the unit. The electrical unit generates voltage from which the walk-behind tractor battery operates.

The power of the selected generator should not exceed 220 V. It is recommended to select a spare part whose power will correspond to the expected load.

Belt adjustment and dimensions

The V-belt on the walk-behind tractor helps the unit move forward and backward. When the drive belt slips, the equipment stops functioning correctly.

In order to determine the size of this part, it is necessary to measure the gap from the pulley to the rollers. Recommended belt parameters: width - 0.85 cm, height - 0.6 cm.

To tighten the belt, you must do the following:

- Remove the casing.

- Loosen the tension screw of the standard belt part.

- Remove all the screws that hold the bracket to the walk-behind tractor body.

- Remove the old part and adjust the pulleys.

- Wipe the space between the parts and blow out the rods.

- Install a new belt, one end of which must be connected to the shaft part, and the other to the pulley.

Replacement of gearbox seals

The cause of gearbox failure may be improperly functioning oil seals. Therefore, repairing the Neva walk-behind tractor gearbox may include the following actions:

- Removing cutters from the shaft part.

- Cleaning the shaft and cover from dirt and oil residues. Remove all screws from the cover and wash them.

- Replace the old part with a new one and wipe the entire mechanism dry.

- Return the cover to its place and secure it with bolts.

In some cases it is necessary to disassemble the gearbox:

- Remove the head from the gear shift knob.

- Remove the bushing and spring from the shaft part.

- Remove all screws and tie bolts.

- Using a thin screwdriver or knife, remove the right half of this part.

- Removed parts must be washed, and faulty parts must be replaced.

- Reassembling the gearbox is carried out in the reverse order.

How to set the ignition

Before carrying out the procedure, it is recommended to make sure that the design can cause a spark that will ignite the fuel in the internal combustion chamber.

Procedure for adjusting the ignition of a walk-behind tractor:

- Rotate the crankshaft so that the marks made on the pulley and the gas equipment of the unit coincide.

- The slider, which is responsible for the distribution of gas flows, must be directed to the high-voltage wire of the cylindrical part.

- Loosen the nut and remove the high-voltage wire from the cover of this system.

- Place the contacts at a distance of 0.5 cm from the equipment.

- Turn the ignition on.

- Turn the mechanical structure in the opposite direction.

- Once a spark appears, quickly tighten the screw.

Major equipment failures

The walk-behind tractor consists of main units and additional accessories.

The engine, gearbox and carburetor are the main components of the Cascade walk-behind tractor. The repair instructions give clear instructions on the sequence of actions. In case of minor breakdowns, they are repaired quickly. This means replacing a worn belt or burnt out spark plugs. As for serious damage, they can occur due to filling with low-quality fuel or improper maintenance.

Possible engine malfunctions

After 5 years of operation, the engine begins to lose power and often runs intermittently. First of all, attention is paid to the exhaust. If it is black, then one of the reasons is the rich mixture that comes from the carburetor. To detect another cause, the spark plug is unscrewed . Three things indicate the presence of soot:

- the air filter is clogged;

- the carburetor fuel valve has lost its tightness;

- wear of oil scraper rings.

Adjusting the carburetor and replacing the air filter are minor repairs. The rings are replaced when a lack of compression is noticed. In the case of such repairs, carbon deposits are simultaneously removed from the surface of the cylinder block seats and valve edges.

Inspection of gearbox faults

The gearbox of the Cascade walk-behind tractor, the design of which is quite complex, can fail as a result of rare oil changes. In this case, the following breakdowns may occur:

- chain alignment due to displacement of bushings;

- when the walk-behind tractor operates at an angle to the ground, the support washer wears out;

- the bushings fall apart and the chain falls off;

- oil seal leak.

All breakdowns can be felt by listening to the operation of the unit. Repairing the gearbox of a Cascade walk-behind tractor with your own hands is quite simple, but it requires acquiring skills. After draining the oil and disassembling the gearbox, unusable parts are replaced and new ones are installed. The main thing is to install them correctly, in accordance with the alignment requirements.

Carburetor problem

The carburetor may not receive fuel. In this case, the following actions are taken:

- when the tank is filled, the fuel tap opens;

- The hole at the bottom of the gas tank is cleaned;

- if it does not help, then the tank is removed and it is completely cleaned;

- The hose is disconnected from the carburetor and cleaned.

Purchasing a walk-behind tractor with attachments greatly facilitates work on a summer cottage. Now all work can be mechanized, which means speeding up activities several times. Moreover, the use of this equipment is ongoing. Even in winter it can be used to clear snow.

Operation and maintenance of Neva MB-2

Malfunctions with spark plugs

First of all, check the performance of the spark plug.

To do this, you need to unscrew the spark plug, wipe the electrodes and remove carbon deposits. Then follow the steps described above in adjusting the ignition. The spark plugs are OK if there is a spark. If there is no spark, the spark plug will probably need to be replaced.

In the operating instructions for the Neva MB-2 walk-behind tractor, the manufacturer indicates the size of the gaps between the electrodes of the spark plugs and the recommended models of spark plugs:

- spark plug A11P (made in Russia) - gap 0.5÷0.6 mm. Wrench dimensions 20.8 mm;

- spark plug NR17С (BRISK) - gap 0.5÷0.6 mm. Wrench dimensions 20.8 mm;

- spark plug WR8AC (BOSСH) - gap 0.5÷0.6 mm. Wrench dimensions 20.8 mm.

Before starting to operate the walk-behind tractor, it is necessary to check whether the sealing washer is installed on the spark plug and whether the sealing washer from the previous spark plug remains in the hole of the cylinder head.

The spark plug can be removed and installed only after the cylinder head has completely cooled down to ambient temperature. If, when removing the spark plug from the engine, the tightening torque was exceeded by more than 50%, further use of such a plug is NOT PERMITTED.

Checking and adjusting the clutch of the Neva MB-2 walk-behind tractor

The main function of the clutch is to connect the gearbox to the engine, disengage it, and also connect other operating devices to the engine. If an overload occurs during operation, the clutch begins to slip - this is how other parts of the walk-behind tractor are protected from damage.

Checking the clutch operation can be done according to the diagram below.

If the clutch lever is in the disengaged position, the clutch cable is loose. Consequently, the tension roller lowers and comes into contact with the drive belt. After which the drive belt and small roller move to the lowered position - this stops the supply of power from the engine to the transmission.

When the clutch lever is moved to the "ON" position, the clutch cable pulls the idler pulley, therefore the bottom of the belt is pressed tightly, the small pulley moves the large pulley and power is transferred.

Adjusting or adjusting the clutch of the Neva MB-2 walk-behind tractor is performed as follows:

- if the clutch lever is engaged, it will lift the tension roller, setting the walk-behind tractor in motion. The correct position is for the V-belts to be parallel on either side of the engine pulley.

- If the clutch lever is loose, the tension roller will drop and disengage the clutch. To avoid disabling the clutch, and therefore slipping the walk-behind tractor, you need to monitor the position of the V-belts, bringing them to a parallel position.

Replacement of gearbox seals

The oil seals in the Neva MB-2 walk-behind tractor are replaced if an oil leak is detected.

This condition is dangerous because the walk-behind tractor gearbox may be left without oil, and this will lead to rapid wear of the unit.

The sequence for replacing oil seals is as follows:

- Remove the cutters from the shaft, cleaning the shaft and covers from dirt and oil residues.

- Unscrew the cover bolts, tap off the oil and debris, and remove the cover from the gearbox.

- The old oil seal is replaced with a new one and wiped dry.

- The cover is returned to its place (if necessary, it is placed on sealant) and fixed with bolts.

Adjustment of valves

Adjusting the valves is a fairly simple procedure that requires wrenches, screwdrivers and a feeler gauge. The valve adjustment process is needed to establish optimal and technically correct clearances between the valves of a walk-behind tractor engine. Adjusting valves using the example of the Neva MB-23 walk-behind tractor (the principle is the same for everyone)

The adjustment sequence is as follows:

- remove the casing that covers the engine;

- remove the valve box cover;

- make adjustments (see below);

- Reinstall the valve box cover;

- Replace the casing.

The valves are located under the valve cover. The gap size can be checked with a feeler gauge. The intake valve clearance is 0.15 mm, and the exhaust valve clearance is 0.2 mm. The dipstick should fit under the valve with the correct gap size.

To adjust, the valve nuts are loosened, then a feeler gauge is inserted, after which the adjustment itself is made, and the valve nut is tightened.

The manufacturer emphasizes that in Neva MB-2 walk-behind tractors, the gaps between the ends of the valves and the ends of the pushers (0.1÷0.2 mm) are ensured by grinding the ends during the initial assembly of the engine and are not adjusted during operation!

How to replace oil seals on a walk-behind tractor

Replacing the oil seal in the gearbox of a Cascade walk-behind tractor is a necessary measure if this part fails.

Faulty oil seals cause oil leakage, as a result of which moving parts run dry, quickly wear out and become inoperable. This is interesting: video repair of a Cascade walk-behind tractor.

This repair is carried out as follows:

- Remove the cutters and clean them of dirt.

- Unscrew the bolts holding the cover and remove it from the unit.

- Remove the faulty oil seal and replace it with a new one, pre-lubricated with oil. If necessary, treat the connector with sealant. If the oil seals are protected by a special part, in order to remove and replace them, the gearbox must be disassembled.

Motoblock device

All existing Oka walk-behind tractors have the following device:

- Gas engine;

- rigid frame;

- adjustable steering bars with rubberized handles;

- transmission (reinforced chain reducer, V-belt transmission, mechanical gearbox, clutch, PTO drive);

- chassis (wheel drive);

- gas tank;

- filters (oil and air);

- ignition system;

- inertial starter.

The kit may include tillers and a hitch.

Depending on the modification, Oka walk-behind tractors can be equipped with various engines:

- The Oka MB-1D1(2, 3)M9 walk-behind tractor is equipped with a Honda carburetor engine (HONDA GX-200) with a capacity of 6.5 horsepower.

- Models MB-1D1 (2, 3)M10 have a Lifan gasoline power unit (Lifan168 F-2A) with a capacity of 6.5 liters. With.

- The MB-1D1 (2, 3) M15 walk-behind tractor was equipped with the original factory KADVI 168F-2A 6.5 liter engine. With.

- Modifications MB-1D1 (2, 3) M13 and M14 received a Robin Subaru EX17 or EX21 power plant, with a capacity of 6.0 and 7.0 liters. With. respectively.

- Models MB-1D1 (2, 3)M and MB-1D1 (2, 3)M1 are equipped with DM-1M and DM-1M1 engines with a power of 8 hp. With.

Common to all listed power plants:

- one cylinder;

- cycle for 4 cycles;

- forced air cooling;

- use of AI-92 or AI-95 gasoline.

The ignition system is electronic, which includes: magneto, spark plugs, high-voltage wire.

It is necessary to start the engine correctly, according to the algorithm specified in the instructions. If certain actions are not followed, there is a high risk of engine failure. We invite you to watch a short video on how to start the Oka walk-behind tractor:

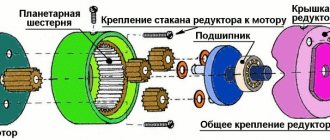

Gearbox device

The walk-behind gearbox transmits torque from the engine to the wheel drive. Its design is as follows:

We suggest studying the cross-sectional diagram of the Oka walk-behind tractor gearbox:

What type of gearbox can be installed on the Oka walk-behind tractor?

It is best to use a collapsible chain gearbox, which consists of a collapsible housing with bolted connections. Unlike a non-separable gearbox, such a mechanism can be easily repaired and will last for many years. A gear reducer can be installed on more powerful equipment; a worm gearbox is rarely practiced in walk-behind tractors.

The design and principle of operation of the carburetor

Carburetors are gas distribution devices inherent in gasoline engines. The function of the carburetor is as follows:

- regulates the amount of incoming gasoline and air;

- saturates the air with gasoline vapors.

We suggest that you familiarize yourself with the carburetor diagram for the Oka:

Description of the MB-1 walk-behind tractor

Motoblocks MB-1 are very popular in our country. They began to be produced in the 80s and are constantly being improved. Their towing class is 0.1, with additional and trailed equipment. This figure indicates the traction force of the vehicle.

If we consider that walk-behind tractors and mini-tractors are divided into 7 classes, then this unit is in the first row.

Attachments allow the motorized cultivator to plow the soil, hill it, loosen it, dig up root crops and rake grass. A trailer is used to transport various loads. The optimal cultivated area is 6-40 acres.

After purchasing the MB-1 unit, you need to carefully study all the recommendations presented, which are contained in the operating manual.

For the MB-1 cultivator, the characteristics are as follows:

- The main part on which all units are mounted is the cylinder block.

- An internal combustion engine is a gas distribution mechanism that controls gas flows. This mechanism consists of a camshaft and adjacent components (exhaust and intake valves).

- The camshaft diameter is 30 mm, length is 280 mm.

- The crank mechanism, the crank mechanism, ensures the rotational movement of the piston.

- Fuel system - supplies and filters fuel from the tank and delivers it to the cylinders.

- There is an ignition system to produce an electric spark.

- A starting device that assists in starting the engine.

- Cooling system that prevents engine overheating.

One of the manufacturers of the MB-1 Oka walk-behind tractor is located in Kaluga. It produces three variants of walk-behind tractors: A, B and C:

- Option A. Motoblock MB-1D1M 10.

- Option B. Motoblock MB-1D2M.

- Option B. Motoblock MB-1D3M.

Each of them has different engines:

- MB-1D1(2, 3) M - DM 1M engine, power 8.0/5.9 (hp/kW);

- MB-1D1(2, 3) M 1 - DM 1M engine, power 8.0/5.9 (hp/kW);

- MB-1D1(2, 3) M 1 - Mitsubishi GT600 engine, power 6.0/4.4;

- MB-1DK (2, 3) M 7 - I/C 6.0 HP engine, power 6.0/4.4;

- MB-1D1(2, 3) M 9 - engine NONDA GX - 200, power 6.5/4.8;

- MB-1D1(2, 3) M 10 - Lifan 168 F-2A engine, power 6.5/4.8;

- MB-1D1(2, 3) M 10 - Lifan 168 F-2A engine, power 6.5/4.8;

- MB-1D1(2, 3) M 11 - Vanguard 6.5 HP engine, power 6.5/4.8;

- MB-1D1(2, 3) M 12 - Lianlong 168F 1A engine, power 6.5/4.8;

- MB-1DK (2, 3) M 13 - Robin Subaru EX 17 engine, power 6.0/4.4;

- MB-1DK(2, 3) M 14 - Robin Subaru EX 21 engine, power 7.0/5.2;

- MB-1D1(2, 3) M 15 - KADVI 168F - 2A engine, power 6.5/4.8.

When working with the MB-1 motor-cultivator, the operating instructions will help the farmer understand the main aspects of the unit’s operation.

There is another walk-behind tractor from a Chinese manufacturer, which is approved by our GOST. This is an MB-2 m walk-behind tractor. The engine power of the walk-behind tractor is 6.5 hp. It copes well with the ground and at the same time consumes little gasoline. In user reviews regarding the Chinese model, there are dissatisfaction with parts that are made not of metal, but of plastic. During intensive work there is one minus: the cutters often break and the starter cord breaks.

Forza walk-behind tractors from , which produces advanced equipment, as well as spare parts and attachments, are also popular. The basic model is the FZ-01-6.5F cultivator. They have a modern design, they are quite reliable and durable.

Motor oils for walk-behind tractors - types and characteristics

A modern walk-behind tractor consists of many mechanisms, which require lubricant for proper and coordinated operation. Not only the durability of the unit’s elements, but also the effectiveness of its use in certain conditions depends on the quality and properties of the latter.

It’s not for nothing that the motor is called the “heart” of the walk-behind tractor. The performance of the unit largely depends on the condition of the first. The engine, in turn, will not be able to operate without properly selected engine oil.

The latter performs several important functions at once:

- cools the walk-behind tractor engine under heavy loads;

- lubricates the rubbing parts of the engine;

- cleans the internal cavities of the engine from blockages;

- compacts the fuel mixture, making it of higher quality.

During operation of an air-cooled engine, the lubricant used evaporates and accumulates on the surface of the hot cylinder. As a result, the oil along with the fuel turns into smoky exhaust gases. All fuel combustion products collected on the parts of the walk-behind tractor significantly complicate their lubrication. To prevent this, many companies that produce walk-behind tractors advise using special antioxidants along with lubricants, the task of which is to clean engine parts from harmful deposits.

All commercially available motor oils are divided among themselves according to the SAE system.

According to it, the following lubricants are distinguished on the market:

- summer oils – these products are intended for use primarily in the summer. They have a high viscosity, and there are no letter markings on their packaging. These compositions include SAE 20, SAE 30, SAE 40;

- winter oils - materials of this type are used to lubricate walk-behind tractor engines in the winter. They are characterized by low viscosity and the presence in the marking of the letter W, which stands for “Winter”. Winter oils include SAE 0W, SAE 10W, SAE 20W;

- all-season oils - these compounds are in the highest demand. They are universal, as they can be successfully used in both winter and summer. Their packaging is double labeled. These oils include 5W-30 and 10W-40 formulations.

To choose oil for a walk-behind tractor, you should also consider its composition.

Manufacturers produce lubricants for engines with the following compositions:

- synthetic oils;

- semi-synthetic compounds;

- mineral oils.

You can also find oils on the market for both 2-stroke and 4-stroke engines. Most modern walk-behind tractors are equipped with 4-stroke engines with built-in air cooling systems. Such engines should only be filled with 4-stroke oil.

A forced air-cooled motor heats up significantly more during operation than an active water-cooled motor. In this regard, the oil in a walk-behind tractor with such a cooling system must have high thermal-oxidative stability and fairly low volatility. In addition, the oil used to lubricate the engine must certainly meet all known modern environmental requirements, in other words, show the permissible level of toxicity of emitted exhaust gases and smoke.

Motoblock Oka - operating instructions

When purchasing any Oka model, the first thing you need to do is read the operating instructions for the motorized device, which contains the following sections:

- The design of the unit (as well as the design of its components: gearbox, carburetor, etc.).

- Assembling the Oka walk-behind tractor, according to descriptions and diagrams.

- Technical characteristics of the selected model.

- Instructions for starting the engine for the first time (Lifan, Honda or any other).

- The procedure for proper running-in of the power plant.

- Maintenance.

- Troubleshooting the Oka walk-behind tractor.

Instructions

The operating instructions supplied with the equipment suggest preparing the device for operation in several stages. You will need to assemble the walk-behind tractor and refuel it using the diagram in the instructions. Next, you need to measure the oil level, check the fastenings, valve clearances, and also break in the device.

After the above steps have been successfully completed, it is enough to configure the device accordingly and also follow the operating recommendations.

Setting up a walk-behind tractor

The cascade is delivered to customers in a fully ready-for-use condition, which does not require adjustment of the carburetor or other elements. During the entire warranty period, you should refrain from performing such work yourself, since they should be handled by service center specialists.

Launch and running-in

If the assembly was completed according to the instructions, there should be no problems starting the walk-behind tractor engine. If the engine starts unsuccessfully, you should inspect the spark plug: if it is wet, the problem is related to the ignition system, and if it is dry, the problem is with the carburetor. Running in is an important stage that affects the service life of the product. It involves following a number of rules:

- warm up the engine before performing work, allowing it to idle;

- do not load the power unit;

- All work must be carried out at 1st speed.

Such rules must be followed for 30 operating hours, after which you will need to check the connections in the engine and adjacent components, and also change the engine oil.

Possible breakdowns

According to the manufacturer, it guarantees stable operation of the device for 5 years, subject to compliance with operating rules and timely maintenance of the unit. At the same time, the warranty period is much shorter - 2 years, during which the owner can contact the service center to troubleshoot problems.

Among the most common problems that Cascade owners most often encounter are:

- the engine does not start;

- the ignition system does not work properly;

- unstable engine operation;

- changing the exhaust color to black;

- The walk-behind tractor does not move.

A fairly common problem seems to be the delamination of the belt used to change gears. Such a breakdown cannot be corrected by adjustment, since a damaged element will require immediate replacement.

Trouble-shooting

It should be remembered that the repair instructions are useful only if the warranty period has completely expired. Attempting to repair it yourself and breaking the integrity of the seals will result in termination of the warranty and significant costs to eliminate the damage.

When carrying out repair work yourself, you will need to follow the instructions supplied with the unit. The algorithm of actions depends on the type of breakdown, but it can be divided into several main stages:

- fuel system breakdowns. Check for blockages in the tank plug and remove them, blow out the jets, rinse the tank with gasoline;

- Ignition fault. Replace the spark plug or its tip, check the gap between the stator and the flywheel, and adjust it if necessary;

- clean the filter elements.

After performing such manipulations, the unit most often returns to working condition. If you have the necessary knowledge and qualifications, you can try to adjust the carburetor, but this is a difficult task, the incorrect execution of which can lead to serious damage.

How to change oil

Most often, the speed of oil changes depends on the engine and its performance. Changing the oil in the gearbox can be done in conjunction with changing engine lubricants. It all depends on the type of engine:

- Robin Subaru. The first replacement process is after 20 hours of working procedure, and then every 100 hours.

- Honda and Lifan - 20 hours, and then after 6 months.

- Briggs & Stratton - 5 hours. Subsequently, regular checks are carried out after 8 hours. A full replacement process must be carried out every 50 hours of operation.

Replacement:

- the equipment is placed vertically without even a slight tilt;

- the breather is unscrewed and cleaned;

- after unscrewing the screw, the oil is drained into a container of at least 3 liters;

- the screw returns and tightens;

- oil is poured;

- the breather closes;

- The functionality of the equipment is checked.

Don't forget to follow the oil change instructions.

This is a standard lubricant change plan.

It is worth considering that according to standard recommendations, the frequency of shifts is regulated in the following order:

- running-in – 30-35 hours;

- simple – 1-2 years;

- working process – 150-200 hours.

These parameters are set for the work process without increased load on the walk-behind tractor. During heavy-duty operation, it is better to change the oil every 50 hours of operation, which will prevent the entire lubrication system from becoming clogged. This will increase the chances of full operation without breakdowns.

Engine assembly

Wash before assembly

and clean all

parts

and assemblies to be assembled.

Lubricate the engine cylinder

, pushers, piston with

connecting rod

, and crankshaft journals with engine oil.

Install the cylinder

to the workplace.

Insert the crankshaft

into the support bearing of the cylinder block.

Let's introduce

piston with connecting rod into

the cylinder

using a sheet of

tin

and pliers.

Let's start the lower one

the connecting rod head onto the

crankshaft

journal, put on the connecting rod cap,

oil sprayer

,

lock

and tighten.

Let's bend the carpentry whiskers of the lock washer

.

Let's install

pushers

into the cylinder block .

We will install the distribution

shaft so that the mark on the

gear

is opposite the mark on

the camshaft

gear cavity.

Let's check the crank

shaft, while checking that

the oil sprayer

does not touch the wall of the

cylinder

.

Let's check the ease of rotation

gears

of the centrifugal

regulator with weights on the axis of the

cylinder

.

Let's install the gasket

and the

cylinder

, while turning the crankshaft slightly so that the gear with

weights

engages with

the camshaft

gear.

We tighten

cylinder

block cover bolts Install on the cone

crankshaft

key

and put on

the flywheel

with a washer

Lubricate the internal cavity of the ratchet clutch

body

with a thin layer of LITOL-24, put it on and

tighten

it.

To the end part of the crankshaft

the shaft we will put on a ring and

a ratchet

.

Lubricate the clutch balls with motor

oil, install them in

body

, put on the cover and

protective

casing.

the head on the cylinder block

with

gasket

fuel

mounting bracket .

Let's take a puff

head

mounting bolts .

Let's check it out

and

adjust

the gap between

the stator

and the magnetic shoe.

Install the fan

, reflector and protective cover.

Let's install

key and

pulley

on the crankshaft.

Put it on the pipe

carburetor air

filter

, install the fuel tank and

gas hose

.

Source

Gearbox products

Please note that you must not forget to change the oil in the gearboxes. If you miss this point, after some time the additives lose their properties. To increase their service life, their characteristics must be protected with oil. Failure to replace it in a timely manner may cause the product to foam, resulting in the gearbox jamming.

Before changing the oil, you need to check the previous level, then remove the oil dipstick and clean it with a soft cloth. The monoblock gearbox should be filled with oil at a medium level.

Oil is the key to long-term operation of the gearbox. When looking for the best product, be sure to read the instructions. It is important to consider the conditions under which it will be used. The most popular oil is the Motul brand, which is used by almost all owners of walk-behind tractors.

DIY gearbox repair

Easy maintainability is one of the reasons why Cascade agricultural units have gained their popularity. When operating these walk-behind tractors, it is not difficult to independently adjust and repair almost any of its parts.

The most common cause of malfunction is wear of parts, which occurs naturally sooner or later. To increase the service life of the device, it is recommended to adjust it as needed during operation and carry out technical inspections at the required intervals.

Let's look at the most common breakdowns:

- problems with spark plugs (oxidation, contacts come off, the shape of the gap has changed);

- insufficient oil level;

- cylinder gasket wear;

- contamination of the fuel system (resulting in difficulty getting fuel into the carburetor);

- The chain or belt tension has weakened.

As a result of malfunctions in various parts of the device, several types of malfunctions are possible. Let's take a closer look at them:

Excessive heating of the transmission during operation is a malfunction that is caused by bearing wear or oil problems (low level or poor quality). To avoid interruptions in operation due to oil, it should be replaced. If the malfunction remains, it is necessary to disassemble the transmission, inspect the bearings and replace those that have become unusable. Uneven running of the unit with stable engine operation is a problem usually associated with wear of the treads

It is important to consider here that you cannot work on worn out protectors. If everything is in order with the treads, there may be a problem of uneven pressure on each of the wheels. Vibration of a walk-behind tractor during operation is a malfunction that occurs if the equipment attached to the unit is poorly secured

To avoid this, before starting work you need to make sure that the bolt connections are made correctly and securely.

https://youtube.com/watch?v=RRTkdkVAccQ

Another problem that sometimes occurs is difficulty starting the engine. There may be several reasons for this, and in order to determine which one is interfering with the correct operation of the unit, it is necessary to check it according to the following scheme:

- inspect the appearance of the device and make sure there is no damage;

- make sure that the fuel tank is more than half full and the quality of gasoline meets that required by the manufacturer;

- place the walk-behind tractor on a flat horizontal surface;

- make sure that the fuel supply system is working correctly;

- check the ignition system - make sure that a spark is being supplied;

- Check the operation of the carburetor and, if necessary, adjust the fuel mixture.

Repairs and malfunctions

Despite the fact that walk-behind tractors of the Salyut model range are reliable, in some cases malfunctions occur in the gearboxes. Let's look at the main problems you may encounter and how to deal with them:

- Weak return after oil change (no sealing, the oil seal needs to be reinstalled and sealant applied).

- A metallic noise is heard (usually due to lack of lubrication, service should be carried out immediately).

- The mechanism hums (there is an excess of mixture in the gearbox, the excess liquid needs to be drained).

This is interesting: repair of the gearbox of the Neva MB 2 walk-behind tractor.

Other malfunctions may also occur related to the breakdown of bearings or gears, as well as anthers; here it is necessary to immediately replace worn parts.

Currently, special equipment includes many high-quality structural elements. However, even despite this, it can be subject to breakdowns. Often the failure of components is associated with a lack of lubrication, which has an extremely detrimental effect on the metal. That is why, in order to avoid unnecessary waste of funds, it is recommended to carry out maintenance in a timely manner. In this case, the working apparatus will perform all the duties assigned to it for a long time.

Basic rules for performing work

Any work on disassembling and assembling the gearbox, as well as its maintenance, must be carried out at a previously prepared workplace with all the necessary tools. The cleanliness of the workplace must be ensured to prevent dust, dirt and debris from entering the mechanism. It is advisable to carry out all work wearing clean work gloves, which will provide both protection of hands from injury and contamination, and protection of gearbox components from unwanted debris and dust.

Carefully monitor the condition of the tool you are using - there should be no noticeable damage, especially cracks. Failure to do so may result in serious injury.

Before disassembling the gearbox, drain the oil from it. After this, you need to thoroughly clean all parts of the device from possible contamination.

After repairing and assembling the gearbox, be sure to fill it with fresh oil before operating it.

MB-1 cultivator gearbox design

Let's look at the design of the gearbox of the MB-1 walk-behind tractor. This is a device responsible for rotation, movement from the engine to the wheels. The MB-1 walk-behind tractor gearbox is assembled in such a way that on its outer side there are elements responsible for changing gears. The gearbox has five positions. When pressed, the fork disengages the clutch. When reset, it returns to its original position.

When the drive is connected to the right side, the unit will stop. The rotation comes from the sprocket. When the handle catches the left sprocket, the gear is reduced. If maximum gear is desired, the handle is pulled out all the way.

Assembly and adjustment of the gearbox is carried out after repair or malfunction. Before the procedure, each part is inspected for damage and contamination.

Sometimes the engine on the MB-1 walk-behind tractor is replaced. This is done if you want to install an imported engine on a domestic model. For this purpose, a kit is used, which includes a plate (platform, pulley), belt transmission, and a set of fasteners. There is an engine replacement diagram. Thanks to the drawings, it will be possible to easily cope with the replacement.

Old-style motor cultivators are also popular. The first Soviet walk-behind tractor, MB-1, is a very durable and reliable technique that was used for various purposes. They were produced on the basis of Soviet cultivators, which were quite durable.

Operating principle and purpose

The main purpose of the walk-behind tractor is to plow the field or hill it. Secondary tasks assigned to it may include snow removal and cargo transportation (with an attached trailer). A walk-behind tractor is a device built on the basis of a single-axle frame and developed on the basis of a small-sized tractor device. The user, controlling the movement of the walk-behind tractor, follows him.

The idea of creating a small device that performs the work of a full-fledged tractor when processing arable land arose at the beginning of the 20th century in Europe due to the inconvenience of full-fledged tractors in private fields. Thus, in 1912, the German company Siemens-Schuckertwerke launched mass production of motor cultivators under the name Siemens Bodenfrase. At that time, the company produced both small-sized lightweight devices and heavy, powerful devices that were not inferior in performance to full-fledged tractors.

During the 20s, other concerns, such as SIMAR, British Anzani Iron Horse, Beeman Tractor, became interested in the prospects of producing devices and set up their production. After which competition appeared on the market, developing and improving the production of walk-behind tractors.

Lighting

The most popular modifications, unfortunately, are not yet equipped with a headlight, but some equipment owners themselves regulate this nuance.

In the basic models produced by Kadvi, there is no light on the walk-behind tractor.

It is very easy to make lighting on a walk-behind tractor; a basic electric generator is usually used for this. The connection is made as follows:

- a device that generates electricity is connected to a button on the steering wheel;

- lay the necessary wires from the button to the electrical equipment (for example, a headlight);

- the wires are insulated in any way from mechanical damage and water (most often a corrugated pipe is used).

If the generator power is sufficient, the headlight will be bright. If there is insufficient power at low engine speeds, the light will go out. Some craftsmen replace the walk-behind tractor generator with a car or tractor generator.

How to make a light for a walk-behind tractor or mini tractor with your own hands:

In any case, even without using a generator, you can make light on a walk-behind tractor. All you need is a 12-volt battery and an LED lamp. The battery can be taken from an electric bike or scooter.

It is recommended to place it between the gearbox and the engine. According to the diagram above with an electric generator, connect the battery. The wires from the battery are routed to a switch and then to a headlight or other electrical equipment.

Be sure to insulate the wires.

Possible malfunctions of the V-belt drive

Possible reason: the belt tension when the clutch lever is pressed is greater than normal.

Elimination method: set the normal belt tension when the clutch lever is pressed, ensuring the deflection of the upper belt branch within 8-10 mm when applying a force of 5 kgf to the middle branch, often between the pulleys.

Incomplete clutch engagement

Possible reason: the belt tension when the clutch lever is pressed is less than normal.

Remedy: The same (see point 1)

Possible cause: belt delamination.

Remedy: Replace the drive belt.

This is interesting: Bush hydrangea: description, planting, care and propagation

Communities › Motoblocks (and everything connected with them) › Blog › Restoring the MB1 walk-behind tractor

Good afternoon everyone! I seem to be new to your forum, but I decided to share my story of restoring the MB1 walk-behind tractor as far as I know. In general, the walk-behind tractor is probably already 30 years old, if not more, but when I was with me, it lay disassembled in the shed for 15 years, and yet I got around to putting it back together. I couldn’t completely restore the original engine, and there’s no way to find one for it in my city. at least some attachments, so I bought a Chinese Forza 6.5 hp. They were also full

All bearings and seals on the walk-behind tractor have been replaced, the mount has been redesigned for reverse gear, etc. I don’t have many photos because I was busy with the assembly process and didn’t have time to paint everything, but I think I’ll fix this in the summer since it was time to start gardening))) In general, more photos. By the way, I can sell the old engine for spare parts to anyone. If no one needs it, I’ll rent it out on metal)) (the engine is spinning, compression is there, the guy said that it was even capitalized but was never installed on the walk-behind tractor)

Using soil tillage equipment

The use of attachments turns the walk-behind tractor into a good assistant for summer residents. Such units include:

- Trailer. Using such a device you can transport a weight of 500 kg. This could be construction waste, grass clippings or grown crops.

- Potato planter. The tool not only digs furrows for planting, but also buries the planted tubers.

- Plow. Used when cultivating heavy areas of land.

- Lugs. When the walk-behind tractor is operating, these units improve its grip on the ground.

- Hiller. Performs the work of adding soil under the root part of plants.

- Mower. This device is used to prepare hay for the winter.

- Flat cutters. The grass between the rows is removed.

- Snow plows. Used in winter.

Description

This article will discuss the design, repair and maintenance of the OKA walk-behind tractor. Since 1991, this motorized device has been produced at the Kaluga Motor Plant under the name Motoblock MB-1.

Starting in 2011, the unit was renamed “Oka”. Its purpose is to carry out all types of agricultural work on small and medium-sized plots of land with different types of soil. Functional attachments, presented in the assortment by the manufacturer KaDvi, significantly expand the capabilities of the walk-behind tractor.

Varieties

The manufacturer of the domestic brand "Cascade" produces several models of walk-behind tractors on the market, which differ in design.

- Reverse gearbox is a mechanism with a reverse function, which is mounted on the main shaft. True, it has two disadvantages - low speed, poor performance.

- Gear – designed for large size models. Despite the simple design, the robust, reliable body is quite difficult to maintain.

- Worm - the main parts include a special screw and a toothed worm wheel. Each spare part is made from durable material, which allows us to call this type of gearbox the most reliable. Among the advantages, the manufacturer highlights a reduced angular velocity and a higher type of torque. In operation, the gearbox does not create much noise and operates smoothly.

Recommendations for disassembly and assembly

Disassembling gearbox is not difficult, the main thing is to remove it from the main device.

- unscrew all screws;

- remove the covers,

- disconnect the input shaft bushing;

- remove the control fork and lever;

- pull out the input shaft with gear;

- remove the shaft from the bushing and the chain from the shaft;

- remove the sprocket block;

- remove the intermediate shaft with gears;

- dismantle the clutch axle shafts and other axle shafts.

Assembling the gearbox is also easy; you need to follow the reverse disassembly scheme.

Varieties

The manufacturer of the domestic brand "Cascade" produces several models of walk-behind tractors on the market, which differ in design.

- Reverse gear – is a mechanism with a reverse function, which is mounted on the main shaft. True, it has two disadvantages - low speed, poor performance.

- Gear – designed for large size models. Despite the simple design, the robust, reliable body is quite difficult to maintain.

- Worm - the main parts include a special screw and a toothed worm wheel. Each spare part is made from durable material, which allows us to call this type of gearbox the most reliable. Among the advantages, the manufacturer highlights a reduced angular velocity and a higher type of torque. In operation, the gearbox does not create much noise and operates smoothly.

What to do to make the walk-behind tractor last as long as possible?

As mentioned above, choose the appropriate power unit that will match the size of your site. Do not overload the equipment, especially if it is not intended for serious work.

Don't forget to monitor the oil and fuel levels. Always buy high-quality gasoline and oil from well-known manufacturers, which will guarantee the normal operation of the car for many years.

If a breakdown does occur, immediately begin to find and fix it. Do not delay repairs, because this can only worsen the situation, and in the end the walk-behind tractor will completely fail and you will have to buy a new one.