Metal ruler

This measuring instrument is perhaps the simplest in its design. With the help of metal rulers, the value of the measured quantity is determined directly.

Metal ruler

It should be noted that these measuring devices are also widely used for marking materials and parts. Modern industry manufactures them with measurement limits of 1000, 500, 300 and 150 millimeters, and either one or two scales are applied to them.

Classification of measuring instruments

There are several types of measuring instruments, distinguished by certain parameters.

By type of work.

Types of measuring tools

The following types of tools are distinguished:

- building;

- locksmith;

- carpentry

Most of the tools used in measuring operations are universal. Therefore, this classification is very conditional.

According to the material of manufacture . Measuring instruments can be made from the following materials:

Marking and measuring tools

- metal;

- wood;

- plastic.

Any tool can be combined, that is, made from several materials, for example, metal and wood.

By method of use . According to this parameter, hand tools are distinguished, mechanical and automatic.

According to design features . The design of the instrument used for measuring work can be simple or complex.

This classification helps ensure that the tool is used and stored correctly.

Calipers

measuring instrument, widespread and actively used in technology (especially in mechanical engineering), is much more complex than a metal ruler and provides much higher measurement accuracy. A caliper consists of such main parts as a ruler-bar, on the edge of which the main scale with equidistant divisions of 1 millimeter is applied, and a vernier - a reading device with an additional dashed scale.

Calipers

The division price of the verniers of modern calipers is either 0.1 or 0.05 millimeters, and as for the measurement limit, it reaches 2000 millimeters.

Calipers are used to measure both the external and internal dimensions of parts, as well as the depths of holes. In addition, they are used for various marking works.

Shtangenreysmas

Hand construction tools

Roulette . The main tool that no builder can do without is a tape measure. A tape measure is something like a ruler, made in the form of a metal tape with divisions equal to 1 mm. The tape is wound into a housing, which can be made of either plastic or metal. The tape can have different widths and lengths.

Of course, a tape measure is universal, required for carrying out measuring work in any field of activity.

Technical characteristics of the roulette

Spirit level (level) . This device is used to determine the evenness of horizontal and vertical surfaces. The length of the level can vary from 0.3 m to 2.5 m. The body of the level is made of any lightweight material, such as plastic, and is equipped with several windows.

Through the windows you can see a glass tube partially filled with a special liquid. It is this liquid that allows you to determine the evenness and level of slope of the surface.

Plumb . This is the simplest but indispensable measuring tool that every builder uses. The plumb line represents a rope (twine), at the end of which a metal cone-shaped weight is tied. It is used in cases where it is necessary to control the verticality of work, for example, during brickwork.

Square and grinder . A square is made of wood or metal and is used to create right angles. Malka is made from the same materials. Its design consists of a clip and a ruler, fastened together with a hinge. While the square can be used in any area of construction, the square is most often used when installing rafters.

Magnetic square

Shtangenreysmas

This measuring tool is designed to measure the heights of parts and accurately mark them. The maximum measurement limit of height gauges is 2500 millimeters, and the division price of their verniers is 0.1 or 0.05 millimeters.

In most cases, this measuring tool is used when working on special cast iron plates. It is on them that it is installed along with those parts that need to be measured or marked.

In order to draw a line on the part to be marked using a height gauge, a special replaceable leg is used. The measuring tool itself moves directly along the surface of the slab.

Application of measuring machines

Classification of analog measuring instruments

To make accurate measurements, not only hand-held measuring instruments can be used, but also special machines called coordinate measuring equipment. The peculiarity of this equipment is the ability to take measurements in three coordinates, which ensures maximum accuracy of calculations.

The design of the machines resembles a table on which working heads equipped with sensors are installed. To make a control measurement, the workpiece is placed on the table, and sensors read the parameters of the part.

Machines can capture data in two ways:

- contact, involving the use of a probe sensor;

- contactless, in which reading occurs by sending a light signal to the surface of the part.

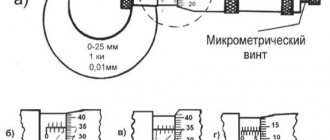

Micrometer

A measuring instrument of this type is designed to make fairly accurate measurements of small linear dimensions. The maximum measurement limit of modern micrometers reaches 600 millimeters, and the accuracy is 0.01 millimeters.

Micrometer

Micrometers (as, indeed, all micrometric instruments) are equipped with special reading units based on a screw pair with a thread pitch of 0.5 millimeters. With its help, the longitudinal movement of the measuring screw is converted into circumferential movements made by the drum scale. It is on the basis of the angle of its rotation that the value of the measured size is determined.

Micrometric depth gauge

Object being tested or measured

The measurement process cannot be started without the presence of the above elements. If at least one component is missing, running the process will be pointless.

However, in the age of modern technologies and measuring systems, the absence of human presence in the measurement process is not necessary. Most measurements are made on a computer with special programs, thanks to which you can easily read the results.

Micrometric depth gauge

In essence, this measuring instrument is designed exactly the same as a micrometer. The only difference is that it is equipped not with a bracket, but with a base. It is in it that the so-called measuring stem is installed. In order to measure depth using a micrometric depth gauge, a special rod is used. It is installed on a screw and has a special shape. The measurement limit of modern micrometric depth gauges is up to 300 millimeters, and the division price of their verniers is 0.01 millimeters.

Dial indicator

Equipment operating conditions

Preserving the functionality of devices allows periodic maintenance and checks of their condition. Measuring instruments with complex design features are most susceptible to failure.

Each device comes with an instruction manual, which you should read before using it. The instructions set out all the operating rules that are relevant specifically for this model.

Automatic and electronic models of measuring machines are sensitive to temperature and air humidity. Equipment that uses a non-contact measurement method reacts especially sharply to them.

It is equally important to provide the instrument with decent storage conditions. Tools made of wood and metal are sensitive to moisture. And plastic can deform under direct sunlight and when exposed to high temperatures. Therefore, all tools should be stored in cases or boxes in a dry room.

Compliance with these rules will ensure the quality and accuracy of measurements, and will also help extend the life of the instruments.

Dial indicator

This measuring instrument is a device where very small movements made by the measuring probe are converted into angular movements of the arrow. Dial indicators are used when it is necessary to determine with a significant degree of accuracy those deviations that a certain part has in its geometric shape in relation to the specified parameters. In addition, these devices are used to control the relative position of surfaces.

Mechanical goniometer

Hand carpentry tools

In addition to universal instruments, carpentry workshops use specialized carpentry measuring tools. Every carpenter uses the following:

Carpentry tools

- folding meter;

- triangle with angles of 90, 60, 30° or 2 by 45°;

- calipers that allow marking on wooden structural elements;

- Bore gauge - a device for marking and measuring the parameters of grooves and holes;

- protractor - a device consisting of a scale and an arc mounted on a plate;

- A thicknesser with or without a vernier helps to draw parallel lines on surfaces.

Thread gauge

This measuring tool is used to accurately determine the thread pitch and profile. Structurally, it is a package of metal templates, each of which exactly repeats the configuration of a particular thread. Thread gauges that are designed to determine the pitch of metric threads are marked M60°, and those measuring devices that are intended to determine the number of threads per inch when measuring inch and cylindrical pipe threads are marked as D55.

Radius meter

Radius meter

This measuring tool is designed for measuring fillets and radii. It is a set of metal templates made in the form of plates from high-quality alloy steel. Moreover, they are all divided into those that are used to measure protrusions and those that are intended to measure depressions.

Gauge blocks

For pressure and current

Everyone from school or university is familiar with the names of measuring instruments such as barometers and ammeters. The first ones are designed to measure atmospheric pressure. There are liquid and mechanical barometers.

Liquid varieties are considered professional due to the complexity of the design and the features of working with them. Weather stations use barometers filled with mercury inside. They are the most accurate and reliable, allowing you to work under temperature changes and other circumstances. Mechanical designs are simpler, but they are gradually being replaced by digital analogues.

Ammeters are used to measure electrical current in amperes. The ammeter scale can be graduated in standard amperes, as well as micro-, milli- and kiloamperes. It is best to connect such devices in series. In this case, the resistance decreases, and the accuracy of the readings increases.