This type of corrugated sheeting is known under the names S10 and S10-1100 TU (according to GOST 24045-94).

It is, as it is, mainly used for roofing work.

The sheet profile C10-1100 is completely identical in terms of shape, size, cross-sectional area and other data with the grades C10-899 and C10-1000. The only difference between these two brands of corrugated sheets is the length of the original blank. For brand S10-899, the length of the profiled sheet is 1 meter, for brand S10-1000 the length is 1.1 meters and for S10-1100 the length is 1.25 meters.

The following materials are used as the material for the initial profiled sheet blank:

- Galvanized sheet metal grade 01 (GOST R 52246-2004)

- Galvanized rolled products with polymer coating (GOST R 52146-2003)

It is worth noting that the maximum length of the sheet produced is 12.5 meters.

The cross-section of the material can be seen in the following picture: (click to enlarge).

Scope of application of corrugated sheets

Profiled steel sheets are used in the manufacture of walls, partitions, fences (fences). Corrugated sheets with large corrugations are used as a reinforcing element for the construction of building roofs and flooring.

For installation of profiled sheets

- flashing elements (flashings) - galvanized and polymer-coated;

- additional elements for mounting corrugated sheets or sandwich panels;

- fasteners - self-tapping screws, screws, rivets.

Sheet dimensions and weight

| Designation of profiled sheet | Sheet thickness t,mm | Installation width of sheet, mm | Weight of 1p/m length, kg | Weight of one useful sq.m., kg | Workpiece width, mm | Maximum deviation, mm | ||

| By profile height | By profile width | By profile length | ||||||

| С10-1100-t | 0,4 | 1100 | 4,45 | 4,0 | 1250 | ±1,5 | ±8,0 | +10 |

| 0,45 | 1100 | 4,9 | 4,5 | 1250 | ±1,5 | ±8,0 | +10 | |

| 0,5 | 1100 | 5,4 | 4,9 | 1250 | ±1,5 | ±8,0 | +10 | |

| 0,55 | 1100 | 5,9 | 5,4 | 1250 | ±1,5 | ±8,0 | +10 | |

| 0,6 | 1100 | 6,4 | 5,8 | 1250 | ±1,5 | ±8,0 | +10 | |

| 0,65 | 1100 | 6,9 | 6,3 | 1250 | ±1,5 | ±8,0 | +10 | |

| 0,7 | 1100 | 7,4 | 6,7 | 1250 | ±1,5 | ±8,0 | +10 | |

| 0,8 | 1100 | 8,4 | 7,6 | 1250 | ±1,5 | ±8,0 | +10 | |

If you look closely at the table, you can see that the weight of C10 corrugated sheet depends on the thickness of the sheet. With a sheet thickness of 0.5 mm, the weight of a linear meter is 5.4 kg.

Types of profiled sheets and technical characteristics

Profiled sheet C10

| 4,77 | 4,77 | GOST 24045-94; TU 1122-025-00110473-97 It is used in the manufacture of walls, partitions, fencing of buildings and structures, as well as in the construction of arched elements of buildings for various purposes. |

| С10-1000-0.55 | 5,23 | 5,23 |

| C10-1000-0.60 | 5,60 | 5,60 |

| C10-1000-0.70 | 6,50 | 6,50 |

| С10-1000-0.80 | 7,40 | 7,40 |

| S10-1100-0.50 | 4,93 | 5,42 |

| S10-1100-0.55 | 5,40 | 5,94 |

| S10-1100-0.60 | 5,85 | 6,43 |

| S10-1100-0.70 | 6,74 | 7,42 |

| S10-1100-0.80 | 7,64 | 8,41 |

| Profiled sheet CC10-1100-0.50(0.55; 0.6; 0.7; 0.8) | |||

| Brand of corrugated sheet | Weight 1 sq.m, kg | Weight 1 linear meter, kg | GOST, Purpose |

| CC10-1100-0.50 | 4,93 | 5,42 | GOST 24045-94; TU 1122-025-00110473-97 It is used in the manufacture of walls, partitions, fences, etc., buildings and structures, as well as in the construction of arched elements of buildings for various purposes. |

| CC10-1100-0.55 | 5,40 | 5,94 | |

| CC10-1100-0.60 | 5,85 | 6,43 | |

| CC10-1100-0.70 | 6,74 | 7,42 | |

| CC10-1000-0.80 | 7,64 | 8,41 | |

Profiled sheet C21

| Profiled sheet C21-1000-0.50(0.55; 0.6; 0.7; 0.8) | |||

| Brand of corrugated sheet | Weight 1 sq.m, kg | Weight 1 linear meter, kg | GOST, Purpose |

| С21-1000-0.50 | 5,42 | 5,42 | GOST 24045-94; TU 1122-025-00110473-97 It is used in the manufacture of walls, partitions, fences, etc., buildings and structures. |

| S21-1100-0.55 | 5,94 | 5,94 | |

| S21-1100-0.60 | 6,40 | 6,40 | |

| S21-1100-0.70 | 7,40 | 7,40 | |

| С21-1000-0.80 | 8,41 | 8,41 | |

Profiled sheet NS35

| Profiled sheet HC35-1000-0.55 (0.60; 0.70; 0.80) | |||

| Brand of corrugated sheet | Weight 1 sq.m, kg | Weight 1 linear meter, kg | GOST, Purpose |

| HC35-1000-0.55 | 5,94 | 5,94 | GOST 24045-94; TU 1122-025-00110473-97 It is used in the manufacture of walls, partitions, fences, etc., buildings and structures. |

| HC35-1000-0.60 | 6,40 | 6,40 | |

| HC35-1000-0.70 | 7,40 | 7,40 | |

| HC35-1000-0.80 | 8,41 | 8,41 | |

Profiled sheet C44

| Profiled sheet C44-1000-0.7 (0.8) | |||

| Brand of corrugated sheet | Weight 1 sq.m, kg | Weight 1 linear meter, kg | GOST, Purpose |

| S44-1000-0.7 | 7,40 | 7,40 | GOST 24045-94; TU 1122-025-00110473-97 Used in the manufacture of walls, partitions, fences, etc., buildings and structures. |

| S44-1000-0.8 | 8,41 | 8,41 | |

Profiled sheet H57

| Profiled sheet H57-750-0.7 (0.8) | |||

| Brand of corrugated sheet | Weight 1 sq.m, kg | Weight 1 linear meter, kg | GOST, Purpose |

| H57-750-0.7 | 8,70 | 6,50 | GOST 24045-94 Used in the manufacture of cold and insulated roofs of buildings and structures. |

| H57-750-0.8 | 9,80 | 7,40 | |

Profiled sheet H60

| Profiled sheet H60-845-0.55 (0.6; 0.7; 0.8; 0.9) | |||

| Brand of corrugated sheet | Weight 1 sq.m, kg | Weight 1 linear meter, kg | GOST, Purpose |

| H60-845-0.55 | 6,80 | 5,70 | GOST 24045-94 It is used in the manufacture of cold and insulated roofs of buildings and structures. |

| H60-845-0.6 | 7,40 | 6,20 | |

| H60-845-0.7 | 8,70 | 7,40 | |

| H60-845-0.8 | 9,90 | 8,40 | |

| H60-845-0.9 | 11,10 | 9,30 | |

Profiled sheet: GOST

Today, the production of profiled sheets in Russia, Belarus, Kyrgyzstan and Armenia is subject to GOST 24045-2016. Directly related to this document:

- GOST 9.401-91, regulating corrosion protection and protective coating methods.

- GOST 7566-94, which regulates the conditions of storage, transportation, packaging and labeling of rolled metal products.

- GOST 14918-80, regulating the production of thin-sheet galvanized steel with continuous lines on the profile.

- GOST R52246-2004, regulating hot-dip galvanized sheet metal.

- GOST 19904-90, regulating the assortment of cold-rolled sheet metal.

- GOST 30246-94, which regulates the conditions for the production of thin-sheet rolled products with a paint coating for protective and decorative properties.

GOST establishes the presence of maximum deviations in the geometric dimensions of a profiled sheet. The largest error is allowed in width for sheets with a corrugation height from 75 to 160 mm - 15 millimeters in any direction. For all other sheets, the deviation in width should not exceed 8 mm in any direction. In the first case considered, deviations in the height of the corrugation (profile) should not exceed 2.5 mm in any direction. For heights 60-74 mm, a deviation of 2 mm is permissible; from 20 to 59 mm, a deviation of 1.5 mm is allowed, and for heights up to 19 mm inclusive, a deviation of more than 1 mm in any direction is unacceptable.

Information about the profile is contained in the markings, which are applied to the complete package of sheet products in the form of an inscription on the label. The label contains the manufacturer's trademark, profile designation according to GOST, length and number of sheets, weight of all sheets, batch number and specific packaging. The information is certified by the stamp of the manufacturer. The designation of a profile according to GOST includes (sequentially) the type of profile, the height of the corrugation, its overall length and thickness, as well as the steel grade, the type of coating on each side, the color if a colored coating is applied, and the GOST number itself, which regulated the production of the product.

Technical information about steel sheet.

Manufacturers and cost

You can purchase C10 corrugated sheets on the market, on the Internet, directly from the manufacturer, or in specialized stores. Today, the price category of coverage ranges from 165 to 500 rubles per square meter.

As for manufacturers, today a huge number of enterprises provide their services. However, if you need to purchase material of the highest quality and reliability, then you should give your preference to those companies that have modern high-quality equipment, qualified craftsmen and an excellent reputation.

Division into types according to the type of coating used

The layer on profiled sheets plays a protective function to extend the service life without corrosion. The variety of colors allows you to create aesthetically complete designs and be used by designers in any combination.

Polymer coating . The materials obtained as a result of such coating combine two useful properties: metal strength and resistance to corrosion of zinc and polymers. The result is an effective material with a beautiful appearance. This sheet processing can be done in one or two layers. For different purposes, corrugated sheets are made with coating on one side or on both sides.

The acrylic coating is specially formulated to protect the material from ultraviolet radiation in addition to standard anti-corrosion protection. The service life of corrugated sheeting coated with acrylic glaze is determined to be up to 25 years in an aggressive coastal climate with salty rains. This is 7 times longer than the life of the sheet without treatment.

Polyvinyl chloride (plastisol) coating is a balanced mixture of polyvinyl components and plasticizers. This profiled sheet is used for the manufacture of pipes of various configurations, gutters, ducts and shaped parts for roofing. The material is resistant to mechanical damage, but quickly ages under the influence of the scorching sun, therefore it is not recommended for use in southern regions.

made of pural has greater durability and resistance to chemical influences . This is a relatively new material and has only recently been used. During its production, polyamides are added to the polyurethane base. The protective layer is famous for the fact that it can easily withstand sudden changes in temperature without loss of quality. Can be used at temperature thresholds from -25ºС to 100ºС.

Polyvinylidene fluoride coating contains up to 30% acrylic, which makes it highly resistant to corrosion, fading, and destruction by moisture, salts, and alkalis. The coating retains its properties at temperatures below 60ºС and is resistant to ultraviolet rays.

Application of corrugated sheet C10

Basically, C10 corrugated sheeting is used for wall coverings, but sometimes it can also be found as a roofing material (subject to frequent lathing, as discussed above). The fairly good strength and rigidity of this material, due to the corrugation height of 10 mm, make it an excellent solution for fences, but, at the same time, the low-waviness of the material contributes to its successful use for structures of higher complexity. Cost-effectiveness and resistance to difficult climatic conditions make it possible to use C10 corrugated sheets for the manufacture of formwork before pouring the foundations of buildings with concrete.

You can learn how to install a fence made of corrugated sheets from the following video:

The relatively low weight of C10 corrugated sheeting (from 5 kg per square meter) allows it to be used not only in roofing coverings with a large angle of inclination, but also in the manufacture of sandwich panels. In addition, C10 profiled sheet is very practical for reconstruction and modernization of outdated buildings and structures. Like C8 corrugated sheeting, its more durable version is good for the construction of small temporary buildings, for example, change houses, warehouses, sheds and ceilings.

How to calculate the weight of corrugated sheets?

Knowing the number of square meters of corrugated sheets required for the work, simply calculate the total weight by multiplying this amount by the weight of 1 square meter. meters.

When determining the weight of a corrugated sheet, you must use the following formula: length x width x thickness (characteristics of a corrugated sheet).

IMPORTANT

when purchasing corrugated roofing!

When calculating the roof frame with rafters, you must know what the weight of 1 square meter is. meter of selected roof covering. Knowing the weight will allow you to calculate the total load that the structure will experience. Accordingly, you can understand how thick the structure should be and what elements it should be built from.

Main application in modern construction and daily life

C10 profiled sheet is currently used in many places. For example, for roofing with pitches (lathing) up to 0.8 m, metal roofing, external walls of a building.

C10 is also widely used as a structural element of prefabricated buildings and as the main element from which fences and gates, as well as other fencing structures, are built.

Many consumers use corrugated sheets as a facing material for the walls of houses, garages and other buildings.

Profiled sheet is a durable and low-maintenance material.

Photos of how the material is used in life:

The thick material is often used for element-by-element sandwich panels, as well as formwork and partitions in the construction of buildings. One of the most common markings and the most frequently used is the C10-1100-0.5 and 0.7 brand.

Influencing factors

Many people determine the weight of a corrugated sheet by its dimensions. This is not entirely true, since 2 products of the same dimensions, but different brands have different weights. This value is determined by the thickness of the material, the shape and size of the wave, as well as the mass of the steel alloy from which it is made.

Most often it is made of galvanized metal, but alloys can be used. Each raw material has its own weight and plays one of the main roles in forming the mass of the finished product. Modern technologies make it possible to use alloys of different metals in the production of profiled sheets. Due to this, the manufacturer tries to reduce material costs, but not at the expense of its strength.

Another important factor is thickness . There is a standard GOST 24045-94, according to which manufacturers produce products 0.6–1 mm. Sometimes in retail outlets you can find products 0.45–1.18 mm.

Products of any brand have a wave. The greater its height, the heavier the product will be. So why is the weight per square meter of corrugated sheeting of the same thickness, but with different wave heights, so different? It all depends on the amount of metal falling per 1 m2 of the product. A high wave requires more steel or alloy to produce than a low profile, so the overall result will vary.

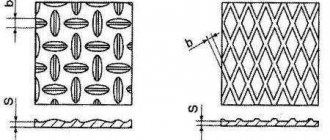

In addition to height, the wave differs in its shape. The profile of the corrugated sheet is made rectangular, trapezoidal or traditional wave. If we take, for example, a specimen with a trapezoidal profile, then its weight of 1 m2 will exceed the mass of a similar-sized wavy product.

The last factor to consider is width. There are two concepts: working area and total. The difference between these two definitions is the width of the overlap. The product manufactured in accordance with GOST has a total width range of 646–1060 mm. The width is affected by the same wave height indicator. The higher the wave, the narrower the product, but the weight of 1m2 is greater.

Areas of application

The main area of use of this material is construction, especially industrial type. The coating is literally indispensable when creating walls using sandwich panels.

Thanks to C10 corrugated sheets, it is possible to build very warm warehouses, production premises, various hangars and other buildings. Moreover, it has an important undeniable advantage - speed of construction and ease of installation.

The material can significantly enhance the strength and reinforcement of a structure. The coating is actively used in the process of insulating various types of buildings, since its price category is much lower than the cost of polymer siding.

Therefore, this type of material is ideal for budget construction. The coating is also used to create ventilated facades because it has durability, excellent performance qualities and a high degree of resistance to ultraviolet rays.

However, it is necessary to use C10 corrugated sheets with extreme caution during the construction of interfloor and monolithic-basement coverings, since rectangular corrugation has a lower strength and fracture toughness. Today, the material has become widely used in the construction of fences and enclosures.

It is not at all surprising that builders give their preference to C10 corrugated sheeting, as it is easy to install, durable, reusable, and has excellent aesthetics of the finished structures. The material can be used even in complex configuration structures, which not every coating can boast of.

The material has gained enormous popularity among those consumers who want to build a reliable roof without having special knowledge and skills. In fact, this design made from C10 corrugated sheets is distinguished by its simplicity and incredible rigidity.

Installation of the coating does not require the creation of battens and rafters, which significantly simplifies the time and complexity of installation. But not only aesthetics and ease of operation attract consumers, since the possibility of inexpensive roof insulation also does not leave them indifferent.

Technical features

This type of corrugated sheeting is characterized by low weight and thickness, flexibility, ease of cutting and ease of installation. Increased reliability allows its reuse in various designs. Environmental friendliness, decorative properties, and a wide selection of colors inherent in this type of product make it especially attractive for private construction.

The production uses thin-sheet galvanized steel, galvanizing thickness is 0.4-0.9 mm. This coating significantly increases resistance to corrosion and external influences. The durability of the material exceeds in its parameters many building materials for roofing and cladding. The sheathing pitch for this type of sheet can reach 1.5 meters, the rib pitch width is 200mm.

External protective and decorative coating is made using polyester, polyurethane, plastisol.

The Profile company offers you supplies of building materials from a warehouse in St. Petersburg, as well as the possibility of producing NS35 profiled sheets to order in any volume. We have been working in the market for more than eleven years and are ready to fulfill orders of any complexity. The color range of products will allow you to choose the material that best suits your taste and desires. We are engaged in the manufacture of roofing products in strict accordance with GOST standards. The quality control system implemented in our production allows us to control the entire process and provide you with materials that meet the highest requirements.

Corrugated sheet C18 - price and purchase

The table below shows the average market price of profiled sheet C18-1150, made from thin sheet galvanized steel grade 01 according to GOST R 52246-2004.

For painted corrugated sheets, the price of corrugated sheets is indicated. Price of corrugated sheets C18-1150

| Brand of corrugated sheet | Sheet thickness, mm | Weight linear meters, kg | Sheet width, mm | Price, including VAT, rub. | |||

| up to 3 t | from 3 to 20 t | from 21 t | |||||

| working | full | linear meters | linear meters | linear meters | |||

| Corrugated sheeting with zinc protective coating | |||||||

| S18-1150 | 0,4 | 4,4 | 1150 | 1190 | 168 | 158 | 154 |

| 0,5 | 5,4 | 183 | 180 | 174 | |||

| 0,55 | 5,9 | 205 | 201 | 195 | |||

| 0,7 | 7,4 | 253 | 242 | 237 | |||

| Galvanized corrugated sheeting with a polymer protective and decorative coating | |||||||

| S18-1150 | 0,4 | 4,4 | 1150 | 1190 | 220 | 210 | 206 |

| 0,5 | 5,4 | 242 | 231 | 227 | |||

| 0,7 | 7,4 | 341 | 325 | 319 | |||

Useful article? Save it on social networks so you don’t lose the link!

Top ↑

Team oprofnastile.ru

Read on topic:

Profiled sheeting N20 - technical characteristics, dimensions, prices, application, description

What are the features of N-20 corrugated sheeting? When is it best to use it? What are the technical characteristics of the H20 profiled sheet? Read the article.

MP35 corrugated sheets - technical characteristics, prices, dimensions, application, description

Everything about the MP-35 universal corrugated sheet: technical characteristics, areas of use, production and advantages.

Production

The coating is created using cold-rolled steel sheet material, which is pre-treated with zinc using the so-called “hot method”. Using an industrial press, the characteristic wavy shape is achieved, after which the huge sheet is cut into individual pieces of the required size.

In order to minimize the possibility of corrosion, the coating is treated with a paint or polymer composition. Today there are for the main types of corrugated sheet C10:

- one-sided - its price category is low. On one side it is coated with polymers, and on the other it is treated with varnish. This category is perfect for wall cladding and roofing;

- double-sided - this option is more expensive. Both sides are covered with polyester or a special polymer film made from pural. Widely used to create various fences and fences.

Weight of the most popular brands of corrugated sheets

The basic parameters of metal profiles are important both in the reconstruction of buildings and structures, and in the design of newly erected buildings. One of the main parameters is the weight of the corrugated sheet.

But for each profile it has its own meaning. Weight is influenced by several factors

:

- thickness of the sheet metal from which the profile is made;

- brand of corrugated sheet;

- coating or painting material.

The main parameter influencing the weight of a corrugated sheet is the thickness of the metal. In reference books and on the Internet you can find tables showing dimensions and weight. This parameter is very important when designing objects

.

If this characteristic is unimportant when calculating a fence, then it is impossible to calculate a roof without this parameter. It is important for calculating the loads on the rafter system

.

It should be taken into account that the weight of a galvanized sheet is heavier than a painted sheet with the same thickness of corrugated sheets.

In a painted sheet, the thickness has a structure

:

- metal base, often made of galvanized steel;

- a protective coating that ensures good adhesion of paint to the galvanized surface;

- decorative coating.

Be sure to read: C8 corrugated sheets: technical characteristics

Painted material is used where aesthetic appearance is important. The polymer coating can be inexpensive from polyester or expensive from pural.

The weight of a galvanized sheet is determined only by the thickness of the metal.

The industry produces various types of corrugated sheets. They are labeled depending on their purpose

:

- “C” – intended for fencing and wall installation (wall);

- “N” – used for structures that can withstand significant loads (load-bearing);

- “NS” is a multifunctional material (universal).

They are manufactured on a production line with a continuous process using the cold rolling method from standard rolled metal. Workers set the required dimensions and customize profile shapes, which have a wide range. What is the reason for the variety of types of corrugated sheets?

Wall profiled sheet

It is used for the manufacture of fences, partitions, ceiling linings, cladding of buildings, as roofing material. However, it should be borne in mind that the lack of rigidity of the sheets is compensated by continuous sheathing and a large angle of inclination of the rafter system

.

It is well suited for decorating buildings. If the building is not warm enough, then insulation is installed under it. Galvanized profile, or painted white, is used for lining ceilings, making partitions at industrial facilities to highlight separate rooms.

Multi-colored is suitable for the construction of small pavilions and fencing areas. The fence, made of painted corrugated sheets, has an attractive appearance on both sides.

The most common are five to six types of wall material. It is marked depending on the profile size S-8, S-10, S-15, S-18, S-21, S-44. For example, corrugated sheet C-10 has a profile height of 10 mm, and C-21 – 21 mm, etc. Thus, the marking indicates the height of the trapezoid.

The working width of the sheet varies from manufacturer to manufacturer and you should pay attention to this.

The length of the sheet is determined by standards and ranges from 0.5 meters to 12 meters.

Load-bearing corrugated sheet

Used on objects where increased strength characteristics are required. Used for making

:

- The formwork is not removable, which gives additional rigidity to the structure.

- Interfloor floors that are affected by constant dynamic and static loads.

- Roofs. Due to the increased strength and thickness of the metal sheet, a lightweight rafter system is erected. This design allows you to avoid installing lathing at all. Purlins are installed along the rafters in increments of 0.8–1 meter. This makes it possible to significantly reduce the cost of the roof.

- Warehouse premises. Granaries, warehouses, production halls, and workshops are often erected.

Be sure to read: Basic characteristics of metal profiles and installation instructions

The material not only has high strength characteristics, but is also resistant to adverse conditions. Galvanization in combination with a polymer coating increases the service life of the product up to 25 years, and indoors this material can last longer.

Increased resistance to precipitation, chemical influences and a long period of use allows it to be used in the construction of industrial premises. At the same time, the material has a small mass.

Thus, corrugated sheet N-75-0.6 has a trapezoidal height of 75 mm, with a galvanized thickness of 0.6 mm, and the weight of 1 m2 meter is 9.8 kg. Weight with a thickness of 0.8 mm – 11.2 kg.

Additional strength is provided by a stiffening rib rolled at the top of the trapezoid. When reconstructing the roof of a building covered with asbestos-cement material, recalculation of the load-bearing beams is not required. Since the mass of 1 m2 of asbestos-cement coating is significantly greater than the mass of the corrugated sheet.

Universal corrugated sheet

It is most in demand and used in private and industrial construction.

Used as a building material for

:

- Fencing the territories of organizations, transshipment bases, cottages and summer cottages. The fence has an aesthetic appearance. The strength of the sheets allows you not to be afraid of strong gusts of wind.

- Installation of formwork, as well as as a roofing material (with a thickness of 0.6 mm or more). At the same time, the appearance and quality are not inferior to load-bearing metal products.

- Installation of walls of warehouses and industrial premises. Due to the low mass of corrugated sheeting, the load on the support posts and base is reduced.

- Facilities under construction. The color is standardized and corresponds to the RAL catalog. This applies to all brands of corrugated sheets.

Its versatility allows it to be used in all areas of construction. It has increased strength, which is combined with the low weight of a square meter of corrugated sheeting.