In order to bend metal sheets in production, additional processing of the workpiece is not necessary. For this, special equipment is used. It may vary in design and principle of operation. Metal bending is considered a separate technological process that requires certain skills and knowledge to perform.

Metal bending

DIY sheet metal bending technology

In the process of building a house or cottage, there is often a need to equip drains, sewers, and metal frames.

When manufacturing such products, it is necessary to give the flat workpiece the necessary spatial shape. Advice from experienced craftsmen on how to bend a sheet of metal at home will allow you to produce good quality structures that will last a long time.

Bending technology - basic information

Metal bending is performed without welding seams, which avoids corrosion in the future and produces a product of increased strength. Deformation does not require significant effort and is usually performed in a cold state.

The exception is hard materials such as duralumin or carbon steels. Sheet metal bending technology is developed according to the assigned tasks in such options as:

- radius,

- multi-angle,

- single-angle,

- U-shaped.

A special case is flexion with stretching. This technology is used in the manufacture of parts with large bending radii and small diameters. When making parts with your own hands, the process is combined with operations such as cutting or punching.

Soft types of metals and alloys, such as brass, copper, and aluminum, are well suited for home processing. The production of products by bending is carried out on rolling or rolling machines, or manually.

The last procedure is quite labor-intensive. Bending is done using pliers and a rubber hammer. If the sheet is thin, use a mallet.

How to bend at right angles

To bend a bracket from a metal sheet, you will need a set of tools and accessories, consisting of:

- vice,

- hammer,

- power saws,

- bar,

- frames

The length of the strip is made according to the scheme, with the calculation that there should be a margin of 0.5 mm for each bend, plus another millimeter for folds on both sides. The workpiece is placed in a vice with squares. Clamping it along the fold line, process it with a hammer.

After this, the future bracket is unfolded in a vice, clamped with a frame and a block, and the other side is formed. The workpiece is pulled out, the required length of the sides is measured, making bends along the bottom.

Use a triangle to check the correctness of the angle, correcting inaccuracies with a hammer. When performing both operations, the workpiece is pressed with a block and a frame. The finished staple is filed to the desired size.

:

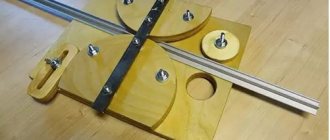

How to make a sheet bending machine yourself

To give the metal the desired configuration, tinsmiths use a sheet bending machine. But what should a master do if he doesn’t have special equipment at hand?

In fact, the question of how to bend sheet metal at home is easily resolved. It is enough to use your own ingenuity and basic equipment to make a simple machine.

To make a bender for a metal profile, you will need:

- I-beam 80 mm,

- fasteners (bolts),

- loops,

- corner 80 mm,

- clamps,

- a pair of handles.

You will also need a welding machine and a stable table on which the finished machine is mounted.

The basis of the device is an I-beam, to which a corner is screwed with two bolts, holding the workpiece during the bending process. Three door hinges are attached under it by welding. Their second part is welded directly to the corner.

In order for the machine to easily turn while bending sheet metal, handles are attached to it on both sides. The finished machine is secured to the table with clamps. Before laying the workpiece, the corner is unscrewed or lifted. The sheet is pressed, aligned along the edge and folded, turning the machine by the handles. The homemade device is only suitable for processing workpieces of small thickness.

:

Bending a metal sheet with a hammer

In order to bend a sheet up to 1.2 mm thick at a right angle, use the simplest tools - pliers (clamps) and a rubber hammer.

The processing is carried out on a flat wooden block. The fold line is drawn using a pencil and ruler. Then the sheet is clamped with pliers so that their ends fall exactly on the marking line.

The edge is gradually bent upward, moving along the fold. Once the angle approaches 90 degrees, the sheet is placed on the block and finally leveled using a hammer.

Narrow parts, such as tin edges, are made in this way.

Tip: Use a rubber or wooden hammer to prevent dents from forming on the metal. If bending is performed with a conventional tool, you need to take a textolite plate as a gasket.

It is convenient to bend sheets up to 2 mm thick on a desktop. The metal is positioned so that the marking line falls on the edge. A steel corner is placed under the material being processed.

The sheet is clamped in a vice using two wooden blocks. Bending is done using a hammer, tapping the metal from one end to the other. At the same time, the edge of the sheet is directed downward so that it ultimately lies completely on the corner fixed along the edge of the table. This method can be used to make products of any width, including boxes or barbecues.

:

Making pipes without using a machine

Home craftsmen have invented a lot of ways to bend a metal sheet into a pipe without using a machine.

We propose to consider the simplest option using a blank of suitable size. It is made from an old pipe of suitable diameter.

A sheet of metal is laid out on the floor and a piece of the required length is cut from it. To determine the required size, the required pipe diameter is multiplied by 3.14 and added 30 mm for the seam.

A pair of tubes are welded to the blank on both sides, perpendicular to one another. The crowbar should be freely inserted into their holes.

Master's recommendation: by bending a metal sheet using a blank, it is convenient to make pipes no more than a meter in length.

To use the device, the effort of three people is required. The blank is placed on the edge of the sheet. One person stands on top, two others screw the metal onto the blank, turning the crowbar 90 degrees.

The entire length of the sheet is rolled in this way, the remaining edge is hammered. The seam is secured by welding.

:

It must be taken into account that the bend radius of sheet metal depends on its thickness and manufacturing method.

Hot rolled steel is more suitable for pipes; profile products are made from cold rolled steel. ( 1 5.00 out of 5) Loading…

Edge bending process

We place the anvil on its side on a massive and durable base. We cut out a pair of approximately square plates from different sized corners. Using a grinder and pliers, we round two corners of each of them.

Approximately in the middle of one side of the large plates, we mark and make a horizontal cut with a length equal to the height of the rail base. From its end downwards at an angle coinciding with the inclination of the rail neck, we make a second cut.

We place the steel strip that is to be bent across the anvil.

To the strip held on the edge, we apply smaller plates on both sides, which with their flat edges are in contact with the side of the rail head.

Holding the plates in this position, with the workpiece located between them, we attach them to the anvil by welding.

After making sure that the workpiece slides freely between the stops, we weld along their perimeter.

In the same way, using the strip as a template, we weld large plates to the base and neck of the rail thanks to the cutouts. We make sure that the strip moves freely, without jamming, between two pairs of limiters in the longitudinal direction in both directions.

We place the workpiece with one end between the smaller stops welded to the base of the anvil, and begin to strike the upper edge of the strip measuredly and with equal force, gradually pushing it from the head to the base of the anvil.

If the strip bends to the side, we remove it by hitting it with a hammer in the opposite direction.

When I reach the middle of the strip, we bring its other end into the limiters and repeat the previous operation.

Gradually, the free ends of the workpiece will begin to converge, and depending on their relative position, by adjusting the location and force of the blows, we ensure that its ends rest against each other.

If there is lateral curvature, the product is straightened on a flat and hard surface.

Bending and bending of sheet metal using various methods and devices

Bending sheet metal allows you to obtain a product of the desired shape with relatively little effort. Because welding requires more effort, both physical and financial. A sheet of metal can be bent manually or using automation, but the general principles of operation remain the same. It is the features of this process that will be discussed.

Metal bending is carried out using various methods. Welding is often used, but temperature exposure can change the shape and properties of the finished product. This reduces performance properties and manufacturing accuracy.

Since when bending metal, the outer layers of the metal stretch, and the inner ones begin to compress, it is necessary to bend part of the rolled metal relative to another by a given angle. The angle can be found using calculations.

The product is deformed to those values that are within the specified limits. They depend on the following parameters:

- Thickness of the metal sheet;

- How much is the bending angle?

- How durable is the material;

- Speed and time of the procedure.

The permissible deformation indicator will depend on them. The next step is to select the type of bending.

Types of bending of metal products

Metal bending is done manually and using automatic devices. In the first case, the process will be quite labor-intensive, requiring the use of pliers and a hammer, as a result of which this procedure will take a lot of time.

It will be much easier and better to mechanize the process with the help of machines and corresponding devices. The cylinder shape is given to the product by special rollers. With their help, chimneys, gutters, and pipe products are created.

The development of machine tool production has made it possible to achieve bending of material for the manufacture of the most complex products. And the quick replacement of the working tool allows you to reconfigure the machine device as efficiently and quickly as possible.

For the modern metal bending process, there are many options for the latest devices. In production, presses are usually used , which can be divided into the following types:

- Rotary, bending metal by moving between special rollers. Suitable for the production of large-sized products in small batches.

- Rotary presses bend the plates using bending beams and two plates. The stationary plate is located at the bottom, and at the top there is a rotating plate. The optimal option for processing sheet metal products with a simple relief and small dimensions.

- Standard pneumatic or hydraulic presses are used for mass or small-scale products made of stainless steel or other metal. Bending is done between the punch and the die. Due to this, even thicker products can be processed. It should be noted that hydraulic presses are used more often than pneumatic ones due to their simpler operation and cost.

Of all the types of equipment described above, the most modern is rotary. It operates automatically, and the worker does not need to calculate the optimal force value in advance.

Rotary presses are also considered automated. Here one sheet is sent to the device, which must be positioned as required by the task. Most often used in small enterprises where they work with metal parts.

Handmade

This work is usually done with hand scissors . Marks are placed in the right places along which manual bending of the metal will be carried out. The sheet is securely fixed in a vice. The first fold is made with a massive hammer. The product is moved to a new bend location, clamped with a block of wood, and bent in the desired direction.

Upon completion of the work, you must ensure that the product meets the established standards. The check is carried out using a square and, if necessary, defects are eliminated.

Sometimes you need to make a machine at home . This will make bending metal easier and increase productivity. Here you will need a corner, a metal beam, hinges with bolts, clamps, handles, a table and a welding machine. The procedure is as follows:

- The base is made of metal; an I-beam profile is suitable.

- The corner is attached to the top of the beam using bolts.

- Three hinges are welded under the corner using a welding machine.

- We bend the aluminum sheet by turning the corner.

- Two clamps ensure tight pressing of the metal.

- The corner does not have to be removed; you can raise it. Place the product between the profile and the corner. Then a metal sheet is aligned along the edge.

Check the bolts to ensure they are secure. Turn the crossbars and bend them so as to form the desired angle. This will avoid wasting time on angle calculations.

Whatever the devices, the main principles remain the same . By following them, you can obtain products that meet the standards and wishes of the customer.

Handmade

This work is usually done with hand scissors . Marks are placed in the right places along which manual bending of the metal will be carried out. The sheet is securely fixed in a vice. The first fold is made with a massive hammer. The product is moved to a new bend location, clamped with a block of wood, and bent in the desired direction.

Upon completion of the work, you must ensure that the product meets the established standards. The check is carried out using a square and, if necessary, defects are eliminated.

How to bend sheet metal at home?

Bending sheet metal allows you to obtain a product of the desired shape with relatively little effort. Because welding requires more effort, both physical and financial. A sheet of metal can be bent manually or using automation, but the general principles of operation remain the same. It is the features of this process that will be discussed.

Metal bending is carried out using various methods. Welding is often used, but temperature exposure can change the shape and properties of the finished product. This reduces performance properties and manufacturing accuracy.

Since when bending metal, the outer layers of the metal stretch, and the inner ones begin to compress, it is necessary to bend part of the rolled metal relative to another by a given angle. The angle can be found using calculations.

The product is deformed to those values that are within the specified limits. They depend on the following parameters:

- Thickness of the metal sheet;

- How much is the bending angle?

- How durable is the material;

- Speed and time of the procedure.

The permissible deformation indicator will depend on them. The next step is to select the type of bending.

How to bend sheet metal with your own hands - How to bend sheet metal at home

alexxlab | 05/04/2019 | 0 | Questions and answers

Bend and install drywall end strip

The length of the end strip should be slightly longer than the arc of the arch. This is necessary so that after installing the end strip, you can trim its ends and make a smooth transition from the drywall to the end walls of the opening. To bend a pre-cut strip of drywall onto the end of the arch, we will use the dry method of cross cuts.

On the tensile (inner) side of the drywall, you need to make transverse cuts every 5-7 cm to 2/3 of the thickness of the drywall core. Once the cuts are made, the strip of drywall can be easily attached to the arc of the arch frame. You need to attach from the middle of the arch moving towards the edges. Drywall-metal screws are screwed into each section of the strip between the slots. The protruding drywall is cut off with a knife or hacksaw. The door arch is made of plasterboard; painting work remains.

How to bend a sheet of metal evenly

Many people ask the question: how to bend a sheet of metal evenly? And it is not surprising, because when carrying out construction work it may be necessary to perform a similar procedure.

Small diameter pipes are bent using a vice. Very often during construction processes there is a need to bend pipes of quite large diameter. For such work, special machines are needed that bend metal sheets and pipes. The bendable component is not deformed.

How to bend a sheet of metal evenly? Stages:

| General technology, principles and features of bending metal sheets. |

| What metal can be bent? The best materials for processing and shaping are brass, copper and aluminum. |

| Bending tools. Before starting work, you should prepare a diagram of the future product and calculate the required angle. After this, you need to acquire tools and materials. |

| Handmade production of a machine for bending sheet metal. Materials and action plan. |

Tip: when bending parts, its thickness, ductility are taken into account and the radius of curvature is determined.

Metal bending technology

Bending sheet metal involves performing certain actions that cause the material to take the desired shape. The process of bending metal is performed without the help of welding or other connections that reduce the durability and strength of the material.

When folded, the outer layers of the product are stretched, and the inner layers are compressed. The technology is to bend one part relative to the other at the required angle.

During bending, the metal sheet undergoes deformation. Its value depends on the thickness of the product, ductility, bending angle and bending speed.

The process itself is performed on equipment, due to which no damage is caused.

If a part is bent incorrectly, various defects may occur on its surface, as a result of which the metal receives various damage along the bending line, which can lead to its breakage.

The bending stress must be greater than its stiffness limit. Plastic deformation may occur as a result of bending. Moreover, after the bending operation, the finished structure will retain the shape that was given to it.

Advantages of the process of smooth bending of metal sheets:

- High process productivity.

- As a result of bending, you can obtain a workpiece without a seam.

- The finished structure is highly resistant to corrosion.

- No rust will form at the bend.

- The design is solid.

- High strength.

Flaws:

- Special equipment is quite expensive.

- Manual bending is quite labor-intensive.

Unlike structures made by bending metal, welded structures have a weld that is susceptible to rust and corrosion.

Product bending is done manually or using special devices. Manual bending is a complex and time-consuming procedure that is performed using pliers and a hammer. If you need to evenly bend a sheet of metal of small thickness, use a mallet.

Bending of sheet metal is carried out using rollers, roller machines or a press. To shape the material into a cylinder, hydraulic, manual or electrically conductive rollers are used. Pipes are produced using a similar method.

Sheet metal bending is used for home construction purposes to produce gutters, metal frames, profiles, pipes and other structures. When bending the material with your own hands, you can make pipes of different diameters. Using machines, zinc-coated products are bent. To do this, you should make a machine, preferably using a template.

When bending any product, its parameters should be determined. The length of the structure is calculated taking into account the radius. For workpieces that are bent at right angles, without the formation of roundings, the allowance should be 0.6 mm of the total thickness of the sheet.

You can bend the following metals with your own hands:

The bending radius will depend on the quality of the metal and the bending option.

How to bend a sheet of metal evenly with your own hands?

To make brackets using the bending method, the following tools and materials are used:

- vice;

- a metal sheet;

- frame;

- hammer;

- power saw for metal;

- bar.

In advance, according to the scheme, the length of the workpiece strip is calculated and the bending of the metal sheet is calculated. For each bend, a reserve of 0.5 mm of thickness is made and 1 mm for bending the ends to the side. According to a pre-drawn diagram, the workpiece is cut out and the bending point is marked. In order to bend the material, use a vice with squares.

First, at the bending level, you need to clamp the workpiece in a vice. Then the first bend is made using a hammer. The workpiece is rearranged in a vice and clamped by the frame together with the block, after which a second bend is performed.

The workpiece is removed and the length of the staple legs is marked. It, together with the block and frame, is bent and both of its legs are simultaneously bent. The triangle is used to clarify the bend. If it is not done correctly, the bend should be corrected using a frame block and a hammer. When the bending procedure is completed, the structure is filed to the required parameters.

How to bend a sheet of metal evenly: making a machine with your own hands

In order to create a device that allows you to bend a metal sheet at home, you need to prepare the following materials and tools:

- corner 80 mm;

- bolts;

- metal beam I-beam 80 mm;

- loops;

- welding machine;

- clamps;

- handles;

- table.

All work begins with preparing the base of a homemade machine from a profile - an 80 mm I-beam. After this, an 80 mm corner is screwed onto the top of the I-beam with two bolts. During bending, it will secure the workpiece. Three hinges from steel doors are welded under the corner, the other halves of which are welded to the corner itself.

To perform bending, two 800 mm handles are welded to the corner, with which you can turn the machine. The sheet bender is pressed to the table using two clamps. The clamping angle is unscrewed. Then the workpiece is laid, and the corner is moved into place.

If necessary, it can be raised without removing it. After this, the material is threaded between the I-beam and the angle. The metal sheet is carefully aligned. The bolts are tightened and by turning the workpiece is bent to the required angle.

A homemade machine is not a universal device, since it is used for bending sheets of small thickness. If there is a need to bend material with a large thickness, you should use machines made in production.

Bending strips using a vice

First, let's consider the option of bending on a bench vice at an angle of 90 0. To do this, you need a square block of steel. We clamp the strip together with the block so that the block is located on the side of the fixed jaw of the vice and protrudes 1-2 cm above the upper edge.

After such a “sandwich” is firmly clamped, take an ordinary hammer and bend the strip towards the block with light blows. If it is required that the bend surface is not damaged by impacts, then you need to use a copper or brass gasket, which we will hit with a hammer, and from it the force will be transferred to the strip.

In this way, you can bend the strip at any angle; it is only important to select a support block with the desired cutting angle. Without such solid support, achieving the desired angle will be very difficult.

Similar operations are performed in the manufacture of clamps, only in this case we use a thick-walled pipe or rod of the required diameter as a matrix. As in the case of a rectangular bend, blows with a hammer are applied towards the stationary jaw of the vice. This kind of strip bending is a slow process and requires care.

How to bend metal at home

In order to bend metal sheets in production, additional processing of the workpiece is not necessary. For this, special equipment is used. It may vary in design and principle of operation. Metal bending is considered a separate technological process that requires certain skills and knowledge to perform.

Metal bending

Types of bending machines

Before bending an aluminum angle, a steel pipe or a metal sheet, you need to select the equipment for the work. Metal bending is performed on different types of machines:

- Manual models. This is equipment for placement in private workshops. It has small dimensions and does not require additional skills to carry out the work. Using hand tools, you can bend metal sheets and parts of small thickness.

- Mechanical models. They are a structure that is driven by energy transmitted from the flywheel. Initially, the master must unwind this element.

- Hydraulic machines. The equipment contains a hydraulic cylinder.

- Electromechanical units. Common industrial machines that operate using an electric motor. It drives other mechanisms using belts and gears.

- Pneumatic models. This is a design whose mechanisms are driven by pneumatic cylinders.

- Electromagnetic machines. Powerful electromagnets are used to operate the equipment.

On sale you can find mobile devices for bending metal sheets and parts. They are used in garages, private homes, and workshops.

Operating principle of the machines

A variety of equipment is used when bending metal parts. These can be machines for bending strips, pipes, sheets. In order to do quality work, it is important to understand how certain mechanisms work.

Manual sheet benders

Designed for bending metal sheets. They differ in the width of the working surface and the depth of the workpiece feed. Work order:

- The master presses the sheet of metal using a special beam.

- Using a bending beam, the sheet is bent to the desired angle.

- The workpiece is wrung out and pulled out of the machine.

On construction sites, in garages, workshops, it is more convenient to use manual sheet benders, but they are only suitable for bending metal sheets whose thickness does not exceed 2 mm. Manual sheet bender

Hydraulic sheet benders

This is modernized equipment that makes workers' work easier thanks to the use of hydraulic cylinders. Operating principle of the equipment:

- The fluid in the hydraulic cylinder drives the operating mechanism. It pushes the plunger, which changes the position of the cross member with the strikers.

- The sheet begins to bend under the influence of the working part of the machine.

The operation of the cylinders allows you to perform work accurately and quickly.

Electromechanical sheet benders

The operating principle of this equipment is the movement of an electric drive. On the basis of such machines, sheet metal presses are manufactured. Sheet benders equipped with an electric drive are available through and through. With their help, you can process workpieces of different lengths, heights and widths.

Metal bending and its main methods

Not many novice craftsmen know how to bend a profile or metal pipe. To do this, it is important to know the technologies for bending various workpieces.

At home, you can bend sheet metal using hand tools. Before you start bending sheet metal with your own hands, you need to accurately calculate the dimensions of the workpiece. It is important to understand that the length of the part to be processed must be greater than that of the finished product. For calculations, ready-made tables are used, which can be found in engineering reference books or on the Internet.

Bending sheet metal at home

Metal pipe bending

When replacing plumbing, it is important to know how to bend water and sewer pipes at home. For this purpose, a manual or mechanized method is used. The process of changing the shape of the pipe represents a force impact on the workpiece.

To bend the pipe without breaks or folds, a cold and hot method is used. The first option is suitable for bending pipes with a small diameter. Large-diameter pipes are initially heated to increase ductility.

Metal bending

To bend the profile, it is necessary to use the rolling method. In this case, there is not enough information on how to bend an aluminum sheet. For this purpose, profile bending machines are used. They can accommodate up to 5 rolls. To make it easier to bend high-strength workpieces, the metal can be preheated. In this case, high frequency current is used.

Equipment Maintenance and Safety

When working with industrial equipment, you must follow safety precautions:

- Before work, employees are given instructions.

- In mechanized machines, electronic control is used to start the working mechanisms. This reduces the risk of injury while working.

It is important to periodically lubricate the moving elements with machine oil to increase the service life of the sheet bender.

Machines for bending metal are used both in enterprises and in private workshops. When choosing equipment, you need to take into account the size and thickness of the workpieces being processed. The type, size and characteristics of the machine depend on this.

Subscribe to the channel, like, repost, and we will post useful information about metals for you! You can also visit our website, where you will find a lot of information about metals, alloys and their processing.

Homemade sheet bending machines (sheet benders)

Many products are made from sheet metal - drainage systems, shaped parts for roof cladding covered with corrugated sheets or metal tiles, flashings for plinths, corners for structures made of corrugated sheets, etc. All this can be done by a special bending machine for sheet metal. We’ll talk about how to make a sheet bending machine with your own hands in this article.

Types of sheet benders

There are three types of sheet metal bending machines:

- Simple manual ones, in which metal bending occurs when force is applied in a certain place. These units make it possible to bend sheet material in a straight line at any angle - from several degrees to almost 360°. For bending sheet metal

- Hydraulic machines in which sheet metal is bent to the shape of a matrix using impact. The matrix can be straight or curved. This equipment is professional, used in medium and high-power enterprises.

- Roller or roller bending machines. In them, the sheet of metal is not bent in a straight line but is rounded. Using this equipment, you can make pipes or other similar products yourself. To obtain radial bending of a metal sheet

All these devices are classified as sheet bending machines. The easiest way to make one with your own hands is the unit of the first group, a little more difficult - the third (rollers for sheet metal). So we’ll talk about them - from how to make a sheet bending machine with your own hands.

Simple manual

Shaped metal parts cost a lot of money. Even more than corrugated sheeting or metal tiles, therefore it makes sense to make a simple machine for bending sheet metal, and with its help make as many corners, ebbs and other similar parts as you need, and exclusively to your own dimensions.

Drawing of a bending machine for sheet metal Sheet bender - side view Another model

If you're worried about appearance, you shouldn't be. On sale today there is sheet metal not only galvanized, but also painted.

In all designs, the sheet is fixed tightly, so that when working it does not slide on the table, which means that the paint does not rub off or get scratched. It is also not damaged in places of bending.

So the products will look quite decent. If you try, they will look even better than what they sell on the market.

Powerful sheet bending machine from brands

This sheet bending machine will require a flat surface (table), preferably metal, three corners with a shelf width of at least 45 mm, and a metal thickness of at least 3 mm. If you plan to bend long workpieces (more than a meter), it is advisable to take wider shelves and thicker metal. You can use brands, but this is for bending metal sheets of large thickness and length.

You will also need metal door hinges (two pieces), two large diameter screws (10-20 mm), wings on them, and a spring. You will also need a welding machine - weld the hinges and make holes (or a drill with a metal drill bit).

For a homemade sheet bender, a 70 mm brand was used - three pieces of 2.5 m each, two bolts of 20 mm in diameter, a small piece of metal 5 mm thick (for cutting jibs), a spring. Here's the procedure:

- Two brands are folded, and grooves are cut into them at both ends for hinges.

The edges of the recesses are beveled at 45°. The third tee is cut in the same way, only the depth of the recess is made a little larger - this will be the clamping bar, so it should move freely. Cutting notches for hinges - Weld the loops on both sides (weld on the front and back).

Boil the loops well - Two jibs on each side are welded to one of the brands (the one farthest from you, if you “open” them).

They are needed so that you can install the clamping bar clamp bolt on them. Such jibs - Weld the bolt nut to the jibs.

Weld the nut - Install the clamping bar (third cut tee), weld metal plates with a hole in the middle in the upper part.

The diameter of the hole is slightly larger than the diameter of the bolt. Center the holes so that they are on the same vertical line with the welded nut. Weld. Center, weld - Cut the spring so that it raises the pressure bar by 5-7 mm.

Pass the bolt into the “ear” of the clamping bar, put on the spring, and tighten the nut. After installing the same spring on the other side, the clamping bar rises on its own when unscrewed. Little things left - Weld two pieces of reinforcement to the screw head to serve as handles for tightening.

Weld pieces of reinforcement to the bolt head - Weld a handle to the movable (closest to you) brand.

That's it, you can work. Homemade sheet bender in progress

This option is very powerful - you can bend long workpieces and sheets of considerable thickness. Such scales are not always in demand, but they can always be reduced.

The video suggests a similar design of a smaller size, but with a different fastening of the clamping bar. By the way, no one bothers you to also install a spring on the screw - it will be easier to raise the bar.

What’s interesting about this design is that you can make beading on it, something that such devices usually cannot do.

This model is welded from a thick-walled angle, the frame is made like an ordinary construction sawhorse, which is welded from the same angle. The handle is from a luggage trolley. The design of the screws is interesting - they are long, the handle is curved in the shape of the letter “L”. Convenient to unscrew/screw.

Small manual sheet bender for DIY production

This homemade sheet metal bending machine has many features:

- The corners are not arranged with shelves facing each other, but are directed in one direction. Because of this, attaching the loop is not the most convenient, but it can be done. Features

- On the bend of the far (fixed) corner, small stop plates for the pressure strip are welded on both sides.

- The screw nut is welded on the same strip (on both sides).

Pressure bar

Now let's move on to the design of the clamping bar (pictured above). It is also made from a corner, but is laid on the machine with an upward bend. To ensure that the bar does not bend during operation, reinforcement is welded on - metal jumpers. Small metal platforms are welded at both ends of the strip, in which holes are drilled for bolts.

Another important point is that the edge that faces the bend is cut off to obtain a sharper bend angle.

The bar is set like this

The clamping bar is placed on the machine, and a spring is placed in the place where the nut is installed. The handle is installed in place. If it does not press the bar, it is raised above the surface due to the elastic force of the spring. In this position, the workpiece is tucked under it, positioned, and pressed.

Place a spring under the hole, then a bolt

A good option for home use. It will not be possible to bend thick metal, but tin and galvanized steel can be bent without difficulty.

Sheet metal rollers or roller bender

This type of sheet bending machine can have three types of drive:

- manual;

- hydraulic;

- electric.

They make rollers for sheet metal with manual or electric drive with their own hands. Manual ones have 3 shafts, electric ones can have 3-4, but usually there are also three.

Roller bending machine

This machine needs a good solid foundation. This could be a separate bed or some kind of workbench or table. The basis of the structure is rolls. They are made the same size. The two lower ones are installed permanently, the upper one is movable, so that in the lower position it is located between the rollers. By changing the distance between the lower rollers and the upper one, the radius of curvature changes.

The machine is set in motion using a handle attached to one of the shafts. Then the torque is transmitted to other rollers through sprockets. They are selected so that the rotation speed is the same.

If the equipment is intended to produce pipes, the upper roller on one side is made removable, with a quick fixation system. Once the sheet is rolled into a pipe, there is no other way to pull it out.

Air bend

Air bending (three-point bending): Only the top two corners of the V-die touch the material, and the inside radius of the bend is determined by the width of the V-die opening rather than the radius of the punch tip. Embossing or Bottom Bend: The material is in contact with the entire inner surface of the V-die and the tip of the punch forms the inside radius of the bend. Much more force is required compared to air bending.