Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations. During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension. Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

DIY wire bender - Do it yourself

Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations.

During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension.

Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

Manual bending rules

If you are going to manually bend the wire, you must adhere to a number of recommendations that will allow you to complete this procedure without harm to your own health.

- All bending procedures should be carried out only with gloves made of thick fabric.

- The wire that is being bent must be secured in a vice as securely as possible so that it does not jump out during operation.

- All tools and equipment that you are going to use for work must be in good working order and perform their assigned functions efficiently.

- Heavy tools and equipment that you use when bending should not be placed on the edge of the workbench, so as not to accidentally hit them and drop them on your feet.

- When carrying out all manipulations with the wire bending tool with one hand, the other should be kept as far as possible from the future bend. Pliers or any other tool can break off and injure a hand located close to the bending area.

Wire bending using improvised means is possible only in small quantities, since such a procedure is quite labor-intensive. In addition, this operation can only be used to create products of the simplest configuration.

A specialized wire bending machine allows you to produce various products in large volumes, including those with complex shapes.

Working with a wire bending machine

To produce a large number of bent products from wire, various techniques can be used, each of which uses special equipment. The most common and economical method is the coil bending method.

Bending using this technology occurs in several stages.

- The wire, which is wound on coils, is fed to a two-plane roller machine, which aligns it.

- After alignment, the wire is fed to a wire bending machine, on which the product of the required configuration is formed.

- The formed product is cut off, and the entire bending cycle is repeated again.

The use of this technology allows you to fully automate the bending process and thereby achieve high productivity.

Budget wire bending machine

A wire bending machine can also look like a stationary template around which the wire is rolled using movable pressure rollers.

Using such devices, bends of even the smallest radius can be formed on the surface of the wire, the value of which is comparable to the outer diameter of the workpiece.

At the same time, the configuration of the product formed on such a machine can be quite complex.

The adjustable stops and variable arms of this template allow you to create many combinations of wire bends

A wire bending machine can also operate on the principle of pushing the workpiece through a system of rollers.

When using such equipment, the end of the wire is connected to a special wire, which pulls the product through the working parts of the machine.

A wire bending machine of this type, due to the features of its design, allows the production of products with even very complex shapes.

When leveling the wire, a wire bending machine is also used, which in this case is used for straightening.

The working parts of such equipment can be straight frames or two-plane straight blocks.

At the same time, rotating straightening frames are more efficient, which is why they are used in cases where leveling the surface of the wire needs to be done as smoothly and efficiently as possible.

Types of professional equipment

The simplest type of professional equipment used to bend wires are machines with one console. Meanwhile, such devices can only produce products of simple geometric shapes, the development length of which does not exceed 1000 mm.

More complex products with a development length of over 1000 mm make it possible to create double-cantilever equipment, in which the workpiece is deformed simultaneously from both ends. This machine can produce products with many complex curves.

The most complex wire products allow the creation of 3D machines on which bending can be performed simultaneously in three dimensions.

The machines of this category are endowed with such unique functions by a rotary bending console, all movements of which are controlled by an electronic automated system.

Despite all the advantages of processing using such equipment, it is quite expensive, so these machines are used in exceptional cases.

What is used for bending wire? How to make a machine with your own hands!

Objects of various configurations and purposes can be made from wire. During work, it is important to bend the material correctly, therefore, when the diameter of the metal thread is more than 1 mm, it is advisable to use special devices.

The main types of this type of tool, as well as how to make a wire bending machine with your own hands, will be discussed in this article.

Basic bending methods

If it is necessary to perform a small amount of work, then hand tools are used to bend the wire. For bending soft metal materials or when the wire diameter does not exceed 3 mm, pliers or round nose pliers are used. These tools allow you to securely clamp a part of the product in one tool, and use another to bend the wire to the desired angle.

In this way, you can bend the material using a carpenter's vice. In this case, the wire is fixed in a vertical position, and the change in direction is also carried out using pliers or any other clamping device or mechanism.

If it is necessary to make a rounded bend, then for this purpose any rod of suitable diameter is used, which is also clamped in a vice. A rounded bend will need to be made when making springs from elastic wire yourself.

To do this, it is enough to clamp a rod or pipe of a suitable diameter in a vice, fix the end of the wire on one side, and use pliers to wind the wire the required number of turns.

If the wire has to be bent too often, then the most correct solution would be to purchase special devices or machines.

Tools for bending this material are a design in which the wire is clamped and bent using human muscle power. Machine tools usually use electric drives, and for the manufacture of complex products such machines are equipped with electronic controls.

Rules for work

Wire bending is not a complicated process, but to work effectively with this material you must adhere to the following rules:

- For work, you must use gloves made of thick fabric.

- Use only working tools and automatic machines.

- If a vice is used to perform this operation, then before starting the process, you must make sure that the workpiece is securely fixed.

- Before bending, the workpiece should be leveled.

Following these recommendations will help prevent scraps and injuries in the event of a sudden release of material from the holding device. You should also take care of the wiring and proper grounding when using machines that run on electricity.

Equipment use

If the volume of work is large enough, then equipment equipped with an electric motor will allow you to perform a large number of operations. The use of machines will significantly increase labor productivity, but at the initial stage it will be necessary to make some efforts to study the process of operation of a wire bending machine.

The most economical machine for bending wire is considered to be coil equipment, in which the material is supplied from bulk coils.

The process of bending wire on such equipment is carried out in the following order:

- The wire from the coil is fed to a roller mechanism, which aligns the material.

- The straightened wire enters the bending mechanism.

- At the next stage, bending and separation of the wire products occurs.

- After cutting the finished product, the process is repeated.

To make wire bending work as comfortable as possible, CNC machines are used.

Despite the significant cost of such equipment, the return on investment in a business occurs within a few months. Machines equipped with a microprocessor allow not only to fully automate the process, but also to carry out welding work on curved products.

DIY device

If the wire bending device will be used only for home work, then you can make a manual machine yourself. Equipment made with your own hands will not be highly productive, but for performing daily operations in a small volume such a product will be quite sufficient.

Processing methods

If we talk about bending wire on a large scale (in production or a specialized plant), then various methods are used to plastically deform it.

One of the most common and economical is the bay processing method.

In this case, wire rings are wound onto coils, and then they are fed to two-plane roller machines that straighten the wire.

Video:

Afterwards, the material is processed on bending equipment (the required shape is created), at the end the wire is cut, and the entire work cycle is repeated again.

IMPORTANT TO KNOW: How is sheet metal bending carried out?

Moreover, all work is fully automated, which allows you to save time and money and use the device to create a simple curved structure with a development length of about 1000 mm.

For rolling wire with your own hands, there are special devices that consist of fixed templates of certain radii of curvature (the radius can be one or several).

The material is rolled around the created template using pressure rollers.

Basically, this technology is used to create bent products that have a small bending radius (about the same as the diameter of the wire).

The method of pushing the wire is reminiscent of the way 3-roll equipment works on a profile bending and spring-coiling machine.

The material is pushed into the device using a special wire, then it is pressed against various rollers, which makes it possible to change the bending parameters and make transitions to different radii.

This device allows you to bend various structures that have a complex configuration and large bending radii on the development - from 1000 mm or more.

Video:

You can straighten the wire using straightening equipment or a special device. This equipment includes units consisting of rotating leveling frames or two-plane leveling blocks.

In this case, rotating frames are preferable, as they allow the material to be aligned more smoothly.

Wire bending: with your own hands and using machines

14.11.2018

Wire is a metal product in demand in construction and many industries. Hand tools, fixtures and machines are used to bend the wire into the required shape. The choice of the appropriate bending method depends on the diameter and hardness of the wire, as well as the required productivity.

Bending wire at home

To give simple shapes to not very stiff wire, use metalworking tools, available in almost every home workshop:

- Pliers . With their help, you can bend or securely fix the end of the product.

- Pliers . A type of pliers.

- Wire cutters . With their help, metal products are cut into measured pieces.

To create complex shapes, templates are used, which are checked against during the bending process. To bend a rectangular clamp, the end of the wire is clamped in a vice, and bending is carried out with pliers or hammer blows.

Safety rules for manual bending:

- work must be carried out wearing thick fabric gloves;

- it is necessary to ensure tight fixation of the material being processed;

- There should be no heavy objects on the table on which work is carried out that could fall to the floor.

Simple DIY wire bending devices

To perform bending in single or small-scale versions, sets are used, consisting of two steel plates, axles, rollers and a bushing with a central channel of 6 mm. The number and location of axes can be changed.

Operating principle of the bending device:

- The bottom plate is secured in a vice.

- The top one is turned to a certain angle. If it is necessary to make precise shapes, a protractor is built into the device.

- Due to the protruding axes and the support sleeve, the product bends at the desired angle.

Using such a bending device, you can work with unalloyed and stainless wire with a diameter of 3-4 mm, welding rods, fittings with a smooth surface of class AI of small diameter.

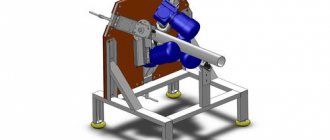

Homemade manual machine for artistic wire bending

In order to bend wires to create metal patterns on fences, stair railings, and for decorating facades, special factory-made equipment is used.

However, it is also possible to independently manufacture such a device.

Rice. 1

Rice. 2

Brief manufacturing steps:

- Make a frame (2) measuring 150x80 mm from a steel plate 30 mm thick.

- A through hole is drilled at the end of the frame (visible in Fig. 1) for the adjusting bolt, blind holes (2) and (3) for fixing the rollers, (4) and (5) for fixing the frame to the corner. The holes are threaded with M8 threads.

- An unequal angle 60x40 mm with a shelf thickness of 5 mm and a length of 200 mm is screwed to the table.

- For the groove in Fig. 1, a steel block 90 mm long is made. A blind hole with a thread (1) for the adjusting bolt, a through hole (2) for fixing the rotation angle adjustment knob, a hole (3) 10 mm deep with an M8 thread for a roller with a corrugated surface are drilled in the block.

- The assembled frame (2) with guide rollers (3), two handles (5) and (6), and a roller with a grooved surface are screwed to the corner.

Industrial wire bending machines

In serial and large-scale production, machines that work with wire in coils are used. Such units provide cost-effectiveness and good productivity when producing metal products of the same type. Devices are installed on the machine, configured to obtain a specific configuration.

Work process:

- installing a coil of wire on the unwinder;

- a long product is affected by two mechanisms - roller and flat;

- the aligned wire enters the machine into bending devices;

- the part of the required configuration is cut off by a mechanical cutting device.

This type of wire bending equipment produces parts of simple shapes. The number of bending operations usually does not exceed 5.

CNC machines for wire bending: types and main characteristics

Technologically advanced machines are numerically controlled. They make it possible to obtain parts of complex shapes. To change the bending shape and size of the product, change the program on the computer.

There are several types of machines that operate using computer programs:

- With one bending console. This type of unit produces products that are simple in shape. The sweep length is limited to 1 m.

- With two consoles. With their help, metal products of complex configurations with long development lengths are produced. The work is done with wire cut into measured lengths. Bending is carried out in counter directions. On double-cantilever machines it is possible to obtain closed bends.

- Volumetric bending. 3D bending allows the production of complex three-dimensional shapes. The disadvantage of this technology is the high cost of the units and their inability to provide high performance. Such machines produce seamless products that will be subject to high demands on strength during operation.

Professional equipment

If only the simplest devices (vises, pliers) are used to bend wire on their own, then for mass industrial processing of the material professional machines are used (for example, for the production of key rings or springs for handles).

IMPORTANT TO KNOW: Technology for stamping sheet metal parts

A wire bending machine with one bending console is one of the simplest and makes it possible to create bent products of simple shapes. The length of the sweep in this case should not exceed 1000 mm.

Double-cantilever machines can work with a reaming length of more than 1000 mm.

The material is cut into the required pieces, then it is deformed from both ends simultaneously.

Such equipment allows you to create products with a large number of bends. Machines with only one console can no longer perform this work.

Also, on double-console machines you can make figures with closed bends.

Wire bending on so-called 3D machines is becoming more and more popular these days.

Video:

Three-dimensional spatial bending can be done using a rotary bending console, which is controlled by an automated system.

Unfortunately, such material processing is quite expensive, so parts are mainly created using simple flat bending, and then, if necessary, individual parts are automatically welded.

But due to welding seams, products become more fragile and short-lived, so their cost is relatively budget-friendly.

DIY wire bending machine

Wire is a metal product in demand in construction and many industries. Hand tools, fixtures and machines are used to bend the wire into the required shape. The choice of the appropriate bending method depends on the diameter and hardness of the wire, as well as the required productivity.

Industrial wire bending machines

In serial and large-scale production, machines that work with wire in coils are used. Such units provide cost-effectiveness and good productivity when producing metal products of the same type. Devices are installed on the machine, configured to obtain a specific configuration.

Work process:

- installing a coil of wire on the unwinder;

- a long product is affected by two mechanisms - roller and flat;

- the aligned wire enters the machine into bending devices;

- the part of the required configuration is cut off by a mechanical cutting device.

This type of wire bending equipment produces parts of simple shapes. The number of bending operations usually does not exceed 5.

All about wire bending

- Basic bending rules

- Equipment overview

- How to bend?

Wire bending is a popular technological process with which it is possible to give a product the required shape.

The procedure involves changing the configuration by compressing the inner metal fibers and stretching the outer layers.

It is worth taking a closer look at what the process is and what equipment is used to carry it out.

Basic bending rules

Wire bending is not difficult. However, to achieve the best result, several rules should be taken into account.

- When performing the task and working with the tool, thick gloves should be used to prevent injury.

- Only working tools or automatic machines are suitable for the job. Before you begin bending metal, you should check the equipment for damage or deformation.

- If a vice is required for the operation, you should first make sure that the workpiece is securely fixed.

- Before starting work, it is necessary to level the position of the workpiece.

- If you operate the tool with one hand, you should keep the other one away from the place where you plan to make the bend. This is explained by the fact that pliers or other tools can break off and injure your hand.

- It is not recommended to place heavy instruments on the edge of the work table during the procedure. Otherwise, when bending, they can be touched and dropped on your feet, which will result in injury.

Taking into account these rules will allow you to achieve a reliable result and avoid defective products or injuries if a sudden release of material occurs.

Additionally, during the bending process, it is recommended to pay attention to the integrity of the wiring and the organization of grounding when it comes to using electrical machines.

It is worth noting that manual bending allows you to work with small volumes of materials.

This is explained by the fact that the procedure is highly labor intensive, which has an adverse effect on the condition of the human body.

Equipment overview

For large volumes of work, various automatic metal bending machines are used. It is not necessary to use only the manual method of changing the shape of the material. You can use machines or other machines that can increase productivity. It is worth taking a closer look at the range of tools and equipment for bending wire.

For manual bending

Metal wire is in demand in everyday life. Mostly, manual plumbing equipment is used to change the configuration. This allows you to obtain the following elements:

- clamps;

- brackets;

- hangers.

To achieve the desired result, you should use soft and flexible types of wire.

This will reduce the effort required during manual bending and will also significantly speed up the process.

At home, to change the shape of metal elements it is customary to use:

- round nose pliers;

- pliers;

- bench vice.

If the wire needs to be cut, you can use wire cutters or purchase special side cutters.

Such a tool is sufficient to provide the necessary result in giving the wire the required shape. Difficulties arise when it becomes necessary to bend products of large diameters.

To do this, you will need to purchase special devices. You can also make them yourself.

Machine tools

When it becomes necessary to produce a large number of metal products from wire of different diameters, manual bending is out of the question. To carry out the operation, special equipment and special techniques are used. The coil method of changing the metal configuration is considered in demand. When using this technology, the following steps are performed.

- The wire is wound onto special coils and fed to a machine with rollers, which additionally has two planes. They will ensure the alignment of the product.

- After this, the material is fed to the machine, which will form the required product configuration.

- The formed wire is cut off to begin the first stage again.

This process allows you to automate the bending procedure, which increases productivity. A wire bending machine is a static template.

The design of the machine includes pressure rollers that ensure winding of wire around the template.

With the help of such devices it is possible to achieve any configuration, as well as provide bending of even the smallest radius. The latter cannot be provided by manual bending.

Some machines have special rollers installed that facilitate bending of products.

Such equipment uses the principle of pushing the processed material to further change its shape. The end of the wire is connected to the wire before the operation.

He pulls it through rollers, which give the material the desired shape established by the program. A separate machine is also used for straightening the wire.

The role of working bodies that ensure the achievement of the desired result can be:

- frames of the correct shape;

- blocks with two planes.

The former are highly efficient, therefore they are in demand in production, where a smooth and high-quality procedure is required. Modern technologies in the field of machine tool construction have made it possible to begin producing machines equipped with several bending consoles. This type of equipment is called CNC machines. They are designed for the production of flat and 3D products.

Wire bending using such shaped technology makes it possible to increase the productivity of factory capacities, as well as to organize the production of products of various shapes. To carry out the procedure, it is enough to set the necessary parameters in the program, the machine will independently cope with the task.

How to bend?

To bend small diameter wire at home, you will need to find and prepare a vice, hammer or pliers. However, using the listed tools requires a lot of time and effort to carry out the procedure.

If you want to speed up the process, you should think about making a more reliable device.

Such a tool is a manual bar bender, which allows you to bend wire. To make it you will need to take:

- two sections of profile pipe;

- grinder;

- welding machine.

The design of the bar bender includes a handle and a working part. To assemble it, you will need to do the following.

- Cut the edge of a long piece at a 45 degree angle using a grinder.

- Cut a U-shaped part from the short part.

- Weld both elements together at a certain angle.

- Beat off the slag and clean the surface with a brush.

- Sand the tool.

When all steps are completed, the tool will be ready for use. If necessary, it can be painted. Working with a bar bender is not difficult. The device operates like a lever. To bend, you need to insert the wire into the working part and press on the handle.

The most popular question is how to make a ring with your own hands from wire. To do this, you will need to use a block of wood of the required diameter or use a small piece of steel pipe.

In the case of a pipe, you will also need to select the required diameter of the product in advance.

When the required materials and blanks have been found or made, it is necessary to wind at least two turns of wire onto the template and make marks. After completing the techniques, all that remains is to remove the wire from the pipe or blank and weld an even ring along the prepared marks.

Options for devices for bending wire materials with your own hands

For bending, sometimes it is enough to use improvised tools. Much depends on the thickness of the material used.

For bending products with your own hands with a diameter of up to 3 mm, the following are suitable:

- bench vice;

- pliers;

- round nose pliers.

The material is cut with side cutters or ordinary nippers.

Products with a large diameter will require the use of a home-made device. The assembly of the machine is carried out in stages:

- a steel corner 19 cm long is screwed to the table with bolts;

- a frame is made from a metal plate, holes are drilled in it;

- a frame with guide rollers and handles is screwed to the corner;

- a metal block is selected to the frame groove;

- several through and blind holes are made in the block;

- a handle and a corrugated roller are bolted to the block;

- plates are welded at the bottom of the frame;

- the block is inserted into the frame groove so that it slides in it and does not fall out;

- guide rollers are screwed in;

- the bar structure is screwed to the corner.

A self-made mechanism will allow you to make products of more complex configurations.

What is used for bending wire? How to make a machine with your own hands!

Objects of various configurations and purposes can be made from wire. During work, it is important to bend the material correctly, therefore, when the diameter of the metal thread is more than 1 mm, it is advisable to use special devices.

The main types of this type of tool, as well as how to make a wire bending machine with your own hands, will be discussed in this article.

Conclusion

What is used for bending wire is described in detail in the article. To work with this material, you can use both simple tools and complex installations that allow you to perform a large number of operations per minute.

If you have a limited budget, you can independently make a mechanical device that will not be inferior in quality to factory products.

Manual bending rules

If you are going to manually bend the wire, you must adhere to a number of recommendations that will allow you to complete this procedure without harm to your own health.

- All bending procedures should be carried out only with gloves made of thick fabric.

- The wire that is being bent must be secured in a vice as securely as possible so that it does not jump out during operation.

- All tools and equipment that you are going to use for work must be in good working order and perform their assigned functions efficiently.

- Heavy tools and equipment that you use when bending should not be placed on the edge of the workbench, so as not to accidentally hit them and drop them on your feet.

- When carrying out all manipulations with the wire bending tool with one hand, the other should be kept as far as possible from the future bend. Pliers or any other tool can break off and injure a hand located close to the bending area.

Wire bending using improvised means is possible only in small quantities, since such a procedure is quite labor-intensive. In addition, this operation can only be used to create products of the simplest configuration.

A specialized wire bending machine allows you to produce various products in large volumes, including those with complex shapes.

DIY wire bending machine [instructions, video]

Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations.

During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension.

Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

Differences in 3D wire bending

Custom bending of steel and stainless galvanized wire is done either on two-dimensional machines or on 3D CNC machines. The advantage of a two-dimensional machine is the low final price of the finished product, the disadvantages are everything else. Products made on 3D machines cost a little more, but the advantages justify it

:

- you can make complex three-dimensional parts and fasteners from any wire;

- you can add automatic welding, thread rolling, chamfering, pressing to the process;

- CNC allows fully automated production, which saves time and eliminates human errors;

- The machine can be retooled and reconfigured very quickly if the order includes different parts - this will not lead to an increase in production time.

We have experience, personnel, and good 3D bending machines, so if you need a custom-made finished product, according to your or standard drawings, you have come to the right place. We work in Moscow and the Moscow region, we will send orders anywhere in Russia.