- Groundtech /

- LIGHTNING PROTECTION GROUNDING /

- Conductors /

- Wire straightening device (photo, video)

Rice. 1 – appearance of the device for straightening wire

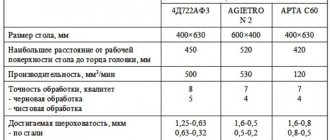

| Material | Number of rollers | Drive unit | Weight | Round conductor | Flat conductor | vendor code |

| Cink Steel | 9 | Manual | 12 kg | 6-10 mm | 20x3.30x4 mm | M10251 |

Rice. 2 – appearance of the wire straightening machine

Rice. 3 – appearance of the wire straightening machine

Rice. 4 – roller of the device for straightening the wire

Rice. 5 – drive handle of the device for straightening wire

Rice. 6 – clamping screw of the device for straightening the wire

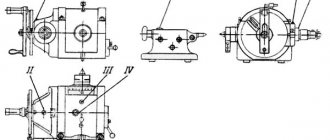

A manual wire straightener is a hand-held tool that is widely used for straightening round and flat conductors for lightning protection and grounding systems.

The tool consists of a metal body with nine rollers. The movement of the rollers is carried out using a handle. The roller gears are connected by a chain.

Principle of operation:

When the handle of the tool mechanism is rotated, the conductor passes between two rows and rollers. The top row of rollers is tightened with screws, while pressing the conductor. After passing between the steel rollers, the bend radius is removed and the conductor arrives straight.

Sequence of work:

— place the tool on the surface so that the handle rotates freely, and secure the body to the surface with screws;

— loosen the screws of the pressure roller blocks;

— install the conductor into the tool and tighten the screws of the blocks with rollers

— tighten the screws in the blocks in order;

- tighten 1 block. all the way;

- tighten block 2 without force

Add a comment

JComments

How to straighten a wire with your own hands

If the wire rolled into coils can be considered conditionally smooth, then in order for it to become straight, we just need to get rid of the large radius curvature.

But how to straighten the wire in the form of crumpled remains and poorly stored waste? They represent not only turns, but various zigzags located in different directions from the axis. In this case, straightening the wire with the right approach to the state of an ideal straight rod is quite achievable. There are several most effective ways to align the wire. Depending on the choice, they will have slightly different quality results.

So, from simple to complex:

- You can remove creases from the wire by securing both ends in your hands and starting to forcefully roll it through a pipe or door handle.

Straightening the wire works well if its straightened sections are placed on a flat surface of the workbench. Cover it with a wooden block and start rolling it over her so that she can move freely. Just a few such rollings give quite good results.- To straighten soft copper wire, you need to secure it at one end at a height. To the other hang a not very heavy load, such that it cannot tear it. By rotating the load clockwise and back several revolutions around its axis, you can achieve an ideal result.

- Straightening the wire will follow a similar method. If one end is secured in a vice, and the other is clamped in the chuck of a screwdriver or electric drill. The straightening process will occur from slow rotation and at the same time holding the wire under strong tension. Just a few turns will be enough for complete straightening.

- Also, a screwdriver or electric drill will be needed to straighten small pieces of wire up to 30 centimeters. To do this, make a spinning hole in a wooden block with a diameter slightly larger than the wire one and pass one end of the rod through it. We fix this end in the chuck and begin to slowly rotate, pulling the wire through the hole.

- To align a wire of not very large diameter, you can make a fairly simple and cheap device with your own hands.

For this we need a massive wooden board measuring 500 x 120 x 50 mm. We hammer 5-7 nails with a diameter of 3-5 mm into it in a straight line with an indentation to the diameter of the wire. The distance between the nails directly depends on the diameter of the wire and its elasticity. The higher these indicators, the larger the gaps between the metal rods. The process of straightening the wire will consist of simply pulling it between the nails along the marking line. For clarity, a schematic photo will help you.

If you know your original way to straighten the wire with your own hands, then please share it with us in the comments block.

Wire straightening machine

How to Manually Align and Straighten Wire

Sometimes, for household needs or in the workshop, you need to use pieces of straight wire for work. But the question immediately arises: how to straighten the wire? After all, it is produced in factories and immediately packaged in round coils. This form is very convenient for storage and transportation. Therefore, in order to make a metal wire straight, it is necessary to expend not only some effort, but also use a number of simple devices.

Industrial methods

In production, specialized straight cutting machines are used to straighten almost all types of metal wire. The process is based on two main methods:

- straightening by rolling through a system of 5-6 pairs of rollers, which are located sequentially in different planes so that each subsequent pair is perpendicular to the neighboring one;

- straightening by drawing through several specially made dies.

As a rule, such machines must have a special device for automatically unwinding wire from coils or coils.

To work with elastic types of wire and alloy steel rod, the production technology involves heating and tempering the steel structure of the workpiece using gas burners or high-frequency inductive heaters.

How an industrial straightening and cutting machine works can be seen in the video:

How to straighten wire without a machine

Unfortunately, at home, making a good roller machine capable of straightening wire with a diameter of over 2 mm is quite expensive and labor-intensive. Moreover, if the need for a straight wire rod is one-time.

An example of one of these devices can be seen in the photo.

Therefore, in order to straighten the metal wire from the coil, it is worth using the most common method of force stretching, for this you must be guided by the following sequence:

- First you need to firmly fix one end of the wire in something massive and solid. To do this, you can wrap its end around the base of a power line pole or a strong tree with a trunk diameter of at least 25 centimeters.

- Next, we manually unwind the coil on the ground and, if possible, stretch it as much as possible.

- At the second end of the unwound wire we make a loop and secure it in a device capable of pulling it with force, that is, moving it a certain distance.

- The straightening process itself consists of slowly stretching the metal wire with great force until it becomes shaped like an ideal string. To secure the straight shape, you can leave it in this tense state for some short time, from about 5 to 30 minutes.

A fairly wide range of devices can be used as a tensioning device, depending on the diameter of the metal wire. So, for a wire 2-3 mm in diameter, a steel scrap with the effort of two strong men or the use of a manual mechanical winch may be enough. But straightening wire for a diameter of 5 mm or more will require much significant effort and for this you will need to use either the towbar of a personal car, or the dynamic force of a tractor or truck.

It is worth keeping in mind that straightening a wire with a diameter of more than 5 mm, made of alloy steel, will require not just tension to the shape of the string, but stretching until the wire breaks. As a rule, the rupture occurs at the attachment point on one of the ends, and for safety reasons you should not be near the stretched wire.

How to straighten a wire with your own hands

If the wire rolled into coils can be considered conditionally smooth, then in order for it to become straight, we just need to get rid of the large radius curvature. But how to straighten the wire in the form of crumpled remains and poorly stored waste? They represent not only turns, but various zigzags located in different directions from the axis. In this case, straightening the wire with the right approach to the state of an ideal straight rod is quite achievable.

There are several most effective ways to align the wire. Depending on the choice, they will have slightly different quality results.

So, from simple to complex:

- You can remove creases from the wire by securing both ends in your hands and starting to forcefully roll it through a pipe or door handle.

- Straightening the wire works well if its straightened sections are placed on a flat surface of the workbench. Cover it with a wooden block and start rolling it over her so that she can move freely. Just a few such rollings give quite good results.

- To straighten soft copper wire, you need to secure it at one end at a height. To the other hang a not very heavy load, such that it cannot tear it. By rotating the load clockwise and back several revolutions around its axis, you can achieve an ideal result.

- Straightening the wire will follow a similar method. If one end is secured in a vice, and the other is clamped in the chuck of a screwdriver or electric drill. The straightening process will occur from slow rotation and at the same time holding the wire under strong tension. Just a few turns will be enough for complete straightening.

- Also, a screwdriver or electric drill will be needed to straighten small pieces of wire up to 30 centimeters. To do this, make a spinning hole in a wooden block with a diameter slightly larger than the wire one and pass one end of the rod through it. We fix this end in the chuck and begin to slowly rotate, pulling the wire through the hole.

- To align a wire of not very large diameter, you can make a fairly simple and cheap device with your own hands. For this we need a massive wooden board measuring 500 x 120 x 50 mm. We hammer 5-7 nails with a diameter of 3-5 mm into it in a straight line with an indentation to the diameter of the wire. The distance between the nails directly depends on the diameter of the wire and its elasticity. The higher these indicators, the larger the gaps between the metal rods. The process of straightening the wire will consist of simply pulling it between the nails along the marking line. For clarity, a schematic photo will help you.

If you know your original way to straighten the wire with your own hands, then please share it with us in the comments block.

Search for records using a filter: Select BendingProtectionForgingCuttingWeldingDrilling Select RebarSquareCircleSheetStripWirePipeAngleChannel/Beam Select AluminumBrassCopperStainless SteelTitaniumCast Iron

wikimetall.ru

How to straighten a wire: a homemade device

Sometimes neat wire rods of not very long length are required. How to align them quickly and perfectly without using a hammer? For such a case, there is a ready-made solution, which will be discussed in this video tutorial.

To make this homemade device, which will free you from the need to crumple the wire in your hands, trying to do the almost impossible, you will need a blank from a 70-gauge angle, three bearings and bolts with nuts for fastening the bearings. Two bearing units are installed stationary, and one can change position. This bearing is used to press the wire against two others during the pulling process. By changing the gap between the bearings, you can gradually narrow the space in which the wire will be located in this process.

How is alignment carried out?

A wire is inserted into the device, clamped in a vice, one end of which is clamped with a screwdriver. By pushing the rotating wire between the rollers and gradually clamping it between them, it is drawn and aligned.

izobreteniya.net

Gromovod

- - accessible and inexpensive

- — quick installation

- - always in stock

- — quick registration

- — discounts from 5 days

- - folding tripod base

- - one person management

- - ease of use

- - light and durable

- — buying as a set is cheaper!

- - alignment of wire in coils

- — electrolytic galvanization Fe/Zn12/C/T2

- - control both manually and remotely

- — bearings do not require lubrication

- — thermal protection of electric motors from overload

A truly reliable device that has never let me down. And believe me, we have enough work for him.

The price won him over. Or more precisely, value for money. So far it hasn't let me down, it works fine.

There were fears at the beginning, but completely in vain. A normal workhorse. The further it goes, the more it makes our work easier.

Still have questions? Just leave your number to receive a free consultation. Or call right now! We are available on Whatsapp, Viber and Telegram.

gromovod.ru

i-perf.ru

Method three: creating and using a mobile machine

You need to build this one yourself. But I assure you that this will not take long at all and is as budget-friendly as possible. What I've done:

- I took a thick board (disassembled the old ladder);

- drove the nails strictly in a row so that the head protruded 2 cm from the board;

- then I just put a piece of wire between the nails and pulled it through.

The effect turned out to be quite good, and the string itself was now suitable for reuse.

Source stolica-s.su

Method two: using a one-way tensioner

This method is relevant if you need to straighten twisted pieces that have already been used on the farm. Any strong and sufficiently stable object can be used as a tensioner. For example, I used a metal pipe that served as the base of the gate. You can find something more convenient. Then all the actions were performed according to this algorithm:

- I threaded the end of the wire through the pipe and moved it a distance so that alignment occurred along the entire length.

- I attached wooden blocks to both ends of the string to make the movements more convenient and painless. I strongly recommend not to ignore the creation of such handles, otherwise there is a very high risk of tearing or cutting the skin of your hands with sharp ends.

- I began to alternately tighten one side and then the other to the maximum range (as far as my hands can reach).

- Then he unscrewed the bars and cut off the uneven edges using metal scissors. The wire straightened out quite well.

If you need to align a wire of a certain length, then it is better to take it with a reserve, since the curved edges to which the handles are attached for convenience will have to be removed.

Advice! If the wire is old or rusty, then it is dangerous to align it in this way, since there is a risk that it will burst during tension and you will get injured.

Source russian.alibaba.com

Method four: using a drill

I also tried this option. True, it is more suitable for small pieces - up to 30 cm. How to align the wire in this way, read the algorithm below:

- I clamped one end of the wire in a vice, and the other in a drill.

- I pulled the string well and started the cartridge to rotate slowly.

- Until the piece of material was maximally leveled, I kept it in tension.

This method turned out to be the easiest, but again, not everyone has such a tool, especially if you live in an apartment.

Source liveinternet.ru

How to straighten wire without a machine

Unfortunately, at home, making a good roller machine capable of straightening wire with a diameter of over 2 mm is quite expensive and labor-intensive. Moreover, if the need for a straight wire rod is one-time.

An example of one of these devices can be seen in the photo.

Therefore, in order to straighten the metal wire from the coil, it is worth using the most common method of force stretching, for this you must be guided by the following sequence:

- First you need to firmly fix one end of the wire in something massive and solid. To do this, you can wrap its end around the base of a power line pole or a strong tree with a trunk diameter of at least 25 centimeters.

- Next, we manually unwind the coil on the ground and, if possible, stretch it as much as possible.

- At the second end of the unwound wire we make a loop and secure it in a device capable of pulling it with force, that is, moving it a certain distance.

- The straightening process itself consists of slowly stretching the metal wire with great force until it becomes shaped like an ideal string. To secure the straight shape, you can leave it in this tense state for some short time, from about 5 to 30 minutes.

A fairly wide range of devices can be used as a tensioning device, depending on the diameter of the metal wire. So, for a wire 2-3 mm in diameter, a steel scrap with the effort of two strong men or the use of a manual mechanical winch may be enough. But straightening wire for a diameter of 5 mm or more will require much significant effort and for this you will need to use either the towbar of a personal car, or the dynamic force of a tractor or truck.

It is worth keeping in mind that straightening a wire with a diameter of more than 5 mm, made of alloy steel, will require not just tension to the shape of the string, but stretching until the wire breaks. As a rule, the rupture occurs at the attachment point on one of the ends, and for safety reasons you should not be near the stretched wire.