The price is for one sheet. When ordering more than 500 linear meters, check the price with our manager.

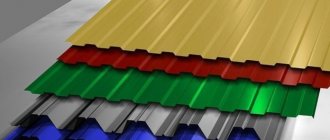

Colored corrugated sheeting (green, red, blue), which appears every now and then on the exteriors of residential buildings and commercial buildings, is not only a decorative design for facades. Painted corrugated sheeting, due to its design features, is a very strong, durable and corrosion-resistant material. A fence or roof made from such sheets can withstand mechanical influences from the outside, and also withstand any vagaries of the weather. The type of product dictates the purpose of the product, for use as roof coverings, walls, or independent fences.

Corrugated sheeting differs in corrugation height, sheet thickness, and profile shape. Material with a protective color coating is used as wall and roofing material, for the construction of temporary structures and for the construction of fences. The marking of the corrugated sheet indicates the height of the corrugation (in mm) and purpose. On the website of the Metal DK company you can buy galvanized corrugated sheets for fences and roofing at a low price of grades C8, 20, 21, as well as other modifications of the material. The consumer can buy corrugated sheets in Moscow in the color of the RAL palette required for their own design solution.

Popular colors of corrugated sheets, which one to choose?

If you look at Soviet-era houses, you can see that they are quite boring and dull.

The monotonous, boring color scheme of the most popular roofing materials gives them a gloomy look: gray slate, black roofing felt, galvanized steel, plaster. Currently, the construction market has changed a lot; manufacturers make sure that their products are not only durable and reliable, but also aesthetically pleasing. Thanks to modern roofing coatings, the roof can be of almost any shade chosen by the homeowner, matching the color scheme of the exterior of their home. In this article we will talk about the most popular colors of corrugated sheets and the principles of their selection to create a unified architectural image.

What is corrugated sheeting?

Corrugated sheeting is a modern roofing material that is obtained from steel blanks, giving them a wavy relief in the press. Trapezoidal, rectangular or wave-shaped ribs give the material additional rigidity and load-bearing capacity.

The structure of the corrugated sheet has a three-layer structure, including a steel base, a zinc anti-corrosion coating, and a top protective and decorative coating. Corrugated sheeting is considered the most common and affordable roofing material, as it has its own advantages:

Important! In addition to excellent performance characteristics, corrugated sheets have high decorative potential. This is explained by the richness and huge variety of colors of the profiled sheet. A roof made of corrugated sheets in a bright, rich color looks much more original and beautiful than a boring, monotonous gray roof.

Popular colors of corrugated sheets

Among the huge palette of profiled sheets, some colors are in particular demand among consumers. The most popular of them:

- Light colors are suitable for decorating facades and balconies. Sometimes they are used for fencing.

- Blue color is usually used for fencing and finishing the facades of non-residential buildings.

- A black roof combined with white walls looks very impressive.

- Brown color is used for country roofs and fences.

- The dark red roof gives the building sophistication and nobility.

This is interesting: the weight of the profiled sheet is MP 20.

Colored corrugated sheet is a modern universal material suitable for finishing roofs, erecting fences, and decorating facades. It has excellent technical and aesthetic qualities. The right choice of color will allow any building to blend harmoniously into its environment.

Types of protective and decorative coatings

The corrugated sheet consists of 3 layers: a steel base, a zinc layer applied using galvanization, and a protective and decorative coating. Steel gives the material strength, zinc coating provides resistance to moisture, and the top coating protects from mechanical damage and gives an aesthetic appearance. There are three or two protective and decorative coatings for corrugated sheets:

Remember! If you want to purchase a roofing covering made of profiled steel in an original shade, rather than using the most common colors of corrugated sheets, it is better to give preference to products with a polymer coating, despite the high cost, since their color range is much richer.

Palette standards

Profiled sheets, like other building materials, are manufactured in accordance with the standards defined by regulatory documents. The color range of corrugated sheets is also standardized. There are three generally accepted world color standards:

- RAL is a European standard with a wide color palette, the code of which consists of 4 digits.

The most common standard for corrugated sheet painting is the European RAV standard. - RR is a Finnish standard with 2 digits in the code.

- HPS is the English standard with the fewest colors. Its code consists of 4 numbers and 1 letter, which is not always present.

The most widely used corrugated sheet is Ral color. It is usually seen by customers in stores. Each seller has a color chart with markings. Standard colors of RAL corrugated sheets have more than 1000 positions and are divided into 9 main shades.

There are several RAL catalogues:

- Classic - the scale consists of 9 series of shades, which are indicated by the first number in the designation. 1 - yellow; 2 - orange, 3 - red, 4 - purple, 5 - blue, 6 - green, 7 - gray, 8 - brown; 9 - black and white. It was developed immediately after the adoption of the RAL system in 1927.

- Designс is an improved color catalog adopted in 1993. It consists of 1688 shades, which are designated by a 7-digit code.

- Effect is a catalog of industrial colors consisting of 490 shades. Of these, 420 are matte, 70 are glossy. The encoding includes 4 numbers and the letter M, meaning “metallic”.

- Digital is an analogue of RAL Design, created to work with computer programs and computer-aided design (CAD) systems.

Usually, when they talk about the RAL palette, they mean RAL Classic. This standard is used for the manufacture of paint and powder coating of corrugated sheets. Since 2013, corrugated sheets in standard RAL color have been available for sale with a hologram. This allows you to avoid fakes. According to the RAL system, sheets are painted in two ways:

- The paint is evenly distributed over the surface to be painted, without penetrating deep into the material. These sheets are intended for indoor use.

- Coloring is done using electrolysis. In this case, paint and high-frequency current are simultaneously applied to the metal. The top layer of metal melts and interacts with paint particles. The result is a very durable coating. Corrugated sheets painted in this way are used for interior work.

Often, corrugated sheets are painted using an electrolysis process.

Color marking

The colors of corrugated sheets are the same characteristic of the roofing material as the thickness and dimensions of the sheet, the height and shape of the profile. The name of the colors, as well as other coating parameters, are in the product labeling. There are three generally accepted color coding for profiled sheets:

Note! The color coding of corrugated sheets, each of which has a numerical designation, unifies the products of different manufacturers, simplifying the selection and purchase of roofing material and additional elements, that is, roof fencing.

Advantages of painted corrugated sheets

Painted corrugated sheeting is usually installed using a welding machine. If you are planning to install a durable fence that will withstand unwanted guests, gusts of wind and other influences, you should pay attention to a number of additional measures. Usually a frame is assembled for fences, on which metal sheets will subsequently be hung. The design involves installing strong pillars from a pipe into holes, subsequently filled with concrete.

Our managers will always help you calculate how much painted corrugated sheeting you need to buy for your specific case. When ordering a large number of linear meters of painted corrugated sheeting, the price will be reduced from the retail price.

Color palette

If it were not for the protective and decorative coating, the color of the corrugated board would be quite boring - gray, then all the houses would be of the same type and faceless. However, with the help of paint or polymer, the profiled sheet can be given almost any shade; it can be purple, blue, black, it can be dark blue, pale green, single with blue, yellow, orange, hot pink. The most common colors, which are found in all palettes of corrugated sheet manufacturers, are:

Remember that light and dark shades of profiled are the most impractical option for the home. The dark color attracts the sun's rays, so a roof coated with this color gets very hot. Light shades are impractical due to the fact that they get dirty easily, losing their attractive appearance. Therefore, black and white colors of corrugated sheets are rarely used by corrugated sheet manufacturers.

RAL color catalog for corrugated sheets (CLASSIC)

Below is the complete RAL CLASSIC catalog for corrugated sheets.

It is divided into groups of colors, with pearlescent, luminescent and metallic colors highlighted separately. Yellow RAL colors of corrugated sheets

| Corrugated sheet colors according to RAL (number, names in Russian and English) | Appearance | Color name | Appearance |

| RAL 1000 (green beige) | RAL 1001 (beige) | ||

| RAL 1002 (sand yellow) | RAL 1003 (signal yellow) | ||

| RAL 1004 (golden yellow) | RAL 1005 (honey yellow) | ||

| RAL 1006 (maize yellow) | RAL 1007 (pale yellow, daffodil yellow) | ||

| RAL 1011 (brown beige) | RAL 1012 (lemon yellow) | ||

| RAL 1013 (greyish white, oyster white) | RAL 1014 (ivory, ivory) | ||

| RAL 1015 (light ivory, light ivory) | RAL 1016 (sulfur yellow) | ||

| RAL 1017 (saffron yellow) | RAL 1018 (zinc yellow) | ||

| RAL 1019 (gray beige) | RAL 1020 (olive yellow) | ||

| RAL 1021 (rapeseed yellow) | RAL 1023 (traffic yellow) | ||

| RAL 1024 (ochre yellow) | RAL 1027 (curry yellow, curry) | ||

| RAL 1028 (melon yellow, melon yellow) | RAL 1032 (broom yellow) | ||

| RAL 1033 (dahlia yellow) | RAL 1034 (paste yellow) | ||

| RAL 1037 (sun yellow) |

Top ↑

Orange RAL colors of corrugated sheets

| RAL 2000 (yellow orange) | RAL 2001 (red orange) |

| RAL 2002 (scarlet, vermilion) | RAL 2003 (pastel orange) |

| RAL 2004 (pure orange) | RAL 2008 (bright red orange) |

| RAL 2009 (traffic orange) | RAL 2010 (signal orange) |

| RAL 2011 (deep orange) | RAL 2012 (salmon orange) |

Top ↑

Red RAL colors for corrugated sheets

| RAL 3000 (flame red) | RAL 3001 (signal red) |

| RAL 3002 (carmine red) | RAL 3003 (ruby red) |

| RAL 3004 (purple red) | RAL 3005 (wine red) |

| RAL 3007 (black red) | RAL 3009 (oxide red) |

| RAL 3011 (brown red) | RAL 3012 (beige red) |

| RAL 3013 (tomato red) | RAL 3014 (antique pink) |

| RAL 3015 (light pink) | RAL 3016 (coral red) |

| RAL 3017 (pink, rose) | RAL 3018 (strawberry red) |

| RAL 3020 (traffic red) | RAL 3022 (salmon red, salmon pink) |

| RAL 3027 (raspberry red) | RAL 3031 (orient red) |

Top ↑

Violet palette of RAL colors for corrugated sheets

| RAL 4001 (red lilac, red lilac) | RAL 4002 (red violet) |

| RAL 4003 (heather violet) | RAL 4004 (claret violet) |

| RAL 4005 (blue lilac, blue lilac) | RAL 4006 (traffic purple) |

| RAL 4007 (purple violet) | RAL 4008 (signal violet) |

| RAL 4009 (pastel violet) | RAL 4010 (teleagent, telemagenta) |

Top ↑

Blue RAL palette of corrugated sheet colors

| RAL 5000 (violet blue) | RAL 5001 (green blue) |

| RAL 5002 (ultramarine blue) | RAL 5003 (sapphire blue) |

| RAL 5004 (black blue) | RAL 5005 (signal blue) |

| RAL 5007 (brilliant blue) | RAL 5008 (gray blue) |

| RAL 5009 (azure blue) | RAL 5010 (gentian blue, gentian blue) |

| RAL 5011 (steel blue) | RAL 5012 (light blue) |

| RAL 5013 (cobalt blue) | RAL 5014 (pigeon blue) |

| RAL 5015 (sky blue) | RAL 5017 (traffic blue) |

| RAL 5018 (turquoise blue) | RAL 5019 (capri blue) |

| RAL 5020 (ocean blue) | RAL 5021 (water blue) |

| RAL 5022 (night blue) | RAL 5023 (distant blue) |

| RAL 5024 (pastel blue) |

Top ↑

Green RAL colors for corrugated sheeting

| RAL 6000 (patina green) | RAL 6001 (emerald green) |

| RAL 6002 (leaf green) | RAL 6003 (olive green) |

| RAL 6004 (blue green) | RAL 6005 (moss green) |

| RAL 6006 (olive gray, gray olive) | RAL 6007 (bottle green) |

| RAL 6008 (brown grey) | RAL 6009 (fir green, fir green) |

| RAL 6010 (grass green) | RAL 6011 (reseda green) |

| RAL 6012 (black green) | RAL 6013 (reed green) |

| RAL 6014 (olive yellow) | RAL 6015 (black olive) |

| RAL 6016 (turquoise green) | RAL 6017 (May green, may green) |

| RAL 6018 (yellow green) | RAL 6019 (pastel green) |

| RAL 6020 (chrome green) | RAL 6021 (pale green) |

| RAL 6022 (olive grey, olive drab) | RAL 6024 (traffic green) |

| RAL 6025 (fern green) | RAL 6026 (opal green) |

| RAL 6027 (light green) | RAL 6028 (pine green, pine green) |

| RAL 6029 (mint green) | RAL 6032 (signal green) |

| RAL 6033 (mint turquoise) | RAL 6034 (pastel turquoise) |

Top ↑

Gray RAL colors for corrugated sheets

| RAL 7000 (squirrel gray, squirrel grey) | RAL 7001 (silver grey) |

| RAL 7002 (olive grey) | RAL 7003 (moss grey) |

| RAL 7004 (signal grey) | RAL 7005 (mouse grey) |

| RAL 7006 (beige grey) | RAL 7008 (khaki grey) |

| RAL 7009 (green grey) | RAL 7010 (tarpaulin grey) |

| RAL 7011 (iron grey) | RAL 7012 (basalt grey) |

| RAL 7013 (brown grey) | RAL 7015 (slate grey) |

| RAL 7016 (anthracite grey) | RAL 7021 (black grey) |

| RAL 7022 (umbra grey) | RAL 7023 (concrete grey) |

| RAL 7024 (graphite grey) | RAL 7026 (granite gray) |

| RAL 7030 (stone grey) | RAL 7031 (blue grey) |

| RAL 7032 (pebble grey) | RAL 7033 (cement grey) |

| RAL 7034 (yellow grey) | RAL 7035 (light grey) |

| RAL 7036 (platinum grey) | RAL 7037 (dusty grey) |

| RAL 7038 (agate grey) | RAL 7039 (quartz grey) |

| RAL 7040 (window grey) | RAL 7042 (traffic gray a, traffic gray a) |

| RAL 7043 (traffic gray b) | RAL 7044 (silk grey) |

| RAL 7045 (telegray 1, telegray 1) | RAL 7046 (telegray 2, telegray 2) |

| RAL 7047 (telegray 4, telegray 4) |

Top ↑

Brown colors from the RAL catalog for corrugated sheets

| RAL 8000 (green brown) | RAL 8001 (ochre brown, ocher brown) |

| RAL 8002 (signal brown) | RAL 8003 (clay brown) |

| RAL 8004 (copper brown) | RAL 8007 (fawn brown) |

| RAL 8008 (olive brown) | RAL 8011 (nut brown) |

| RAL 8012 (red brown) | RAL 8014 (sepia brown) |

| RAL 8015 (reddish brown, chestnut brown) | RAL 8016 (mahogany brown) |

| RAL 8017 (chocolate brown) | RAL 8019 (gray brown) |

| RAL 8022 (black brown) | RAL 8023 (orange brown) |

| RAL 8024 (beige brown) | RAL 8025 (pale brown) |

| RAL 8028 (terracotta, terra brown) |

Top ↑

White and black RAL colors of corrugated sheets (metallics)

| RAL 9001 (cream) | RAL 9002 (grey white) |

| RAL 9003 (signal white) | RAL 9004 (signal black) |

| RAL 9005 (charcoal black, jet black) | RAL 9006 metallic (white aluminum) |

| RAL 9007 metallic (gray aluminum) | RAL 9010 (pure white) |

| RAL 9011 (graphite black) | RAL 9016 (traffic white) |

| RAL 9017 (traffic black) | RAL 9018 (papyrus white) |

Top ↑

Pearlescent colors of the RAL palette for corrugated sheets

| RAL 1035 (pearl beige) | RAL 1036 (pearl gold) |

| RAL 2013 (pearl orange) | RAL 3032 (pearl ruby red) |

| RAL 3033 (pearl pink) | RAL 4011 (pearl violet) |

| RAL 4012 (pearl blackberry) | RAL 5025 (pearl gentian blue) |

| RAL 5026 (pearl night blue) | RAL 6035 (pearl green) |

| RAL 6036 (pearl opal green) | RAL 7048 (pearl mouse grey) |

| RAL 8029 (pearl copper, perl cooper) | RAL 9022 (pearl light grey) |

| RAL 9023 (pearl dark grey) |

Top ↑

Luminescent RAL colors of corrugated sheets

| RAL 1026 (luminous yellow) | RAL 2005 (luminous orange) |

| RAL 2007 (luminous bright orange) | RAL 3024 (luminescent red) |

| RAL 3026 (luminous bright red) |

Useful article? Save it on social networks so you don’t lose the link!

Top ↑

Team oprofnastile.ru

Read on topic:

Corrugated sheet RAL 6005

Corrugated sheeting color Moss Green (RAL 6005) - use cases, examples of objects. Description of the Green Moss profiled sheet, its combination with other materials and design application.

Corrugated sheet color 3005

All about Red Wine corrugated sheeting (RAL 3005) - optimal areas of application, successful and unsuccessful combinations with other materials. Read the article.

Selection principles

The color of the roof should organically fit into the design of the house, complementing and decorating its appearance. A correctly chosen shade does not destroy the unity of the architectural image, but makes it whole, harmonious, and complete.

Thanks to the richness of the color palette offered by roofing material manufacturers, it has become possible to bring the wildest ideas of designers to life. The main thing is to follow the following principles when choosing the color of the roof:

Please note! By choosing corrugated sheeting in colors that differ from the standard color scheme, you run the risk that if you need to repair the roofing after 3-4 years, you may not find the ideal shade. Therefore, when purchasing material of specific colors, do it with a reserve, so that in the event of a breakdown, you do not make a patch from corrugated sheets that are not the right shade.

Source

Scope of application

Colored corrugated sheeting is used as roofing material, for the construction of fences and temporary structures. The corrugated sheeting for the fence is painted on both sides, which increases resistance to negative influences.

Our company's assortment includes colors corresponding to RAL: 3005, 5005, 6005, 7004, 8017

are always in stock, additional colors

1014, 1018, 1021, 3011, 3020, 7024, 9002, 9003, 9005

will be produced and delivered within 3 - 4 days after payment. If the required type of painted corrugated sheet is not in production at the time of request, the delivery time increases to 14 days.

Types of corrugated sheets

Profiled sheets are made from durable thin-sheet cold-rolled steel using special equipment. The production technology consists of installing drums with steel rolls of different thicknesses.

With the help of special devices, pressing the steel sheet, corrugations (stiffening ribs) appear. Corrugations come in rectangular, trapezoidal, wavy and other shapes.

The sheets differ from each other also in wave height. Depending on the purpose, they come in heights of 8-150 mm. Give the sheet high strength and resistance to loads.

They produce corrugated sheeting with a thickness of 0.5-1.5 mm and a width of 600-1150 mm. The length of corrugated sheeting, if you buy it from a manufacturer, can be ordered from 0.1 to 12 meters.

To protect the sheet from corrosion, moisture and environmental influences, it is coated with zinc or aluminum zinc as well as a polymer coating. Galvanized coating is a protective layer applied to a steel sheet by hot-rolling. In this way, a protective layer against corrosion is achieved by applying a layer 25-30 microns thick.

After this procedure, the output is a galvanized sheet or corrugated sheet. Such sheets are usually produced without color coating. In terms of pricing, it is cheaper than all types of corrugated sheets. Zinc-alumina coating is a more resistant coating than zinc, consisting of two components (zinc, aluminum).

The aluminum-zinc coating becomes slightly stronger with the addition of a third component, silicon. Such sheets are also produced without color coating.

Let's look at corrugated sheeting with a decorative coating.

Polyester (gloss) is one of the simplest coatings for galvanized or aluminum-zinc sheets. Its properties include corrosion protection. Not expensive for the price. It is in great demand among buyers.

One of the disadvantages is that the protective layer is not very thick, which contributes to rapid damage to the gloss if it is not handled carefully during installation.

Polyester (matte) is a more effective way of decorative coating of corrugated board. The protective layer of the coating is greater than that of a glossy coating and therefore the coating retains its original qualities longer.

Polymer coating protects the corrugated sheet from accidental impacts and damage. To enhance the coating of the sheet, it is first primed and then coated with plastisol (this is a polymer). The coating can withstand minor impacts and protect against scratches and exposure to aggressive substances. But it is not very resistant to sudden drops in temperature and ultraviolet rays.

Pural matt is a new technology from Rukki based on polyurethane coating. A corrugated sheet with such a coating can withstand direct sunlight and is not susceptible to corrosion. It is used when installing corrugated sheets on the roof, but is also suitable for facade coverings

PVDF coating – reliable protection of corrugated sheets from sunlight and corrosion. The color scheme of such sheets does not change color for many years. Having such characteristics, such sheets are often used for house facades.

Colors coated polyester

Polyester is the most popular and universal coating for corrugated sheets, so the colors with this coating are very diverse. Possible colors according to RAL map with polyester coating:

| RAL 9002 | RAL 9003 | RAL 9006 | RAL 1014 |

| RAL 1015 | RAL 1018 | RAL 1036 | RAL 3003 |

| RAL 3005 | RAL 3009 | RAL 3011 | RAL 5002 |

| RAL 5005 | RAL 5021 | RAL 5024 | RAL 6002 |

| RAL 6005 | RAL 6019 | RAL 6020 | RAL 7004 |

| RAL 7005 | RAL 7024 | RAL 8017 | RAL 8019 |

Types of corrugated sheets

Since corrugated sheets are produced for various purposes, for the convenience of buyers, each type of corrugated sheet is given a letter designation.

In terms of strength, corrugated sheeting can be load-bearing, wall, load-bearing-wall.

Load-bearing corrugated sheet – class N

It is mainly used for flat roofs and interfloor monolith floors and is the most durable and load-bearing profiled sheet.

The load-bearing capacity of a profiled sheet means the load that it can withstand without deformation or destruction. It differs from other groups in the largest thickness and height of the corrugation. For even greater rigidity, it has another additional groove inside the corrugation. The average weight of 1 m2 of such a sheet is 8 kg/m2.

And let's compare the weight of 1 m2 of concrete flooring. These two characteristics seem inappropriate, but in terms of strength they are almost as good as each other. And if you also compare their prices, then, of course, the profiled sheet is the leader in all respects.

It is also very convenient for installation and does not require much special skills. The thickness of the steel of such sheets is 7-2 mm. Overall width 633 mm. Installation width 600 mm.

Load-bearing wall corrugated sheeting (universal) – class NS

It is used for any structures and structures, but is inferior in strength to the load-bearing profiled sheet. With the help of such corrugated sheeting it is easy to install a roof, sheathe walls, install a fence, and is even suitable for formwork during concrete work. Versatile lives up to its name.

The thickness of such sheets is in the range of 0.4-1 mm. Width 1045-1050 mm.

Facade corrugated sheeting – class C

It is mainly used for building facades; it has a small wave and thickness. The width of such sheets is 1-1.2 m, the height of the ribs is 0.8-20 mm. The thickness of such sheets is 0.4-0.8 mm. To fully understand the name of the profiled sheet, let's look at the numbers in their designation.

Immediately after the letter in the name there is a number:

There is a fairly wide range of corrugated sheet colors that will not spoil your home interior.

Types of coatings

Manufacturers produce a huge number of different types of corrugated sheets, which differ in profile, shape, thickness, composition and color of the coating. Color coating increases the service life of the metal profile. If a simple galvanized sheet lasts up to 30 years, then a colored sheet lasts up to 50. There are the following types of coating, differing in composition and characteristics:

- Plastisol is the most durable type. The coating has excellent anti-corrosion properties. Its thickness is 200 microns. The coating is chosen if the corrugated sheet is exposed to an aggressive environment. Its color palette is small. It consists of black, white, burgundy and cream colors.

- The polyester coating has a wide range of colors. Corrugated sheets painted with polyester paint are very popular among consumers. The thickness of the matte layer is 35 microns, the glossy layer is 25 microns.

- Acrylic coating (PVDF). The thickness of the decorative layer is from 20 to 40 microns. It has excellent anti-corrosion properties.

- Pural is a polyurethane coating with the addition of polyamide. It is durable and UV resistant.

In this video you will learn how to choose the right color for corrugated sheeting:

A colored polymer or paint layer can be applied in different ways. They come in the following types:

- The sheet is painted on one side only. This method is used for products that are exposed to an unfavorable environment on only one side, for example, the roofs of houses.

- The corrugated sheets are painted equally on both sides. They are used for fences and other enclosures that will look aesthetically pleasing on both sides.

- Both sides of the sheet have a coating that is different not only in color, but also in composition. At the same time, the front side looks aesthetically pleasing. This profiled sheet is used for the construction of objects in which the material is exposed to various aggressive factors, for example, for a garage.

Which corrugated sheet is better to cover the roof?

There are several types of corrugated sheets that are in demand for roofing. One of the first on the list of profiled sheets is C-21.

It has good load-bearing capacity in combination with price and quality. Suitable for roofs with an average slope. For flat roofs, the most reliable is the N-75 corrugated sheet, which can withstand enormous loads.

For example, sheet N-75 with a thickness of 0.5 mm with a rafter pitch of 2 meters can withstand a load of up to 800 kg/m2. By placing such a sheet on the roof, you can make an eco-roof (green roof) on top.

NS-35 or 44 corrugated sheets are often used. Such sheets are distinguished by great rigidity and strength. NS-44 has additional stiffening ribs, which gives it even more strength and reliability.

If we talk about price, the greater the thickness of the metal, the higher its price. For example, a C-21 sheet with a metal thickness of 0.7 mm costs 260 rubles per 1 meter, and the same sheet with a thickness of 0.5 mm costs 190 rubles.

The color scheme of the profiled sheet also sometimes matters for its price, but not so significant.

Do-it-yourself installation of profiled sheets

To fully cover this topic, you will need to write an entire article. Let's look at some of the stages of installing corrugated sheets. Before you decide to cover your roof with corrugated sheets, you need to know a few important tips.

First of all, we choose the angle of inclination. After all, if you do not pay attention to this, in the future there may be problems with free space in the attic, accumulation of snow, and even during storms, the roof may be demolished. And this can happen.

The most optimal and practice-tested angle for a roof is considered to be 15-30 degrees. With a smaller angle of inclination, a more complex rafter system will be required, and more overlap of the corrugated sheet will be required. There is a risk of roof leakage and additional sheathing.

Before installing the profiled sheet, several types of work should be performed. To prevent moisture under the roof from the heat inside the house, it is necessary to insulate the roof. The first task is to cover the entire rafter system with an antifungal solution, after which we lay the waterproofing film with an overlap of about 150 centimeters, allowing it to sag slightly.

Be sure to tape the joints. Thermal insulation is carried out using mineral wool in mats or rolls, placing them between the sheathing on a waterproofing film in the sheathing. We lay a vapor barrier film on top of the wool.

Before installing the corrugated sheet, check all the cracks and joints, because properly laid such a cake will save more than 20% of heat.

It is better to supply corrugated sheets to the roof individually. It is advisable that there is not much wind. You need to start laying the corrugated sheet from the lower end of the roof edge. How you lay the first sheet will determine the geometry of the entire roof.

The corrugated sheets are fastened using special screws for roofing on wood or metal, depending on the roof. They need to be fastened at the bottom of the sheet corrugation.

In places of overlap and ridge in the upper part of the corrugation. Try not to overtighten or tighten the screws at a degree (crooked). This method of twisting threatens leakage and damage to the waterproofing layer. Self-tapping screws are attached to the bottom of the wave through the corrugation; approximately 6-8 screws are required per 1 m2. The overlap between the rows at a tilt of about 30 degrees is 15-20 cm.

Photo of corrugated roofing

Source