The most durable, lightweight and economical material with high anti-corrosion characteristics is considered to be galvanized steel sheet or galvanized sheet steel. This material is widely used for the manufacture of roofing elements, ventilation ducts, as well as drainpipes, etc.

Description of galvanized sheet

Regardless of the size of the galvanized sheet, at the time of creating products at the plant, preference is often given to metal marked ST08PS.

In this case, the abbreviation “PS” means the presence of semi-quiet steel in the body. The quality of this type of raw material is very high, which puts it much higher than boiling or semi-boiling metals.

Depending on the needs of production or individual orders, the introduction of other classes of steel is not excluded:

- Art. 1.

- 08KP.

- 08PS.

- 08YU.

It is better to clarify all the subtleties of the characteristics of the finished product directly at the time of purchase and compare the data with the drawn up diagram of the future object.

Main advantages of galvanized steel sheets

Galvanized rolled metal has increased resistance to the negative effects of moisture. Subject to strict compliance with the technology for applying the iron-zinc or zinc alloy, its diffusion is guaranteed. Molecules of substances penetrate each other, forming an inextricable bond. This allows you to avoid damaging the integrity of the protective layer during cutting, chopping and other types of sheet processing. The undeniable advantages of steel sheets include:

- a wide range of product thicknesses and protective layers;

- ability to withstand exposure to aggressive environments without change;

- high resistance to mechanical loads;

- relatively low production cost;

- long service life without loss of original characteristics.

Sheet production technology

To adjust the weight of galvanized sheets, there is a special scheme that is consistent with the requirements of GOST. After processing the hot-rolled strip using modern equipment with the ability to perform acid pickling, the workpiece is sent further along the conveyor.

Volumetric machines roll out steel to a given thickness, and then the metal is sent for annealing. The final stage will be galvanizing, which can only be done using a specialized apparatus.

Important! Enterprises adhere to GOST 19904-74, deviating from the requirements generally accepted by regional authorities, products may be rejected.

The beginning of the mass use of galvanizing

In 1824, Briton Sir Humphry Davy suggested that the copper bottoms of wooden warships could be protected by attaching iron or zinc plates to them. In 1829, Henry Palmer, inventor of the monorail and pioneer of elevated transport from the London Dock Company, received a patent for "cut or corrugated sheets of metal." His discovery would later have a significant impact on industrial design and galvanizing. From here it’s a stone’s throw to both galvanized rolled steel and thin-sheet galvanized steel, but more on them later.

In 1836, the French company Sorel received a patent for the process of applying zinc to steel (galvanizing). Thus, almost a hundred years later, the scientific discovery of the Frenchman Melouin found its commercial embodiment. The British patent for galvanizing was issued in 1837 to politician and businessman William Crawford. It is believed that the first infrastructure facility to be constructed using galvanized iron (these were corrugated galvanized sheets) was the naval docks in Pembroke, UK, in 1844. By 1850, British industry was using up to 10 thousand t. zinc. And in 1883, the Brooklyn Bridge was opened in New York - one of the most famous and oldest bridges in the world, which is still successfully and intensively used. During the construction of the facility, galvanized cables with a total length of 14.6 thousand miles were used for the first time.

Types of specimens

The assortment of goods in construction stores is large enough that you don’t have to face problems at the stage of choosing the ideal version; you should prepare for the purchase in advance.

Among the most popular and sought-after samples are sheets for purposes such as:

- For painting.

- General purpose.

- For cold profiling.

- Instances for cold stamping.

The last type of product is divided into several items, including normal, deep and very deep hoods. You can find out about the markings by looking at special abbreviations in documents or quality certificates for the product.

Quality control

To evaluate the quality characteristics of a zinc-coated sheet, just look at it. The surface must be flat, smooth, without cracks.

In sheets of cold stamping and general purpose, roughness, spots, and sagging are allowed. In other types of galvanized metal, there should be no defects.

Thus, we found out that galvanized sheet steel has almost the same characteristics as stainless steel, but at the same time its price on the market is much lower.

The main cost consists of the price of rolled metal, the cost of zinc and the cost of a specific coating method. For example, a sheet coated by galvanizing will cost more than by hot-dip galvanizing. Also, the price depends on the thickness of the sheet, zinc coating and its quality. In any case, if the sheet is suspiciously cheap, it means the manufacturer has saved on the quality or thickness of the zinc layer.

Scope of application of parts

Since the sheets are quite durable, companies producing various goods are interested in purchasing such material for the production of all kinds of products. We are talking about mechanical engineering, the creation of buckets or tanks, drainage communications, roofing coverings and heating pipes.

Blanks for further processing are selected taking into account the wall thickness of the planned elements produced at the plant; the raw materials are quite convenient to store, because the influence of corrosion is minimized.

The material is not eternal, since only the top surface coating protects the metal from external factors.

Interesting fact! The effect of rust on galvanized elements from the inside can be noticed when inspecting hot water pipes in residential multi-storey buildings; over the years, such circuit elements change color and even leak.

Who discovered galvanized metal and when?

So, in a nutshell, galvanizing (also known as galvanizing or simply “galvanizing”) is the process of applying a protective coating of zinc to a metal product, including steel and other iron alloys. This technique is used to prevent rust from forming on the base metal and provide long-term weather protection. Zinc is the most common material for protecting steel products from corrosion; more than 40% of the zinc mined in the world is used for this purpose. Zinc coating is applied to sheet and long products, machine parts, fasteners, pipes and other products.

In general, the history of galvanizing is closely connected with the history of zinc: jewelry made from alloys with a zinc content of up to 80% was created 2.5 thousand years ago. Brass, an alloy of copper and zinc, can be traced back to at least the 10th century BC. Pure zinc was first obtained in 1738.

The first (officially recognized) step towards galvanized rolled metal was made by the French chemist P. J. Melouin. It was chemistry, which seemed not far removed from alchemy. Pure iron is dropped into a tank of molten zinc, and a shimmering silver coating miraculously appears on the iron (and Melouin receives a galvanized sheet). The scientist presented his 20-page report on the experiments to the Royal Academy of Sciences in 1742.

Interest in Melwin's discovery quickly spread in scientific circles. First, molten zinc was used as an inexpensive protective coating for household utensils. Already in the second half of the 18th century, this method of protecting metal utensils from corrosion was used very widely in some parts of France.

Calculation of the weight of galvanized sheet

Regardless of the industry in which galvanized workpieces are used, before starting the product manufacturing process, professionals calculate the weight of the profiles.

A special formula was developed for this stage; it looks like this: M = M1 + M2. M refers to the weight of the material, M1 indicates the weight of the steel used, M2 corresponds to the amount of zinc.

To simplify the work of employees, tables were developed; thanks to them, calculations can be made much faster, this is due to the similarity of the raw materials supplied from the manufacturer’s plant.

Galvanized sheet at the METAL-ENERGY company

The METAL-ENERGY company supplies various types of rolled metal. Among other things, our company offers to purchase galvanized sheets. Please note that we sell galvanizing wholesale and retail. In the catalog on the website you will find products of various sizes. You may be interested in other types of products: 12 by 12 square, strip steel.

To estimate how much a galvanized sheet will weigh when ordering, we suggest you use a simple calculation form. In the table located on this page there is an empty column “Number of sheets”. Indicate how many sheets you need and the program will show the weight of the order. This is convenient as it allows you to determine whether you need to order additional vehicles for transportation.

The company provides delivery services by road vehicles of various carrying capacities, wagon standards. Deliveries are made from rolled metal manufacturing plants or from a warehouse in the Moscow region.

Our company's employees provide individual service to each client. We complete orders of various sizes and deliver products throughout Russia in the shortest possible time. Extensive experience in this area, direct cooperation with leading metal manufacturers allow us to offer high-quality products at affordable prices.

If you need more detailed information, please contact our consultants.

Tags: galvanized iron, galvanized metal, galvanized rolled steel, galvanized coating, sheet steel, roofing steel, sheet steel, steel sheet, metal sheet, sheet metal, sheet metal, sheet iron, iron sheet, rolled metal, metal, steel

We invite you to familiarize yourself with the Calculation of roof aerators TechnoNIKOL

GOST requirements

At the time of creating sheets, professionals in their field must adhere to generally accepted laws regarding the manufacture of products.

These documents indicate important technical points, including:

- Thickness of the zinc layer.

- No torn edges.

- Areas with sagging on the surface are excluded.

- Items with mechanical damage are prohibited for sale.

All companies that care about their customers and image closely monitor compliance with GOST requirements. Employees are allocated for the work, they check the visual conformity of the product and, if necessary, carry out a number of research activities.

Hot dip galvanizing method

The most profitable, practical and popular technology. To apply a protective layer to a metal workpiece, after preliminary degreasing, it is immersed in a bath of molten zinc, after which it is removed and dried. The temperature of the zinc in the container is 450–460 °C.

The quality of the resulting zinc coating is carefully controlled. The protective layer is assessed visually, its thickness is checked (magnetic or metallographic) and the strength of adhesion to the surface (by heating, hammering, scratching).

The hot-dip galvanizing method has the following advantages:

- High mechanical strength of the protective coating.

- Zinc covers the entire area of the metal structure, including hard-to-reach places.

- The service life of the coating is up to 60 years, even when interacting with aggressive environments.

After galvanizing, the steel sheet has all the advantages of stainless metal and lends itself well to various types of processing. To further protect the surface after galvanizing, it is painted with decorative powder paint.

Galvanized steel is used to create modern lighting lanterns

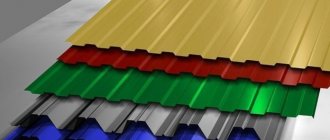

Corrugated sheet

The building material is in great demand; it belongs to one of the varieties of galvanized sheets.

- When creating products, manufacturing plants are guided by another regulatory document, it is GOST 24045-94.

- Since the service life of this type of product is at a high level, it is often used for roofing; reliability and resistance to mechanical damage protects the roof of a building from bad weather conditions.

- The low price on the shelves encourages people to increasingly use corrugated sheets when constructing various fences; the transverse rigidity is quite good; the finished work has an attractive appearance due to the coating in one of the shades the client likes.

Application

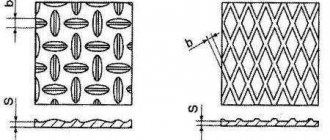

In practical life, galvanized sheets are used everywhere. Elements from it can be found in various structures around us, on ships, train stations, billboards, cars, fences and other metal structures. Since the sheet is resistant to corrosion, it has found wide application in modern industry. Such rolled products are used in various areas of production: in the heavy, chemical industries, and in instrument making. Due to the fact that the sheet can be machined, stamped parts and deep-drawn and profiled products are produced from it.

Galvanized sheets are in demand in the mechanical and automotive industries. For example, for the production of a van body or trim. But still, the main area of application for zinc-coated sheets is construction, because it is a durable and high-quality material. It is applicable for construction and installation work, for the construction of metal structures. The structures are quite light, with little load on the walls and ceilings. It can be used to construct a hangar, garage, warehouse, etc. Galvanized sheets are used to line roofs, install ceilings, or use them as a material for walls and flooring.

The sheet is used for exterior finishing of walls, roofs, fences, balconies. It is excellent for cladding buildings. Zinc coated sheet is the basis for the manufacture of a wide range of construction products:

- corrugated sheeting (galvanized or with the addition of polymers to impart protective and decorative properties);

- metal tiles (which are in demand in roofing work);

- picket fence;

- construction profile;

- strip.

Galvanized sheets are used to produce water pipes, air ducts and drains, brackets and all kinds of fasteners, as well as household items. Ventilation systems and kitchen hoods are made from it.

Useful tips

When visiting a specialized store, experts recommend taking a closer look at the product labeling, which can tell you a lot.

Depending on the task at hand, a person can easily select the ideal execution option and complete his plan in the shortest possible time; working with ready-made sheets is very convenient.

It would not be superfluous to inquire about the availability of quality certificates, because only these documents will confirm the absence of possible defects in the product.

Dimensions of wall profiled sheets

Galvanized products are in steady demand in many areas of industry:

- Construction - products are used for roofing work, as fences, floors, in a variety of modular designs, galvanized construction and painting tools are produced.

- Mechanical engineering - car bodies, refrigerator or washing machine bodies, galvanized tanks for liquids and much more.

The demand for galvanized steel sheets in construction and in various industries is enormous. Metal tiles, fencing made of corrugated sheets, mounting profiles, body parts of cars and ships, pipes for various purposes, elements of the drainage system, containers for transporting liquids - this is not a complete list of products where the metal segment is used.

Based on the standards for the use of the material, it is divided into the following types, which are indicated by markings.

- OH – general purpose.

- KhSh – used for cold stamping.

- HP – used in cold profiling.

- PC – galvanized, awaiting painting work.

The low weight characteristic of galvanized sheets has made it popular in the manufacture of packaged products and household items. As an example, let us give the following figures: one square meter of galvanized steel 0.5 mm thick weighs only 4.13 kg.

When subsequently treated with a polymer coating, the product receives additional protection from precipitation and mechanical influences. Such products are widely used as roofing materials and in the construction of fences.

If we summarize all the positive qualities of this popular metal, we get the following picture.

- It has a long working life, which amounts to decades.

- Great design. Galvanization looks great on its own, without any finishing.

- Reliable material. Not afraid of moisture, temperature changes, ultraviolet rays. It is resistant to mechanical stress, has good ductility, and has excellent anti-corrosion qualities.

- Environmentally friendly material.

- Production variations. Galvanization can be produced with different thicknesses of steel and the galvanized coating itself. It is offered to consumers in rolls or sheets.

- Has the ability to restore damaged surfaces in areas of processing, perforation, cutting. A kind of tightening of the edges of the sheet occurs.

- Reasonable price for galvanized sheet.

Various operations can be carried out with galvanizing. Thus, with the help of stamping, popular building materials such as metal tiles or corrugated sheets are obtained. Rolling, bending and drawing are used to produce siding components, profile and drain pipes, etc.

Among the disadvantages, which are practically non-existent, we note minor difficulties during welding work, as well as the fact that this product requires additional actions before painting. It should also be taken into account that over time, galvanized sheets “age” and lose the original thickness of their protective coating. The operating temperature has an upper limit: at 420 degrees it begins to melt.

However, using sheets that are too large or too small is usually not very convenient. The most popular are 1000x2000 mm or 1250x2500 mm and up to 1 mm thick.

The range of materials in terms of their main indicators is quite large, so before choosing, you should decide what size sheet will be most suitable for carrying out certain work.

You should be especially careful when creating a roofing covering, since a large number of factors must be taken into account:

- Roof dimensions;

- Possibility of delivery of sheets of certain sizes;

- Technological methods for lifting to the roof;

- Unloading methods and many other nuances.

As a rule, when building private houses or country cottages, standard sheets are used, the dimensions of which are 1 by 2 meters with a thickness of 0.55 mm. Instead, sometimes they take material 1250 mm by 2500 mm.

Not a single state standard strictly stipulates the weight of one galvanized sheet. However, this indicator is often very important, especially when you need to find out whether the vehicle can withstand the load. To calculate the mass of one sheet, you can use an indicator such as the specific gravity of the material, which is approximately 7.8 g per cubic centimeter.

Galvanized profile sheet, the dimensions and thickness of which depend on the application, is rolled metal with an anti-corrosion coating. Steel blanks are cold rolled on special machines that form so-called corrugations. They have a trapezoidal shape and act as stiffeners. It is thanks to them that steel profile sheets have an increased level of strength.

The shape of the profile and the height of the ribs affect the strength of the steel sheet. This type of corrugated sheeting is used for various purposes - from installing gates, fences and ending with roofing.

The main advantages of profile sheets are ease of installation and maintenance, durability, versatility and low cost compared to analogues. In addition, corrugated sheets have a low specific weight: depending on the thickness of the metal and the presence of a polymer coating, a square meter of this material weighs from 5 to 10 kg. The most durable metal profile copes well even with load-bearing functions.

Among the disadvantages, it is worth noting the high noise level during physical impact on steel sheets. For example, during rain, a corrugated sheet enhances the sound of drops falling on it. Another disadvantage of galvanized sheets without polymer coating is their unattractive appearance, but not everyone shares this opinion. It has a slightly yellowish steel color and, due to the lack of paintwork, is more affordable.

Standard galvanized iron sheet sizes range from 2.4 to 12 meters (NS). Depending on the area of application, the size has different multiples. So, for example, roofing sheets (H) have a length from 3 to 12 meters and a multiplicity of 25 cm, and rolled products for wall fencing (C) - from 2.4 to 13 m with a multiplicity of 30 cm. However, upon individual orders, manufacturers produce sheets of any sizes.

Roofing sheets (marked “N” - load-bearing) are also used for the construction of load-bearing and supporting structures. Thanks to their high profile, large metal thickness and wide wave pitch, these sheets can withstand heavy loads. For example, with a certain installation, H75 grade corrugated sheeting with a sheet thickness of only 0.9 mm can withstand a load of up to 720 kg/m2.

- C – wall profiled sheet;

- 21 – profile height;

- 0.45 – thickness of the metal base;

- 750 – width of the profiled sheet;

- 11000 – length of the profiled sheet.

In most cases, the following grades of sheet profiles are used for the installation of walls, fences and gates: C8, C10, C18, C21, C44.

C8 corrugated sheet has a useful length from 1 to 11.5 m and is often used for installation of facade and wall coverings, as well as ceilings. The height of the corrugation is 8 mm, and the thickness of the sheet is from 0.4 to 0.7 mm, making this brand one of the most affordable. Another advantage of this type of corrugated sheet is its low weight, which greatly facilitates installation, transportation and increases economic benefits in general.

Galvanized profiled sheet of grade C18, despite its belonging to the category of wall profile, is often used for roofing installation. As you know, one of the disadvantages of a seam roof is noise during strong gusts of wind. The design of the C18 brand with small stiffening ribs and wide shelves almost completely solves this problem.

Corrugated galvanized sheet of grade C21 has a high level of rigidity, despite the small profile height. The waveforms ensure reliable joining, and their frequency and symmetry increase the stability of the sheet. Profiled sheet C21 is used for the installation of fences and walls, as well as for the roofing of residential buildings.

The most popular brands of galvanized roofing sheet are H60 and H75.

The H60 brand is distinguished by high performance characteristics, versatility and a relatively low price. It is often used as an independent roofing profile and for the installation of formwork. The useful width of the profiled sheet is 8.45 meters.

It is believed that N75 grade corrugated sheet metal is the most popular roofing metal product. It is used in many areas of modern construction for the installation of membrane-type roofing, seam roofing and permanent formwork. This brand is made from the highest quality steel and is the leader among roofing corrugated sheets in terms of production volumes. Tall, rigid ribs and thick galvanized steel sheets can withstand enormous loads.

The most popular universal brands of corrugated sheets are NS44 and NS57.

We invite you to familiarize yourself with Moldings for walls - 100 photos of the best modern design ideas

NS44 is a typical representative of the class of universal corrugated sheets. It is equally suitable for both roofing and wall coverings. The increased strength of this brand allows you to fasten the rolled steel in increments of 2.5 meters.

NS57 differs from the previous one in its higher resistance to mechanical loads. The maximum thickness of the steel sheet is 1 mm, and the height of the waves is 60 mm.

Of course, these are not all the sizes of galvanized profile sheets. Their range is much wider, and it is unlikely that it will be possible to list all the features of each brand in one article. However, this information is quite enough to select profile rental for a fence or house.

General recommendations for choosing corrugated sheets for your home:

- For roof installation, it is recommended to use a galvanized profile marked H and a sheet height of 20 mm.

- For the installation of fences, gates or walls, it is advisable to use profiled sheets up to 20 mm high. Brands C10 and C14 are good.

The color of the rental is a matter of taste. But one thing is for sure - it is better to choose corrugated sheeting with a protective paint coating. It is slightly more expensive than a simple galvanized profile, but has a longer service life and a more aesthetic appearance.

Galvanized products are in steady demand in many areas of industry:

- Construction - products are used for roofing work, as fences, floors, in a variety of modular designs, galvanized construction and painting tools are produced.

- Mechanical engineering - car bodies, refrigerator or washing machine housings, galvanized tanks for liquids and much more.

| Type of corrugated sheet | Sheet thickness | Cost, rub.m.sq. | ||

| Profmetall LLC | LLC "Krona" | Yugmontazh LLC | ||

| PS-8 | 0,35 | 167 | 143 | 159,01 |

| 0,40 | 175 | 154 | ||

| 0,45 | 196 | 176 | 201,97 | |

| 0,50 | 208 | 191 | 220,16 | |

| 0,55 | 225 | 218 | 243,19 | |

| 0,60 | 246 | 237 | ||

| 0,65 | 264 | 253 | 283,17 | |

| 0,70 | 279 | 269 | 301,70 | |

| PS-20/PK-20 | 0,35 | 126 | 149 | – |

| 0,40 | 183 | 160 | 181,55 | |

| 0,45 | 204 | 183 | 230,61 | |

| 0,50 | 217 | 199 | 251,37 | |

| 0,55 | 235 | 228 | 277,67 | |

| 0,60 | 257 | 246 | – | |

| 0,65 | 276 | 265 | 323,32 | |

| 0,70 | 291 | 273 | 344,48 | |

| PK-44 | 0,40 | 236 | – | – |

| 0,45 | 263 | 208 | – | |

| 0,50 | 287 | 208 | 249,24 | |

| 0,55 | 306 | 226 | 275,31 | |

| 0,60 | 325 | 249 | 300,20 | |

| 0,65 | 344 | 288 | 320,57 | |

| 0,70 | 358 | 306 | 341,55 | |

| PN-75 | 0,70 | – | 385 | 482,39 |

| 0,80 | 619 | 437 | 541,94 | |

| 0,90 | 681 | 490 | 606,25 | |

| 1,00 | 735 | 550 | 671,44 | |

| 1,10 | 789 | – | – | |

| 1,20 | 859 | – | – | |

- WITH - ;

- 21 – profile height;

- 0.45 – thickness of the metal base;

- 750 – width of the profiled sheet;

- 11000 – length of the profiled sheet.

- The H57 profile is used for roofing with sheathing pitches of up to 3 meters, sheet reinforcement of reinforced concrete floors, and stiffening diaphragms in buildings with a metal frame.

- H60 is characterized by greater thickness and height of the corrugation. Application areas are similar to H57.

- H75 is one of the most powerful modifications of load-bearing flooring; it can be used for constructing roofs with sheathing pitches of up to 4.5 m, manufacturing structural elements for the construction of temporary and prefabricated buildings, for external walls of garages, change houses, and retail outlets.

| Profile brand | Sheet thickness, mm | Sheet length, m | Sheet width, mm | Profile height, mm | Trapezoid pitch, mm | |

| General | Working | |||||

| H57 | 0,6, 0,7, 0,8, 0,9 | 0,5-14,0 | 801 | 750 | 57 | 187,5 |

| H60 | 0,7, 0,8, 0,9, 1,0 | 0,5-14,5 | 902 | 845 | 60 | 211,25 |

| H75 | 0,7, 0,8, 0,9, 1,0 | 0,5-14,5 | 800 | 750 | 75 | 187,5 |

| Profile brand | Sheet thickness, mm | Sheet length, m | Sheet width, mm | Profile height, mm | Trapezoid pitch, mm | |

| General | Working | |||||

| NS35 | 0,5, 0,55, 0,6, 0,65, 0,7, 0,8, 0,9 | 0,5-12,0 | 1060 | 1000 | 35 | 200 |

| NS44 | 0,4, 0,5, 0,7, 0,8 | 0,5-12,0 | 1070 | 1000 | 44 | 250 |

- C8 – wall cladding, installation of panel and enclosing structures. Can be used for roofs with continuous sheathing;

- C10 – installation of fencing, construction of walls and wall structures in the manufacture of change houses, small trade stalls, for installation of roofs with a sheathing pitch of 0.8 m;

- C18 – cladding of walls, ceilings, roof structures with frequent lathing, the angle of inclination of which does not exceed 25°;

- C21 - compared to previous products, it has greater strength and rigidity, and is used for erecting fences, constructing outbuildings, and installing roofs with a sheathing pitch of no more than 0.8 m.

| Profile brand | Sheet thickness, mm | Sheet length, m | Sheet width, mm | Profile height, mm | Trapezoid pitch, mm | |

| General | Working | |||||

| C8 | 0,55, 0,65, 0,7 | 0,5-12,0 | 1200 | 1150 | 8 | 115 |

| C10 | 0,4, 0,45, 0,5, 0,6, 0,7, 0,8 | 0,5-12,0 | 1150 | 1100 | 10 | 115 |

| C18 | 0,4, 0,45, 0,5, 0,6, 0,7, 0,8 | 0,5-12,0 | 1023 | 1000 | 18 | 115 |

| S21 | 0,4, 0,45, 0,5, 0,55, 0,6, 0,65, 0,7, 0,8 | 0,5-12,0 | 1051 | 1000 | 21 | 100 |

how much does a sheet of iron cost for a roof depending on the width

We recommend

According to professionals, the most convenient to use and fairly reliable option for roofing iron is considered to be a material with a thickness of 0.45 - 0.55 mm.