Steel marking expresses the chemical composition and properties of the metal, allows you to differentiate products by quality, purpose, deoxidation and other characteristics. Knowledge of these properties allows you to correctly use steel when obtaining rolled products, selecting grades according to the required characteristics of the final product and the conditions under which it will be used. Therefore, the primary designations in order to distinguish one type of steel from another appeared even before the start of mass industrial smelting in the 19th century.

In general, a wide range of steel grades makes it possible to create and produce rolled products with the required set of characteristics - for various features of further use. At the same time, the manufacturer is required to strictly adhere to the specified physical and chemical parameters of the brand so that the operation of products made from it occurs as usual, without deviations or unforeseen events. The parameters of each brand are recorded in the relevant national standards and regulatory documentation of manufacturers.

At the same time, different countries and their associations have different labeling systems, and in some countries there are several systems at the same time (for example, in the USA). The European Union, China, Japan, the CIS, and Ukraine have historically developed their own systems. The differences between these systems sometimes make it difficult to select the right steels for the final product. The implementation of EU standards taking place in Ukraine simplifies this task. In general, over 1,500 different grades of steels and alloys are known in the world today for a variety of purposes and operating conditions. Most likely, in the future, with the development of metal application technologies, new varieties of alloys involving new materials will appear, and the number of grades will increase.

Designation of steels in Ukrainian and CIS standards

In the state standards of Ukraine (DSTU) and CIS countries (GOST) there is an alphanumeric system for designating steel and alloy grades, where the names of chemical elements and steel smelting techniques are expressed in letters, and the content of elements is expressed in numbers. Letter designations are also used to indicate the deoxidation method (kp - boiling steel, ps - semi-calm, sp - calm). Separate groups of steels are marked in a special way - construction, structural, stainless, tool, etc.

Unalloyed structural steels of ordinary quality (GOST 380, DSTU 2651) are designated as Art., example - Art. 3. The number after the letters characterizes the conditional percentage of carbon. In turn, the marking of structural unalloyed quality steels (GOST 1050, DSTU 7809) is a two-digit number showing the average carbon content in hundredths of a percent (say, 10).

High-quality steels for boilers and high-pressure vessels in accordance with GOST 5520 and DSTU 8804 are marked as structural non-alloy steels, but with the addition of the letter K (for example, 20K).

Structural alloy steels according to GOST 4543 and DSTU 7806 are designated by letters and numbers. The numbers after each letter are the approximate content of the corresponding element (but if the indicator is less than 1.5%, then the number is not included). Additional quality parameters (reduced content of impurities such as sulfur and phosphorus) are indicated by the letter A or Ш at the end of the designation, for example - 12ХНЗА, 18ХГ-Ш. Cast structural steels (GOST 977, DSTU 8781) are designated in the same way as high-quality and alloyed steels, but with the letter L at the end of the name.

Designation of the main alloying elements when marking steels according to GOST/DSTU

| A (in the middle of the marking) – nitrogen | N – nickel |

| B – niobium | R – boron |

| B – tungsten | C – silicon |

| G – manganese | T – titanium |

| D – copper | F – vanadium |

| E – selenium | X – chrome |

| K – cobalt | C – zirconium |

| M – molybdenum | Yu – aluminum |

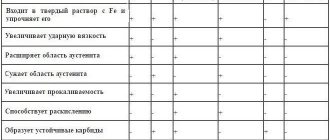

In particular, adding chromium and nickel to steel improves its strength characteristics and imparts corrosion resistance, cobalt increases heat resistance and impact resistance, and niobium improves hardness, fatigue strength and weldability.

Construction steels, according to DSTU 8539/GOST 27772, are marked with the letter C and numbers illustrating the minimum yield strength. Additionally, there are the following designations: T - heat-strengthened rolled steel, K - increased corrosion resistance (say, S345T, S390K), D - increased copper content.

Unalloyed tool steels according to GOST 1435 are divided into

- qualitative: indicated by the letter U and the number of average carbon content (U7, U8, U10);

- high-quality, with an additional letter A at the end of the brand (for example, U8A) or an additional letter G, indicating a high manganese content (for example, U8GA).

Alloyed tool steels (DSTU 3833, GOST 5950) are marked in the same way as alloyed structural steels (4Х2В5МФ, etc.).

Further, in the formulation of the grade, high-speed steels are assigned the letter P (at the very beginning), then there is a figure for the average proportion of tungsten in the composition, after that there are letters and numbers reflecting the mass content of the elements. However, the content of chromium (it is stable, about 4% in all high-speed steels) and carbon (it is always proportional to the vanadium content) is not indicated. On the other hand, if the vanadium content is >2.5%, the letter F and a number are given (Р6М5, Р6М5Ф3, etc.).

Standard stainless steels (GOST 5632) are marked with letters and numbers in the same way as structural alloy steels (say, 08Х18Н10Т or 16Х18Н12С4ТУЛ).

The naming of automatic steels (GOST 1414) begins with the letter A; if the steel is alloyed with lead - then with the letters AC. To show the content of alloying additives, markings similar to structural steels are used.

Electrical steels are designated by the letter E, the first number indicates the silicon content, the second number indicates the electrical properties. Thus, E21 is electrical steel containing 2% silicon and about 0.1% carbon.

Steel classification

To understand the markings, you need to understand how steel alloys are classified according to their intended purpose. It is customary to determine properties according to several parameters:

- The chemical composition determines the strength indicators. Here the properties are determined by the compositional ratios between iron and carbon. Along the way, changes in characteristics depend on the presence of alloying elements or substances that impair performance.

- The structure changes depending on the production methods. Forged products are stronger, cast ones may form pores or other defects. When rolling through rollers, hardening is achieved and the desired shape is obtained.

- For proper use, certain brands are determined by their intended purpose. Such information is especially important for special-purpose steels. In them, even small changes in the chemical composition can significantly change the behavior under load or operation in an aggressive environment.

- The quality of steel ingots depends on the content of harmful components. Sulfur and phosphorus lead to cold brittleness and red brittleness, so metallurgists try to remove deteriorating ingredients from the alloy.

- Oxygen in steel products changes the structure. To remove it, deoxidizers are added to the molten mass; they form oxides and do not cause negative changes to the metal.

Classification of steels according to main indicators

Classification by structure

The structure is studied on special thin sections. They are examined under a microscope, having previously treated the polished surface with sulfuric acid. It is customary to define the following states:

- Hypoeutectoids are characterized by a high ferrite content. Low carbon content does not allow the metal to exhibit sufficient resistance under mechanical loads;

- eutectoid correspond to the best ratio between strength and plastic properties;

- hypereutectoid steels are used in the manufacture of tools. They are distinguished by high surface hardness, as well as resistance to loading;

- ledeburite contain carbides. The metal exhibits excessive fragility;

- Ferritic indicators correspond to the properties inherent in pure iron.

Eutoctoid steel

Hypoeutectode steel

Ledeburite. Iron carbide inclusions are visible

To improve properties, normalization is carried out. It consists of relieving stress from parts that have had heat treatment associated with improved properties. Prolonged heating and holding at temperatures above 720...750 °C, and subsequent cooling leads to annealing. Metal grains change their appearance.

The top row shows the sections before normalization, and the bottom row shows them after

Marking of steels according to European standards

According to part 1 of the European standard EN 10027 and its Ukrainian version DSTU EN 10027, according to the order of naming, steels are differentiated into 2 groups.

Group 1 unites steels, the grades of which depend on their purpose, as well as physical or mechanical properties. Grades consist of one or more letters that indicate the purpose of the steel, followed by numbers that describe the properties. The numbers may contain symbols that identify the delivery status and the purpose of the product. For example, the S355J0 marking indicates a structural steel with a minimum yield strength of 355 N/mm2 and a work of fracture on impact of 27 J, measured at 0°C.

Group 2 includes steels whose grades are determined by their chemical composition. This group is divided into subgroups according to the purpose and content of alloying elements. Thus, 13CrMo4-5 is an unalloyed steel with an average content of 0.13% carbon, 1% chromium, 0.5% molybdenum and more than 1% manganese.

In addition to basic markings, steels according to European standards have serial numbers. The procedure for their assignment is determined by the European standard EN 10027-2 and the Ukrainian DSTU EN 10027-2. The serial number of steel is presented in the form “1.XXXX”, where “1.” demonstrates that the material belongs to steels, the next two digits are the number of the steel group, and the last two are the serial number of the steel in the group. By the group number you can clearly determine the type of steel.

Steel marking according to American standards

In the USA, several systems for marking metals and alloys are used; these systems are associated with various standardization agencies. The most famous are AISI - American Iron and Steel Institute, ACI - American Casting Institute, ANSI - American National Standards Institute, AMS - Aerospace Materials Specification, ASME - American Society of Mechanical Engineers, ASTN1 - American Society for Testing Materials, AWS - American Welding Society, SAE – Society of Automotive Engineers. The designations used by organizations stem from the history of their work as well as the development of correlated industries.

In particular, in the AISI marking, carbon and alloy steels are usually designated using 4 digits. The first two digits indicate the steel group number, the next two indicate the average carbon content multiplied by 100. In addition to numbers, steel grades may contain letters. Moreover, the letters B and L, indicating doping with boron (0.0005-0.03%) or lead (0.15-0.35%), respectively, are placed between the 2nd and 3rd digits of the brand, for example, 51B60, 15L48. Whereas the letters M and E are placed at the beginning of the designation if the steel is intended for the production of non-critical rolled products (M) or is produced in an electric furnace (E). Along with this, the letter H may be present at the end of the brand formula, indicating that the characteristic property of this steel is hardenability.

AISI grades of standard corrosion-resistant steels include three numbers and then, in some cases, one, two or more letters. The first of the numbers determines the class of steel: thus, grades of austenitic corrosion-resistant steels begin with the numbers 2ХХ and 3ХХ, while ferritic and martensitic steels are determined by the formula 4ХХ. Please note that the last two digits - unlike carbon and alloy steels - are in no way related to the chemical composition, but simply indicate the serial number of the steel in the group.

Marking according to ASTM standards includes the letter A (i.e. we are talking about ferrous metal), the serial number of the ASTM regulatory document (standard), and the actual wording of the brand. Usually within the framework of ASTM there is an American system of physical quantities, but if the standard uses the metric system of notations, the letter M is entered after its number. ASTM standards most often determine not only the chemical composition of steel, but also the full range of product requirements. To indicate the actual grades and their chemical composition, both ASTM designations can be used (when the chemical composition and marking are determined directly in the standard), and those borrowed from other systems, say, from AISI - for rods, wires, from ACI - for castings made of corrosion-resistant steels.

UNS is a universal marking system for metals and alloys. It was developed in 1975 to unify various labeling systems in the United States. In UNS, steel grades include letters indicating the steel group and five numbers. According to UNS principles, the easiest way to classify steels is from the AISI system. Thus, for structural and alloy steels included in group G, the first four digits of the formula are the name in AISI, while the last digit replaces the letters found in AISI. In particular, the letters B and L, indicating alloying with boron or lead, correspond to numbers 1 and 4, and the letter E (the product is smelted in an electric furnace) corresponds to number 6. Grades of corrosion-resistant AISI steels begin with the letter S and include the AISI steel designation (the first three digits) and two additional numeric values corresponding to the additional letters in AISI.

Correspondence between AISI and UNS characters

| AISI symbol | XXXL | XXXS | XXXN | XXXLN | XXXF | XXXSe | XXXB | XXXH | XXXCu |

| UNS symbol | XXX01 | XXX08 | XXX51 | XXX53 | XXX20 | XXX23 | XXX15 | XXX09 | XXX30 |

Steel brand

Heat-resistant alloy

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Carbon tool steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Casting steel, corrosion-resistant

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ordinary steel for castings

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High-alloy heat-resistant steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low-alloy heat-resistant steel

|

|

|

|

|

|

|

|

Heat-resistant, relaxation-resistant steel

|

|

|

|

|

|

|

|

|

|

Alloy tool steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Die tool steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High-speed tool steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rolling tool steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alloy structural steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low-alloy structural steel for welded structures

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Structural steel with increased machinability

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Structural bearing steel

|

|

|

|

|

|

|

Structural spring steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quality carbon structural steel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Structural carbon steel of ordinary quality

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Corrosion-resistant, heat-resistant steel

|

|

|

|

|

|

|

|

|

|

|

|

|

Corrosion-resistant ordinary steel

|

|

|

|

|

|

|

|

|

|

|

High alloy cast iron

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Malleable cast iron

|

|

|

|

|

|

Cast iron foundry

|

|

|

|

|

|

|

|

|

|

|

|

|

Low alloy cast iron

|

|

|

|

|

|

|

|

|

|

|

|

Pig iron

|

|

|

|

|

|

|

|

|

|

Gray cast iron

|

|

|

|

|

|

Shipbuilding steel grades

Steels for shipbuilding are marked according to the standards of the International Association of Classification Societies (IACS). In international practice, unified categories of hull steels (A, B, D, E, F) are adopted, characterized by yield strength and impact work at different temperatures. The letter illustrates impact characteristics: steel grade (category) A is not tested for impact bending, B, D, E and F must provide a certain impact work at test temperatures of 0°C, -20°C, -40°C, -60, respectively °C. If there is no number after the letter definition, the steel has normal strength (yield strength of at least 235 MPa or 24 kgf/mm2). High-strength steels are followed by numbers 32, 36 or 40, indicating a minimum yield strength of 315, 355 or 390 MPa, respectively.

The mechanical characteristics of ship hull steels of normal and high strength are determined by international maritime registers BV, ABS, DNV, RINA, etc., national and interstate standards.