P12 steel is a high-speed alloy that is actively used in industry for the manufacture of various types of cutting tools. Due to its strength characteristics, this metal has also found its application in knife production. Products made from it have excellent working properties, high hardness and wear resistance - that is, the basic parameters of a high-quality knife.

Quick cutter P12.

Specifics of the material and its general characteristics

The name P12 is not a simple set of letters, but a marking that contains some information about the alloy:

- “P” - all high-speed steels are marked with this letter, from the English name rapid (speed);

- 12 is the percentage of tungsten in the metal, which forms very hard chemical compounds - carbides, which sharply increase strength and red-hardness.

Quick cutters have long been used to create edged weapon blades, due to their following characteristics:

- good hot hardness, which characterizes what temperature steel can withstand without loss of performance;

- increased red resistance - indicates how long the alloy will withstand this temperature;

- Great resistance to wear and external loads.

As a result, knives made from P12 will have strong blades that can easily withstand severe mechanical stress without deforming the structure of the product.

High hardness is a characteristic feature of such cutting tools; this important property affects both the service life and the quality of the cut. Although such an alloy can withstand bending loads, its weak point is increased fragility, since the hard metal is susceptible to brittleness.

pros

High speed steel is a material used to make sharp steel tools. The composition of p12 is of high quality compared to conventional material. In addition, it has the most important property - wear resistance, because under the influence of friction, steel heats up and, accordingly, deteriorates over time. Today, manufacturers add compounds to high-speed alloys for strength to avoid heating.

When making knives, p12 steel has a consistency similar to powder, to which carbides are added. Due to these components, the knives become very durable. The marking “p” indicates that the product is high-speed, and the number “12” indicates the percentage of tungsten in it.

The undoubted advantages of knives made from p12 steel include the high-speed cutting properties of the blade . The p12 alloy can be sanded well. List of advantages:

- Excellent cutting characteristics.

- Long lasting performance.

- High strength.

- Steel is not affected by maximum temperatures.

- The structure is homogeneous.

- Not subject to destruction under the influence of the environment.

- Easily processed by grinding.

- Profitability of high-speed material production.

Minuses

The main disadvantage of P12 is its increased fragility, which somewhat limits the use of this alloy.

This high-speed steel cannot be used to make products that are subject to high impact loads, that is, axes, throwing knives, machetes, etc.

In addition to increased fragility, the metal in question has other minor disadvantages, which are completely offset by its advantages:

- quite high cost of final products;

- the production process is technically complex and expensive;

- lower toughness compared to tool steels.

So, P12 steel occupies its own niche, despite increased competition. All this is ensured by its characteristics: excellent viscosity, long service life, strength, etc. Knives made of this material remain in their original form for a long time, but they can break due to their high fragility. Careful operation and careful maintenance are what will allow such products to serve their owner faithfully for a long time.

The downside of P12 is increased fragility.

Mechanical properties of steel 25 at elevated temperatures

| Test temperature, °C | Steel condition, test conditions | σ0.2 (MPa) | σв(MPa) | δ10 (δ5) (%) | ψ % | KCU (J/cm2) |

| 20 | After rolling. Deformation speed 0.8 mm/min | 310 | 490 | 28 | 58 | 78 |

| 200 | 320 | 560 | 13 | 44 | 97 | |

| 300 | 200 | 540 | 22 | 57 | 88 | |

| 400 | 165 | 165 | 25 | 66 | 69 | |

| 500 | Sample with a diameter of 6 mm and a length of 30 mm, rolled. Deformation speed 16 mm/min. Strain rate 0.009 1/s | 150 | 330 | 28 | 70 | 49 |

| 700 | 130 | 145 | -42 | 77 | — | |

| 800 | 69 | 96 | (57) | 78 | — | |

| 900 | 47 | 79 | -53 | 95 | — | |

| 1000 | 40 | 54 | -60 | 100 | — | |

| 1100 | 24 | 38 | -66 | 100 | — | |

| 1200 | 14 | 23 | -101 | 100 | — | |

| 1300 | 20 | 25 | -67 | 100 | — |

Chemical composition

In its original form, any steel is a compound of iron and carbon. In this form, it is highly susceptible to corrosion, quite soft, and completely unsuitable for creating a cutting tool. During production, various other elements are added to it, which, when interacting with it, make it possible to achieve the necessary qualities.

All the properties for which R12M quick cutter is so valued are the result of the interaction of alloying components that are included in the alloy during production. Among them are the following:

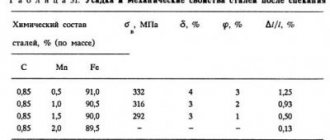

- Carbon – from 0.80 to 0.90%. With increasing carbon content, the hardness, strength and elasticity of steel increase, but ductility and impact resistance decrease, and machinability and weldability deteriorate.

- Chromium - from 3.1 to 3.6%. This is the cheapest and most common alloying element. It is able to slightly increase hardness, however, its main property is an increase in corrosion resistance. The higher its content in the alloy, the more resistant it is to rust (steel becomes completely stainless when the chromium content is more than 13%).

- Vanadium – 1.5 – 1.9%. It increases hardness and strength, grinds grain. It increases the density of the steel structure, as it is a good deoxidizer, but it is expensive and scarce.

- Tungsten – 12.0-13.0%. In such an alloy it is the main component. Together with iron, it forms new carbides, which significantly increase such important characteristics as strength and red-hardness. It helps eliminate brittleness during tempering. It has a fairly high cost.

- Molybdenum – up to 1.0%. Increases red resistance, has a positive effect on elasticity, resistance to corrosion and oxidation at high temperatures.

- Cobalt – 0.1%. Improves heat resistance, magnetic properties of steel and shock load tolerance.

- Nickel – up to 0.4%. Increases the strength of steel while maintaining high toughness, prevents grain growth when heated, reduces warping during hardening, increases corrosion resistance and hardenability. With a nickel content of 18-20%, the steel becomes non-magnetic, heat-resistant, heat-resistant and corrosion-resistant.

The P12 quick cutter is produced by the powder method, that is, after smelting, the metal is crushed and blown into the workpiece. At this stage, all alloying additives are added to it, after which everything is fused under high pressure into the finished product. This method is more economical compared to traditional casting or forging and allows for improved performance.

Quick cutter P12 is produced using the powder method.

Standards

| Name | Code | Standards |

| Classification, nomenclature and general norms | IN 20 | GOST 19281-89 |

| Steel pipes and connecting parts for them | B62 | GOST 20295-85, GOST 24950-81 |

| Sheets and strips | B23 | GOST 82-70, GOST 19903-74, GOST 19282-73, GOST 19903-90, TU 14-1-4632-93 |

| Long and shaped rolled products | B22 | GOST 8278-83, GOST 8281-80, GOST 8282-83, GOST 8283-93, GOST 9234-74, GOST 11474-76, TU 14-1-1762-76 |

| Welding and cutting of metals. Soldering, riveting | B05 | OST 36-58-81 |

| Sheets and strips | B33 | TU 14-1-4431-88 |

| Long and shaped rolled products | B32 | TU 14-136-367-2008 |

Classification of material and application of grade P12

P12 is classified as high-speed steel. High-speed steels are alloyed alloys intended primarily for the manufacture of metal-cutting tools operating at high cutting speeds.

P12, due to its positive properties, is actively used in knife production. Such cutting tools have all the necessary characteristics. Due to the high resistance of the surface to external loads, they can easily cut thick ropes, wood, bones, etc.

They can handle steel plates several mm thick.

A knife made of P12, even with intensive use, holds an edge for a long time, but it is worth considering that due to its high strength properties it is difficult to sharpen, especially at home.

R12M steel is widely used in industry. The most striking example is the manufacture of drills for a variety of purposes: from wood to heavy-duty metals. They are also used to make countersinks, crowns, conical machine reamers, drills, slotting cutters, hacksaw blades, etc.

R12M steel is widely used in industry.

Domestic quick cutters

Part 3. P12, P9, P6

P12 and P9 are tungsten steels, in which the amount of tungsten was successively reduced and the amount of vanadium was increased.

The online store offers knives with blades made of P12 steel , which in structure and properties is close to P18, but has better mechanical properties.

P12 steel in various modifications is used for the manufacture of cutting tools - taps, milling cutters, drills, cutters, etc. It is used instead of the P18 grade, since P12 steel is excellent for the production of blades due to its technological properties.

P9 steel is used for the manufacture of simple-shaped tools used in processing stainless and structural steels, fiberglass, hard rubber and other materials.

P6 steel is perhaps a universal and widely used high-speed steel all over the world. Like the P18, it is also long-lived - it was developed in the 30s of the 20th century. It is still a kind of standard with which new steel grades are compared. In various modifications it is also used for the manufacture of cutting tools: taps, milling cutters, drills, cutters, etc.

For some materials, steel is more economically feasible than P9 or P18.

A common feature common to all of the listed steels when used for the production of knives for household use is high durability of the cutting edge. Blades made of these steels allow them to be sharpened even at a small angle of rotation (up to 10-15 degrees) without chipping.

Due to their relative fragility, machete-type knives, throwing knives and axes are not made from these steels.

It is also necessary to take into account that the blades are hardened to high hardness, and in the field they are very difficult to sharpen.

We hope that the review was useful and interesting to you.

Methods and methods of sharpening

Even high-speed steel P12 is subject to wear and dullness, despite its impressive strength properties. If we take into account the information about the use and properties of this alloy, then we can safely say that it will not be possible to sharpen them using grinding wheels from electrocorundum: the surface after such treatment still remains rough, and the cutting qualities do not improve.

The most correct option would be to take the knife to a specialized workshop for sharpening, which has CBN wheels at its disposal. Having such cars in your garage is an unaffordable luxury and simply not advisable.

You can, of course, try sharpening at home, but it’s worth considering: at a minimum, this will require diamond stones, the prices of which have been very high lately. In this case, processing will be carried out in 2 stages:

- First, use a stone with a large grain - the so-called coarse sharpening.

- Then use a fine-grain abrasive for final sanding.

It is better not to try to sharpen it in a garage, as there is a chance of damaging the tool beyond its original state.

Mechanical properties of forgings steel 25

| Heat treatment | Section, mm | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | NV, no more |

| no less | |||||||

| Hardening. Vacation | Up to 100 | 175 | 350 | 28 | 55 | 64 | 101-143 |

| Normalization | 100-300 | 175 | 350 | 24 | 50 | 59 | 101-143 |

| 300-500 | 175 | 350 | 22 | 45 | 59 | 101-143 | |

| Up to 100 | 195 | 390 | 26 | 55 | 59 | 111-156 | |

| 100-300 | 195 | 390 | 23 | 50 | 54 | 111-156 | |

| 300-500 | 195 | 390 | 20 | 45 | 49 | 111-156 | |

| Up to 100 | 215 | 430 | 24 | 53 | 54 | 123-167 | |

| 100-300 | 215 | 430 | 20 | 48 | 49 | 123-167 | |

| Up to 100 | 245 | 470 | 22 | 48 | 49 | 143-179 | |

| Hardening. Vacation | 100-300 | 275 | 530 | 17 | 38 | 34 | 156-197 |

Analogs

P12 has a large number of analogues around the world. This is due to the fact that high-speed steels have the same requirements. The result is a similar chemical composition, production technology, and characteristics. Below is a table with identical alloys from different countries of the world, but it is worth considering that their properties, and even more so their cost, are not identical, but simply have many similarities.

| Germany | Japan | Poland | Czech |

| S12-1-2 HS12-1-2 1.3318 | SKH6 | SW12 | 19802 19810 |

Previous

KnivesSteel 420: brand characteristics

Next

KnivesSteel 40Х13

Designations

| Name | Meaning |

| Designation GOST Cyrillic | R12F2K5M3 |

| Designation GOST Latin | P12F2K5M3 |

| Translit | R12F2K5M3 |

| By chemical elements | — |

| Name | Meaning |

| Designation GOST Cyrillic | EP863 |

| Designation GOST Latin | EP863 |

| Translit | EhP863 |

| By chemical elements | — |

Physical properties of steel 25

| Temperature | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| 0C | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.98 | 7820 | 169 | |||

| 100 | 1.96 | 12.2 | 51 | 470 | 219 | |

| 200 | 1.91 | 13 | 49 | 483 | 292 | |

| 300 | 1.86 | 13.7 | 46 | 381 | ||

| 400 | 1.63 | 14.3 | 43 | 521 | 488 | |

| 500 | 14.7 | 40 | 571 | 601 | ||

| 600 | 15 | 36 | 758 | |||

| 700 | 15.2 | 32 | 925 | |||

| 800 | 26 |

Calculated properties: steel density is 7840 kg/m3

Mechanical properties of steel 25 at normal temperature

| Type of delivery | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Heat treated sheet, GOST 4041-71 | 4-14 | 390-540 | 26 | |||||

| The rod is calibrated, GOST 10702-78 | 540 | 50 | Annealing | |||||

| Rolled products, GOST 1050-88 | up to 80 | 450 | 275 | 23 | 50 | Normalization | ||

| Rolled products cold-hardened, GOST 1050-88 | 540 | 7 | 40 | |||||

| Rolled products annealed, GOST 1050-88 | 410 | 19 | 50 | |||||

| Annealed tape, GOST 2284-79 | 340-590 | 18 | ||||||

| Cold-worked tape, GOST 2284-79 | 540-880 |