At the moment, the most productive machine for bending spatial parts from thin-walled pipes is a CNC mandrel pipe bender with automatic change of equipment

.

The main distinctive feature of this machine is the presence of a set of bending equipment

; accordingly, it is capable of very quickly and extremely accurately producing products of complex shapes from pipes

with different bending radii

. Of course, such a machine is best suited for mass production, and the number of items can be large, thanks to the CNC system, changeover does not take much time.

Before we consider an automatic pipe bender with an automated tool changer, we will answer a few introductory questions to understand what a mandrel pipe bender is and what it is needed for.

Why does a pipe bender need a mandrel?

It has long become clear that bending a pipe is not as easy as bending a rod, because... it breaks or the profile is deformed (for example, from round it becomes oval). The solution to the problem was special (shaped) equipment

, where the place where the pipe is placed repeats the shape of this pipe.

But working with shaped equipment had limitations in terms of bending radius and wall thickness

.

If the wall was too thin or the bending radius was too small, then the products came out with defects (corrugation along the inner radius, severe thinning of the outer wall, jamming, tearing, etc.). And then the idea came to place a special device in the pipe

that would support the pipe from the inside right at the bending point, this is

a mandrel

.

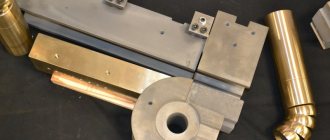

Roller pipe bender for car hubs

The limitation of homemade roller pipe benders is the difficulty of producing replaceable profiled rollers. You can get around this difficulty if you use car hubs as sectors

The dimensions of the device will increase, but in return its reliability and stability will increase, which is important when bending long and thick-walled pipes. For production you will need:

- Three automobile hubs: two movable, located in a cantilever, and one fixed, which is placed longitudinally to the axis of the device.

- Two short axles that are assembled on a rigid welded bracket.

- A rotary mechanism of cam or eccentric types, with which you can change the distance between the hubs.

- An axial longitudinal guide, which can be used in size from a cold-rolled channel.

- Flat travel stops.

- Internal guide channel with holes for bolting stops.

- Rotary handle.

This design is justified in the manufacture of spatial tubular elements of complex shape. The presence of two hubs, the disks of which are spaced on opposite parts of the base, allows you to apply force locally, only to that part of the pipe that is currently bending. This makes up for such design shortcomings as the complexity of installation and adjustment, as well as increased overall dimensions.

How does a mandrel pipe bender bend?

The figure on the left shows a schematic diagram of bending on a pipe bender with a mandrel.

1 – bendable pipe

2 – mandrel (block)

3 – mandrel

4 – fixing clamp

5 – accompanying clamp

Bending process: pipe 1

is put on

mandrel 3

fixed to the rod.

After this, the pipe is pressed against the mandrel 2

using

a fixing clamp 4

an accompanying clamp 5

is also applied to the pipe . After fixing the workpiece, the mandrel rotates around its axis, the fixing clamp moves with the mandrel, and the accompanying clamp moves linearly with the pipe, eliminating friction. In this case, the mandrel remains motionless in the place of deformation, supporting the pipe from the inside. After bending, the pipe is expanded and removed from the mandrel. This is a simplified description of how a mandrel bender works.

The most popular options for homemade pipe benders

The most technologically advanced and versatile are pipe benders that operate on the rolling principle. It is these devices, often equipped with an electric drive, that are used by professionals who are constantly faced with the need to bend pipes made of various materials, including stainless steel.

Homemade pipe bender option

The design of such a device is based on three rotating rollers, one of which is a pressure roller. Thanks to the gradually increasing pressure of the pressure roller and rolling repeated for each new position of the roller, bending of the pipe is carried out in the most gentle way, its walls are subjected to tensile manipulations very evenly.

Homemade electric pipe bender, made by yourself

Computer model of a pipe bender Computer model of a pipe bender Drawing of a clamping screw Drawings of shafts Drawings of shafts Drawing of a ring Pipe bender components Pipe bender components Assembly process Motor drive Motor drive View from the shafts

The most important thing that such a pipe bender allows you to do is adjust the bending radius of the workpiece. There can be several design options for such a universal device: on the elements of the frame structure there are rotating thrust rollers, as well as a wheel with which the pipe is rolled; The side supporting surfaces and the base are made of sheet metal, and a screw drive is used to move the pressure roller. On devices of the second type, the minimum bending radius can be changed, which is achieved by changing the position of the support rollers.

The shafts of this pipe bender allow you to comfortably work not only with round pipes, but also with profile ones

The supporting structure for such a pipe bender can be made of wood. The roller axles, rod, fasteners and handle for turning the rollers, which can also be made of wood or polymer materials, will remain metal.

Above we looked at pipe benders in which the pulling process is ensured by rotating the pressure roller. There is also a category of devices in which the movement of the pipe is controlled by rotating support rollers.

Option with screw jack

An electric or manual pipe bender, in which rotation is transmitted to one roller, has limited capabilities. A pipe bender in which both support rollers rotate is characterized by a more complex design, since it is necessary to transmit rotation to two elements at once.

More convenient, according to many experts, is a pipe bender in which the pressure roller is located at the bottom. Some craftsmen are of the opinion that it is much easier to control the bending of pipes on it; they are not blocked by the upper supporting structure.

Pipe bender with electric motor and drive via two chains

Any device for bending pipes is a fairly simple device, the operation of which is based on the elementary laws of mechanics. If the need for bending stainless steel, metal-plastic pipes, as well as pipes from other materials arises infrequently, then you can limit yourself to a manual device.

What types of mandrel pipe benders are there?

There are several classifications based on different criteria; we will consider the most basic in terms of the degree of automation:

Automatic

: when working on such a pipe bender, the CNC system controls all working movements - bending, rotation of the pipe along the axis, linear movement of the pipe, movement of the accompanying clamp, movement of the mandrel, so the operator only loads the workpiece and monitors the progress of the machine

Semi-automatic

: on these machines, the working movements of the machine are mainly performed automatically, the operator loads the workpieces and feeds the pipe if there are several bends on the part.

Manual

: these are the simplest machines that are used in single production; accordingly, all working movements on them are performed manually: installing the workpiece, clamping the workpiece, bending, etc.

Electric drive

It takes a lot of effort to push a workpiece through a machine using a mechanical handle. Therefore, mechanization of manual labor is a completely justified goal.

A suitable electric motor and a small mechanical gearbox will help you bend pipes “with a cup of coffee in your hands.” These devices are installed on the frame of the pipe bending machine in accordance with the prepared drawings. The drive sprocket mounted on the gearbox shaft can be connected to the support shafts with a metal chain (for example, from the timing belt of a passenger car).

Human

I had a 380V electric hoist lying around in the garage for about 15 years, and I was still thinking about where to use it. It weighs 40 kg and lifts up to 500 kg. A long time ago I bought a small hoist, which, with a weight of 8 kg, lifts the same amount. So: I disassembled it, removed everything unnecessary, after which I got an electric motor and gearbox in one bottle. This item weighs 6–7 kg.

We looked at the main elements of a pipe bending machine, which, if desired and with some ingenuity, can be made independently. At the end of the article, we’ll talk about how to use this equipment correctly so as not to spoil the workpiece.

Why do you need a CNC mandrel pipe bender with automatic tool change?

Conventional automatic mandrel pipe benders are designed for bending complex spatial parts, but in practice, complex spatial pipe parts usually have several radii, and this greatly complicated the matter, because the equipment had to be rearranged for each bend, and accordingly productivity decreased and accuracy was lost. To solve this problem, mandrel pipe benders were developed, where several sets of equipment are installed simultaneously, and it changes according to the program.

Advantages of an automatic mandrel pipe bender with automated change of equipment compared to a conventional one:

- productivity increases

: due to the fact that there is no need to change equipment or perform separate operations on several machines, time is reduced and therefore productivity; - accuracy increases

: accuracy increases due to the fact that all bends on the part are performed in one setup; - saving working space

: in order to increase productivity on conventional automatic mandrel pipe benders, they installed a whole line of machines that made bends each with its own radius, and a machine with automatic tool change replaces this entire line; - fewer workers

: this is also due to the fact that this machine replaces an entire line, therefore fewer workers are required.

Do-it-yourself pipe bender for a profile pipe

Profile pipe is rightly considered one of the most popular materials in the household. Up to 90% of the frames and load-bearing structures of homemade garages, outbuildings, and all kinds of tools and devices are made from pipes. Often, in order to achieve the necessary curvature of a profile pipe, for example, to build an arched roof, you need a pipe bender that can work with both regular and profiled pipes.

How to make a homemade pipe bender for a profile pipe

There are several ways to bend a profiled pipe along a given radius:

- By rolling a profiled pipe blank heated with a gas burner around a template blank or in a special clamp. This type of pipe bender can be assembled in 10 minutes; you only need to fill the pipe with sand and select the correct caliber of the blank on which the bend is formed;

On a homemade pipe bender of a lever-roller design. In this case, the profiled pipe is bent in separate sectors. The design of the pipe bender is very simple to manufacture, but when forming an arc, a certain skill in work will be required so that the same radius of curvature is maintained throughout the entire profiled pipe; Using a rolling roller pipe bender. The advantage of such a scheme is the ability to maintain the radius of curvature as accurately as possible, so it is possible to produce the required number of curved profiled sections of almost any length.

Therefore, both manual and lever-roller pipe benders are used for individual production of all kinds of parts and adapters, for example, when repairing water supply systems and simple building structures. The rolling-roller design of the pipe bender allows you to bend relatively simple products from a profiled pipe, but in an unlimited number of times.

The manual method of bending a heated profile pipe on a calibrated blank has been used since time immemorial and gives good results. It is best to bend a regular pipe; for a profiled one, you will need to double the number of bending transitions so that the formation of ruffles or waves does not occur on the edges. Before heating, the pipe is filled with clean and dry calcined sand. The ends are welded or pressed with metal plugs.

Do-it-yourself real pipe bender for a profile pipe

The device of a rolling pipe bender differs from previous versions in that before bending a profiled pipe, the required radius of curvature is set, after which the pipe blank is quickly rolled into a curved profile using a chain drive and a pair of rollers.

The easiest way is to assemble a pipe bender with your own hands, the drawings of which are given below.

CNC Mandrel Bender Options with Automated Tool Changer

The automatic pipe bending machine with automatic tool changer has the same options as conventional pipe bending machines:

— kits for various profiles

: additional equipment can be ordered for the machine for various sizes and profile shapes

— laser measuring instrument

: allows you to quickly and accurately control products when setting up the machine and subsequently

— automatic hole punching unit

: a punch is built into the fixing clamp, the mandrel acts as a matrix; the punching is mandrelless, so the first wall is punched with slight deformation; one or both walls can break through

— workpiece cutting unit

: a knife is built into the fixing clamp, cutting the pipe in the right place; accordingly, it is possible to obtain several parts at once from one length of workpiece in a continuous cycle (the arrow points to the groove where the knife is located)

Accessories

The advantages of Cansa CM series machines are European quality, components from the world's leading manufacturers, a friendly Russian-language interface, versatility and quick change of equipment, low cost of equipment and accessories with high bending quality.

| Semi-automatic | Auto | |

| Electrical components | Eaton (formerly Moeller - Germany) | Eaton (MoellerGermany) |

| PLC components | Fatek (Taiwan) | Fatek (Taiwan) |

| PLC screen | Delta (Taiwan) | Delta (Taiwan) |

| Hydraulics | Atos (Italy) | Atos (Italy) |

| Guides | INA (Gremany) | INA (Gremany) |

| Servo motors | *** | Delta (Taiwan) |

| Planetary drive (carriage) | *** | LIMING or Apex (Taiwan) |

| Cable connections | *** | Igus (Italy) |

| Machine lubrication | Dropsa (Italy) | Dropsa (Italy) |

| Asynchronous motors | Gamak (Turkey) | Gamak (Turkey) |

Summarize

Currently the most productive

A mandrel pipe bender is a

CNC machine equipped with an automatic tool changer

, thanks to the ability to bend parts with different radii without interruption.

And when using such options as “automatic hole punching unit” or “blank cutting unit”, the machine is capable of producing finished products

that do not require further processing.

Of course, equipment of this level is used in large factories focused on mass production

one product or the same type of product.

Often, in conditions of mass production, machines require some special modifications, i.e. making design changes, adding the necessary components to the machine, introducing the machine into an automatic line, etc., therefore it is important that the manufacturer is ready to adapt the machine to each specific task

.

If you have a need for pipe bending, our specialists are ready to help with the selection of equipment

, equipment and options that are best suited to solve your production problem, call the toll-free number 8-800-100-42-28 and send applications by email.

Specifications

| CM 32 | CM42 | CM51 | CM76 | |

| Max. diameter (mm) | 32 | 42 | 51 | 76 |

| Max. wall thickness (mm) | 2 | 2 | 3 | 4 |

| Max. radius (mm) | 275 | 250 | 250 | 250 |

| Max. bend angle (˚) | 190 | 190 | 190 | 190 |

| Bending speed (˚/sn) | 60 | 40 | 35 | 20 |

| Motor power (kW) | 2,2 | 4,0 | 5,5 | 7,5 |

| Mandrel rod length (mm) | 1650 | 2600 | 3150 | 3150 |

| Accuracy | ± 0,2 | ± 0,2 | ± 0,2 | ± 0,2 |

| Weight (kg) | 220 | 750 | 1000 | 1000 |

| Length (mm) | 1950 | 3150 | 3700 | 4000 |

| Width (mm) | 850 | 1000 | 1000 | 1000 |

| Height (mm) | 925 | 1050 | 1050 | 1050 |