How to work with a caliper correctly?

To determine the readings of a caliper, it is necessary to add the values of its main and auxiliary scales.

- The number of whole millimeters is counted on the bar scale from left to right. ...

- To count fractions of a millimeter, it is necessary to find the vernier stroke that most accurately matches one of the strokes of the main scale.

Interesting materials:

How to restart an LJ washing machine? How to restart a quest in Fallout New Vegas? How does Pepin the Short become king of the Franks? How to eat during breastfeeding? How do Achatina snails reproduce? How to log into VK using ID? In gypsy terms, how are you? How to overcome social media addiction? How to fix Elytras in Minecraft? How to fix the camera on a laptop?

The history of the creation of calipers and interesting facts about it

When carrying out construction work or minor repairs, measuring tools are often required. Usually they are rulers or tape measures. But when measuring pipe diameter or hole depth, these tools are not suitable. For such purposes, more precise measuring instruments are used - calipers.

This device is universal. It can be used to measure the external and internal dimensions of parts. Calipers have gained wide popularity in everyday life, as they have a simple design and are easy to use. Using such a device, you can quickly and easily take measurements with high accuracy.

Vernier caliper device

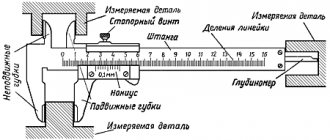

1 — Jaws for internal measurements 2 — Jaws for external measurements 3 — Clamping screw 4 — Movable frame 5 — Vernier 6 — Rod 7 — Rod scale 8 — Depth gauge

All instruments similar to calipers have a measuring rod, which is how the device gets its name. There is a main scale on the rod, which is necessary when measuring first.

A movable frame with a printed scale can move along the bar. The scale on the rod is called a vernier, which has more precise markings in fractional divisions. This provides increased measurement accuracy. The degree of accuracy of a caliper, depending on the design, can reach hundredths of a millimeter.

Calipers have two types of jaws:

- For measuring internal dimensions.

- For measuring external dimensions.

There is also another measuring element of the device, which is called a depth gauge. It can be used to measure hole depth and other dimensions.

Digital calipers are designed in a similar way. However, instead of a vernier, a digital scale is used, which increases the ease of use and measurement accuracy of the device.

1 — Clamping screw 2 — Battery 3 — Length change roller 4 — Zeroing 5 — On/Off 6 — mm/inch switching

Like all measuring instruments, digital instruments are equipped with a scale with a division value of 0.01 mm. The permissible error is considered to be a deviation of the measurement result down or up by 10%. In industry, all measuring instruments are subject to metrological control every six months.

The retail chain sells calipers packaged in a case. When purchasing a tool, it is recommended to inspect the measuring jaws. They should be smooth, and there should be no gap when they are compressed.

The vernier scale should be in the zero position when the jaws are closed. The lines marking the scale divisions along the vernier must be clearly marked. The kit of the device must include a passport with a mark on the accuracy verification performed.

Types and features

Main types of calipers:

There are several subtypes of different calipers depending on the size, design features and principle of operation. Below we consider the main types of such measuring instruments.

This is the simplest and most popular model of the device, which is widely used in industrial production. It is called a “Columbian” after the name of the manufacturer that produced the instrument during wartime (Columbus).

The device can measure internal and external dimensions and depth. The measurement interval is from 0 to 150 mm. The measurement accuracy reaches 0.02 mm.

This digital measuring tool model has a similar design to the classic caliper. Measurement interval 0-150 mm. One of its advantages is higher measurement accuracy due to the presence of a digital indicator.

The convenience of using such a digital device is that the indicator can be reset to zero at any measurement point. You can also easily switch from metric to inch with just one button.

When purchasing a digital model, you need to pay attention to the presence of zero readings when the jaws are closed, and also when the locking screw is tightened, the numbers on the display should not jump.

In this design of the caliper there is a rotary indicator with a round scale, the division value of which is 0.02 mm. These calipers are convenient to use for frequent measurements in production. The indicator arrow is clearly visible for quick control of the result; it does not have jumps, unlike digital models. This device is especially convenient to use in the technical control department for measurements of similar standard sizes.

Such rulers are used for measuring internal and external dimensions, as well as for marking parts before processing. Therefore, their jaws have attachments made of hard alloy to protect them from rapid wear. The measurement interval of the ShTs-II series of devices is in the range of 0-250 mm and the measurement accuracy is 0.02 mm.

ШЦ-III and ШЦЦ-III

Large parts are most often measured with this model of tool, since its measurement accuracy is higher than other models and is 0.02 mm for mechanical instruments, and 0.01 mm for digital ones.

The largest dimension to measure is 500mm. The jaws in such models are directed downwards and can have a length of up to 300 mm. This makes it possible to measure parts over a wide range.

Components and Applications

The tool consists of a fixed base and retractable fittings. They are made of tool steel. The caliper includes the following components:

- The main rod on which all movable fittings are attached. The main scale is located on it.

- A movable frame with a screw lock and pressed by an internal spring plate. There is a vernier scale on it. It can be applied directly to it, or it can be on a plate secured with screws. This allows you to adjust it relative to the scale on the bar.

- Sponges for measuring external surfaces, or large sponges. One of them is mounted on a fixed rod, and the other on a movable frame. The ends have narrow surfaces, which provide additional measurement possibilities.

- Sponges for measuring internal surfaces, or small sponges. They are located according to the same principle opposite the previous ones along the central axis.

- Ruler for measuring depths. Attached to a movable frame.

The ruler for measuring depth is mounted on a movable frame and moves along a groove made in the plane of the rod. It can also be used to measure internal grooves and shoulder distances. The rod is placed on its end perpendicular to the object being measured. The ruler extends until it rests on the bottom. To measure conical holes, its end has a slight point. After receiving the measurement result, it is recommended to fix the position of the instrument with a locking screw, and only then take readings.

Tags

a caliper such a caliper in a small caliper was called a heightened caliper, and the calipers of the USSR supplied calipers small calipers vernier calipers. Calipers. A caliper is a measuring device. Measuring in Measurements perform dimensional measurements quick measurement with for measuring quantities taking external measurements performing measurements accuracy measurements. For internal measurements. perform depth measurements Vernier by vernier. by vernier. retractable depth gauge can has a depth gauge Depth gauge allows

readingsmessagedeptharticlebarsholesshtstshareanswersnecessaryfeatureslinksviews

Why do measurement errors occur?

The most common errors that reduce the accuracy of measurement results with a working instrument:

- Excessive pressure on the frame causes misalignment relative to the rod. The same effect is obtained if, when measuring with the lower jaws, the caliper is brought together by the upper jaws.

- Installation of jaws on fillets, chamfers and roundings.

- Distortions during positioning.

- Instrument calibration violation.

The first three mistakes most often arise from lack of experience, and go away with practice. The latter must be prevented at the stage of preparation for measurements. The easiest way is to set “0” on an electronic caliper: there is a button for this (in Fig. 6 the “ZERO” button). The hour indicator is reset by rotating the screw located at its bottom. To calibrate the vernier, loosen the screws securing it to the frame, move it to the desired position and fix it again.

Deformation of the caliper elements and wear of the measuring surfaces make the tool unsuitable for use. To reduce the number of defects in production, calipers undergo periodic verification by metrological services. To check the accuracy of a tool and acquire skills at home, you can measure parts whose dimensions are known in advance: for example, drill shanks or bearing rings.

What types of vernier tools are there?

Currently, three groups of lifting tools are produced:

- mechanical vernier instruments with readings on a bar scale, equipped with a vernier;

- caliper tools with dial reading;

- electronic caliper tools with digital readout.

Interesting materials:

How to protect water from pollution around the world? How have animals adapted to life in water? What bottled water is suitable for a coffee machine? What kind of water is there in nature? What proportion of the Earth's area is covered by water? What should be the electrical conductivity of water? What is the electrical conductivity of distilled water? What kind of root system is formed if the bulb is placed in water or in the ground? What is the maximum hot water temperature at the tap? Which mineral water cleanses the kidneys?

Possibility of use

They are limited only by the scale size and accuracy requirements.

The device is quite simple, and the main element is a fixed rod with jaws and a scale for internal and external dimensions, to which fixing and movable elements are attached.

Device:

- Movement frame.

- Movable lips to determine the internal size.

- Movable lips to determine the outer size.

- Depth gauge scale.

- Vernier scale.

- Screw to secure the frame.

Some models have a moving scale at the top with an inch measuring system.

Verification method

The verification of measuring instruments, as well as their production, is carried out in accordance with the standards of GOST 8.113-85. Control and measurement manipulations are carried out in special laboratories and performed on ultra-precise machines. However, you can perform a simple verification of a caliper at home. To do this, the tool is thoroughly cleaned of dirt, dust, adhering sawdust, metal shavings and lubricants, and then wiped dry with a clean cloth. Then bring the caliper jaws all the way and watch the position of the zero strokes.

If the device is adjusted correctly, the marks should match. Otherwise, you need to contact a specialized center, where they will check and configure the device, on the basis of which they will issue a certificate of the established type. When using a caliper regularly, verification is performed at least once a year. If the metal of the working jaws wears out, the tool becomes unusable for further use and must be replaced with a new one. To increase the service life of the device, it is necessary to keep it clean and store it only in a case or case.