GC "Center of Fasteners"» specializes in the sale of riveting equipment and, due to the nature of their activities, our specialists receive feedback on quality riveters And rivets

Often customers claim that the rivets are not installed properly or that the rivet gun is not working properly. But, usually, after a conversation with the client at the production site, problems are identified in violation of the rivet installation technology, adjustment of the rivet gun and lack of routine maintenance.

Below are the main issues and rules, the observance of which guarantees high-quality installation of rivets and a long service life of the riveter:

- Compliance with the technology for selecting and installing rivets

- Installing a rivet in two iterations

- Routine maintenance

- Pneumatic air preparation

Compliance with the technology for selecting and installing rivets

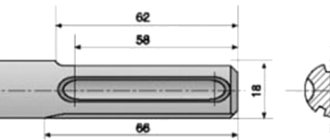

- Determine the thickness of the materials to be joined

The length of the rivet is calculated as the sum of the diameter of the rivet and the thickness of the materials being fastened. For example: the thickness of the materials being fastened is 4.0 mm, the diameter of the rivet is 4.0 mm. Rivet length = 4.0 + 4.0 = 8 mm.

- Drill a hole for the rivet

The hole diameter is indicated in the rivet manufacturer's table.

You can also use the rule - Hole diameter = rivet diameter + 0.1 mm. For example: rivet diameter 4.0 mm, Hole diameter = 4.0 + 0.1 = 4.1 mm.

It is convenient to drill thin sheet steel with double-sided drills; they have a short working part.

- Install the appropriate equipment on the riveter

Install the appropriate blind rivet attachment, stud and rivet nut mouthpiece. If the wrong nozzle is installed, this can lead to jamming of the rivet leg and subsequent repair of the rivet maker.

- Setting the rivet into the material

Install the rivet into the rivet gun, then insert the rivet into the hole at a 90 degree angle and rivet.

Important!

During the riveting process, the tool must be strictly at an angle of 90 degrees to the material, the rivet must be completely inserted into the hole. If this rule is not followed, the rivet will not be installed evenly and the connection of materials will not be tight, which may cause the leg to jam in the rivet maker.

When installing a nut rivet not perpendicular to the material, the threaded rod becomes jammed in the rivet or the stud breaks.

Frequent breakdowns of mechanical riveters and their prevention

Modern mechanical riveters are very reliable tools that, with proper care and compliance with all operating rules, can last quite a long time. However, as we know, nothing in the world lasts forever; any mechanism, even the most reliable one, can someday fail.

To successfully cope with the repair of a riveter, you need to have an understanding of the general principle of its structure and operation. The principle itself is simple: when the handles are compressed with a special collet device, the rivet is captured and pulled out of its tube. After this, the tube is crushed by the working head of the tool: a locking cap is formed, which rivets the mounting hole.

Rules necessary to ensure that the tool lasts as long as possible:

- the head of the riveter is pressed against the head before the tool handle is pressed and the rod is pulled out;

- experts recommend using rivets made of the same material as the parts being fastened;

- It is important to correctly determine the thickness of the elements to be connected. The length of the rivet must be equal to the sum of its diameter and the total thickness of the elements to be connected;

- You also need to choose the right nozzle for the blind rivet. Otherwise, you may encounter jamming of the rivet in the device;

- Correct work with the tool involves installing the rivet in the rivet gun at a right angle to the hole. It must fit completely and evenly into the hole itself;

- After work with the tool has been completed, in order to avoid wear of the pusher and spring, they must be cleaned. The same is done with sponges;

- To avoid rapid wear of the tool, you must also ensure the cleanliness of the jaw cartridge. Metal shavings that remain on the working elements of the riveter can accelerate wear and cause breakdown;

- The pneumatic manual riveter must be cleaned. In particular, clean the filter system from metal shavings every week;

- The stud is also cleaned and lubricated - after about 50 installations;

- After 1,000 installations, it is recommended to lubricate the rotation parts on the riveter. Otherwise, this will cause rapid wear and make working with the tool more labor-intensive.

Of course, like any tools, riveters also need regular preventive inspection and scheduled maintenance. Fortunately, there are not many such operations. Mainly they come down to:

- cleaning the working jaws, springs, pusher element;

- cleaning the filter system, as well as automatic rivet suction units;

- cleaning threaded rods;

- lubricating the moving parts of the riveter;

- changing the oil - in the case of a hydraulic riveter. It is recommended to carry it out at a specialized service center.

Timely maintenance work will help keep the riveter in perfect order for a long time. If you have doubts about your abilities, you can seek help from professional craftsmen or experienced users.

The principle of operation of the rivet maker is that when the handles are compressed, the collet device grabs and draws a rod from the rivet tube, then with a head placed at the other end it crushes the tube, creating a cap, tightly riveting the hole.

We invite you to familiarize yourself with Thorn: beneficial properties, composition, berry recipes

In order for the riveter to serve for a long time, without breakdowns, you should adhere to the following rules:

- the head of the riveter must be pressed against the head before pressing the handles and pulling out the rod;

- it is more prudent to use rivets made of the same material from which the parts being connected are made;

- for the riveter to work successfully, it is necessary to correctly determine the thickness of the materials being joined: the length of the rivet must be equal to the sum of the diameter of the rivet and the thickness of the materials being fastened;

- if the rivet maker is equipped with a nozzle for blind rivets, a mouthpiece and a pin that is unsuitable for the work being performed, this may cause the rivet leg to jam;

- For proper operation of the tool, it is necessary to install the rivet in the rivet gun, then insert the rivet into the hole at an angle of 90 degrees and rivet it. It is very important that during the riveting process the tool is at an angle of exactly 90 degrees, and the rivet is completely inserted into the hole, otherwise the rivet will not be installed evenly, and the connection of materials will not be tight; the leg in the rivet maker may jam;

- after using the rivet gun for 25 hours or at the end of the working day, the jaws, pusher and rivet spring should be cleaned or even replaced if worn;

- You should regularly wipe the jaw cartridge, the jaws themselves and the jaw pusher from metal shavings. This will increase the service life of the tool.

- if you select an inappropriate hose diameter for a pneumatic riveter model, the operation of the tool will be incorrect;

- when working with a pneumatic riveter, you should clean the container filter from chips weekly using a blow gun;

- the pin of the pneumatic model should be cleaned of chips and lubricated every 50 installations;

- The rotating parts of the rivet nut should be lubricated every 1000 installations. Otherwise, friction will increase and the speed of work will decrease;

- The hydraulic oil should be changed at a service center once a year.

Installing a rivet in two iterations

If the length of the rivet is chosen correctly, the installation of the rivet will occur in one iteration, that is, you will need to bring the handles of the manual riveter together once or press the trigger of the pneumohydraulic riveter once.

The following are the main reasons why a rivet does not install in one iteration:

- Jaws, pusher, rivet spring are worn or dirty

It is necessary to clean the jaws, pusher, spring or replace them.

- Low air pressure in the air line

It is necessary to adjust the pressure in the pneumatic line.

- Insufficient air supply

The wrong diameter of the riveter connection hose has been selected. When connecting a hose with a diameter smaller than the recommended one, the amount of compressed air supplied is less than the riveter needs, which leads to its incorrect operation.

- Loss of hydraulic oil

The pneumohydraulic riveter operates from compressed air, which is supplied to the riveter cylinder and drives the hydraulic rod and piston. A hydraulic piston and rod operate the rivet picking and setting mechanism. Any loss of oil results in reduced piston stroke and rivet installation over several iterations.

Routine maintenance

For long and flawless operation of the riveters, it is necessary to carry out timely maintenance of the tool:

- Cleaning jaws, pusher, springs

It is necessary to wipe the jaw cartridge, jaws, jaw pusher and pusher spring free of metal shavings every day at the end of the working day or every 25 hours of work. This will increase their service life. When cleaning the elements, pay attention to their wear and replace the corresponding element if necessary.

- Cleaning the filter of the rivet auto-suction system

For pneumohydraulic models of riveters, it is necessary to promptly empty the container with the torn legs of the rivets during the day.

Once a week, clean the container filter of chips using a pneumatic blow gun.

- Cleaning the threaded rod of the riveter

The pin must be cleaned of chips and lubricated every 50 installations. This will increase the life of the pin and mouthpiece and make it easier to install the rivet.

- Lubricating the rotating parts of the rivet nut

Rotating parts should be lubricated approximately every 1000 rivet installations. Lack of lubrication increases friction and reduces speed

stud rotation and torque reduction

- Changing hydraulic oil

Hydraulic oil is changed at least once a year. This service function must only be performed by an authorized service center.

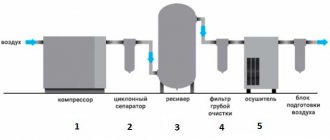

4. Pneumatic air preparation

- Pneumatic tool connection diagram

For the operation of pneumohydraulic riveters, clean, dry air with a pressure of 5.0 – 6.9 atmospheres is required. For a pneumohydraulic nut riveter, it is also necessary to lubricate the supplied air with a small amount of appropriate oil. Exact data on air pressure and the type and amount of hydraulic oil are given in the instructions for the riveter.

Clean, dry air – a filter must be installed.

The filter removes small abrasive particles from the air, under the influence of which rubber seals and mirror surfaces of the cylinder wear out. This leads to oil leakage and failure of the riveter.

The filter removes moisture from the compressed air, which leads to corrosion of the mechanism and deterioration of the hydraulic oil.

Pressure limitation - installation of a reducer or filter with a reducer is required.

Exceeding the operating pressure leads to extrusion of the rubber sealing rings, oil leakage and breakage of the rivet.

Air lubrication – it is necessary to install a lubricator or a filter + gearbox + lubricator unit. Air lubrication is required only by the riveter for rivet nuts.

Air with oil from the lubricator can be supplied to a distance of no more than 5 meters, so the length of the hose should be no more than 5 meters from the lubricator connection point.

Use POP riveters with pleasure and remember: high-quality results can only be achieved with high-quality tools!

In industrial enterprises, when manufacturing products, it is often necessary to perform operations to connect various elements and parts. This can be done using such a reliable method as connecting with rivets. Its help is resorted to in cases where structural elements cannot be welded. Compared to welding, this method has many advantages. A similar connection is created using a special tool for riveting rivets.

How does a manual riveter work?

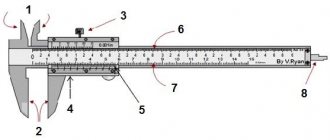

The riveter consists of the following parts:

- Heads that fit onto the rivet core.

- The body, which is a frame for the stop and a lower handle at the same time.

- Top handle. This part of the tool rests on the body using an axis and serves as a power lever.

- The working sleeve, after compressing the handles, compresses the collet jaws. As a result of their joint work, the rivet rod is firmly fixed.

- Next, using the same collet jaws, the rod is pulled out of the sleeve. A riveted ring is formed.

- While the master opens the handles, the conical bushing opens the collet mechanism and it returns to its original position.

- The spring stop is the cover. If it is necessary to inspect the cams, the riveter is disassembled and removed.

- The case has space for replaceable heads. They are selected depending on the diameter of the rivet.

The first pulls the stave in, where it is flattened using a lever system. As a result, the parts are firmly connected to each other.

Each riveter has several nozzles of different diameters. This allows you to use fasteners of different lengths.

Description of the tool and its types

A riveter is a type of tool whose operation is based on the same principle as a pistol. It is used to connect structural elements and their parts with a thickness of no more than 1 cm.

When using such a mechanical gun, connections of parts are most often made from the inside. The manual riveter is a lever version of the gun, the design of which can be divided into two main elements:

- A lever system that provides the necessary force when connecting product elements.

- The spring mechanism necessary to pull the rivet inward.

Manufacturers produce two types of manual riveters - pull-out and threaded.

Exhaust type

This type of tool ensures the connection of parts due to the traction force through which the rivet is fixed. When the gun lever exerts force, the rivet rod begins to retract into its tubular part, pushing its rod head apart. On the outside, the rivet head is also flattened, and the result is a fairly strong connection of the parts.

Threaded riveters

Riveters of this type work on a similar principle with some exceptions. Here the ball is drawn into the working part due to the rotation of the thread in the tubular part of the rivet. In other words, the elements are connected by fixing the head by twisting the handle. This method of fixing parts elements is less common; it is mainly used to connect parts of small thickness.

As a rule, rivet tools are sold together with a set of attachments of various diameters.

Depending on the type of drive used, riveters can be classified into several main groups:

- pneumohydraulic;

- battery;

- electrical;

- mechanical (manual);

- pneumatic.

Mechanically driven devices are used most often in the domestic sphere. Manufacturers produce them in two versions: the first involves connecting parts using one hand, and the second - due to the force exerted by two hands.

The principle of connecting parts with one hand is the basis for the work of a manual riveter, known as an “accordion.”

Manual riveters can be purchased at various prices, which depend on several factors - type of drive, model, connection method and manufacturer. Devices from famous brands are more expensive than products from unknown manufacturers.

Battery, pneumohydraulic and electric modifications of the tool can also be considered expensive when compared with manual riveters. This can be explained by the use of a more complex structure in them. Most often, such devices are used in industrial production.

Frequently asked questions about using a riveter

In private and industrial workshops, a manual riveter is widely in demand, which is designed for reliable fastening of sheet materials. Specialists most often use this tool for sheet metal whose thickness does not exceed 3 mm. In addition, it is the riveter who helps to attach a metal sheet to a corner or profile with his own hands and without any extra effort.

Many experts remember that until quite recently the principle of joining metal with rivets was characterized by many disadvantages and technical nuances. That is why it was almost impossible to perform this procedure at home. Initially, it is worth noting that the riveting process itself was accompanied by a huge number of different technological difficulties, which made it very difficult to make a high-quality connection.

To install the rivet in the right place, the craftsmen had to make titanic efforts. In addition, it was not always possible to securely fasten on both sides of the material being processed. That is why specialists were often interested in the question of how to fasten a rivet without a riveter, having only improvised devices at hand. But in practice, this procedure was particularly difficult, since flaring takes a lot of time and effort.

Against the backdrop of these disadvantages, numerous specialists from different countries worked to create a high-quality and easy-to-use tool for solving such problems. Thanks to this, a manual type of riveter has appeared on the mass market, which is distinguished by its compactness and versatility.

A high-quality rivet tool is distinguished by its versatility and simplicity; it is very easy to use. It allows for unobstructed access to the connection, without any auxiliary devices. Separately, it is worth considering that to work with a rivet device, it is necessary to pre-drill a small hole in a metal workpiece to install the rivet. The fixation will be performed by the main tool.

Experts say that the specifics of this work are distinguished by their simplicity, thanks to which even a beginner can now cope with it. It is also important that you can buy a tool for riveting rivets at a very affordable price.

Many will agree that no repair work is complete without a riveter. The versatility of this hand tool is considered most in demand in cases where it is necessary to connect several workpieces, and the use of other fastening methods is impractical. As practice shows, this device is most often used to connect various fasteners.

As for the lever riveter, the working mechanism itself is presented in the form of a pistol and consists of two parts. The main work is performed by a spring mechanism that pulls the rivet into the inside of the tool. Then the lever system flattens it evenly. The unique structure of the manual lever riveter allows you to connect together those parts whose thickness may exceed 10 mm.

Fixing various workpieces using rivets is of high quality due to the fact that this tool contains the following technical characteristics:

- High degree of reliability. Under the action of a manual riveter, a permanent connection is created, due to which the highest degree of strength is achieved. It is worth noting that the versatility of the rivet connection was used in the construction of the well-known Shukhov Tower in Moscow, as well as the Eiffel Tower in Paris. But these architectural beauties have existed for decades. This once again proves the effectiveness and reliability of using rivets.

- Good resistance to vibrations.

- Preparation for installation of rivets is carried out as quickly as possible. The operation of the hand tool lasts only a few seconds, which significantly speeds up the pace of riveting work.

- Unlike welding seams, rivets do not burst or crack. When the connecting element is exposed to an unfavorable factor, it begins to stretch, so that existing faults can be seen in a timely manner and quickly eliminated.

- Unlike screw connections, rivets are much cheaper because they are small cylindrical pieces of metal.

It is worth noting that today several types of rivet mechanisms are produced, which can have both simple and complex shapes. For example, on sale you can find universal rotary heads that can be used in the most difficult to reach places. As for installing rivets, this process only takes a few seconds.

To date, several types of rivets have been produced that are used in the home workshop. Threading and drawing tools fall into this category. To understand which of these tools is better, you need to study their characteristics and functionality in detail.

A manual pull riveter fastens the rivet by creating a certain traction force. A small through hole is drilled in those workpieces that need to be connected to each other, and after that a rivet is fixed in a certain way in the device itself.

For domestic needs, you can purchase a threaded riveter, the operating mode of which is almost similar to an exhaust unit. The only difference is that in the working body the ball is pulled into the rivet due to the rotation of the thread. This joining method is considered optimal for workpieces with small thickness.

Despite the fact that novice craftsmen are often faced with the question of how to use a manual pull-type riveter at home, this particular tool is considered the most popular. It is more affordable and allows you to perform many more tasks that arise during repairs.

Those who have already encountered a riveter know that using this tool is quite simple. The main thing is to remember the principle of operation. Initially, everything should begin with the preparation of the material being processed. This procedure is carried out as follows:

- The surface of the metal is carefully leveled so that both workpieces fit well against each other (you can use a hammer).

- At this stage, both parts must be placed on a special wooden blank and secured well.

- Using a marker, place dots at the places where small holes for the rivets will be drilled. It is worth considering that this point must be performed with maximum accuracy so that in the future all the holes match.

- Using a conventional drill, holes for the rivets are drilled. Be sure to take into account the size of the drill and rivets. For example, if the hole diameter is 4.8 mm, then you need to take a 5 mm drill.

- At this stage, you must check that the fixing skirt fits tightly to the metal workpiece.

We invite you to familiarize yourself with Infectious burn (stem cancer) of roses

It is important to remember that the length of the rivets must correspond to the thickness of the parts being fastened and the load that will ultimately affect them. Compact rivets are designed for those metal sheets that will not be loaded.

All further manipulations must correspond to the following diagram:

- You need to correctly install the thin end of the rivet in the sharpener so that the attachment sits in place.

- The rivet head is placed exactly in the hole on the part. It is worth considering that the rivet should protrude slightly, no more than 12 mm.

- You need to put a rivet on the top of the part, which should be located perpendicular to the base.

- Now all that remains is to apply strong pressure. If after this procedure the rivet leg does not fall off, then you need to make several powerful pressures.

In order for the result of the work done to differ not only in quality, but also in durability, it is necessary to carry out broaching using a lever system. In this case, it is better to choose steel mounting wire. Due to the strong pressure, peculiar fusions are formed along the edges, which will provide reliable grip. If the metal workpiece will be subject to heavy loads, several rivets should be located along the connecting seam. All wire fragments must be removed from the tool. A slotted screwdriver is best suited for this.

Possible difficulties

Those who are new to processing metal workpieces are often interested in how to use a riveter and what difficulties may arise during the work process. Experts say that the main percentage of difficulties is always associated with improper use of the tool:

- After the manipulations, sharp edges were formed - this means that the working head was selected incorrectly (large diameter).

- Incorrect riveting may be accompanied by backlash. Most often this is due to the fact that the master drilled too large a hole in the metal workpiece. But there is a way out of this situation - install a rivet of a larger diameter.

- There is wire left in the riveter. This situation occurs against the background of severe deformation of the working rod.

Blind rivet device

To learn how to work with a manual riveter, the master should, first of all, become familiar with the design of fastening elements, which are rivets designed to connect elements in a similar way .

This rivet looks like a fastener that contains two parts: a hollow tube in the form of a cylinder, at the end of which there is a head and a metal rod. The hollow cylinder is often called a rivet body or sleeve. Each riveter has a cylinder with its own special diameter, which corresponds to the size of the rivet fastener.

A hollow hole located in the cylinder passes through the entire body, including its head. The metal rod is made in the form of a regular nail with a rounded head. It is installed in a cylindrical hole, where it is subsequently retracted until the head stops using a latch.

To connect elements using a manual pull-out riveter, manufacturers produce threaded rivets, which have a thread inside the cylindrical body. Threaded threads are also present on the rod, which is placed in the cylinder by screwing it in.

To achieve a strong connection, a bolt or screw is usually used as fastener. This type of rivet also has another name - blind rivet. It differs from conventional exhaust in increased strength.

Various materials are used to create rivets used to connect elements with a blind riveter. The sleeves are made of copper, aluminum or steel alloys. The main requirement that the sleeve material must satisfy is not to lead to corrosion of the metal from which the connected elements are made. This means that during their contact there should not be a cathode-anode pair .

To make the rod, steel is used, the strength of which should be several times greater than the strength of the body. The rivet body cylinder may differ in both diameter and length. These are the main parameters of rivets that should be taken into account first when choosing. It is important that the diameter of the cylindrical body matches the hole for the fastener.

DIY riveter for threaded rivets

Hello to all DIY lovers. You probably had a situation where you needed to screw a bolt into a sheet of metal, but since it was impossible to make a thread in the sheet due to its thickness, there was only one option, to put a nut on the back side, but I find this option not very convenient and practical, especially when the goal is to speed up the process.

After thinking a little, it was decided to make a homemade tool that would solve this problem once and for all. Therefore, in this article I will tell you how to make a riveter for threaded rivets with your own hands, with which you can easily make a threaded part in a sheet of metal for a variety of purposes. This article will help you save your money, as well as gain experience in making such homemade products.

Principle of operation

How to use a riveter is perhaps the most important question that interests the master. In order to create a reliable connection, during its execution you must adhere to the following algorithm of actions:

- Surface preparation.

- Marking and drilling holes.

- Installation of fasteners.

At the first stage, it is necessary to level the surfaces well so that the tightest contact between the parts can be ensured.

When starting to drill holes, you need to ensure that they are positioned strictly along the same line. To properly perform this operation, it is recommended that the surfaces be placed on a flat plane , for example, a wooden piece, to which they should be fixed. After this, they proceed to drawing the locations of future holes. Next, they begin to make holes, making sure that on each part they are located exactly in the designated places.

An important task is to ensure that the hole size matches the required parameters. To do this, it is recommended to take a drill of a slightly larger diameter. For example, if you are creating a 3.8mm hole, you would use a 4mm drill bit.

When the holes are ready, be sure to “try on” the prepared fasteners. If everything is done correctly, the head of the rivet will fit tightly to the surface in the area of the edge of the hole and completely close it.

At the final stage, rivets are installed, adhering to the following order:

- First, the cylindrical body of the rivet must be placed in the hole made in the elements to be connected.

- Using a riveter, you need to grab the rod passing through the entire body, and it must be fixed with the lips or the riveting head of the tool directly at the base of the cylinder head.

- By exerting the necessary force on the rod, it must be pulled through the body of the rivet, simultaneously expanding it with the head and deforming the end of the cylinder. As a result, you should have a reverse wide part of the rivet on the inside of the elements being connected.

- Having selected the necessary force for the riveter, the parts are securely connected, after which all you have to do is break off the protruding parts of the elongated rod.

Recommendations for choosing a tool

Today, stores offer many varieties of manual riveters, which can be purchased at a price of about 2-3 thousand rubles. To choose the most suitable model, you must first understand for what purpose you need the tool. If you decide to purchase it for frequent connection of different elements of parts, then we advise you to opt for a more expensive professional tool. For everyone else, a budget model will be enough, which will cost them about 150-500 rubles.

If you want the tool to serve you for a long time, you must not only know how to choose a manual riveter, but also be careful when using it. Otherwise, it will quickly break in your hands, even if it is an expensive professional tool from a well-known brand.

Price is one of the important factors to consider when choosing this device. But besides this, other characteristics are also important:

- Rivet material. To connect aluminum parts, you can buy any of the tools available in stores. If you have to fix steel parts, we advise you to opt for more powerful riveters.

- Ease of use. If you plan to use fasteners of different diameters and made of different materials for connections, then it makes sense to purchase a two-handed model. When choosing a tool, we advise you to pay attention to its head. It is desirable that it be rotating. Then you can easily make connections even in difficult areas. Before purchasing, it doesn’t hurt to find out whether the set of replacement attachments is included in the package. This is especially worth worrying about for those who plan to use different fasteners for connections.

- An important characteristic that must be taken into account when choosing a riveter is the presence of a waste container. It will be especially indispensable for those craftsmen who are going to build a fence on the territory or lay a roof.