Many farmers ask how to install wheels for a walk-behind tractor with their own hands. Walk-behind tractors are indispensable in summer cottages and fields: they are convenient to use for plowing soil, planting root crops, transporting goods, and clearing the soil of leaves, grass and snow. Sometimes the basic equipment, including wheels, does not fit the cultivator. You can change the chassis yourself by selecting suitable wheels for the walk-behind tractor.

Choosing wheels for a walk-behind tractor and replacing them yourself

Many farmers ask how to install wheels for a walk-behind tractor with their own hands. Walk-behind tractors are indispensable in summer cottages and fields: they are convenient to use for plowing soil, planting root crops, transporting goods, and clearing the soil of leaves, grass and snow. Sometimes the basic equipment, including wheels, does not fit the cultivator. You can change the chassis yourself by selecting suitable wheels for the walk-behind tractor.

Why install wheels on a walk-behind tractor yourself?

Modernization may be associated with various reasons, among which the main ones are worth noting:

- A walk-behind tractor often requires re-equipment when the tire pressure on the walk-behind tractor is low. In this case, the user wants to put new wheels on the walk-behind tractor to improve the quality of plowing the land.

- Rubber tires are not suitable for plowing; they wear out quickly and are expensive to replace. Such products are suitable for working on soft ground, and for hard ground (virgin soil) it is recommended to use Zhiguli wheels on a walk-behind tractor, which are installed without the help of a specialist. They allow you to expand the capabilities of the cultivator chassis.

- It is necessary to increase the chassis, for which wide wheels are installed on a walk-behind tractor or pneumatic ones, which are paired.

The conversion of factory-made products to home-made ones may also be due to the fact that the owner of the equipment wants to expand the range of attachments used.

Why change?

The advantages of changing wheels are:

- increasing the service life of the device;

- increasing its cross-country ability;

- elimination of deformations during operation;

- more comfortable use of walk-behind tractors.

It's best to wait until winter to replace it. Then there comes a pause in field work and you can do this work much more thoughtfully and calmly. It is recommended to improve walk-behind tractors in stages. First, the mass is increased, additional lighting fixtures are installed - and only then comes the turn of the wheels.

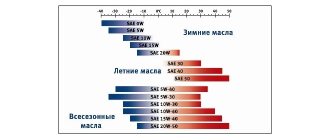

Some experts recommend using only wheels from Zhiguli cars, and selecting lighter brands of the same size tires. In most cases, all-season tires are sufficient. Winter and summer options are unreasonably expensive, require regular replacement when the season changes, but there is still no particular practical difference.

For your information! It is better to prefer a wheel assembly with pipes “native” to the walk-behind tractor. Then there will be fewer problems with fitting onto the shaft. If the length of the guides is initially not enough, they can be extended.

In this case, you need to align all the parts as carefully as possible, otherwise there will be a beating against the ramp when driving. Experts recommend connecting the parts of a walk-behind tractor using the same technology used to assemble it in factories.

How to install the chassis on a cultivator with your own hands

Let's look at how to make wheels for a walk-behind tractor. Craftsmen offer the following homemade products:

- For impassable terrain (swampy area, snowy ground) iron lugs are suitable. Can be used for automotive, all-terrain and snowmobile products. The winter option for the Neva walk-behind tractor will allow you to use the unit for transporting snow, clearing snow from a summer cottage, and transporting goods over different distances.

- The optimal modification option is considered to be Zhiguli wheels on a walk-behind tractor. They have a sufficient disc diameter, and the alteration is carried out using a welding machine, which is easy to use. Moreover, Zhiguli tires are better suited than pneumatic wheels for a walk-behind tractor. The latter are quite difficult to find for a model that has been discontinued by the manufacturer, and ordering new ones via the Internet is expensive and impractical.

- Products can be assembled independently from several disks, creating a new modification with weighting agents.

- You can install wheels for the Neva walk-behind tractor, which are large in size, have excellent maneuverability, and have a long service life.

The Zhiguli chassis has a number of advantages:

- It does not change under the influence of the work performed, so it can be used for a long time and almost constantly.

- An axle shaft is installed on the inside for greater maneuverability. This part must be welded to a plate in which holes for the bolts must be made. They will be needed to connect the axis with the guides that are installed on the product.

- A special protective cap is installed on the outside.

- Good grip will be provided by winter tires. In this case, you can only use Niva tires without tubes.

It is not difficult to install such large wheels on a walk-behind tractor with your own hands, and if necessary, you can remove them and attach them to an all-terrain vehicle or a small tractor, which is often used by farmers in agriculture. To improve the ride of the machine, weights or weights are installed on its chassis. This significantly increases the level of adhesion to the soil.

To work on difficult soils, it is necessary to select products that will ensure the stability of the cultivator and its high productivity.

The lugs will help out; they are a special type of design that has maximum traction with the soil. This is achieved through the installation of spikes that are driven deep into the soil. Such products are made independently. You can take the chassis from a Zhiguli or Neva as a basis.

The remodeling process takes place in several stages:

- Attach the axle shaft.

- Remove the tires, since rubber is not needed for the hooks.

- Weld metal spike teeth that will be responsible for adhesion to the soil. They are installed in the form of strips, which are welded diagonally, or in the form of spikes arranged in several rows. The distance between the hooks should not be less than 15 cm.

- Attach the structure to the rim using bolts.

- To change the disks, you need to unscrew the fasteners.

To create lugs for a walk-behind tractor, you need the following parts:

- old car wheels, maybe without tires;

- a steel corner from which the hook teeth must be made;

- bolts;

- steel thick squares;

- Metal or traction wheels are best for creating lugs.

If there is a need to use not only a cultivator with an improved chassis, but a mini-tractor at the dacha, then you need to create a special frame. To do this, larger products are installed on the motor-cultivator, and a support wheel for the walk-behind tractor is also installed. At home, you can create an economical version of a small all-terrain vehicle, on which products from a VAZ car or a pair of dual Zhiguli products with lugs will stand. Such a machine will be easy to drive off-road, work in field conditions, in swamps. At the same time, the chassis of all-terrain walk-behind tractors must be equipped not only with large, wide products, but also with special body kits. The frame of the equipment must be raised to make it convenient to move around on the cultivator. This is why it is worth installing large wheels.

Procedure

Once a suitable drawing (component layout diagram) has been selected, the necessary tools have been found and the Druzhba saw has been dismantled, you can begin assembly. You should start with the frame, since all the elements of the motor unit will be attached to it. The process is completed by assembling the chassis, as well as additional blocks: if desired, headlights, gearbox and clutch, if the drawing is more complex and requires them. For the first time, it is best to choose a simpler drawing.

Frame assembly

The first stage involves the following actions:

- bend the pipe so that it takes the shape of 2 spars with edges pointing upward;

- the steering wheel is welded at the back (the easiest way is to weld two handles, but if available, you can use a ready-made steering wheel from a motorcycle);

- It is recommended to strengthen the structure with cross members from the same pipe;

- We cut out a “shelf” from a metal sheet for the battery, which we weld to the rear bends of the side members.

It turns out to be a vague resemblance to a sleigh. For heavier structures with more powerful power units, the frame can be made in the shape of a cube or similar to a tractor for 4-wheeled homemade products.

Assembly of the motor block

The most difficult stage is assembling the components. Before you begin, you need to mark on the frame the places to which the parts will be attached. The principle is as follows:

- a motor with a gearbox is mounted on top of the crossbars;

- a fuel tank is installed under the engine (a separate support should be welded under it), the battery is mounted on a special platform;

- To prevent exhaust gases from entering the control unit, you can make an exhaust pipe from a 7 cm metal tube with a diameter of up to 25 cm.

This is the basic version without a gearbox, which can be installed upon request. The drawings will help you understand the assembly in more detail. By and large, the details of “Friendship” are simply rearranged. The hitch is connected to the output shaft of the chainsaw.

Chassis assembly

There are at least two options: you can use a ready-made axle shaft from a car, or you can make a homemade walk-behind tractor driven by physical force (the “chassis” of an old cart or wheelbarrow will come in handy, which will significantly reduce the weight and dimensions, because a car axle shaft will require the use of tires). In the first case, you will have to organize the drive from the motor to the axle shaft, which is not easy, so welding the “running” wheelbarrow to the frame is a more understandable option.

It is not difficult to figure out how to make a walk-behind tractor from a chainsaw if you understand the general operating principle of both units. In addition to “Friendship”, “Ural” and “Taiga” saws are also suitable for the walk-behind tractor. When deciding to experiment, you should understand that the homemade product will have limited functionality and low power, allowing you to process a maximum of 20 acres.

If you find an error, please select a piece of text and press Ctrl+Enter.

The walk-behind tractor is an effective assistant in the processes of cultivating the land, as well as further caring for the garden and garden. The easiest way to obtain this device is, of course, to purchase it. However, there is an option for making it using a chainsaw engine, in particular from the Soviet “Druzhba”. Its powerful engine, simple design and overall unpretentiousness make it well suited for this role.

How to choose a chassis for a walk-behind tractor

Let's look at how to choose wheels for homemade products. It is necessary to take into account the operating conditions of the equipment, which will allow you to select the right products from one or another machine. The rubber passes well on soft ground and on flat surfaces, and for difficult soils it is recommended to use lugs.

For diesel motor cultivators, it is necessary to use metal wheels with an aggressive tread and a large disc diameter.

If Zhiguli products are not suitable, then the chassis for the walk-behind tractor must be selected according to the following parameters:

- diameter - not less than 40 cm;

- width - within 20 cm;

- aggressive drawing;

- entire chambers, sealed areas or damage are not allowed - it will be quite unpleasant when the machine breaks down during operation in the field, where it will be difficult to repair.

For rocky ground and soil that can damage the wheels, only a solid cast chassis should be used.

Be sure to install a support wheel, which helps optimize work on the field, especially during plowing.

The wheels that the master wants to install himself must be of excellent quality.

To ensure a high level of work, it is necessary to take into account the power and performance of the motor cultivator.

Kinds

Pneumatic wheels for Neva walk-behind tractors have 4 elements in their design:

- tire or tyre;

- camera;

- disk;

- hub.

They are placed on the gearbox shaft, the spikes should be directed in the direction of movement. In our country, such wheels are represented by four models.

- "Kama-421" can withstand a possible load of 160 kilograms, while the width is 15.5 centimeters. The weight of one wheel is almost 7 kilograms.

- The L-360 model has less weight, although it looks almost the same - 4.6 kg. On the outside, the diameter is 47.5 centimeters, and the maximum load that the product can withstand is 180 kg.

- The support wheel “L-355” weighs the same as the previous model, the maximum load is also the same, as is the outer diameter.

- “L-365” can withstand 185 kilograms, while the outer diameter of the wheel is only 42.5 centimeters, and the weight of the structure is 3.6 kg.

Metal wheels or lugs are used when there is a need to increase traction. They are also sold in several types:

- wide;

- narrow.

If work is carried out with a plow, then wide ones are the best option. They are also used when equipment has to drive on a wet dirt track. It is recommended to load each wheel with an additional weight of 20 kg.

Narrow wheels are necessary for hilling when plants reach 25 centimeters in height or less.

Traction wheels “Neva” 16*6, 50-8 are necessary if the walk-behind tractor is used as a tractor. There is no tube inside, so there is no fear that the wheel may burst due to heavy load or because it was overinflated. Inside, the pressure is close to two atmospheres.

There are restrictions on the load that can be applied to one wheel, and this is 280 kilograms. The total weight of the entire set is 13 kilograms.

4*8 wheels are characterized by a small diameter and low pressure inside, so it is better to install them on a trailer. They are not tall, but wider than some other types, so they are great for transportation.

Metal “KUM 680” are used during hilling. Features include a rim with a solid surface and spikes, the length of which is 7 centimeters. They are located at an angle, so as they move they lift and turn over the earth. If we take the diameter along the rim, then it is 35 centimeters.

“KUM 540” have a significant difference from the previous model - a non-solid rim. The spikes are V-shaped, so not only they, but also the rim are immersed in the soil. According to the hoop, the wheel diameter is 460 mm. The only drawback of such lugs is the lack of an extension, since they are not sold in the standard version.

The “H” wheels can be praised for their impressive height and width. They are best used when plowing frozen soil. The track width is 200 mm, there are spikes on the surface that penetrate the ground perfectly and lift it with ease. Their height is 80 mm.

The same lugs, but intended for plowing fields, are equipped with a long sleeve. The track remains 650 mm wide.

There is an iron mini model “N”, which has many similarities with “KUM”. The diameter of the wheel is 320 mm, its width is 160 mm.

Mini “H” for hilling is available for sale

These metal wheels differ in diameter, which is 240 mm, if you take into account the hoop. Spikes only 40 mm

Car wheels on a walk-behind tractor: installation tips

For most farmers, a walk-behind tractor is an indispensable device on the farm. Its versatility allows you to simplify many jobs on land. However, modern models are equipped with wheels that are not highly reliable and do not have good driving performance. Many of them are not able to fully work even for one season. The tire sidewall bursts under constant loads, and in wet weather the unit gets stuck in the mud.

And yet there is a way out. The standard disks on the device can be easily replaced with regular car ones. Anyone can do this if they take into account some nuances and follow the recommendations given below.

Pros and cons of car wheels on a walk-behind tractor

To begin with, we should provide a list of the advantages and disadvantages of such a modification.

- Reliability. Passenger tires are designed for more impressive loads than the original tires of a walk-behind tractor.

- Durability. Tires from a passenger car, even in used condition, will last much longer.

- Patency. Thanks to the increased ground clearance, as well as a more impressive tread pattern of car tires, the walk-behind tractor will be able to drive over obstacles more confidently.

- Good traction due to greater tire contact with the ground.

- Increased speed as a consequence of the increased diameter.

- The need to dismantle the arches or redo them.

- The controllability of the device is slightly deteriorated.

Which car wheels to choose for a walk-behind tractor?

For installation on an agricultural device, the simplest wheels from a Zhiguli with a bolt pattern for 4 fasteners are suitable. However, there may be hubs with 5 mounts. For such models it is worth choosing wheels from Moskvich.

As for the tread, it is better if its width and depth are more impressive. This will improve the permeability of the device. And yet, if you have old tires with a worn pattern on hand, they are quite suitable for this device and will last for several more seasons.

For further installation work you will also need worn brake discs.

Instructions for tire pressure of complete wheels for agricultural machinery

1. Complete wheels for tractors, combines and other self-propelled agricultural machinery are shipped to the client or to the branch warehouse with tire pressure as indicated on the tire bead. This applies to all wheels, the tires for which are mounted on disc wheels with mounting holes for installation on the hubs of agricultural machines.

2. This pressure is nominal and in this form the complete wheel is sent to the client - transport pressure.

3. Complete wheels for tractors, combines and other self-propelled agricultural machinery used as dual or additional - discless wheels, consisting of a rim and spacer, are shipped to the client or to the branch warehouse with a tire pressure 0.7 bar less than indicated on the bead surface of the tire .

4. When installing additional wheels, the client must be informed that the air pressure in the tire of the additional wheel must ALWAYS be 0.5 (min.) - 1.0 (max.) bar less than in the main wheel. The client regulates this value (the difference in pressure) himself, depending on the task assigned to the operation of the specific equipment on which these wheels are installed.

5. It is not allowed to operate equipment with additional wheels on spacers when the set pressure in the outer tire is greater than or equal to the pressure in the tire on the inner wheel. The minimum pressure difference should be 0.5 bar downward in the outer tire.

How to install car wheels on a walk-behind tractor?

In general, the process of installing disks from a passenger car to a walk-behind tractor is simple and does not take much time. To work, you need wrenches 12 or 13 (depending on what bolts are used to secure the “original” disks on the device), and 17. You will also need a drill.

Passenger car wheels are placed on the hubs with the inside out. For fastening, you should select bolts with a reserve length. This is necessary in order to be able to put additional brake discs on them for greater weight. There is no need to fix them on a permanent basis. It’s better to just carry it with you and wear it as needed. This is just an additional measure to improve cross-country ability and slightly increase traction.

Installing wider wheels will have a positive effect on the operation of the unit and will allow it to be used many times more efficiently. The agricultural device will become more resistant to all kinds of weather conditions. It will be easier to use in autumn or winter.

Additional designs

For the cultivator, it will be possible to build both transportation elements and additional frame parts. Thus, the unit is “reincarnated” into a small tractor. In this form, the motor cultivator can be used as an all-terrain vehicle. In this case, the wheels of the standard type with low pressure are removed and replaced with lugs (large).

To learn how to make lugs for a cultivator with your own hands, see the following video.

Having become the proud owner of a lightweight walk-behind tractor with a 6.5 hp engine. The first season will be a test for everyone; all the pros and cons of the factory version will be obvious; you don’t need a lot of experience to understand this. Truth is learned in action.

The remodeling process itself will not take much time. No special tools are required.

Next, we secure them using stronger bolts and nuts 17mm to the disk from the car, having previously drilled larger holes in the hubs. We select discs according to the number of holes on your hubs (4-5)

We check whether the cotter pin to secure the hub is inserted freely through the extension. The track will become wider, we check whether the new wheels touch the parts of the walk-behind tractor, in this case the wings

There are holes in them; to please the eyes, you can add color using the paints of your walk-behind tractor.

Thank you for reading to the end? Like it? Subscribe to the channel .

Installation of Zhiguli wheels on a factory trolley for a walk-behind tractor1

How to choose the right low-pressure tires for a walk-behind tractor

Experienced unit owners give their advice and recommendations.

Adviсe

When choosing tires for a motor cultivator, it is necessary and strictly:

- study the characteristics of the device, take measurements to ensure that the selected tire fits perfectly. A correctly selected tire will be the key to excellent performance of the walk-behind tractor;

- decide on the type of work that will be performed on the equipment, based on this, make a choice of wheels, and, accordingly, tires for them;

- decide on the type of soil, based on this you can already make a choice of the type of tread. In some cases, tires from Zhiguli or Oka cars may be suitable. For softer and more viscous soils, tires with a more textured tread and higher cross-country ability are suitable, for example tires from Germany for motorcycles 140 80 15.

Recommendations

It is recommended first of all to pay attention to the following parameters when choosing tires for a walk-behind tractor:

- size, i.e. this is the number that appears after the name of the wheel. Tire size is usually indicated in inches. For example, a tire 6.00-12, where 6.00 is the diagonal width of the tire, and 12 is its seat diameter;

Rubber for walk-behind tractor 12

- purpose – a number of tires are intended only for walk-behind tractors, a number only for transport, and also for other purposes. This must be taken into account when choosing rubber, in accordance with the purpose of the cultivator;

- quality or compliance with standards, quality of materials. It is recommended to purchase tires from well-known manufacturers, which are guaranteed to be durable, strong and resistant to environmental conditions.

Peculiarities

On the market, wheels from the Neva walk-behind tractor are presented in two large groups:

- made of metal;

- pneumatic

The user should select wheels based on the model and the work that will have to be done. Pneumatic tires are very reminiscent of the usual ones that are used to seeing on vehicles, but metal ones have received another name in professional circles - “lug lugs”.

Grousers are necessary when it is very important that the equipment has high-quality traction with the ground. Extensions are often used with them to help determine the track width.

There should be hubs on the lugs; thanks to them, you can create equipment with excellent maneuverability, regardless of the type of soil. First, a metal wheel is mounted on the axle shaft, then a regular wheel is mounted on the bushing.

Wheel extensions for walk-behind tractor

Axle extensions allow you to significantly expand the wheelbase of the walk-behind tractor. With their help, the walk-behind tractor will be more stable at any track width, and balancing will also be significantly increased. You can add additional wheels on each side, which will increase cross-country ability or create it where it is practically impossible.

Extension Cords

In addition, extension cords also perform such important functions as:

- carrying out difficult work and on heavy types of soil;

- equipment equipped with extensions can be used on uneven areas and on any type of terrain, including hilly, rugged terrain, ravines, pits, and so on;

- the walk-behind tractor will not slip and fall over with heavy attachments, as is often the case with narrow wheels or extension cords without additional equipment;

- Cross-country ability and maneuverability are greatly increased thanks to extensions;

- Extensions are indispensable for installing additional lugs, iron and pneumatic wheels on the walk-behind tractor.

DIY making at home

This is done as follows:

- two pipes of equal length with a diameter of 2 mm and above the diameter of the walk-behind tractor axis are required;

- each of them has a thread for screwing onto the axis of the walk-behind tractor;

- on the reverse sides of each of the pipes, holes are made two millimeters thinner than in the disks on wheels; if necessary, the pipes can be filed;

- After this, the wheels are fixed on the extensions with steel plates and secured with bolts.

Do it yourself

Now let's talk about how to make wheels for a walk-behind tractor yourself. Let us immediately clarify that creating pneumatic and cast wheels at home is in principle impossible.

And why reinvent the wheel if you can equip garden equipment with tires from a car or motorcycle. You just need to install a suitable hub and you can get to work.

It's a different matter when it comes to lugs. You can actually make such homemade wheels for a walk-behind tractor yourself. Here is a basic assembly diagram:

- We take old wheels from the car. Please note that only the rim is needed. The diameter of the wheels depends on the power of the walk-behind tractor, given that the design will be all-metal, the weight will be considerable.

- We weld metal plates to the disks. The edges of the plates should touch the edge of the rim. This is an important structural element, so the plates are welded along the entire outer radius; they can be secured with bolts to increase reliability.

- We weld the teeth to the metal plate. They can be made from a corner, after cutting it into pieces of the required length. Please note that the distance between the teeth should not exceed 15-20 centimeters. Otherwise, the effectiveness of such wheels will be reduced to zero.

- We weld the axle shafts into the disk, supplement the structure with bearings and install the chassis on the walk-behind tractor.

You can make lugs from an old gas cylinder. In this case, you need to cut two rims, about 6-7 centimeters wide, and then proceed according to the above diagram.

In general, lugs can be constructed from any available material that has the shape of a circle. The main thing is to show desire and apply a little skill.

How to put Zhiguli wheels on a walk-behind tractor

The sequence for installing Zhiguli wheels on a walk-behind tractor is as follows:

- It is necessary to attach the axle shaft.

- Next, you need to remove the tires, because rubber is not needed for the hooks.

- After this, metal spikes are welded on, which are responsible for adhesion to the soil.

- The structure is attached to the rim with bolts.

- Next, the disks are changed.

Wheels from a Zhiguli on a walk-behind tractor

Many owners of walk-behind tractors quite often put Zhiguli wheels on cultivators and, as practice shows, they are very satisfied with the result. When cultivating the soil, wide car wheels behave more confidently than the narrow ones from a walk-behind tractor, and, as already mentioned, they do not dig into the ground or slip. They are also much more convenient when transporting the unit itself; thanks to the larger diameter, the speed of movement is much higher.

Making homemade lugs

Sometimes pneumatic tires can slip (soft ground, slush after rain, ice) and your work can go down the drain. For better adhesion to the soil, reliable devices are needed. These are ordinary lugs.

You can, of course, buy them in a store, but not everyone wants to spend money on something that is easy to make yourself, and from “waste” materials. Moreover, there are only two requirements for them, and both are necessary to ensure reliable grip:

- Weight 20-30 kg.

- Digging into the ground.

There are many options for DIY lug wheels. We will focus on two of them. For their manufacture, the main tools are:

- Bulgarian;

- welding machine.

To complete the first option, you will need metal strips (about 5 mm thick) and car rims. Their diameter depends on the size of the cultivator blades. Many people take Lada wheels as the best option. Picture 1.

Figure 2. Homemade lugs for the cultivator.

The method for making soil hooks is very simple:

- cut strips with a grinder so that their length is approximately one and a half times the width of the disks;

- they are bent in a vice at an angle so that they are inserted between the two sides of the disk;

- distribute the strips evenly and weld them into place;

- strengthen the resulting lugs on the axle.

The second option is more difficult. For it, they take a sheet of thick metal, mark it and cut out something like a large bicycle sprocket or a ratchet from a watch. Next, parts of the resulting beams are bent and metal plates are welded to them. Figure 2.

Wheels for hilling on a walk-behind tractor

When setting a task such as hilling for a walk-behind tractor, a special type of wheels will be required. Hilling wheels, also popularly known as hillers, are used for both planting and hilling various crops, such as potatoes, carrots, beets, rutabaga, radishes, turnips. The most commonly used are four types of hilling wheel models:

- Lister - you can easily make them with your own hands. They have a number of varieties, including a non-adjustable type, consisting of two plates arranged mirror-like and diverging at an angle with a common stiffener. And also an adjustable type, with which it is possible to change both the width and depth of tillage;

- disk - the principle of their operation is based on the fact that the disks capture the soil and then fill the plant growth areas with it;

- propeller - are a type of propeller. They are valuable because, due to the serrated shape of the blades, they are aggressive towards weeds and are excellent at combing them out of the soil, making them ideal for weeding. It is also possible to make this type of hiller with your own hands, individually for the strictly assigned tasks;

Options for power distribution mechanisms

Structurally, the simplest way to solve the problem arising from the rigid connection of the wheels is to use overrunning clutches, which allow the wheel to rotate faster than the axle driving it.

Overrunning clutches

Overrunning clutches

This mechanism is well known in all its variations: both with a ratcheting mechanism (bicycle wheel hub) and with wedging rollers (electric starter bendix).

Overrunning clutches are also used in the power drive of a number of cars with plug-in axles. However, this solution has a characteristic feature: when cornering, the overrunning clutch is disconnected on the wheel running along the outer radius, as it tends to rotate faster than the drive shaft.

To make it easier to enter a turn, on the contrary, most of the torque should be transmitted to it.

This problem is solved in the classic gear differential, which distributes power in inverse proportion to the rotational resistance of the wheels.