The latest technologies make it possible to choose materials for fencing that do not require maintenance or further finishing. These include Euro picket fences. Having a metal base, structures made from this material are reliable and durable. It is accessible and easy to install. When assembled, the structure perfectly copes with protective and decorative functions.

Users often search for:

- Installation of a fence with brick pillars

- Fence made of metal profiles and bricks

Distinctive features

A metal picket fence is made from sheet steel. Prepared planks are used to fence the local area. For installation, racks and cross bars are required to hold the entire structure together. It will look like a regular wooden fence.

The metal picket fence can be from 0.4 to 1.5 mm thick, but there are other options. To prevent rust, you need to coat the product with a special compound or a layer of zinc. After this, the fence can be painted.

What's the result?

The article provides detailed instructions on how to install a Euro picket fence on a fence with your own hands. It covers not only the installation itself, but also the issues of choosing a metal picket fence, fencing design and calculating the gap between the slats, as well as the preparatory stage: purchasing materials, selecting tools, delivery to the site.

The instructions tell you how to install support posts, make a frame and, of course, how to attach the picket fence to a metal profile correctly. Just follow the recommendations, and you can make a beautiful and durable fence without hiring a professional construction team.

Read on topic:

How to make a gate from Euro picket fence

Which European picket fence is suitable for a gate? How to calculate the number of pickets? How to make a gate from a metal picket fence yourself? Detailed answers are in the article.

Horizontal fence made of Euro picket fence

The advantages of a horizontal metal picket fence over a regular fence and detailed step-by-step instructions on how to make it yourself.

Advantages of a metal picket fence

- Long service life. A metal picket fence will last, on average, 30 years, and with careful care – about 50 years.

- Sustainability. When coated with special products, the metal picket fence will withstand any weather conditions. Additionally, it has good resistance to mechanical damage.

- Easy to install. There is no need to pour a foundation for the construction; you can handle the installation yourself.

- Compatibility with other materials. To create a unique design, wood or brick is suitable.

- Such a fence does not require maintenance; it is only necessary to update the color every few seasons. The metal is not subject to fire and has small dimensions, which facilitates its rapid transportation.

Compared to conventional corrugated sheets, metal picket fence has a high cost, but it pays off with a high service life and structural strength.

Self-tapping screws or rivets

The planks are mounted to pre-screwed, welded joists using self-tapping screws or rivets.

Self-tapping screws are not ordinary ones, but roofing ones with a rubber gasket. They withstand any weather conditions very well. The rubber gasket ensures complete sealing of the hole. Easy to install. They have a large selection of colors, so you can always choose fasteners to match the design. The downside is that they simply unscrew, making it easier for intruders to enter the site.

As for the rivets, you will need a special gun to fasten them. Requires more time to install. Unscrewing them is a big problem. The connection point is poorly protected from rain. The choice of colors is small, so choosing a fence to match is problematic.

Builders recommend rivets for fences in summer cottages, where owners will only use them periodically. In the private sector, where the owners live permanently, it is better to use self-tapping screws.

Types of materials for picket fences

Thanks to the various sizes of metal picket fences, it is possible to design original designs. The strips are made from steel strips that have been processed in a rolling mill.

- Another type of material is metal profile.

- It is considered the most budget option, since the metal sheet is not processed in a rolling mill, but is cut independently.

- A picket fence made in this way will be less durable and have dangerous edges.

- A sheet bending machine is not able to make all the planks the same, which is why the fence will be less strong.

The quality of the fence will depend on the material from which it was made. Most often, cold-rolled sheets are used for picket fences, but sometimes hot-rolled sheets are also used for budget options. In both options, the planks must be treated to increase their service life.

Methods for fixing pickets

If the structure is needed for reliable protection of the house and is located on the street side of the site, then we recommend that you take into account that:

- To install a blank canvas and completely close the estate from prying eyes, you should buy pickets more than 1.8 m long, placing them from the ground at a distance of 3–5 cm.

- If visibility of the area is not important to you, then it is enough to purchase planks 1.5 or 1.25 m long and secure them with gaps.

Now let's look at what methods of fixing a picket fence are used more often.

Vertical

A generally accepted option for installing planks. For construction, you do not need to know special instructions and attach additional transverse joists to increase the rigidity of the structure.

Each plank is fixed in a vertical position to the joists with screws or rivets. This can be done with gaps in one row or you can design a blank canvas in the form of a checkerboard fence.

Horizontal

Not as popular as the previous type, but if you follow the instructions, the fence will be no less attractive.

Installing picket fences horizontally is much more difficult. It will be necessary to attach additional poles, which often must be of non-standard shape. If this is not done, the planks will begin to sag, which will lead to deformation of the entire structure.

And an increase in the amount of materials for construction means an increase in the total cost of the fence.

Checkerboard

Another name is double-row. The planks are mounted to the transverse joists on both sides so that they overlap each other by at least 1 cm. To do this, the step between the stripes is made slightly smaller than their width. The fence turns out to be almost continuous and what is happening on the site is visible only from a certain angle.

For a completely blank canvas, it is necessary that the pickets overlap each other by half.

The disadvantage of checkerboard is that the material consumption per 1 linear meter increases by 50%.

In one row

An economical option for fastening picket fences, since the strips of material are fixed in one layer. Often gaps up to ⅔ of their width are left between the slats, but this is not critical. The step between the elements may be greater, or they may be attached closely.

Disadvantage: due to the gaps, the area remains completely visible.

Types of coating

In addition to coating with a layer of zinc, another coating is applied to the metal picket fence, which comes in two types.

- Polymer. Protects against rust and mechanical stress for up to 20 years.

- Powder. This is a budget option, however, it requires an anti-corrosion coating, otherwise the metal may rust.

After coating the metal picket fence with zinc, you can begin applying paint. You can paint the fence yourself, or purchase a factory-painted picket fence, a wood-look metal picket fence, with patterns, etc.

Interesting design options for the top of structures

Most often found:

- Ladder. The planks alternate with each other. They put one longer, the other shorter, or vice versa.

- Wave. Suitable for sectional assembly. The top is made in a wavy shape.

- Trapezoid. The top of the fence is formed in the form of a trapezoid.

- Herringbone. The planks form a cone, which is very similar to the crown of a spruce tree.

- Arc. The upper cut is made convex or concave.

- Canyon. Long planks are installed along the edges of the span, the height of which gradually decreases as they approach the center.

- Peaks. The upper part resembles the shape of peaks, and there can be several of them in one section.

Less common is the design of the top line like a pyramid or wings.

The unusual spans will be complemented by a stone or brick base.

Size of slats

The top of the metal picket fence is available in three options: flat, semi-oval, or a designer version.

It is advisable that the edge be processed, otherwise it is easy to get injured on the fence.

The bar itself is available in three versions:

- Rectangular profiling. The most common type. The number of ribs must be at least 3.

- Longitudinal profiling. More durable and aesthetic than the previous option.

- Semicircular. It is rarely made and has its own production difficulties.

The dimensions of the planks range from 0.5-3 m. The width is 10-12 cm. The thickness of the plank determines whether it will need a foundation or not.

Color spectrum

With modern technologies, you can design in any color.

Most common colors:

- Green. Blends well with plants in the local area.

- White. Requires frequent maintenance, looks great with the French Provence style.

- Chocolate. Combines with other flowers and trees.

- Grey. Suitable for any design.

The assembly of the structure depends on the fixation methods and has three options:

- Vertical. The most common type of installation. It is permissible to leave gaps between the planks, or fasten them together without gaps.

- Horizontal. Not the most common option, but also quite relevant. Installation requires a lot of time and effort.

- Chess. Installation occurs vertically in two rows, leaving no gaps between the rows. Suitable for those who like privacy.

- A unique approach. You can create a herringbone or wave from the planks. It all depends on your imagination.

If you have no experience, it is better to order the installation of a picket fence from a construction company. You can install the fence yourself without resorting to outside help.

For independent work you will need a metal profile and special scissors. The difficulty is that the edges of the planks must be even, which will require additional time. The best option is to purchase a ready-made fence and install it yourself.

Criteria for choosing a European picket fence

If you initially choose a low-quality material for installing a fence, which is often attractive with low prices, then during operation, no matter how much you repair it, you will not be able to achieve strength or aesthetics. For a durable and reliable fence, it is better to buy a European picket fence, focusing on:

- profile type;

- metal thickness;

- edge processing;

- dimensions;

- coating material;

- external features;

- price.

The main thing is to remember that saving may bring benefits right now, but it will come back to haunt you with large expenses later.

Profile type

Before choosing a metal picket fence, you should pay attention to the profile. Three types are available: C-shaped (semicircular), U-shaped and M-shaped.

The semicircular shape provides good aerodynamic properties of the pickets. It gives the fence originality. The planks are fastened with two self-tapping screws, which, on the one hand, increases the consumption of fasteners, but on the other hand, reduces the likelihood of wind damage or failure.

The U-shape gives the picket the appearance of a trapezoid with flat edges. For fastening here, two self-tapping screws are also required on the sides of the plank, which has a positive effect on the strength of the structure.

The M-shape has a smooth bend. Two bent, corrugated surfaces give the product a high level of rigidity, which makes it possible to fasten it with one self-tapping screw. However, with strong gusts of wind, there is a risk of such a picket bending in the center.

Rolled edge

When choosing which metal picket fence is best, pay attention to the edges of the slats. Cheap pickets usually only have the corners bent. The best option for products that have all edges rolled is along the entire length on both sides. Rolling makes the material safe, preventing the risk of cutting during installation or during operation of the fence, and also increases the overall rigidity of the structure.

Load resistance

Before choosing a European picket fence, you should determine the wind loads in the region to which your fence will be resistant. To ensure that a metal picket fence is not afraid of even a hurricane, it is recommended to pay attention to:

- profile height - the higher it is, the stronger the bar, but don’t get carried away, 20 mm is considered the best option;

- number of stiffening ribs - in addition to profile bends, the planks are equipped with additional grooves that increase strength. The more there are, the stiffer the material;

- metal thickness - it can be in the range of 0.35-0.5 mm;

- The width of the picket fence is optimal 12 cm.

Rounded and U-shaped profiles are firmly attached by fastening them with two self-tapping screws.

Picket sizes

The optimal width of the picket fence is 110-130 millimeters. A narrower one will require more strips, which will increase the total cost and make installation more difficult. A wider one will increase the “windage”.

What picket fence height is best? Focus on installation features, price and needs. If there is no need to completely close the area from passers-by, it is better to install strips 1.8 meters high - this is the optimal height, covering the height of a person’s eye level. And also to attach such pickets you will need two horizontal crossbars, not three,

Life time

The durability of a fence picket is affected by the type of coating it has. Planks with simple galvanization last for 10-15 years. Parts coated with additional polyester last approximately 25-30 years. If you want to put up a fence and forget about it, it is better to buy picket fences coated with pural or plastisol. They ensure safety even in the most aggressive conditions for 40-50 years. Such planks are able to withstand coastal winds, temperature changes, acid rain and the much more caustic microclimate of chemical plants.

Design and color

Euro picket fence allows you to choose any color from the RAL catalogue. The planks can be evenly painted with powder dyes or covered with a layer of polymer materials, imitating, for example, wood. Texturing technology is supported, which makes the picket fence visually indistinguishable from natural wood. This option is in harmony with any area.

To give the fence an airy feel, white pickets are installed. Such planks look elegant and solemn, especially in combination with greenery or flowers.

Horizontal fences in the ranch style can add originality to the exterior. Their price is higher than traditional fencing, but their appearance is also more advantageous.

You can diversify the fence with slats with a semicircular top cut, figured sections, forged elements - for example, on supports.

Metal fence prices

It is better not to skimp on fencing made of metal slats. However, if you need to reduce costs, you can resort to:

- installation of galvanized pickets, which are a third cheaper than polymer-coated products;

- purchasing a European picket fence of 1.8 meters and below, which will allow you to avoid installing a third cross member for support;

- installation of narrower pickets with wide intervals;

- forming a fence from only one row, which will reduce the aesthetics of the reverse side (fastenings will be visible), but will reduce the price.

We do not recommend buying thinner material or strips with a thin coating - they quickly corrode.

DIY picket fence installation

For installation you will need fasteners and diagrams, which are most often sold together with the metal picket fence.

For installation you will need:

- Shovel or drill. Necessary for creating a trench.

- Welding machine. Needed for welding horizontal strips with supports.

- Screwdriver. Needed for fixing planks with guide parts.

- Construction level, tape measure.

Materials needed:

- Hollow pipes for vertical supports.

- Horizontal guides.

- Fence.

- Self-tapping screws.

- Soil mixture.

- Dye.

- Mixture for pouring the foundation.

Installation of metal picket fence

In places where the fence will be built, you need to drive in pegs and stretch the construction cord.

- Mark the installation locations of the support pillars.

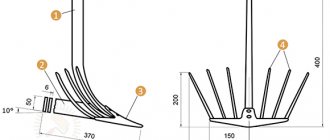

- At the marked points, holes of approximately 60 cm are dug.

- Pipes are installed in the pits and driven in approximately 40-45 cm.

- The pits are concreted.

- The cross beams must be welded to the vertical pipes.

- Next comes the installation of the planks.

- The planks are fastened with galvanized screws.

The fence is covered with primer and paint.