The base of the starter is a magnetic circuit and an inductor. To do this you will need a three-core cable and several contacts.

The second type is used to supply power; it is the most common. Magnetic starters KME in IP65 9-95A housing. Connection diagram for starter 380 and 220V (400 and 230).

On the upper part of the magnetic circuit there are two groups of contacts - movable and fixed. Based on this, the starter control buttons, which are called a push-button post, have two pairs of contacts - normally open open, normally closed, NO, NO and normally closed closed, break, NC, NC see. If after applying voltage the starter does not turn on on its own - already Fine. To achieve this, each product range complements each other.

But, as you understand, this scheme for connecting a magnetic starter is not particularly convenient - you can also supply conductors directly from the power source by building in a regular switch.

For aluminum wires, the ends are cleaned with a file, then covered with paste or technical petroleum jelly. To prevent distortion of the spring washers located in the contact terminal of the starter, the end of the conductor is bent in a U-shape or into a ring.

A good example. The next important parameter will be the operating current.

How to connect a magnetic starter. Connection diagram.

Application of a magnetic starter

A magnetic starter (or contactor) is used to remotely switch on electrical equipment.

The advantage of a starter over simpler circuit closing devices (for example, a switch) is the separation of power and control circuits. This allows the starter to be placed in the power cabinet, and the controls to be placed in the work area. At the same time, control voltage and currents are minimal, which allows the use of wires of smaller cross-section. With increased safety requirements (high humidity in the room), it is enough to simply use a starter with a coil, for example, 24 V. The supply voltage of the electrical equipment can be 220 or 380 Volts.

In addition, the starter connection diagrams ensure safety in the event of a power failure in the network. In the event of a voltage failure, the power contacts open, and if voltage occurs, the starter will not supply voltage to the electrical equipment until it receives power through the start button.

An example from life. Some kind of lathe or milling machine is working. The tension is gone. The machine stopped. The worker started to adjust something in the working area of the machine, and then the tension appeared again. If the machine were controlled by a switch, the engine would immediately turn on, resulting in injury. When controlling the power supply using a magnetic starter, the machine will not turn on until the Start button is pressed.

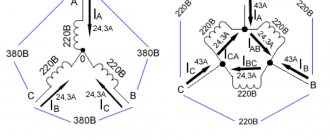

Below is a diagram of a simple starter switch to control the supply of voltage to electrical equipment. In our example, this is an asynchronous electric motor with a phase-to-phase supply voltage of 380 V. Accordingly, the voltage in one phase relative to zero is 220 V. The starter coil is designed for a voltage of 220 V.

In the initial position, we have voltage on power contacts 1, 2 and 3 of the starter, as well as on contact 1 of the “Start” button (normally open).

When you press the “Start” button, voltage is supplied to contact K2 of the starter coil through the normally closed contacts of the “Stop” button, closing the coil power circuit.

The coil creates a magnetic field, the core is attracted, closing the power contacts of the magnetic starter (1 and 4, 2 and 5, 3 and 6, respectively). In this position, voltage is supplied to the electric motor. At the same time, the NO block contact closes, the phase from which is supplied to the starter coil through the “Stop” button. Therefore, even when we release the "Start" button, the coil circuit remains closed, ensuring the closed position of the power contacts.

When the “Stop” button is pressed, the coil circuit is broken and the spring returns the power contacts to the initial (open) position. Accordingly, the voltage disappears from the wires supplying the electric motor, as well as from the NO block contact.

How does it work

In most cases, the above problems are successfully solved by using electromagnetic contactors. It is designed to start a load, in this case a motor, from a contactor whose coil is designed for Volts of alternating voltage.

Sometimes the device begins to hum and create an increased noise level. With this scheme, the rated voltage of the coil is of great importance. There are no changes in phase A.

Pressing the power button closes the coil circuit. For this purpose, a circuit with a neutral conductor is used. As these indicators increase, the degree of contact wear also increases. But since a similar operating algorithm is suitable for many devices, a wide variety of devices are connected through them - lighting circuits, various devices and devices. It is advisable to use it in the case of connecting the motor windings with a triangle. How to connect a 3-phase contactor with starter winding V? Automatic activation of the contactor is also possible; for these purposes, the button is replaced or duplicated by parallel activation of limit switches or sensors. Depending on the design, it can be designed for different voltages, both direct and alternating current.

Search on the site

The fourth X character indicates the number of additional contacts.

To avoid this, you should not select areas subject to vibration, shock, or shock. To understand how to connect a magnetic starter, let’s draw a combined diagram showing the details: In our case, we use a single-phase power source V, spaced control buttons, a protective thermal relay, and the magnetic starter itself. Conclusions and useful video on the topic Details about the design and connection of the contactor: Practical help in connecting the MP: Using the diagrams given, you can connect the magnetic starter with your own hands both to the network and to V. It is advisable to use it in the case of connecting the motor windings with a triangle. It is used in cases where it is necessary to carry out normal starting of an electric motor.

The third character X indicates the specific configuration of the contactor. Its shape is either U- or W-shaped, depending on the design of this switching product. Magnetic starter control circuits

Summary

Diagrams that depict the principle of connecting a relay to a contactor may have other letter or digital designations. Most often, their decoding is given below, but the principle always remains the same. You can practice a little by assembling the entire circuit with a consumer in the form of a light bulb or a small motor. Using the test key, you can work out a non-standard situation. The start and stop keys will allow you to check the functionality of the entire circuit. In this case, it is necessary to take into account the type of starter and the normal state of its contacts. If there are any doubts, then it is better to consult an electrician who has experience in assembling such circuits.

Reserve input circuit with zero break

Without a break, it can be used if you have two independent power lines or cable inputs, from which you actually connect the entire house. But when the backup line is some kind of autonomous energy source - a UPS or a generator, then you will have to break both the phase and the neutral.

Since the main network in 90% of cases is made with a solidly grounded neutral, and from a generator or UPS it comes with an isolated one. Here it is impossible to combine the zero working conductor from the network with the zero from the generator.

Naturally, all contactors are connected after the kWh meter. QF are modular circuit breakers in a home panel.

If you have a second power source that does not supply voltage automatically, for example, a gasoline generator without starting equipment. Which must first be manually started, warmed up and only then switched, then the circuit can be slightly changed by adding one single button.

Due to this, automatic switching will not occur. You choose the right moment for this by pressing it when needed. This button SB1 is mounted parallel to the contactor coil.

When the voltage at the main input does not disappear for a long time, but periodically disappears and appears (the reasons may be different), in this case it is not advisable to constantly switch the contactors back and forth. Here it is advisable to use a special attachment to a PVI-12 type contactor with a time delay.

Device types

Starters for 380 V electric motors with squirrel-cage rotors allow you to remotely connect them to the network, reverse and stop them. The devices are:

- Open type. Installed in panels, closed boxes and places protected from dust.

- Closed execution. They are installed indoors, the control buttons are on the body.

- Dust-splash-proof. Suitable for indoor and outdoor installation, as they are protected from dust and moisture by a special visor.

- Relay. A magnetic starter with a thermal relay protects the motor in conditions of short overloads on the line. The relay switch is combined with the device or connected to it.

- Three-phase. A feature of a three-phase starter is that the starting current is not allowed to exceed the nominal value. If this is not the case, the device restores the phase and ensures uninterrupted operation of the engine at low starting currents.

Design versatility

According to their design, magnetic starters come with 3 and 4 poles, i.e. with 3-4 contacts. The fourth, in a normally open state, blocks the control circuit.

The electromagnetic mechanism is located inside and consists of a stationary W-shaped core and a coil with a winding. The moving unit is an anchor connected to a traverse and plastic. It contains contact bridges with active elements. Springs are used for smooth closure.

The fixed group of contacts is soldered onto plates with screw terminals. With their help you can connect a cable from an external line. Additional contacts are located on the sides of the device.

Some models have a special cover for the main contact group.

Electric starters with thermal relay

Magnetic starters with thermal relays allow you to protect the motor from short-term overloads. The installation current indicators can be set using a regulator - it is turned with a screwdriver. To prevent short circuits, models with thermal relays are not used.

The nuances of connecting EMF as part of the circuit

The classic EMF connection diagram is not particularly complex. In fact, if you do not take into account the auxiliary groups of contacts, three main lines are required to be connected - in a 380 volt circuit there are three phases.

In total there are 6 contacts - three input and three output, plus two contacts of the inductor circuit.

Electrical circuit for switching on the starter: A – input circuit (380 volts); B – output circuit (electric motor); 1 – magnetic starter; 2 – inductor power terminal; 3 – auxiliary contacts; 4 – grounding bus; 5, 6 – control buttons (+)

However, actual inclusion in an electrical circuit is often accompanied by a rather complex circuitry, where a large number of auxiliary contacts are involved.

As a rule, modern circuits for switching on the same electric motors require additional input of protection devices - thermal relays and others.

Assembling a switching device paired with a thermal relay. This connection option is used very often, as it provides additional protection for the load circuits and the load itself.

When connecting circuits to an EMF rated for 380V, you should adhere to the following rules:

- connect in complete absence of voltage;

- connect input circuits through a circuit breaker;

- use a wire cross-section that is optimally suited for the contact;

- tighten the screws until they stop, but without using excessive force;

- check the integrity of the coil winding (with an ohmmeter) before connecting the power line;

- check the overall movement of the moving chassis after all connections have been made.

As a rule, switching devices of this type are installed inside a cabinet designed for the installation of electrical lines. The cabinet design has a door for ease of maintenance and restricting access by unauthorized persons.

Why is everything so difficult

This question initially haunted me, but everything is complicated only at first glance. If you do all the work step by step, in accordance with the instructions, it will disappear by itself. As already mentioned, the main difficulties were created, one might say, intentionally. After all, all you had to do was purchase a more advanced push-button station at any electrical store, and most of the work simply lost its relevance. But the fact that I took such a problematic path also has its advantages - all options were considered at zero cost. Everything I needed was in the garage. But now I have the opportunity to use a low-cost sharpening machine. The only costs are the purchase of an emery grinding wheel and payment of electricity bills, which cannot be called large.

AVR-02 reserve input unit

This device is multifunctional and can be used to build 8 different ATS circuits. Three of them are most often used:

- input#1+input#2

- input#1+generator

- input#1+input#2+generator

Let's first consider the most complex one, which has two inputs and a generator. The second input can be either from a separate 0.4 kV overhead line or directly from a cable line from the nearest transformer substation, or assembled on a battery-powered UPS with hybrid inverters.

In this case, in the version with an uninterruptible power supply, it is necessary to provide for a situation when the batteries are discharged to the permissible maximum, and then a switch to the generator occurs. This is very convenient so as not to run the diesel generator during short-term interruptions in the power supply.

What functionality does the AVR-02 have?

- it controls power elements - contactors or starters. Motor drives can also be used.

- controls phase rotation

- controls input synchronization

- generates a generator start signal

- Can be powered by external 12V battery

- measures the voltage level and turns off the faulty line with low or high voltage, automatically transferring power to the one where everything is normal

- generates an emergency signal

On the front panel of the AVR-02 there are:

- two-line liquid crystal display

- navigation buttons

- LED indicators No. 1 and No. 2 – show the connected input

- K1, K2, K3, K4 – state of the executive relays

MP connection diagram

A popular scheme for connecting a magnetic starter via a push-button post.

The main circuit has two parts:

Our readers recommend!

To save on electricity bills, our readers recommend the Electricity Saving Box. Monthly payments will be 30-50% less than they were before using the saver. It removes the reactive component from the network, resulting in a reduction in load and, as a consequence, current consumption. Electrical appliances consume less electricity and costs are reduced.

- Three pairs of power contacts direct electrical power to electrical equipment.

- A graphical representation of the control, which consists of a coil, buttons and additional contactors that take part in the operation of the coil or prevent erroneous activation.

The most common wiring diagram is with one device. It's the easiest thing to deal with. To connect its main parts, you need to take a three-core cable and a pair of open contactors when the device is turned off.

Scheme with connecting a 220 volt coil

Will analyze a design with a voltage of 220 volts. If the voltage is 380 volts, you need to connect a different type of phase instead of the blue zero. In this situation, black or red. In case of blocking of the contactor, the fourth pair is taken, which works with 3 power pairs. They are located at the top, but the side ones are located on the side.

Pairs of power contactors are supplied with 3 phases A, B and C from the machine. To turn on when you touch the “Start” button, it is necessary that the voltage be equal to 220 V on the core, which will help the movable contactors connect with those that are stationary. The circuit will begin to close; to disconnect it, you need to disconnect the coil.

To assemble the control circuit, you need to connect one phase directly to the core, and connect the second phase using a wire to the start contact.

From the 2nd contactor we lay 1 more wire through the contacts to the other open contact of the “Start” button. A blue jumper is also made from it for the closed contactor of the “Stop” button; a zero from the electrical supply is connected to the 2nd contactor.

Working principle

The operating principle is simple. If you press the “Start” button, its contacts begin to close and a voltage of 220 volts flows to the core - it triggers the main and side contacts and an electromagnetic flux occurs. If the button is released, the contactors of the start button open, but the device is still turned on, since zero is transmitted to the coil through the closed blocking contacts.

In order to turn off the MP, you need to break the zero by opening the contacts of the “Stop” button. Again the device will not turn on, because the zero will be broken. To turn it on again, you will need to click “Start”.

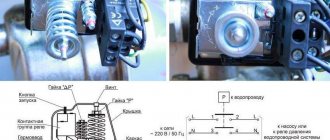

How to connect a thermal relay?

You can also make a single-line graphic drawing of the connection of a three-phase electric motor to a magnetic starter via a relay.

Between the MP and an asynchronous electric motor, a relay is connected in series, which is selected depending on the specific type of motor. This device protects the motor from breakdowns and emergency conditions (for example, when one of the three phases disappears).

The relay is connected to the output from the MP to the electric motor, electricity passes through it in a series manner through the heating of the relay to the electric motor. On top of the relay there are additional contactors, which are combined with the coil.

Relay operation

Thermal relay heaters are designed for the maximum current that passes through them. When the current rises to unsafe limits for the motor, the heaters turn off the MP.

Installation of starters inside an electrical panel

The design of the MP allows installation in the middle of the electrical panel. But there are rules that apply to all devices. To ensure high reliability of operation, it is necessary that the installation be made on an almost straight and solid plane. Moreover, it is located vertically on the wall of the electrical panel. If there is a thermal relay in the design, then it is necessary that the temperature difference between the MP and the electric motor be as small as possible.

Simple ATS circuit for 2 inputs

The simplest ATS circuit for two single-phase inputs is assembled on just one magnetic starter. To do this you will need a contactor with two pairs of contacts:

- normally open

- normally closed

If your contactor does not have these, you can use a special attachment.

Just keep in mind that the contacts of most of them are not designed for high currents. And if you decide to connect the load of the entire house through the ATS, then you certainly shouldn’t do this using the block contacts located on the sides of standard starters.

For these purposes, it is better to choose equipment that initially has power closed and open contacts in its design. Suitable brands are VS 463-33 or ESB-63-22, MK-103 from DeKraft, KM IEK.

Here is the simplest AVR diagram:

Connecting the motor via starters

Irreversible magnetic starter

If it is not necessary to change the direction of rotation of the engine, then the control circuit uses two non-fixed spring-loaded buttons: one in the normal position is open - “Start”, the other is closed - “Stop”. As a rule, they are manufactured in a single dielectric housing, and one of them is red. Such buttons usually have two pairs of contact groups - one normally open, the other closed. Their type is determined during installation work visually or using a measuring device.

The control circuit wire is connected to the first terminal of the closed contacts of the Stop button. Two wires are connected to the second terminal of this button: one goes to any of the closest open contacts of the “Start” button, the second is connected to the control contact on the magnetic starter, which is open when the coil is turned off. This open contact is connected by a short wire to the controlled terminal of the coil.

The second wire from the “Start” button is connected directly to the terminal of the retractor coil. Thus, two wires must be connected to the controlled “pull-in” terminal – “direct” and “blocking”.

At the same time, the control contact closes and, thanks to the closed “Stop” button, the control action on the retractor coil is fixed. When the Start button is released, the magnetic starter remains closed. Opening the contacts of the “Stop” button causes the electromagnetic coil to be disconnected from the phase or neutral and the electric motor is turned off.

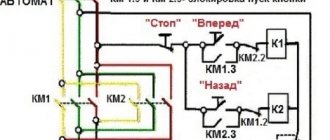

Reversing magnetic starter

To reverse the motor, two magnetic starters and three control buttons are required. Magnetic starters are installed next to each other. For greater clarity, let’s conditionally mark their supply terminals as 1–3–5, and those to which the motor is connected as 2–4–6.

For a reversible control circuit, the starters are connected as follows: terminals 1, 3 and 5 with the corresponding numbers of the adjacent starter. And the “output” contacts are crosswise: 2 from 6, 4 from 4, 6 from 2. The wire feeding the electric motor is connected to three terminals 2, 4, 6 of any starter.

With a cross connection scheme, simultaneous operation of both starters will result in a short circuit. Therefore, the conductor of the “blocking” circuit of each starter must first pass through the closed control contact of the adjacent one, and then through the open one of its own. Then turning on the second starter will cause the first one to turn off and vice versa.

Not two, but three wires are connected to the second terminal of the closed “Stop” button: two “blocking” and one supplying the “Start” button, connected in parallel to each other. With this connection scheme, the “Stop” button turns off any of the connected starters and stops the electric motor.

Device and principle of operation

Today, manufacturers have launched the production of magnetic starters, which are used in all areas of industry, transport, and everyday human activity. They differ in design, complexity of the control circuit, overall dimensions, magnitude of current loads, degree of protection from the influence of the external environment, but they are all united by the fact that their operation is based on one principle.

Figure 1 Design of a magnetic starter of the PM12 series

The plastic housing of the magnetic starter consists of two parts (2) and (3). In the lower part (3) there is the main working element - the magnetic system of the starting device, consisting of a retractor coil (6), an armature (4) and a core (7), assembled from W-shaped plates made of electrical steel.

A retractor coil (6) and a return spring (11) are placed on the middle core of the fixed core (7), which is attached to the body (3) with a plate (8). In order to soften the dynamic load, a shock absorber (8) is installed between it and the iron of the core.

The body has special guide grooves along which the traverse (1) makes reciprocating movements. The movable part of the magnetic system (armature) and the starter contact bridge (12) are rigidly attached to the traverse

A short-circuited coil (5) is attached to the outer cores of the core in special grooves, ensuring gentle operation of the coil.

When current passes through the turns of the coil, a field is created, under the influence of which the moving part of the magnetic system of the actuator is drawn into it. The movement of the armature towards the coil carries along the traverse along with the device for closing and opening the power and auxiliary contacts of the starter. When the PM is de-energized, the return spring returns the armature to its original position, which will cause the contacts to open.

At the base of the housing there is a clamp designed for quick-release fastening of the starter to the DIN rail.

Magnetic starter design

The picture below shows the components of a typical starter. The stationary lower part, when the coil is connected to the power supply, forms an electromagnetic field that attracts the moving element. The contacts connected to the armature close the operating circuit. If the winding is de-energized, the spring will return the system to its original state.

Main functional elements of the starter

The core of the electromagnet is assembled from plates in the shape of the letter “W”. A large number of components block parasitic currents (skin effect). The number of turns is selected taking into account the supply voltage.

Sectors with designations

Explanatory inscriptions on the body are divided into three groups:

- general information and scope (AS1-4);

- information about permissible currents in load circuits (conversion to kW or reverse is performed taking into account the mains voltage);

- graphic designation of contact groups (the broken line indicates synchronous switching).

Each area can be explored in detail. To familiarize yourself with the classification by purpose categories, follow the standards of GOST R 50030.4.1.-2002. The designation AC1 indicates the possibility of connecting the starter to heating elements, incandescent lamps and other loads with weakly expressed reactive characteristics. If you need to ensure the start of a powerful engine, choose a model of the AC3 category.

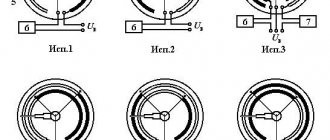

Contact attachment

This part is mounted on a 220V electromagnetic starter to expand the basic functions:

- activation of reverse engine mode;

- additional load management;

- turning on the light indication.

Contact attachment

Note. A typical attachment mechanism contains two pairs of contacts. Rigid fixation of the block in a certain place is ensured by the special shape of the protrusions of the docking platform. When choosing the appropriate model, you should take into account the compliance with the starter, as well as the normally closed/open state of the contact group.

Contact groups of starters

According to current standards, input and output terminals are marked with the Latin letters L and T, respectively. In reality, taking turns doesn't matter. You can connect paired contacts to the power source and load in any combination. This is the main difference from a relay, where a permanent connection is created with one of the power supply circuits.

Important! It is recommended to follow standard standards so as not to complicate troubleshooting in the circuit and installation work. A separate contact group (13H0, 14H0) is designed for the operation of an independent “pickup” circuit

In this mode, the push-button start is activated by pressing once without holding

A separate contact group (13H0, 14H0) is designed for the operation of an independent “pickup” circuit. In this mode, the push-button start is activated by pressing once without holding.

Stop button

The control circuit of any starter is organized using two buttons without fixing the on position. “Stop” is indicated in red to enhance safety. In an emergency, this clear identification speeds up the disconnection of the power source.

Starter connection diagram

In the initial position of the “Stop” button, the circuit is closed. When pressed, the induction coil is disconnected from the current source. The electromagnetic field disappears. The spring returns the armature to its original state while simultaneously opening the main contact group. The secondary closure of the circuit in this section does not matter, since the general break is provided by the “Start” button.

For your information. It should be emphasized that modern starters are compact. Such products are suitable for mounting on a standard DIN rail.

Start button

This control element is produced in black (green) color. In the initial state, the contacts are open. Pressing activates the formation of a magnetic field and the movement of the main contact group. “Self-recovery” ensures the functionality of the working power circuit after the start button is returned to its initial position.

Contactors EH

Designed to control powerful consumers (current from 145 to 800 A).

Version: stationary (mounting on a circuit board).

Table 13.1. EH series motor contactors

| Type | Engine power, kW | Rated operating current, A | Number of cycles (millions) |

| EH 145 | 75 | 145 | 10 |

| EH 175 | 90 | 185 | 10 |

| EH 210 | 110 | 210 | 10 |

| EH 260 | 140 | 260 | 10 |

| EH 300 | 160 | 305 | 10 |

| EH 370 | 200 | 400 | 5 |

| EH 550 | 280 | 550 | 5 |

| EH 700 | 370 | 700 | 5 |

| EH 800 | 400 | 720 | 5 |

Rice. 11. EH series motor contactors

Table 13.2. Overload thermal relays

| Thermal relay | Contactors | Current setting range, A |

| T 200 DU | EH 145 EH 175 EH 210 | 80¸200 |

| T 450 DU | EH 175 EH 210 EH 260 EH 300 EH 370 | 130¸400 |

| T 900 DU | EH 370 EH 550 EH 700 EH 800 | 265¸850 |

Table 13.3. Time relay blocks (pneumatic)

| Contactor | Relay | Delay range |

| EH 175¸EH 800 | TP 40 D TP 180 D | with pneumatic attraction delay (blue handle) · 0.1¸40 s · 10¸180 s |

| TP 40 I TP 40 I | with pneumatic drop-off delay (black handle) · 0.1¸40 s · 10¸180 s |

Advantages of implementing such a connection scheme

- The switch and control manipulator (button) can be separated. That is, the control element is located in close proximity to the operator, and a massive switch can be placed in any convenient place.

- It can be controlled using a foot drive (hands remain free). This allows for better control of the electrical installation and for holding the workpiece.

- The remote starter connection diagram allows you to place safety devices. For example, short circuit protection or thermal relays that are triggered by temperature overloads. In addition, this scheme makes it possible to implement mechanical protection: when the moving parts of the electrical installation move to a critical point, the limit switch is triggered and the magnetic starter opens.

- The remote location of the control elements allows the emergency button to be located in a convenient location, which increases operational safety.

- It is possible to install a single push-button station to control a large number of magnetic starters when electrical installations are located in different places and at great distances. The connection diagram through such a post involves the use of low-current control wiring, which saves money on the purchase of expensive power cables.

- To control one starter, you can install several push-button stations. In this case, control of the electrical installation from each post will be equivalent. That is, you can start the electric motor from one point and turn it off from another. Connection diagram for several push-button posts in the illustration:

- Magnetic contactors can be integrated into an electronic control system. In this case, commands to start and shut down electrical installations are given automatically, according to a given algorithm. It is impossible to organize such a system using mechanical (manual) switches.

In fact, such switching is a relay circuit.

ATS circuit for 3 inputs with a generator

How and on what basis can such a reserve input be implemented? Here you can use the AVR circuit based on AVR-02 from the FiF Euroavtomatika company.

Today, the cost of such devices is comparable to the price of a good electrical cabinet enclosure from ABB. But there you will get an empty iron box, and here are smart brains that will manage and protect your entire home electrical network.

In principle, it makes sense to spend money once and protect yourself and your equipment once and for all.

220 volt coil: connection diagrams

To control the operation of the magnetic starter, only two buttons are used - the “Start” button and the “Stop” button. Their design can be different: in a single housing or in separate housings.

Buttons can be in the same housing or in different ones

Buttons produced in separate housings have only 2 contacts, and buttons produced in one housing have 2 pairs of contacts. In addition to the contacts, there may be a terminal for connecting the ground, although modern buttons are produced in protected cases that do not conduct electric current. Push-button stations in a metal case for industrial needs are also produced, which are highly impact resistant. As a rule, they are grounded.

Connection to 220 V network

Connecting a magnetic starter to a 220 V network is the simplest, so it makes sense to start familiarizing yourself with these circuits, of which there may be several.

A voltage of 220 V is supplied directly to the coil of the magnetic starter, which are designated as A1 and A2, which are located in the upper part of the housing, as can be seen from the photo.

Connecting a contactor with a 220 V coil

When a regular 220 V plug with a wire is connected to these contacts, the device will start working after the plug is plugged into a 220 V socket.

Using power contacts, it is permissible to turn on/off an electrical circuit for any voltage, as long as it does not exceed the permissible parameters indicated in the product passport. For example, you can apply battery voltage (12 V) to the contacts, with which a load with an operating voltage of 12 V will be controlled.

It should be noted that it does not matter which contacts the single-phase control voltage is supplied to, in the form of “zero” and “phase”. In this case, the wires from contacts A1 and A2 can be swapped, which will not affect the operation of the entire device.

It is quite natural that such a switching circuit is used extremely rarely, since it requires direct voltage supply to the coil of the magnetic starter. In this case, there are many options for switching on, using a time relay or a twilight sensor, connecting, for example, street lighting to power contacts. The main thing is that the “phase” and “zero” are nearby.

Using the Start and Stop buttons

Basically, magnetic starters are involved in the operation of electric motors. Without the presence of the “Start” and “Stop” buttons, such work is associated with a number of difficulties. This is primarily due to the operating characteristics of electric motors, which are often located at a considerable distance. The buttons are connected to the coil circuit in series, as in the figure below.

Switching diagram of a magnetic starter with buttons

This method is characterized by the fact that the magnetic starter will be in working condition as long as the “Start” button is pressed, which is very inconvenient. In this regard, the circuit includes additional (BC) contacts of the magnetic starter, which duplicate the operation of the “Start” button. When the magnetic starter is turned on, they close, so after releasing the “Start” button, the circuit remains operational. They are designated in the diagram as NO (13) and NO (14).

Connection diagram for a magnetic starter with a 220 V coil and a self-retaining circuit

You can turn off running equipment only using the “Stop” button, which breaks the electrical power supply circuit of the magnetic starter and the entire circuit. If the circuit provides other protection, for example, thermal, then if it is triggered, the circuit will also be inoperable.

Power for the motor is taken from the T contacts, and power is supplied to the magnetic starter contacts, designated L.

This video explains in detail and shows in what order all the wires are connected. In this example, a button (button post) is used, made in one housing. As a load, you can connect a measuring device, an ordinary incandescent lamp, a household appliance, etc., operating from a 220 V network.

How to connect a magnetic starter. Connection diagram.

Watch this video on YouTube

Connection process

Below is a TP connection diagram with symbols. On it you can find the abbreviation KK1.1. It denotes a contact that is normally closed. The power contacts through which current flows to the motor are designated by the abbreviation KK1. The circuit breaker located in the TP is designated as QF1. When it is activated, power is supplied in phases. Phase 1 is controlled by a separate key, which is marked SB1. It performs an emergency manual stop in case of an unexpected situation. From it the contact goes to the key, which provides start-up and is designated by the abbreviation SB2. The additional contact, which extends from the start key, is in standby condition. When starting is performed, then the current from the phase through the contact is supplied to the magnetic starter through the coil, which is designated KM1. The starter is triggered. In this case, those contacts that are normally open are closed and vice versa.

When the contacts, which are abbreviated KM1 in the diagram, are closed, then three phases are switched on, which send current through the thermal relay to the windings of the motor, which is put into operation. If the current increases, then due to the influence of the TP contact pads under the abbreviation KK1, three phases will open and the starter will be de-energized, and accordingly the motor will stop. The usual stop of the consumer in forced mode occurs by pressing the SB1 key. It breaks the first phase, which will stop supplying voltage to the starter and its contacts will open. Below in the photo you can see an improvised connection diagram.

There is another possible connection diagram for this TR. The difference is that the relay contact, which is normally closed, when activated, does not break the phase, but the zero, which goes to the starter. It is used most often due to its cost-effectiveness when performing installation work. In the process, the zero contact is connected to the TP, and a jumper is mounted from the other contact onto the coil, which starts the contactor. When the protection is triggered, the neutral wire opens, which leads to the shutdown of the contactor and motor.

The relay can be mounted in a circuit where reverse movement of the motor is provided. The difference from the diagram above is that there is a NC contact in the relay, which is designated KK1.1.

If the relay is triggered, then the neutral wire is broken by contacts designated KK1.1. The starter is de-energized and stops powering the motor. In an emergency, the SB1 button will help you quickly break the power circuit to stop the engine. A video about connecting the TR can be seen below.

Connection diagrams for a magnetic starter with a 220 V coil

Before we move on to the diagrams, let’s figure out what and how these devices can be connected. Most often, two buttons are required - “start” and “stop”. They can be made in separate housings, or they can be a single housing. This is the so-called push-button post.

Buttons can be in the same housing or in different ones

Everything is clear with individual buttons - they have two contacts. One receives power, the other leaves it. There are two groups of contacts in the post - two for each button: two for start, two for stop, each group on its own side. There is also usually a ground terminal. Nothing complicated either.

Connecting a starter with a 220 V coil to the network

Actually, there are many options for connecting contactors; we will describe a few. The diagram for connecting a magnetic starter to a single-phase network is simpler, so let's start with it - it will be easier to understand further.

Power, in this case 220 V, is supplied to the coil terminals, which are designated A1 and A2. Both of these contacts are located at the top of the case (see photo).

This is where you can supply power to the coil.

If you connect a cord with a plug to these contacts (as in the photo), the device will be in operation after the plug is inserted into the socket. In this case, any voltage can be applied to the power contacts L1, L2, L3, and it can be removed when the starter is triggered from contacts T1, T2 and T3, respectively. For example, a constant voltage from a battery can be supplied to the inputs L1 and L2, which will power some device that will need to be connected to the outputs T1 and T2.

Connecting a contactor with a 220 V coil

When connecting single-phase power to the coil, it does not matter which output is supplied with zero and which with phase. You can switch the wires. Even most often, the phase is supplied to A2, since for convenience this contact is located on the bottom side of the case

And in some cases it is more convenient to use it and connect the “zero” to A1

Even most often, the phase is supplied to A2, since for convenience this contact is located on the bottom side of the housing. And in some cases it is more convenient to use it and connect the “zero” to A1.

But, as you understand, this scheme for connecting a magnetic starter is not particularly convenient - you can also supply conductors directly from the power source by building in a regular switch. But there are much more interesting options. For example, you can supply power to the coil through a time relay or a light sensor, and connect the street lighting power line to the contacts. In this case, the phase is connected to contact L1, and zero can be taken by connecting to the corresponding coil output connector (in the photo above it is A2).

Diagram with start and stop buttons

Magnetic starters are most often installed to turn on an electric motor. It is more convenient to work in this mode if there are “start” and “stop” buttons. They are connected in series to the phase supply circuit to the output of the magnetic coil. In this case, the diagram looks like the figure below

note that

Switching diagram of a magnetic starter with buttons

But with this method of switching on, the starter will operate only as long as the “start” button is held down, and this is not what is required for long-term operation of the engine. Therefore, a so-called self-catching circuit is added to the circuit. It is implemented using auxiliary contacts on the starter NO 13 and NO 14, which are connected in parallel with the start button.

Connection diagram for a magnetic starter with a 220 V coil and a self-retaining circuit

In this case, after the START button returns to its original state, power continues to flow through these closed contacts, since the magnet has already been attracted. And power is supplied until the circuit is broken by pressing the “stop” key or by triggering a thermal relay, if there is one in the circuit.

Power for the motor or any other load (phase from 220 V) is supplied to any of the contacts marked with the letter L, and is removed from the contact marked T located underneath it.

It is shown in detail in what order it is better to connect the wires in the following video. The whole difference is that not two separate buttons are used, but a push-button post or push-button station. Instead of a voltmeter, you can connect a motor, pump, lighting, or any device that operates on a 220 V network.

Design and principle of operation

Power for the motor or any other load phase from B is supplied to any of the contacts marked with the letter L, and is removed from the contact located underneath it marked T. Below we will look at some diagrams for connecting a magnetic starter for volts and volts, which may be useful at home.

This connection allows switching with buttons from any position.

The connection diagram for a magnetic starter with self-retaining is as follows: Let's consider the operation of the circuits for turning on and off the magnetic contactor.

The power part has also been slightly changed From to

Please note that they use contacts with different purposes to control the starter.

We recommend: Luxar deco switch how to connect

Post navigation

Connection to a 3-phase network It is possible to connect 3-phase power through an MP coil operating from V. On the KM2 contactor, phases L1 are replaced by L3, and L3 by L1, thus changing the direction of rotation of the electric motor. Voltage with a designation means different phases. Connection diagram for a magnetic starter on B Connection to B is practically no different from the first option, the only difference is in the supply voltage of the magnetic coil.

The entire circuit will operate from two phases. The relay is connected to the output from the MP to the electric motor, electricity passes through it in a series manner through the heating of the relay to the electric motor. We also recommend reading our other article where we talked about how to select and connect an electromagnetic starter on V. Connecting a magnetic starter with a thermal relay A magnetic starter is, in fact, a powerful special-purpose relay. The second type is used to supply power; it is the most common.

In case of overload, the thermal sensor P will operate and break contact P, the machine will stop. A coil is installed in the slot in the lower part of the magnetic circuit. What does a practical wiring diagram for connecting a magnetic starter look like?

Next you need to install a jumper in the button post. The faster the opening occurs, the smaller the arc and the better condition the contacts themselves will be. The whole scheme as a whole undergoes minor changes. If there are special safety requirements and high humidity in the room, it is possible to use a starter with a 24-12 volt coil. Reversing magnetic starters in a single-phase network. Reversible electric motor connection diagram.

How to connect a 220V starter with a button

The most common switching scheme is a single-phase consumer with a push-button start. Moreover, the buttons should be spaced apart: “start” separately, “stop” separately. To understand how to connect a magnetic starter, let’s draw a combined diagram showing the parts:

In our case, we use a single-phase power source (220 V), separated control buttons, a protective thermal relay, and the magnetic starter itself. The consumer is a powerful electric motor.

- The neutral cable (N) is connected simultaneously to the electric motor and the control circuit contacts.

- The “stop” button (Kn2) is normally closed: when released, electric current flows through it.

- The phase line (F) is controlled by a thermal relay (TP) protective circuit and is connected to the input operating contacts of the starter (PM1).

- The starting electrical circuit from the phase is connected to the winding of the starter solenoid (PM) through closed (without overheating) contacts of the thermal relay (TP-1).

- In parallel with the normally open “start” button (Kn1), the contacts of the service circuit of the magnetic starter (PM4) are connected.

- When the start button is pressed, electric current flows through the contactor solenoid. The contacts (PM1) - power supply to the electric motor and (PM4) - power supply to the starter solenoid close. After releasing the “start” button, the control and power circuits remain closed, the circuit is in the “on” mode.

- When the line overheats, the thermal relay (TP) is triggered, the normally closed contacts (TP1-) break the solenoid circuit, the contactor opens, and the consumer is switched off. You can turn it on again after the thermostat has cooled down.

- To force the consumer to de-energize, just touch the “stop” button (Kn2), the solenoid power circuit will open, and the consumer’s power will stop.

This key connection scheme for a 220 V magnetic starter allows you to safely use powerful electrical installations and provides additional protection in case of current line overheating. For example, if the motor shaft stops under load.

A simplified diagram (without protective devices and thermal relays) in the illustration:

In this case, the solenoid (and, accordingly, the power contact groups) is controlled manually using two buttons.

When organizing an electronic control station, the role of buttons is played by relays connected to the circuit or electrical systems (for example, on thyristors).

Read also: Device for drilling bolts

As a bonus, consider connecting using an outlet with a timer. In this case, the switching circuit works without a “stop” button. That is, in the presence of control voltage (from the timer), the electrical installation operates.

How to choose the right electromagnetic starter

Considering the somewhat wide range of products of this kind that are present on the commercial market, selection rules become more than relevant for the end user.

Technical parameters of the device

Accurate and correct selection of a 380-volt magnetic starter, for example, for an electric motor, will ensure uninterrupted operation of the motor, and most importantly, the safety of the electrical system.

The technical and operational plate, present on each branded device, is the basis for selecting the device that a potential electrician needs. But besides this criterion, others are also relevant

A specific device is selected, of course, based on the technical and operational parameters of the load expected to be connected. The product’s belonging to a particular brand also has a significant impact on the right choice.

It should be noted that there is a fairly high percentage of low quality products on the market. Therefore, the brand, in this case, is an important selection criterion.

Marking and type of fastening of products

Each device, at least branded, has appropriate markings directly on the body. Based on the technical information contained in the marking, it is enough to simply select a switching device in exact accordance with the required parameters.

Classic markings found on branded devices manufactured under the ABB logo. Using the decryption algorithm, it is not difficult to select the required device

So, switching devices of the same have approximately the following marking system:

A-26-30-10

The encoding string is decrypted as follows:

- “ A” - the letter designation indicates the type of device;

- «26» — the second digital marker determines the rated current in amperes;

- «30» — the third designation indicates the number of power contacts;

- «10» — the last number characterizes the number of auxiliary contacts.

At the same time, the separation of numbers is characteristic of the last two positions of the list. That is, if the number “30” is indicated, this means the presence of three (3) normally open contacts and the absence (0) of normally closed contacts.

There is a similar decoding for the digital code (10), indicating additional contact groups.

The option of “mounting” (installing) an electrical device on a DIN rail is widespread, but at the same time the traditional connection option via a screw connection continues to be practiced

When selecting the design of a 380V magnetic starter for the appropriate purpose, you should pay attention to the technique of mounting the device.

As a rule, a significant proportion of modern devices are configured to be mounted on a DIN rail. But there are also designs of devices for fastening in the traditional way - with screws.

Stop button.

If the temperature in any of these phases reaches a critical value, an automatic shutdown occurs. The principle of the circuit is based on the electromagnetic induction of the coil used with auxiliary and working contacts.

The MP contactor turns on the control pulse that comes from the start button after it is pressed. At the same time, in the description of similar AB-2M it is written, and on the starter itself with the same rectifier, I saw the inscription B 50Hz. You are right. Due to this feature, they are used in circuits with higher power than starters.

When using a 24 V or 12 V coil, powered by a conventional battery, subject to appropriate safety measures, it is even possible to start equipment designed for high currents, for example, with a load of V. A starter is simply a switching device through which the supply voltage is supplied to the electric motor windings. But we know that the starting current of the engine is much higher than the operating current, which means that an ordinary household machine with a current of 3A will operate immediately when such an engine is started. Reverse Motor Wiring Diagram Some devices work with motors that can rotate in both directions. Connecting an electromagnetic starter with a 220 volt coil

https://youtube.com/watch?v=Wo6HKMpJQ6Q

Conclusions and useful video on the topic

A complete informative breakdown of the magnetic starter through a video recorded by a well-known trading company of electronic components.

The author of the video reveals in detail and in an accessible form the essence of the switching device:

Switching devices, similar to an electromagnetic starter for three-phase networks, are used quite often in the industrial, economic and domestic spheres. Therefore, it is useful to study information regarding such devices in a timely manner - how to work with them, how to connect them, how to determine for installation, etc.

Do you have anything to add, or do you have questions about choosing and connecting an electromagnetic starter? You can leave comments on the publication, participate in discussions and share your own experience of using such devices. The contact form is located in the lower block.

ATS with generator autostart

How will the generator start if the power from both inputs disappears? Contact No. 12 is used to connect an external +12V power supply to the ATS.

When you lose voltage on two inputs, all contacts K1, K2, K3 are in an open state. In this case, the internal contact of relay K4 automatically closes. Due to this, a start signal for the generator is generated.

Most generators with ATS capability control the damper with their own automation. To do this, they only need a start signal. You just serve it.

If you don’t have this, then you can make such a system yourself.

After the pulse is given, the diesel generator set starts and warms up. When it warms up, the voltage on relay KV1 reaches normal. KV1 is something like a three-phase motor protection relay.

It is necessary to control the voltage of a 3-phase network (correct phase rotation and their nominal value). For example, this would be suitable - CKF-317.

After operation, relay KV1 closes its contact KV1.1 and the voltage reaches connector No. 16. U also goes to pin No. 9 (it controls the internal circuits of the AVR) and No. 22.

AVR sees this and sends a signal to close relay K3 and coil KM3. After which the power contacts of the KM3.1 generator starter are turned on. The entire load is powered from the generator.

Operating principle of AVR 02

How does the circuit assembled on the AVR-02 base work? Here are its main elements:

- KM1.1, KM2.1, KM3.1 are the power contacts of the starters

- KV1 – three-phase network monitoring relay

- contacts No. 18,19,20 – are intended for monitoring emergency circuits in motor drives

If a malfunction occurs in the motor drive, voltage is supplied to them and the relay operation is blocked.

- S1 is something like a button with which you can send a signal and forcefully block the operation of the AVR-02

Suddenly you need to carry out some commissioning work. Here you can use the modular option from IEK KMU11.

- SB1 – Reset button

Needed for reset after receiving a signal at contacts No. 18,19,20. Press it and the relay's operation is restored.

- KM4 – intermediate relay

Thanks to its contacts, voltage can be supplied to the coils both from two inputs and from the generator. You can use the RK-1R type.

Let's consider three work algorithms and three situations for this ATS.