The gears of any gearbox are subject to intense wear, so manual transmission lubrication can increase the service life and reduce maintenance costs. Transmission oils are classified by several specifications and do not have the same markings and composition, so the user must have at least minimal information about lubrication of a manual transmission.

Manual transmission oil

The gearbox is the largest gearbox in a car transmission. Thanks to a stepwise change in the gear ratio, the driver has the opportunity to combine two ranges - wheel speed in the range of 50 - 1500 min-1 and engine crankshaft speed 800 - 8000 min-1. Depending on the type of transmission, the gears of the gearbox are lubricated in the following ways:

- cylindrical - oil bath with immersion of low-speed wheels to a third of the diameter, high-speed wheels to a depth of h = 5m;

- bevel - crankcase lubrication with the entire lower tooth of the gear immersed in oil;

- planetary - the high-speed stage is immersed in an oil bath to the entire depth of the inner tooth.

Spur gear box

Planetary gearbox

The drain hole must have a diameter greater than 20 mm, and the slope of the crankcase bottom must be within 3 degrees. The filler plug is usually located at the level of the oil bath mirror, which makes it possible to do without a dipstick.

Manual transmission drain hole

Information about what kind of oil to pour into a manual gearbox is relevant when repairing components and assemblies associated with the gearbox (for example, replacing the clutch) when the life of the lubricant itself is exhausted.

Transmission filler hole

The gearbox traditionally belongs to units with high operating loads. In addition, passenger car manufacturers use different gear designs in different car models, so the frequency of oil changes in manual transmissions is required in the manual.

The user should note that changing the oil in a manual transmission has nuances:

- with a minimum maintenance budget (filling with mineral oil), operating costs will increase as the lubricant life will decrease;

- when purchasing expensive synthetics, on the contrary, the initial investment will increase, but the service life of such oil is longer and the replacement frequency is greater than in the previous case;

- Semi-synthetics have a rational ratio of lubricant quality and cost.

Mineral oil

Synthetic oil

Semi-synthetic oil

There are winter, all-season and summer oils that allow you to select a lubricant for different operating conditions.

Thus, oil in a manual transmission solves several problems simultaneously:

- lubrication and reduction of friction of gears;

- heat removal from friction pairs;

- removal of metal filings from the surfaces of wear parts of the gearbox;

- protection of gears and gears from oxidation and corrosion.

The cost of 3 liters of gear lubricant is significantly lower than replacing a manual transmission or breaking a gear while driving.

Manual transmission operating modes

Due to operating conditions, the car's gearbox must provide 1 - 2 lower gears, reverse speed and several higher gears. Large ratios (5/1 – 3.5/1) are used in lower gears. At the same time, the transmission of an SUV reaches a power range of 9 units, while in passenger cars it is limited to 6 units. The traction force in lower gears is maximum, but the car cannot reach high speed.

Low gear

The gear ratios of the middle gears are in the range of 2.5/1 – 1.5/1. Engine noise is reduced at the same speeds. These gears are considered “short” and greatly tire the driver, as they require frequent switching in changing driving conditions.

Middle gear

Higher gears reach a gear ratio close to 1/1, that is, the shafts rotate at the same angular speeds. This is convenient on the highway when driving at a constantly high vehicle speed.

Top gear

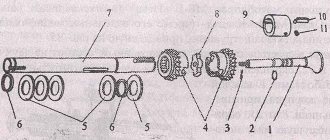

Classic gearboxes usually use 3 shafts - primary, intermediate and secondary. The gear units have helical gears to reduce noise. In addition to gears, the box contains synchronizers, cams and clutches.

For gearboxes with old-style synchronizers, budget manual gearbox oil marked GL-4 is used. For most modern cars, manufacturers specify hypoid oil GL-5.

Gearbox with synchronizer

Attention: An attempt to improve the quality of the lubricant in the gearbox of a domestic VAZ with high mileage will lead to the exact opposite effect - the operation of the synchronizers will be disrupted, since the films from these transmission lubricants have different properties.

The oil should be changed either at a service station, whose employees do not make such mistakes, or you should adhere to the requirements specified in the machine’s operating manual.

Transmission lubricant is considered a consumable material; after a certain mileage, its components begin to deteriorate, and metal shavings and foreign impurities accumulate inside, and the modifying additives decompose. That is why changing the oil in a manual transmission must be timely and technically competent.

Methods

In modern mechanisms, the following methods of cooling the gearbox are used.

- Water cooling is a constructive design solution (artificial water cooling). Used in special gear mechanisms in 1 of 2 options.

- In the first case, perforation of the body is provided (the installation of several channels through which water is supplied).

- In the second, water cooling is carried out using a coil (installed in the crankcase block filled with lubricant).

- Air cooled gearbox. May be artificial or natural.

- With artificial air cooling, a fan impeller (centrifugal) is installed on the worm. Fastening is carried out through the casing in which the impeller is placed. In this case, the body ribs should run along the axis of the box. Artificial air cooling is important to ensure the operation of powerful dimensional gearboxes.

- The self-venting air cooling system is based on the use of aluminum boxes with vertical ribs. This approach is good for lightweight, small-sized devices.

Selecting a lubricant for a manual transmission

According to the international API system, developed by the American Petroleum Institute, manual transmission oil is marked with the letters GL. Of the six existing classes, only GL-3 and GL-4 modifications are used in manual transmissions. However, gearboxes with hypoid gears use GL-5 oil.

| Designation | Compound | Purpose |

| GL-1 | no extreme pressure additives, only base oil | transmissions without synchronizers |

| GL-2 | anti-wear modifiers | not suitable for gearboxes |

| GL-3 | 2.7% anti-wear additives | for MPP with spiral bevel gears |

| GL-4 | 4% extreme pressure modifiers | for manual transmission with synchronizers |

| GL-5 | 6.5 additives, including extreme pressure | for boxes without synchronizers |

| GL-6 | more than 7% sulfurphosphorus-containing additives | only for hypoid gears |

In the domestic GOST standard, transmission oils are designated TM. The marking uses two numbers separated by a hyphen:

- first – viscosity class;

- the second is a group for deciphering operational properties from the table below.

Viscosity class according to GOST

Operating group of oils according to GOST

TM-3 – TM-5 is poured into mechanical boxes for temperature conditions within 150 degrees.

In addition, the gear lubricant has a viscosity classification according to SAE, developed by the American Society of Engineers. There are seven classes in the SAE system:

- four winter ones marked W;

- three summer ones without markings;

- several all-season with double markings.

SAE oil classification

For example, multi-grade gear oil for manual transmissions marked 75W90 simultaneously has the characteristics of a 75W winter gear lubricant and a 90 summer gear lubricant.

Leading gearbox manufacturers General Motors and Ford have additionally developed their own designations for automatic transmission lubricants. The ZF company produces lubricants marked TE-ML 1 and TE-ML 2 for passenger cars and SUVs with manual transmissions.

Despite the fact that GL-5 lubricant has better characteristics compared to GL-4 oil, it is not suitable for manual transmissions with synchronizers for a number of reasons:

- there are more sulfur-phosphorus additives here - 6.5% instead of 4%;

- synchronizers are made of copper-containing alloys;

- in the presence of sulfur, these alloys corrode.

In front-wheel drive cars, the main gear is located inside the gearbox, so the designers had to choose between scuffing the main gears and corrosion of the synchronizers, so in the manuals of cars from French manufacturers, GL-5 oil is poured into the manual transmission, while others consider the best option to be all GL-4.

Attention: Synthetic oil usually has a dual API specification, so it can be used in transmission gearboxes without the above selection problems.

Types of gearbox cooling

The type of natural and artificial cooling is selected depending on its size, performance and design features related to the installation method. There are three of them in total.

- The most common option is air cooling. This may be natural if the device design provides sufficient surface area for self-dissipation of heat. For artificial cooling, the housing is finned or the high-speed shaft is additionally equipped with a cooler (fan). With the artificial method, it is important to place the fins along the line of movement of the injected air. Cooler rotation speed – from 1000 rpm (the most efficient system operation).

- Water cooling of the gearbox is used less frequently and involves installing a coil (collector) in the block with oil, through which water circulates, and installing fins on the housing. It is important that the coil is located as close to the lubricant level as possible.

- Oil artificial cooling operates on the temperature difference between the lubricant leaving the housing and the oil entering the housing. For worm and helical gearboxes, this difference should be at least 5–8 degrees.

Frequency of lubricant replacement

Unlike the engine, the gearbox is located in a hard-to-reach place on the car, so daily monitoring of the level and color of the lubricant is impossible - no one will remove the wheel before every trip, so information on whether the oil needs to be changed should be based on the following factors:

- for manual transmissions, an operating interval of 7 years or a mileage of 100,000 km is accepted (depending on what comes first);

- for the urban cycle it is recommended to reduce these figures by 30%;

- the specified regulation - 70,000 km or 6.5 years of operation - is valid only for synthetic oil with a maximum service life;

- when using semi-synthetics, you should change the oil in the manual transmission more often - after 50,000 km;

- Mineral lubricant must be changed every 40,000 km of vehicle mileage.

Example from the Renault Kengo manual

Attention: When purchasing a new domestic passenger car, information on how to change the oil in the gearbox is relevant on the same day. Since the VAZ comes off the assembly line with mineral oil, which is better to change to semi-synthetic oil immediately.

Purpose

Crane units are a separate group of gearboxes used in production. Their main purpose is to change the rotation speed and torque elements. As a rule, it is advisable to use them either in lifting equipment when transporting goods, or as a drive in equipment for general use. Thus, the RK-500 special crane gearbox is designed to change torques and rotation speeds.

Conditions of use

- Work in intermittent mode, i.e. under variable loads with periodic stops, long-term operation with a constant load is allowed;

- Rotation of shafts in any direction;

- Load of one direction and reversible;

- The peripheral speed should not exceed 12 m/sec;

- The input shaft rotation speed should not exceed 1500 rpm;

- Atmosphere types I and II according to GOST 15150-69 with air dust content not exceeding 10 mg/m 3 ;

- Climatic versions: U, T – for accommodation categories 1-3; UHL and O - for placement category 4 according to GOST 15150-69.

Read also: Partner 360 s chainsaw carburetor malfunction

Ordering a gearbox RK

order and buy the RK-500 crane gearbox by calling: 8-800-2000-220, +7 (8412) 233-133, +7 (8412) 233-134. PTC PRIVOD LLC supplies to such regions as: Moscow, Rostov-on-Don, Voronezh, Krasnodar, Penza. For questions regarding the cost, production, modernization and repair of RK gearboxes, please contact the contact numbers.

The designation of RK gearboxes when ordering: RK-500 -50-12M-U1-48 means that the device is of the RK type, with an axial distance of 500, a nominal gear ratio of 50, assembly option 12, output shaft end version - M and climatic version U1, number of gear coupling teeth 48

Specifications

| Gear ratio | Nominal Actual | 8 8,23 | 10 10,35 | 12,5 12,64 | 16,0 15,75 | 20,0 20,49 | 22,4 23,34 | 31,5 31,50 | 40,0 41,52 | 50,0 48,57 |

| Rotation speed, rpm | Operating mode | Permissible torque on the output shaft of the gearbox, kNm | ||||||||

| RK – 500 | ||||||||||

| 600 | Extra light PV-15% PV-25% PV-40% | 51,27 29,54 25,63 21,73 | 51,88 30,28 26,86 22,74 | 54,36 32,81 28,61 24,22 | 57,38 35,16 30,52 25,88 | 58,29 32,96 28,69 24,42 | 57,77 32,13 28,03 23,58 | 59,60 35,09 30,28 25,96 | 62,87 32,35 28,08 23,80 | 64,85 33,57 29,37 24,80 |

| 750 | Extra light PV-15% PV-25% PV-40% | 48,34 25,78 22,46 19,04 | 50,66 28,81 25,02 21,24 | 53,41 30,52 33,99 31,98 | 56,64 33,99 29,49 23,44 | 57,38 31,98 27,83 23,68 | 57,42 31,72 27,62 23,52 | 60,37 33,84 29,61 25,00 | 62,01 32,23 27,83 23,68 | 64,70 35,57 28,99 24,27 |

| 1000 | Extra light PV-15% PV-25% PV-40% | 51,50 27,01 23,46 19,91 | 54,20 28,27 24,61 20,95 | 55,85 29,66 25,82 21,97 | 55,37 30,35 26,46 22,56 | 59,12 33,17 28,84 24,51 | 61,16 31,49 27,47 23,44 | 61,16 31,49 27,47 23,44 | ||

| 1250 | Extra light PV-15% PV-25% PV-40% | 54,20 28,71 25,05 21,24 | 54,14 28,22 24,61 21,01 | 57,58 29,30 25,61 21,92 | 60,06 30,76 26,66 22,56 | 63,36 32,59 28,57 24,17 | ||||

| 1500 | Extra light PV-15% PV-25% PV-40% | 52,64 25,43 22,15 18,77 | 57,68 26,34 22,88 19,42 | 58,60 29,79 25,88 21,97 | 62,56 31,43 27,47 23,19 | |||||

- during long-term operation with a constant load, the load value should be reduced by 50% compared to the PV mode = 40%;

- the permissible radial cantilever load on double-ended shafts is reduced by 2 times.

Overall and connection dimensions

| Standard size | Center distances | L | L1 | L2 | l | l1 | l2 | l3 | l4 | l5 | |

| awt | awb | ||||||||||

| RK – 500 | 350 | 500 | 1640 | 510 | 550 | 1120 | 610 | 300 | 205 | 546 | 530 |

| Standard size | B | B1 | B2 | B3 | H | H1 | H2 | h | d | Weight, kg |

| RK 500 | 580 | 520 | 580 | 408 | 875 | 400 | 105 | 35 | 32 | 1230 |

Dimensions of high-speed shaft ends

| Standard size | d1 | d2 | d3 | d4 | l1 | l2 | b | h | t |

| RK-500 | 90 | 83,50 | M64 x 4 | 130 | 170 | 130 | 22 | 14 | 9 |

Dimensions of low-speed shafts (for couplings)

In terms of price-quality ratio, the NMRV gearmotor is better than all similar products offered to the Russian market. In any product of a wide model range, high reliability and an optimal reasonable price are guaranteed.

The designers have provided for the unification of the connecting dimensions, which makes it easy to select a UD-RV (analogous to an NMRV) to replace a gearmotor that has encountered problems during operation and has failed from almost any company offering its products to the Russian consumer.

The design developers have selected a very effective lubricant based on high-quality synthetic and semi-synthetic oils; the lubrication scheme contributes to the trouble-free operation of the gear units and does not require replacement throughout their operation.

Lubricant level diagnostics

Due to the use of different gears (planetary, cylindrical, bevel), the oil level in the manual transmission is different.

Transmission manufacturers have made it easier for users to check the oil level:

- either a dipstick is built into the filler plug, or the neck is located at the level of the oil mirror;

- the drain plug is equipped with a magnet that collects metal shavings;

- the bottom of the crankcase has a slope towards the drain hole, but the car must be horizontal, and the lubricant flows through the funnel.

Oil level in manual transmission VAZ 2110

Having decided which oil to pour based on viscosity and operating temperature, you can change the lubricant in the garage yourself. The operating manual indicates the amount of oil. The algorithm for checking the lubricant level in the gearbox is extremely simple:

- the engine must be warmed up and then cooled down within 3 hours after the trip;

- install the machine horizontally;

- clean the gearbox housing near the filler plug and unscrew it with a wrench.

The norm is the level along the lower edge of the filler hole; in all other cases, the user pours it in until the lubricant begins to pour back out.

Checking the lubricant level

Attention: It is not recommended to intentionally install the car with the neck up, since an excess amount of oil will reduce the quality of the lubricant and increase the pressure in the crankcase.

GEAR LUBRICATION

Lubricates gear and worm gears and bearings* reduces friction losses, prevents increased wear and heating of parts, and also protects parts from corrosion. Reducing friction losses ensures increased efficiency of the gearbox.

Based on the method of supplying lubricant to the gearing, crankcase and circulation lubrication are distinguished.

Crankcase lubrication is carried out by dipping gears and worm wheels (or scoops) into oil poured into the housing. This lubrication is used at peripheral speeds in gear meshing up to v £ 12

* Lubrication of bearings in gearboxes is discussed in Chapter. IX.

m/s, in mesh with worm gears at a peripheral speed of the worm up to v

The teeth of the bevel wheels are immersed in oil over their entire length. In multi-stage gearboxes, it is often not possible to immerse the teeth of all wheels in oil, since this requires a very high oil level, which can lead to too much immersion of the low-speed stage wheel and even bearings in oil. In these cases, lubrication gears (Fig. 10.32) or other devices are used. At v £ 0.5 m/s, the wheel is immersed in oil up to 1/6 of its radius. When lubrication by dipping, the volume of the gearbox oil bath is taken from the calculation

0.5 -0.8 liters of oil per 1 kW of transmitted power.

In helical gears, the oil is squeezed out by the teeth in one direction, and in worm gearboxes, a worm immersed in oil drives the oil to the bearing. In both cases, to prevent excessive oil from being thrown into the bearings, oil protection rings are installed (see Chapter IX).

Changing the oil in a manual transmission

After a run of 30 – 70 thousand kilometers, when the oil should be changed according to the manufacturer’s recommendations, you need to buy lubricant in the required quantity and stock up on a container for draining the waste. The main nuances are:

- The oil in a manual transmission should be changed on a warm engine in order to increase the rate of fuel flow out of the drain neck;

- the best oil, diluted with some amount of lubricant remaining inside the crankcase, will last significantly less because it will lose its declared characteristics;

- to access the drain hole, the front wheel on the driver's side is usually removed and the car is hung on a jack;

- Knowing approximately how much oil the manufacturers poured, you can avoid overfilling.

Change of oil

By replacing the used working medium with good oil, gear shifting will improve and extraneous noise will disappear.

Design of keyed connections

Keyed connections are designed to transmit torque from the shaft to the hub or vice versa.

Depending on the design, keys are divided into prismatic, segmental, wedge, tangential, and special. Parallel keys GOST 23360–78 are most widely used in mechanical engineering.

The keys are selected depending on the diameter of the shaft and tested for strength by bearing stress:

,

Where

maximum torque taking into account dynamic loads at start-up, Nmm;

shaft diameter, mm;

key height, mm;

deepening of the key into the shaft, mm;

working length of the key;

MPa – permissible bearing stress.

We will select the main dimensions of the keys according to the table on p. 131, [1].

The length of the key is taken less than the length of the hub according to the proposed range of key lengths.

Parameters of parallel keys for drive shafts are presented in Table A2.9.

Parameters of parallel keys for drive shafts

Source