According to planned economic indicators

Milling processing is used both in small- and medium-scale production (universal milling, console, table-top milling machines), and in serial and large-scale production (turning and milling machines with a CNC module, machining centers). The purchase of high-precision, productive machines with numerical control requires significant financial investments and is justified when production areas are at maximum load.

Types of milling work on milling machines

The equipment is used to treat surfaces of various materials. The main work is performed by the cutting part - the milling cutter. The product makes holes in metal and other raw materials, corresponding to the degree of accuracy from 6 to 10. The roughness index Ra is in the range from 1.25 to 20.

Using the installations, you can perform the following work: milling horizontal, vertical inclined surfaces, bevels, ledges, cylindrical gears, various grooves, etc. For each type of work there is its own cutter shape. Vertical processing with end tools has the highest productivity. Milling work is divided into classifications according to different indicators. Their description is given below.

By type of surface being treated

All existing types of work on metal milling machines are systematized according to their purpose.

Milling horizontal, vertical and inclined surfaces

It is produced on machines with a horizontal and vertical spindle shaft, as well as on universal machines with a rotating spindle head. On a vertical machining center, it is possible to perform motion processing operations along three, four and five axes simultaneously.

When processing inclined planes as the main type of milling work, cutters are used with sharpening the cutting edges at a certain angle, or they use a standard tool and perform work on machines with a rotary spindle head or tilt the workpiece using equipment.

Milling of shoulders, grooves of all types - rectangular, T-shaped, dovetail, keyways

These types of work on milling machines, performed using various cutters (slot, end, T-shaped, radius, etc.), are considered one of the most common. The blades of the tool knives are arranged in such a way that when milling on horizontal, vertical, universal machines, they ensure the required configuration of the part.

Milling of shaped and combined surfaces

Shaped surfaces made when working on a metal milling machine:

- using shaped and combined cutters;

- when using fixtures and turntables;

- by a given mutual movement of the workpiece and the machine spindle (CNC longitudinal milling);

- using copy milling (copy-milling machines).

Cutting work

The separation of large workpieces is carried out on milling and cutting equipment with circular saws. Separation of workpieces of small height is possible on a conventional machine using a finger cutter; it is a more resource-intensive process.

Thread milling work

Helical surfaces are formed using end (finger), disk or comb cutters on gear hobbing machines and CNC machining centers.

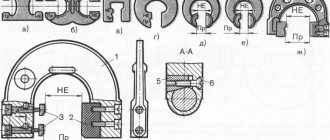

Gear hobbing and spline milling operations

Machining of spur, helical, worm, bevel, cylindrical wheels and gears, milling of splined shafts, etc., performed on gear hobbing, spline milling and universal machines, is carried out using slotted, shaped and modular (worm or disk) cutters.

Drilling, boring, threading

This is also the main type of milling work in demand in production. To reduce the time required to reinstall the workpiece, these operations are carried out on the same machine where the milling was performed. Both special tools and standard drills, taps, countersinks are used, installed in the machine spindle using mandrels and collet chucks (jig boring, drilling and milling machines).

Machining curved surfaces or complex profiles

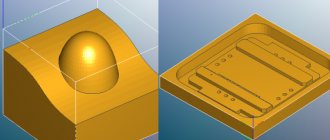

When processing on universal machines, the implementation of this type of milling work on metal is difficult. CNC machines with the required number of degrees of freedom (from 3) do not require additional equipment, processing according to a given program

Purpose of milling processing

Using various types of cutters, you can mill parts more accurately and efficiently. It can be a variety of materials, but the most common treatment is on metals. And with the help of modern machines equipped with CNC systems, it is possible to reduce the amount of defects, as well as control using simple numerical programs. Now the cutter has been replaced by a blade as a working tool, which has reduced the likelihood of defects by making workpieces as accurately as possible.

Why is milling needed in processing? With its help, you can cut metal, grind, apply special patterns, engrave, as well as do turning and other work in various types of activities. The set includes several multi-tooth cutting cutters, and their mounting in machines determines the horizontal or vertical type of work. Milling at a certain angle can also be used in production, for which the cutter is first installed in the required direction. Depending on the type of product being processed, this milling has several methods. But it is worth noting that a considerable number of different cutters are used, in particular cylindrical, end, end, gear, shaped, and also more complex ones.

The areas of application of milling are quite diverse; it can be used in metalworking, mechanical engineering, jewelry production, woodworking, and even in design and architecture.

Metal processing by milling is carried out regardless of its strength. Milling cutters are selected based on the type of processing required; for planes, cylindrical or end-face types of cutters are used; in the latter, asymmetrical cutting patterns are selected. That is, if the parts are of the correct rectangular, square or similar shape, then these two methods are most often used. The same profile part can be made with a cylindrical cutter or from the end.

Milling cutting of aluminum is considered quite popular nowadays, since aluminum is widely used in exclusive design, interior design, advertising elements, camera equipment, etc. Due to its lightness, strength and low melting point, it is widely used and it is not difficult to cut out various products. On the details of souvenir products, marketing and kitchen products, modern high-tech machines can make inscriptions, patterns, relief, etc. At the same time, they are obtained without burrs, the correct size and shape, as well as with perfect edges.

Volumetric milling of plastic has gained considerable popularity these days, especially in 3D form. These are quite popular services that are used for industrial products and housings. Moreover, the parts are made quickly, since the milling and engraving type machine works quite quickly, and the price for the work performed is low. Both splined and shaped and gear parts are processed, as well as processing of holes, ends, and grooves. Decorative and other parts, molds for casting, polymer cases and much more can be milled from plastic in 3D form, creating original and desired product shapes.

In terms of dimensional accuracy and quality of the resulting surfaces

For pre-processing of the workpiece, rough milling . It is characterized by higher cutting power and depth, and the resulting surface roughness is Ra 6.3...20. Requires equipment of great rigidity and power. When rotating at relatively low speeds, a cutter with brazed or replaceable inserts removes a large thickness of metal.

Finish milling gives more accurate dimensions (6-7) and higher surface finish - Ra 1.25...1.6. The metal layer removed during finishing milling operations is minimal, and the cutting speed is high.

Both finishing and rough milling are operations performed on the same or different machines. Semi-finishing is a combination of two types of finishing, usually with different tools.

The accuracy of the result of all types of milling work depends not only on the processing modes, but also on the parameters and technical characteristics of the milling machine itself (normal precision machines and precision milling machines), on the tool used and on the correct positioning and movement of the part.

Technological stages of the process

As for the milling technological process, it consists of several sequences that must be followed:

- The product is carefully brought from the side of the surface required for processing to the milling cutter, which is rotating at this time.

- Moving the table away, turn off the spindle so that it does not rotate.

- After this, you need to set the required cutting depth.

- Start the spindle.

- The product, located on the table, is brought together with it to join the cutter.

Processing of metal parts with a cylindrical cutter is carried out when the length of the cutter is 10-15 mm longer than the product, and its diameter is selected based on the cutting thickness and width. When choosing end mills, the work will be done less noisily, since the parts are more securely attached. The productivity of the enterprise will be high when using a set of cutters, since the task is greatly simplified. It all depends on the cutters used, and these are: joint cutters, chisels, two disks at the same time, a set of cutters located on different sides of the workpiece, etc. Milling planes with several end cutters makes several cuts at once, and also eliminates impacts during work.

Modern technologies make it possible to carry out safe processing with a lower percentage of defects on turning and milling machines equipped with CNC systems. In some cases, as when processing parts of increased hardness, it is possible to grind them. They guarantee the production of products with maximum accurate geometric shape, as well as productivity. There are both special purposes and general use, but small parts of the house can be processed with a hand-held electric router. Computer control allows you to set all parameters and perform them as accurately as possible; in addition, it is possible to calculate and create 3D models directly on the machine.

Thanks to modern technologies, milling is becoming increasingly popular in various industries. As for metal, you can use machines to make both aluminum and steel and titanium products. Regardless of the material, milling can be used to make parts for special purposes, exclusive items, jewelry, etc. And only on machines equipped with CNC systems can laser milling of parts of complex shapes be performed. This is expensive, but high-quality processing is possible without pre-grinding.

According to milling direction

There are two types of such operations.

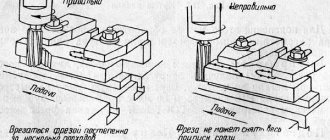

- Counter. The workpiece is fed in the opposite direction from the path of the cutter. This type of processing is characterized by fast work completion. Increased wear of the cutter is observed. Vibrations appear in the process. Suitable for processing large parts.

- Related. The movement of the cutter and the supplied material occurs in one direction. In this situation, a clear, even cut is obtained. This type of processing is characterized by less damage to the cutting element. The force acting on the machine presses the workpiece and reduces the generation of vibration.

According to the cyclicity of processing

A milling tool can make a hole in a material using two types of cycles.

- Intermittent. During processing, it is necessary to stop the machine to change the position of the workpiece, removal, etc. For this purpose, equipment sometimes uses reverse motion. This type of processing requires a lot of time and effort.

- Continuous. In this case, the part is automatically installed into the mechanism after milling. Some machines are equipped with a second cutter, which allows you to process a part simultaneously in several planes. In addition, tool replacement takes place automatically. This type of processing makes it possible to produce a large number of parts. In this case, the operator’s work is reduced to control using the control panel.