Sometimes large metal structures need additional cleaning from dirt, rust and plaque. To avoid spending a lot of time cleaning with a grinder and a grinding wheel, you can use sandblasting. There is a technology that allows not only to clean the material, but also to improve its characteristics. This is shot blasting. It is important to understand how it differs from classic sandblasting and what features this technology has.

Shot blasting

What it is?

This is one of the most popular modern technologies, the essence of the process is the processing of metal using an accelerating gas flow of shot, the quality of which determines the speed and result of processing. Using this method, you can remove environmental influences, corrosion or old decorative coatings. After processing, the metal takes on a new look and becomes smoother. Unevenness and roughness are also eliminated.

Most often this technology is used to remove rust. The method is fast and reliable, which is why it is considered popular. It has been noticed that after treatment the service life is extended and the material becomes more durable.

Application area

Shot blasting is used not only for cleaning metal structures, but also when processing concrete, brick and even wooden surfaces during construction and repair work. Using this technology, large containers and tanks can be cleaned from the inside. But still, the main purpose of this technology is to clean metal structures and prepare them for applying paint and varnish coatings to them.

Thus, the main tasks that shot blasting performs can be classified as follows:

- cleaning metal coatings from plaque, rust, scale, traces of old paint, dirt and grease stains,

- creating a microrelief on the metal surface that will improve the adhesion of the material to various applied coatings,

- improving the strength of metal structures and increasing resistance to constant loads.

After thorough shot blasting and degreasing, the metal surface becomes ready for coating.

The service using this technology that is most in demand is the processing of metal structures. This is the most optimal option for cleaning car wheels in terms of price, quality, reliability and other criteria. This method, using a high-speed abrasive jet, allows you to clean the disc completely, even in the most difficult to reach places. After such treatment, the anti-corrosion and paint coating will be applied much better.

Advantages and disadvantages

The method of shot blasting metal has the following advantages:

- removes scale efficiently;

- removes rust;

- eliminates corrosion that has formed over a certain period;

- allows you to make the surface matte;

- removes roughness and unevenness;

- extends the service life of the material;

- gives the metal strength and reliability.

As with any other method, there are several disadvantages:

- increased consumption of abrasives;

- use of a special protective suit;

- An air conditioner is required to regulate the temperature.

5Conclusions

The results of surface treatment by two methods will be almost the same - high quality and effective.

However, shot blasting and shot blasting differ from each other:

- The principle of operation and the supply of abrasive material to the surface to be cleaned (compressed air under high pressure - shot blasting; mechanical supply of shot by turbine - shot blasting).

- Design differences between shot blasters and shot blasters.

- Type of products to be cleaned (large-sized, complex configurations - shot blasting machines; rolled metal, castings, blanks, pipes - shot blasters).

Rice. 1. Quality of surfaces cleaned using shot blasting or shot blasting units:

Principle of operation

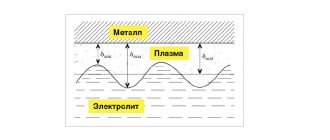

The method of operation is to clean the metal coating with abrasive particles using kinetic energy. A strong jet of air directs particles onto the surface of the material with enormous speed, which can reach 730 m/s.

Due to the strong air flow with a high particle content, processing the material does not take much time, even if the product is large. For processing, special equipment is used, where particles are accelerated to high speed and then directed to the surface.

Principle of transfer of workpieces

Shot blasting chambers can operate either as part of a separate process or as part of a single technological production line. In this context, shot blasting machines can be divided into 2 categories:

- Impassable

- Passing

Non-passage chambers are blind. That is, in such shot blasting machines there is one common entrance and exit. Non-pass machines accept workpieces for processing, clean the parts and return them in the opposite direction.

Walk-through cameras use a separate entrance and a separate exit. Blanks are accepted, processed and transferred further to the next technological processes.

Conveyors serving complex technological processes have become widespread That is, the long chain drive with hook hangers can pass through the shot blasting chamber, washing and painting line . This method of transferring workpieces saves operators a lot of time and effort, since there is no need for manual loading and unloading of workpieces .

Equipment used

The market presents many different types of metal processing machines, but the main components must be present in each equipment.

- Compressor. Needed to create high-speed air flow to quickly eject abrasive particles.

- Chamber for mixing air and shot. The compressor and the container with abrasive are connected to each other by a special tube. The chamber is necessary so that the air entering the tube mixes with particles and moves further along another hose.

- Nozzle. The final element through which the shot reaches the surface being processed.

Important!

The nozzle must be made of carbide materials.

All processing equipment is divided into:

- Manual - devices with low power, designed for light work. Mainly used for processing metal structures.

- Shot blasting chambers are automatic equipment installed in enterprises.

Types of shot blasting machines

Today there are dozens of modifications of shot blasting machines. Many manufacturing companies practice the creation of unique shot blasting machines, which are developed and created individually (in a single copy), for the needs of a specific production.

Shot blasting machines can be classified according to such a parameter as “habitability”:

- Inhabited

- Uninhabited

In the case of manned equipment , an operator must be inside the processing chamber. The shot blaster is equipped with a protective suit, which gives the person the opportunity to breathe and move freely in a dangerous environment. The operator must manipulate the shot blasting gun, from which a stream of airborne abrasive suspension emerges.

Inhabited shot blasting chambers are good because the operator can manually clean some problematic, hard-to-reach places. The weakness of manned shot blasters is the use of manual labor. Because of this, the effectiveness of preparatory operations is noticeably reduced.

Regarding uninhabited chambers , such shot blasters clean workpieces in a fully automatic mode. The operator only needs to press the start button. In this case, the abrasive suspension is fed through nozzles. The position of the nozzles can be either stationary or variable.

What other types of shot blasting machines are there?

Surface cleaning and strengthening technology

Shot blasting can be used to remove old paintwork. The principle is quite simple: abrasive particles under air pressure move at high speed to the surface and form many cracks in it. Such cleaning is a rather complex process that requires the use of special equipment and the help of professionals.

By means of shot-peening the surface, the metal is given strength and durability. The process involves applying spherical abrasive particles (steel shot, ceramic or glass beads) to the surface, which create a uniformly compressed coating. This coating creates tension and thereby increases the strength of the metal.

Main types of fractions for processing

You can regulate the metal processing mode by selecting pellets. Grit particles today are made from various materials that affect the properties of the abrasive. Let's look at the main types of pellets:

- Crushed cast iron shot. Made from cast iron, which undergoes granulation. Suitable for removing rust, carbon deposits and scale. Cast iron shot can also be used to create a matte finish and to create a slight roughness.

- Cast steel shot. Available in several varieties depending on the carbon content of the steel (thanks to this, the hardness of the pellets can be controlled). Cast steel is suitable for processing massive metal structures based on cast iron and steel (rolled steel, beams, metal structures).

- Shot based on chopped steel. Available in several varieties (pellets differ from each other in size, shape, strength, and so on). Great option for heavy-duty metal objects. The main advantage of the material is its high strength (thanks to this, the shot can be used a large number of times, which reduces the final cost of the work).

- Shots based on aluminum or aluminum alloys. Not suitable for hard iron-based alloys, but suitable for processing aluminum and various soft alloys. Aluminum shot does not deform the surface and efficiently cleans it of scale, rust, scale, and soot.

- Glass shot. In the form of heavy-duty balls that do not break or deform with frequent use, which makes the material very economical. Suitable for cleaning medium-hard metal alloys, although glass beads can also be used for cleaning iron-based alloys. The main advantage of the material is the lack of contamination.

Fraction for work

Since the method involves the use of abrasive particles, there are different types, the use of which depends on the material being processed:

- glass - a fairly budget option, does not pollute the surface of the material;

- electrocorundum - the most expensive and effective type, used for complex work;

- ceramic - used quite rarely for final cleaning of metal;

- plastic - used on glossy surfaces;

- cast iron - this type is used for cleaning from rust, plaque and scale;

- aluminum - cleans materials made of soft alloys;

- steel - removes dirt and rust well and increases the physical properties of the metal.

Process description

There are two models of shot blasting - manual and automatic. In the first case, all work is done manually using special sprayers. In the second case, a special shot blasting chamber is used, where everything is automated - workers only clean up problematic fragments (with severe corrosion, with large deposits). Below we will look at these methods in more detail.

Manual metal processing

This method is excellent for processing small batches of metal that has a complex shape). A special shot blasting machine is used, which is connected to an electric compressor. It generates pressurized air, which pushes the particle particles out of the spraying apparatus. The procedure itself looks quite simple:

- Several workers wear special protective suits that help filter the air or contain their own oxygen supply (producing large amounts of pellets that can be inhaled). The work must be carried out in a workshop where favorable conditions for cleaning have been created (low humidity, good ventilation).

- They then connect the shot blasters to the compressor, place the metal objects on supports and perform the blasting. The duration of the work depends on the nature of the damage to the metal, the type of alloy, and so on.

- After processing, workers leave the workshop so that particles of metal and dust can settle. After this, using special liquids, wash off the dust particles that have settled on the metal during storage.

Price of services

With a sufficient number of advantages, the question arises of the cost of these services. Basically, the price depends on the area of the metal surface being processed. On average, they can charge 350–400 rubles for one square meter. This cost is not finite and depends on a number of factors, for example, the degree of contamination or processing of the material.

Shot blasting is a complex technological process. It has a number of advantages and allows for cleaning in a short time. However, it is better to trust professionals in this matter.

Price for shot blasting

| Alloy wheels: | Price |

| R 14-16 | 500 RUR/piece |

| R 17-18 | 600 RUR/piece |

| R 18-20 | 700 RUR/piece |

| R 21-24 | 800 RUR/piece |

| Stamped discs | 400 RUR/piece |

| Motorcycle frame | 1500 RUR/piece |

| Bicycle frame | 800-1000rub/piece |

| Kanguryatniki | 800 -1200rub/piece |

| Bumper | 700-1000 rub./piece |

| Cylinder head block | 1200-2000 rub./piece |

| Small auto-moto parts | from 150 rub./piece |

| Flat metal products | from 600 rub./m2 |

Equipment used for processing, metal cleaning

There are 2 options for impacting metal: through a manual mechanism and a shot blasting chamber. Each of them has its own specific functioning:

- Manual units make it possible to process parts in places with the most difficult access: in ship hulls, on bridges and on many other structures with impressive dimensions. Modern mobile models are equipped with special vacuum cleaners designed to suck in shot particles for cleaning and recycling.

- Shot blasting chambers are most often fully automated, which has a positive effect on their productivity (up to 200 m2). Such equipment is used for industrial processing of products of the same type.

Shot blasting chambers from the manufacturer

offers services for the design and comprehensive supply of abrasive blasting chambers of domestic and foreign production. Each shot blasting chamber is manufactured in full compliance with SNiP. All products are sold at competitive prices. We also provide professional installation, commissioning, warranty and post-warranty service for abrasive blasting chambers. The company’s specialists will professionally train your staff to work with the complex.

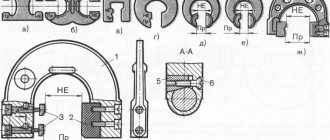

The camera consists of the following components:

1. Camera body. Gates.

Camera body.

The body of the abrasive blasting chamber is made of a metal frame and soundproofing material (sandwich panel). The internal surfaces of the walls are sheathed with a special material that prevents damage to the wall panels and prevents ricochet. The dimensions of the room are selected individually based on the maximum dimensions of the processed products. The number and location of lamps is selected to ensure sufficient illumination of the working area (also taking into account the dimensions of the products being processed).

Gates.

The chamber body can be a dead-end type (gate on 1 side) or a pass-through type (gate on 2 sides allows you to move products right through the chamber). Pass-through chambers are most often used in “preparation-painting” production lines. In shot blasting chambers, swing or lifting roller gates are used. Hinged doors that open manually are cheaper, but require additional space to open the doors. Rolling gates with electric drive do not require additional space and do not require additional actions from the operator (open - close). The slats of such gates in abrasive blasting chambers are additionally protected by special curtains. Type of shell:

2. Ventilation of the chamber Since abrasive blasting is associated with the formation of a large amount of dust, an aspiration installation is necessary to remove it from the room in the chamber. Dust suspended in the air obstructs the operator's visibility and also reduces the quality of the abrasive treatment itself. The parameters of the dust collection installation are selected based on the size of the room.

3. Abrasive collection and recovery system. Reusable abrasives, such as steel shot, require recovery for reuse - cleaning from debris, rust, scale knocked off the workpiece, as well as from small broken particles of the abrasive itself. Such a system, as a rule, can be implemented on the basis of a bucket elevator or a vacuum collector. They may differ in productivity, the number of posts (abrasive blasting machines) with which they can work, as well as the degree and quality of cleaning.

Operating principle of shot blasting machine

The installation consists of a shot-throwing chamber, conveyor, turbines, shot separation system, filter and control device. The workpieces move through the shot-throwing chamber on a roller conveyor. Turbines made of wear-resistant materials ensure the formation of a shot flow. The screw conveyor, elevator and shot filter return and continuously clean the shot. The installations use cast steel shot of special hardness 52-57 HRC. The shot blasting chamber is protected by wear-resistant manganese steel shields. The inlet and outlet sections of the shot blast chamber are equipped with a series of rubber curtains that prevent shot from being ejected from the chamber. Rotating brushes and a high-pressure fan remove abrasive from the surfaces of the workpieces before exiting the blast chamber.

Preparing the surface for coating

Cleaning removes unwanted materials and leaves the surface ready for coating. Using abrasive blasting, metal structures are removed

In addition, blast cleaning removes the secondary scale that forms on new steel.

Angular abrasive particles roughen the surface and create a profile, or notch. Most paint manufacturers specify what the profile should be to ensure effective application of their product.