Every reliable, high-quality pressure gauge must have the accuracy class specified by the manufacturer in its technical documentation. The parameter is especially important for production, industrial and similar conditions. There is an opinion that for household equipment, pressure gauge deviations are less important, since more often the device serves only as an indicator showing an approximate value, and not as a measuring tool, but this is not entirely true. This cannot be said that for home heating systems, boilers, and water supply, accuracy is of little importance, since if the pressure is exceeded, there is a risk of pipe rupture. At the same time, an error of some fractions or even one division may not be taken into account, for example, when inflating tires. Let's consider the existing classes of pressure gauges in terms of accuracy, the range of errors, the dependence of groups according to deviations from the diameter of the scale, the measurement range. We will also describe how to find out, carry out calculations, and check classes of pressure meters.

Importance and relevance of pressure gauge classes

When selecting a pressure gauge (the device is usually abbreviated as “DM”) for ordinary living conditions, users rarely pay attention to its error group.

As we have already said, accuracy is not particularly important for such purposes as monitoring mPa (bar, atm) in tires, when it is enough for the user to know the approximate value, or deviations of fractions of divisions or even several marks will not affect the overall picture and condition of the equipment. But high accuracy of readings is always desirable for boilers, heating, water supply, pumps of this equipment and for similar purposes.

And also the accuracy group is one of the parameters that must be paid attention to when the correctness of measurements is especially necessary. For housing and communal services, industry, production, for pressure-sensitive equipment, where a deviation of even one division leads to wear and tear of the equipment, accidents (central water supply systems, heating systems, boiler rooms).

Why check the pressure

The optimal pressure indicator will provide protection from accidents. If there is too little air, the tires cannot handle the load when cornering and hard braking. Then the stability of the car when driving decreases, the reliability of the tires decreases... If you do not pay attention to maintaining the correct pressure, the tire may burst while driving, which will lead to an accident.

Too much air in the tire is also a negative indicator. High pressure leads to increased load on the car's chassis. The result is uneven tire wear, the inability to drive normally in a straight line, deterioration in dynamic performance and an excessively long braking distance.

Regulations

An explanation of what the accuracy class of a pressure gauge is given by GOSTs, in particular R 8.905:

The main acts on accuracy for pressure gauges are GOSTs R 8.905 and 2405. Documents related to them and those to which they contain links also serve as sources of standards. Further, we will illustrate the article with excerpts of text in the form of images from these two regulatory documents.

For specific areas, the level of correctness can be established by the standards in force for it, including labor protection and safety, for example, for pressure vessels (cylinders and the like) there are the following standards.

The issue of errors is regulated and specified by acts for certain narrow areas, for example, for well pumps:

For which pressure gauges are accuracy classes established?

All pressure gauges positioned as products that meet the standards of GOSTs and other quality regulations have class. exact Let us briefly list the types of devices.

The simplest mechanical pressure meter:

The most common group of DMs is mechanical, also known as deformation, analog.

Mechanical products can be tubular (with a tubular arch-spring, usually single-turn).

This arch is a so-called Bourdon tube, not quite a spring in the traditional sense, but a springy (elastic) arch. The bracket, through the articulation of the levers, at the end of which there is a toothed part, transmits the influence of the measured phenomenon to the pointer gear, moving it along the scale. The mechanism can be supplemented with a regular flat spring.

Strain gauges are also sometimes called "direct gauges".

Analogue DMs include membrane devices, where the main sensitive element is a membrane that responds to pressure. There are also bellows devices, they can be called an improved modification of the latter: the sensitive part is a corrugated (accordion-like) box (chamber), that is, a bellows.

Mechanics include liquid and deadweight pressure gauges. The former have a sensitive element - liquid in the flask, the latter have a special system of counterweights, piston joints.

Deadweight piston products are usually used as exemplary, reference devices:

A separate group of pressure gauges is electrical contact gauges (ECM); they can be mechanical or digital (the latter are usually always like this).

Mechanical ECMs are actually the same spring products, but they have electrical leads for transmitting data to associated control and other equipment.

The third large separate group of types of pressure gauges are digital or electronic. The sensitive elements here are special sensors or the same arc-shaped bow (bracket), spring, membrane, but the readings are interpreted by a microcircuit, which also displays them on the LCD display in numbers, like in calculators.

DMs are also divided into pointer ones and those with results displayed on an LCD display.

There are also the following types of pressure meters:

- exemplary (reference for verification, testing of other such devices);

- highly accurate. Typically these are electronic devices;

- axial, radial.

Below is an example of an exemplary mechanical pressure gauge (the scale is much expanded and, accordingly, especially accurate):

The division into types is not particularly significant for the issue under consideration; the presence of an error class does not depend on the type of device. If this parameter is not specified, it means that the device is not reliable, it is the simplest and cheapest, it is not for serious equipment, not for purposes requiring a certain precision, and its use is extremely undesirable for important tasks.

What can cause incorrect tire pressure?

A reduced or increased amount of atmosphere in tires can lead to a number of problems not only with the wheels, but also with the car as a whole. If you have excess pressure, the following difficulties may arise:

Rubber suffers the most, as its service life is rapidly shortening. Insufficiently inflated tires also lead to a lot of problems:

Effect of tire pressure Important!

It is necessary to measure your blood pressure at least once a week. It is also necessary to carry out the procedure before a long trip.

The most dangerous thing is different pressures in all four tires. A car with such pumping is very difficult to drive. The car constantly moves from side to side. This can be especially dangerous in winter on slippery roads. Therefore, the pressure must be monitored carefully so that no problems arise. For this purpose, there are not only tire shops, but also special instruments and systems that can help measure the amount of atmosphere in a tire.

You might be interested in this About winter tires Sava (Sava)

What is the accuracy of pressure gauges and its classes

Accuracy classes or groups for pressure meters mean the permissible percentage of error (deviation, discrepancy) of the arrow on the scale in relation to the real value of the measured parameter.

On all certified pressure gauges that have passed official verification, the manufacturer indicates the accuracy class (group) number on their scale (on the side, below, in another place).

The definition of the term “error” is provided by GOST; the document distinguishes several types of deviations, but for us it will be enough to know the basic explanations of the term (the first and second options in the list below):

According to GOST 2405 in Russia there is a standard range of error positions for DM: 4, 2.5, 1.5, 1, 0.6, 0.4, 0.25, 0.15. Foreign products may also have one more class - 1.6.

The class, depending on the accuracy of the pressure gauge, is often in the standard, familiar ranges. At the same time, standard, high-precision products (most often these are digital models, but there are also pointer analogue ones with a very large scale diameter) have an expanded range of errors: values of 0.025 can be added; 0.05; 0.1; 0.15; 0.25; 0.4 and even smaller values.

Below are a few more standards from GOST:

Permissible errors and factors are regulated by GOSTs:

The above data is specified by GOST 2405:

When checking and determining deviations, it is necessary to comply with environmental requirements, since, for example, temperature and humidity significantly affect the operation of the DM:

Where and how is it indicated

Questions regarding the dials of measuring devices are regulated by GOST 25741. It is recommended to place the designations in accordance with it (in the figure below, the accuracy class is numbered 8), but these regulatory documents are advisory, so the parameter can be indicated in slightly different places, the main thing is that it is there.

The accuracy class is necessarily indicated in the technical documentation, certificate, passport of the pressure gauge, and almost always on its scale anywhere, but more often at the bottom right.

To indicate the accuracy class, the letters KL, CL, Kl and the corresponding number from the series of this standard are used.

In extreme cases, the data is knocked out or applied with permanent paint on any part of the body, and very rarely they are written down only in technical documentation (but the individual pressure gauge number should always be on the product itself and duplicated in documents).

Sometimes the class is indicated without letters, just a number:

There are devices where the class is not indicated specifically on the scale; it can be stamped on another part. But in any case, whether there is a designation on the DM itself or not, if the device is reliable and has passed official verification, then class. exact must always be specified in the technical documentation.

If the group is not indicated anywhere, then this is the simplest pressure gauge, with the largest possible errors, for example, these are used for simple tasks when it is enough to know the depth of movement of the needle. Such devices are sometimes found complete with tire inflators.

An example of a summary table for one of the measuring lines indicating accuracy classes:

How is tire pressure measured?

The most common measurement tool is a pressure gauge. It can be mechanical, electronic and rack and pinion. Each model has its own accuracy class and differs in size and price. There are pocket models that are very compact and look like a regular keychain. They are very convenient to use and do not take up much space.

There is also a standard TPMS system that some cars are equipped with. It monitors tire temperature and pressure. If any problem occurs, it notifies the driver and displays indicators on the electronic panel. If there is no such system, then you can buy and install it. Some such systems can transmit indicators directly to the driver’s smartphone.

There are also special indicator caps that are installed on the tire valve.

Red, yellow and green markings on them help to visually determine the amount of atmosphere in the tires. Pumps and compressors with a built-in pressure gauge can also be considered very convenient assistants. They help not only accurately determine indicators, but also inflate the tires.

Pressure is measured in kilopascals, bars and PSI. The latter unit of measurement is mainly used abroad. In Russia, you can more often find pressure gauges that give results in bars and kilopascals. Similar indicators are slightly different from each other, for example, one bar is equal to 10,000 kilopascals.

Pressure gauge

How to read labels, calculations

The more insignificant the deviations of the DM, the lower the number in its class designation (numerical expression). The range varies, but the most common is 0.4–4.

GOST 2405 defines how it is recommended to designate the device:

Relationship with dimensions

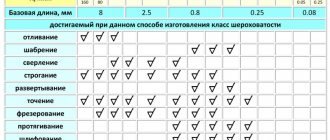

Device type according to class. exact usually associated with the diameter of its graduated part (with the dial). This refers to mechanical devices with an arrow-pointer running along the divisions painted on a given segment.

More details according to GOST 2405:

The same document contains data on the connection between the dial and accuracy classes:

There are also drawings of scales and graduation options:

The diameters of the scales of pressure meters are usually within the following range (in mm): 40, 50, 63, 80, 100, 150, 160, 250.

The values may be different and depend on the standard size according to the agreed specifications with the licensing authorities.

The larger the scale diameter, the smaller the deviations and the lower (better) the accuracy class. The pattern can be traced from the table (see above), for example, a device with Ø50 has groups 2.5 and 4, and a DM with Ø250 has the best (high) accuracy of readings and characteristic smaller values of error groups.

So, the lowest accuracy is for products with a dial Ø40–50, the highest is for standard sizes with a dial Ø160–250.

Dependence on measuring range

Errors depend not only on the classes, but also on the measurement range for which the pressure gauge is designed.

The limits of the pressure gauge's capabilities in terms of the measured value can be any - different manufacturer decisions are allowed. For standard instruments they are extended. But the most standard, statistically average are the following:

Recommended measurement ranges are indicated in GOST R 8.905 in table. adj. A.

How to calculate and determine the class (error) of pressure gauges

Initial data: we have a DM with a range of 10 mPa, group KL 1.5. This means that the greatest possible error of the meter should not be higher than the test result. You can calculate it using the following algorithm:

10×1.5/100=0.15 mPa

You can also find out the maximum deviation as a percentage, this method is consistent with the above formula (0.15 in the example described above is 1.5%). This can be done simply by looking at the class marking number. The number means the following: the greatest error in the pressure gauge readings will be 2.5% of its measurement range.

How to Determine If a Pressure Gauge Is Out of Class

To check whether the level of error is within the assigned class, it is necessary to compare the experimental product with the reference one.

Order:

- Take 2 devices: the reference and the one being tested.

- Measurements are taken with two meters under similar conditions, especially temperature.

- Record the readings. They look at how the readings differ, draw a conclusion about the magnitude of the deviation, and whether it is within the permissible error for the assigned class.

- Carry out the above several times and find the maximum deviation.

The above procedure allows you to assign the meter to a certain accuracy class. In a similar way, manufacturers verify products at factories, but to make the results official, the algorithm is more complex, taking into account many factors, with additional tests. Displayed in journals, procedural acts, certified by seals, signatures of responsible persons, regulated by GOSTs and other regulatory documents. An example of groups of such norms:

We have already described how to calculate the percentage of deviation; here it is also performed as the last step of the verification procedure. For example, the scale range of the test sample was 300 bar, revealing deviations of 3 bar from the reference device. Let's calculate the % error:

3×100/300=1. The result does not exceed 1.

Accuracy class for the above case is 1. If the figure is higher, even by a fraction, then this is the next group.

Calibration, calibration

Calibration is a slightly different issue, since with it the needle may be lower or higher than the actual indicators, but with such incorrect positions, it is the error range itself, the level of accuracy of the pressure gauges that can be within the limits declared by the manufacturer. Although usually it goes beyond the boundaries of the norm in this phenomenon.

Pressure gauges that have been in storage for very long periods, have been in use for a long time, or have been used under conditions with heavy loads can be calibrated. A manufacturing defect cannot be ruled out. Deviations of this kind are also associated with non-compliance with storage rules and the like. Over time or under specified circumstances, the spring, metal parts that directly perform measurements can “get tired” and stretch, so miscalibration occurs quite often.

If a mechanical device provides the possibility of calibration, then it is usually carried out by adjusting bolts on the pressure gauge body or inside it (usually the product can be easily disassembled - just unscrew the screw and remove the top cover) on the force-transmitting unit. The element is rotated by tightening or loosening the spring until the measurement results correspond to the reference device. Calibration of digital models is done by entering corrections according to instructions with control buttons or software - when connected to a computer or tuning equipment. Only the procedure carried out by accredited, certified institutions with the issuance of an approved act will have official significance.

Problems that arise when the pressure inside the wheel is incorrect

A car tire is a sealed elastic shell that contains a certain amount of air. As soon as the opportunity arises, such air comes out, and this entails deformation of the product and subsequent problems due to high loads.

Such problems may be surface heating, which changes the physical parameters of the rubber compound. Because of this, complete destruction of the tire may occur. They can also change geometric shapes, which will lead to cornering control and unstable directional stability. In addition, the contact patch with the road surface increases. Friction and damage to the side elements may occur.

You should also not forget that some engine power is spent on overcoming additional obstacles, so more fuel is consumed. And the danger of wheel disassembly when cornering increases significantly.

Excessive pressure also causes many problems. This is excessive rigidity of the wheel, which increases vibration and provokes beating against the metal elements of the car. Because of this, the suspension may fail. The braking distance increases as the contact patch becomes much smaller, and in snowy areas and on ice there is an additional danger of losing control control.