Probably in every home there are at least two screwdrivers - a Phillips and a flathead. For many people, this is enough to screw in or unscrew a screw once a year. But screwdrivers, like any tool, do not last forever, and when the time comes to choose new ones to replace the old ones, a person will be surprised and confused. It turns out there are not two or even two dozen types of screwdrivers; in a decent store they can have a whole section dedicated to them. How to choose a screwdriver that suits your needs, and most importantly, a high-quality screwdriver, and not get confused in their diversity? We will try to answer this question in our article.

Typically, a screwdriver consists of three parts: a handle, a shaft, and a tip. It is clear that the strength of a screwdriver is determined by the reliability of its weakest link.

Preface

Preface

1 PREPARED by the Open Joint Stock Company "VNIIINSTRUMENT" (JSC "VNIIINSTRUMENT") on the basis of the official translation into Russian of the English versions of the international standards specified in paragraph 4, which was carried out by FSUE "Standardinform"

2 INTRODUCED by the Technical Committee for Standardization TC 95 “Tool”

3 APPROVED AND ENTERED INTO EFFECT by Order of the Federal Agency for Technical Regulation and Metrology dated November 22, 2022 N 1800-st

4 This standard includes modified substantive provisions of the following international standards:

ISO 2380-1:2004* Fastening tools for screws and nuts. Screwdrivers for slotted screws. Part 1. Blades of hand- and machine-operated screwdrivers" (ISO 2380-1:2004 "Assembly tools for screws and nuts - Screwdrivers for slotted-head screws - Part 1: Tips for hand- and machine-operated screwdrivers", MOD) ;

ISO 2380-2:2004 Fastening tools for screws and nuts. Screwdrivers for slotted screws. ISO 2380-2:2004 “Assembly tools for screws and nuts — Screwdrivers for slotted-head screws — Part 2: General requirements, lengths of blades and marking of hand-operated screwdrivers", MOD) by introducing additional provisions.

International Standards are developed by Technical Committee ISO/TC 29 Tools, Subcommittee SC 10 Assembly Tools for Bolts and Nuts, Pliers and Cutters of the International Organization for Standardization (ISO).

The needs of the national economy and the features of national standardization are taken into account in additional paragraphs 3.1, 3.3, which are highlighted by enclosing them in thin lines or in bold italics**, and information explaining the reasons for the inclusion of these provisions is given in additional Appendix YES. ________________

* Access to international and foreign documents mentioned in the text can be obtained by contacting the User Support Service.

** In the original, the designations and numbers of standards and normative documents in sections 2 “Normative references”, 3 “Types and sizes” and marked in the “Preface” section with the sign “**” are highlighted in italics, the rest of the document text is given in normal font. — Notes from the database manufacturer.

A comparison of the structure and numbering of the structural elements of this standard and the main regulatory provisions of the specified international standards is given in the additional appendix DB.

Information on the compliance of the reference national standard with the international standard used as a reference in the applied international standards is given in the additional appendix DV

5 INTRODUCED FOR THE FIRST TIME

6 REPUBLICATION. August 2022

The rules for the application of this standard are established in

Article 26 of the Federal Law of June 29, 2015 N 162-FZ “On standardization in the Russian Federation”

**. Information about changes to this standard is published in the annual (as of January 1 of the current year) information index “National Standards”, and the official text of changes and amendments is published in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the next issue of the information index “National Standards”. Relevant information, notices and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet (www.gost.ru)

Additional features

The shaft of some screwdrivers can be replaced by a flexible shaft or equipped with a hinge, thanks to which you can screw the screw into a place where a regular screwdriver cannot reach.

There are also screwdrivers with ratchet. Thanks to the ratchet, free rotation of the handle in one of the directions is ensured, that is, you can screw in the fasteners without taking your hands off the handle.

Nowadays, screwdrivers with replaceable tips are increasingly common, which will satisfy the majority of ordinary users, but pros will bypass them, like any other “universal tool.”

Remember that you can only evaluate the quality of a screwdriver on a store counter visually. Therefore, all manufacturers (conscientious and not) try to make their products look as attractive as possible. We advise you to only buy products from well-known brands.

Appendix A (mandatory). Test torques

Appendix A (mandatory)

A.1 Test torques that determine the strength of the working part and the strength of the connection of the rod with the handle of screwdrivers with the working part of types 1-5 and type 6 versions A and B of hand-held screwdrivers - in accordance with GOST 17199 (clause 1.8).

A.2 For hex drive screwdrivers, the hex joint near the handle must withstand a test torque of 1.5 .

A.3 Test torques that determine the strength of the working part of type 6 version C of powered screwdrivers are indicated in Table A.1.

Table A.1

| Dimensions in millimeters | ||

| nom. | nom. | Test torque, Nm, not less |

| 0,4 | 2,0 | 0,35 |

| 2,5 | 0,45 | |

| 0,5 | 3,0 | 0,80 |

| 4,0 | 1,10 | |

| 0,6 | 3,0 | 1,20 |

| 3,5 | 1,40 | |

| 4,5 | 1,80 | |

| 0,8 | 4,0 | 2,90 |

| 5,5 | 3,90 | |

| 1,0 | 4,5 | 5,00 |

| 5,5 | 6,20 | |

| 6,0 | 6,70 | |

| 1,2 | 6,5 | 10,50 |

| 8,0 | 12,90 | |

| 1,6 | 8,0 | 22,90 |

| 10,0 | 28,70 | |

| 2,0 | 12,0 | 53,80 |

| 2,5 | 14,0 | 98,00 |

A.4 The test equipment must support the test screwdriver sample from buoyancy forces, prevent the occurrence of bending moments, and be strong enough to prevent deformation during testing. The hardness of the testing equipment must be at least 64 HRC.

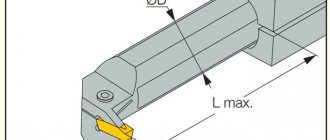

A.5 Test equipment spline dimensions are shown in Figures A.1 and A.2 and Table A.2.

| Figure A.1 - Test equipment slot for type 6 version A of the working part of the screwdriver | Figure A.2 - Test equipment slot for type 6 versions B and C of the working part of the screwdriver |

Table A.2

| In millimeters | ||

| +0,085 +0,060 | +0,04 | +0,14 |

| 0,4 | 0,2 | 0,7 |

| 0,5 | 0,3 | 0,9 |

| 0,6 | 0,4 | 1,1 |

| 0,8 | 0,5 | 1,4 |

| 1,0 | 0,6 | 1,8 |

| 1,2 | 0,7 | 2,2 |

| 1,6 | 1,0 | 2,9 |

| 2,0 | 1,2 | 3,6 |

| 2,5 | 1,5 | 4,5 |

Kernel

Screwdriver shafts can vary in length, diameter, shape and strength. The strength characteristics of a rod are characterized by its hardness. According to GOST, it should be in the range of 47-52 HRC. If the hardness is lower, the rod may bend, if higher, it may crack. It is possible to ensure satisfactory hardness by using high-alloy chrome-vanadium steel; in this case, “CR-V” or “chrome-vanadium” may be written on the rod. But such an inscription does not always guarantee quality, because it is not difficult for unscrupulous manufacturers to apply it. Conversely, famous manufacturers do not always write what, in their opinion, goes without saying. To ensure corrosion resistance, various protective coatings are sometimes applied to the rods. Sometimes the rods are covered with rubber or plastic, this makes the work of electricians easier, but it makes the rod thicker than the tip, so it is not always possible to reach the head of the fastener, which is deeply recessed into the part.

The length of the rod is usually 100-200 mm. For working in tight spaces, screwdrivers with a short shaft and a shortened handle are produced. If the fastener is located in a hard-to-reach place, it is more advisable to use a screwdriver with a long shaft and take a telescopic screwdriver with an adjustable extension of the shaft.

The diameter of the rod depends on the size of the tip and the loads for which the tool is designed. The cross-section of the rod can be not only round, but also hexagonal or square. This shape allows you to grip the rod with a wrench and provide more torque.

We must not forget that the rod must not only be durable, it must be securely fixed in the handle. This factor cannot be controlled visually, so unscrupulous manufacturers often pay insufficient attention to fixing the rod, and over time it begins to rotate. You can safely throw away such a screwdriver, because it will not be possible to revive it.

Sometimes the shaft of a screwdriver extends through the entire handle and ends at a heel that can be struck with a hammer. This screwdriver will come in handy if you need to unscrew a screw with a painted slot.

Upgraded screwdrivers

The professional tool has an additional set of functions.

Of course, a sonic screwdriver in the image and likeness of the universal model from the Doctor Who series, capable of influencing various mechanisms through cybernetic waves, has not yet been created.

But progress does not stand still, and who knows, maybe in the near future humanity will receive new and cutting-edge devices.

There are already models that make a bench screwdriver look like a model of a tool from the past.

But as before, a set of reinforced all-metal screwdrivers remains a popular case for specialists of various profiles.

So what is remarkable about the modernized types of screwdrivers?

More about this.

Dielectric

Screwdrivers of this type are used for electrical installation work.

Special insulation of the screwdriver shaft protects the technician from electric shock, which allows the tool to be used for unscrewing high-voltage parts.

This type of tool is often equipped with an indicator to recognize hidden wiring, which allows you to “call” these areas for the purpose of subsequent repair of electrical networks.

Drums

This type of tool is used to work with large parts, since the principle of its operation is aimed at creating an enhanced impulse.

During screwing, the impact energy is directed directly to the screw, which allows you to sink the part without any special effort.

The set with the impact screwdriver comes with various attachments, all of them, as a rule, of a large size.

This type is often used when fasteners are damaged by corrosion, when the fastener grows tightly into the surface.

Thanks to the impact mechanism, such bolts can be unscrewed without additional physical effort.

Reversible

For long-term work with fasteners, a reversible screwdriver with a ratcheting mechanism is designed.

This type of tool comes with replaceable bits of different sections and diameters.

Thanks to this tool, you can easily screw in and tighten various parts without lifting your hand.

The product has a rotating tip, which rotates due to reverse rotation, while the master’s hand remains motionless at this moment.

An ultra-modern mechanical screwdriver is most suitable for specialists whose line of work involves frequent work with parts.

Rechargeable

Improved design, has a built-in battery, thanks to which the product can work as a screwdriver.

With such a tool, the master does not need to put any effort into screwing at all, and the tightening will be of better quality with a adjusted force than when screwing by hand using another type of tool.

Read also: Horizontal broaching machine 7510 technical specifications

Such models are used for assembling various products and repairing them.

Telescopic

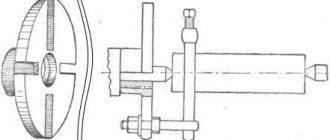

The tool has a special structure of the rod in the form of a fishing rod, which allows you to adjust its length.

Using a special locking mechanism, the set length parameter can be securely fixed.

Such models often have magnetic tips, making the work of the master easier.

For example, using a magnet, you can remove a fallen screw from a hard-to-reach place, or increase the length of the rod to work with a tool with parts located at greater depths.

Dynamometric

Torque models of tools are used mainly in high-tech industries, for example, in aviation, shipbuilding, etc.

A special screen is built into the tool handle, which displays the force applied when tightening any part.

This is a very convenient and useful function, since this is the only way a specialist can set the required torque and fasten all parts with the same force.

What types of screwdrivers are needed for each specific specialist’s work depends on the person’s field of activity.

Today there is a huge number of tools for performing a variety of types of plumbing and installation work.

When choosing a specific tool, it is especially necessary to pay attention to the product markings; this is the only way to protect yourself from buying a counterfeit of dubious quality and to purchase a factory-made tool.

Torx

- a type of slot for threaded fasteners in the shape of a six-pointed star.

Registered trademark [1] of Textron Fastening Systems (now Acument Global Technologies). The official name recorded in the ISO 10664 standard is hexalobular internal

[2];

in the Russian version GOST R ISO 10664-2007 - star-shaped recess for bolts and screws

. Everyday names are star, asterisk, torx.

Features of the flat tip tool

A straight-slotted or, in other words, a flat-head screwdriver is usually marked with several Latin symbols SL. The main purpose is to screw in or unscrew screws that have one straight slot on the heads. It is worth noting that such hardware is not able to withstand heavy loads. It is most often used for minor household repairs.

A flat-head screwdriver does not allow you to screw in the screw tightly, since the peculiar head does not allow you to tighten the fastener tightly. When you press hard on the hardware, the slot of the tool is often cut off. It is not always possible to unscrew a rusted screw with a flat screwdriver.

Features of cross-head tools

A Phillips screwdriver is usually marked with two PH symbols. This is the most common variety. It is worth noting that two in-depth slots on the hardware provide reliable adhesion to the tool tip. Thanks to this, the mount is fixed more securely. A screw with this type of screwdriver can be screwed in more tightly than with a flat-head screwdriver.

If the hardware is made of high-quality metal and not raw steel, then it is simply impossible to rip off the splines of the tool. Screws are used both in everyday life and in professional construction. Therefore, the Phillips screwdriver is used in many fields.

There is another type of instrument. In the furniture industry, a Phillips screwdriver with guides is used. Such a tool has not only a tip, but also additional edges that provide more reliable adhesion to the hardware.

Varieties [ edit | edit code ]

- Torx. Denoted as T or TX. It is a tool in the form of a six-rayed star, inserted into the corresponding recess on the fastener (screw or bolt).

- Torx External. Designated as E. It is an inverted Torx - the fastener has a star-shaped head, and the tool has a corresponding recess. Typically used in cars to reduce the size of a bolt head. There is no such thing as anti-vandalism. Available in sizes E4 to E44. The size numbering does not correspond to a regular Torx - for example, an E4 key will fit a T20 insert.

- Torx Tamper Resistant (anti-vandal) is designated as TR

. In the middle of the slot there is a pin and a hole corresponding to this pin in a screwdriver or key. Other names: Security Torx, pin-in Torx.

- Five-spoke Torx. One of the anti-vandal options. Found under the names 5-lobe Torx, Brigadier Pentahedron key set, sometimes Pentalobe, which is incorrect, since Pentalobe is a separate daisy-shaped slot used in Apple electronics.

- Torx Plus. Improved spline with cut off ends of the star. Designated as IP (Internal Plus), it comes in sizes from 1IP to 100IP (sometimes labeled as IP1-IP100). Partially compatible with Torx - a Torx tool can work with Torx Plus fasteners, but does not provide maximum torque. The Torx Plus tool cannot work with Torx fasteners.

- Torx Plus External. External Torx Plus option. Designated as EP (External Plus), it comes in sizes from 1EP to 42EP (EP1-EP42). Also has mini variants from H7EP to H2EP.

- The anti-vandal version of Torx Plus has five arms and a pin in the center of the recess. The marking is not specified in the standard, but may appear as TS or IPR.

Special screwdrivers

In addition to the main types, there is a whole set of special screwdrivers designed for highly specialized work.

Often such tools are made by manufacturers of branded products, thereby wanting to protect their products from counterfeiting and unauthorized opening.

Specialized types of tools include: hex models, screwdrivers with an asterisk, trefoil, spanner, etc.

Such products have a non-standard spline shape, which allows you to screw in fasteners with a special thread.

Read more about the types of specialized screwdrivers

1. Star screwdriver (TORX marking) – has a tip in the shape of a six-pointed star.

The tool is rarely used - screws for this type are installed if the manufacturer wants to limit unauthorized unproblematic access to technically important parts.

The product is mainly used for repairing small household appliances, mobile phones, etc.

2. The hexagonal spline is a product marked HEX.

A distinctive feature of this model is the high level of torque, which is many times greater than all of the above options.

This type of tool is used for work in the furniture industry, as well as in those places where a reliable connection is especially necessary.

3. Another version of hex screwdrivers is called hexagons and the difference from the previous type is the convex part of the tip.

4. The three-beam screwdriver has a non-standard slot shape in the form of a trefoil, which is actually its advantage.

Fasteners of this form are almost impossible to disassemble on your own; this feature ensures reliability and protection of equipment from unauthorized entry into systems, such as audio equipment.

5. U-shaped screwdriver or “Spanner” - has a tip in the form of two pins.

The spanner is used in the repair of household appliances and elevators; thanks to the unusual shape of the tool, it is often possible to avoid the consequences of vandals.

6. Asymmetrical cross - such a slot of hardware is almost impossible to find in everyday life.

A special feature of this slot shape is that the tool is used in the aerospace industry.

Another advantage of this type is the strong tightening torque, which is not found in any other model.

7. A square screwdriver is also a rare type that has a narrow scope of application, because its tip is made in the form of a square.

This is a kind of hexagonal model.

The unusual shape of the tips of specialized screwdrivers allows you to screw in and unscrew screws with complex threads quickly and without much effort.

What kind of screwdrivers are there?

There are a huge number of types of screwdrivers, and each of them performs different tasks.

We will not write much about the usual options, since everything is clear with them: the Phillips allows you to manipulate screws that have recesses in the form of a cross on the head, and the flat one unscrews and tightens screws with one straight recess.

Now let's take a closer look at special-purpose screwdrivers:

- Dielectric. Allows you to work with electrical network elements and power equipment. Feature: can withstand high voltage.

- Reversible. Thanks to a special mechanism in the handle, they allow you to work with fasteners without tearing off the tip.

- Hexagonal. They have 10 times the torque of a standard tool. Most often they are used when working with machinery and electrical appliances.

- Star-shaped. They are equipped with an asterisk at the end of the rod. This tool is used in working with electrical engineering. Thanks to this type of tip, the grooves in the fastening element are not cut off.

- Square. Equipped with a square tip.

- U-shaped. Manufactured for fasteners with two holes in the head. You can make them yourself by cutting the classic flat tip.

- Triangular. They have a triangular tip.

- One way. Such fasteners are used where it is necessary to secure additional protection. The difference between this type of fastener is that it can only be tightened, but cannot be unscrewed.

- Drums. Allows you to unscrew fasteners that are covered with rust. It is used in cases where the fastening element cannot be unscrewed with a classic screwdriver.

- With flexible shaft. Allows you to work with fasteners in tight spaces. It is used when working on cars or assembling furniture.