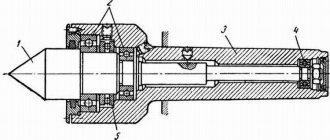

The main purpose of the 7:24 tool cone is CNC machines equipped with a unit for automatic tool change. This type of cone does not have the disadvantages inherent in the Morse taper, which is fixed by self-jamming, which is difficult for automatic installation into the machine spindle. In addition, the 7:24 cone has a larger axial stop area, which affects the accuracy of installation, and the ability to replace the rods designed for tightening and fixing in the spindle with a special mechanism. The dimension of the cone part is indicated by a number from 10 to 80 after the name of the standard, of which there are several.

- ISO. International standard ISO 7388, based on the German DIN. Designation example: ISO30.

- D.V., S.K. German standards DIN 2080, an analogue of the domestic GOST 25827-93 version 1, and DIN 69871 similar to GOST 25827-93 version 2. Designation examples: SK50, DV40.

- BT. Japanese standard MAS 43 BT. Due to the proliferation of machines and equipment manufactured in Asia, domestic manufacturers of tooling and fixtures also produce tooling and fixtures of standard sizes according to this standard.

National standards of other countries, for example, the American ANSI B5.18 with the cone designation as NMTB and NST, ANSI B5.50 with the letters CAT, CV, or the French NFE 62540 are not widely used in our country.

The domestic machine tool industry produces machines and equipment with a tool cone of the German DIN standard (SK - Steil Kegel, “steep cone”) similar to GOST 25827-93, which also displays the standard size “25827-93 version 3” compatible with machines manufactured before 1994, in which are clamped not by a collet that grabs the post by the head part, but by a rotating threaded shaft that performs both clamping with a stop after achieving the required force, and unclamping of the tool.

Morse taper and metric taper

Morse taper is one of the most widely used tool mounts. It was proposed by Stephen A. Morse around 1864.

The Morse taper is divided into eight sizes, from KM0

up to

KM7

(English MT0-MT7, German MK0-MK7). Taper from 1:19.002 to 1:20.047 (cone angle from 2°51'26″ to 3°00'52″, cone slope from 1°25'43″ to 1°30'26″) depending on the size.

Metric cone

As the machine tool industry developed, it became necessary to expand the range of sizes of Morse cones, both larger and smaller. At the same time, for the new standard sizes of the cone, they chose a taper of exactly 1:20 (cone angle 2°51'51″, cone slope 1°25'56″) and called them metric cones

(English Metric Taper). The standard size of metric cones is indicated by the largest diameter of the cone in millimeters. GOST 25557-2006 also defines reduced metric cones No. 4 and No. 6 (eng. ME4, ME6) and large metric cones No. 80, 100, 120, 160, 200 (eng. ME80 - ME200).

There are no design differences between the Morse taper and the metric taper.

Dimensions of the outer and inner cone (according to GOST 25557-2006), mm

Table 1

| Cone designation | Taper | D | D 1 | d | d 1 | d 2 | d 3 max | d 4 max | d 5 | l 1 max | l 2 max | l 3 max | l 4 max | l 5 min | l 6 | |

| Metric | № 4 | 1:20 | 4 | 4,1 | 2,9 | — | — | — | 2,5 | 3 | 23 | 25 | — | — | 25 | 21 |

| № 6 | 1:20 | 6 | 6,2 | 4,4 | — | — | — | 4 | 4,6 | 32 | 35 | — | — | 34 | 29 | |

| Morse | KM0 | 1:19,212 | 9,045 | 9,2 | 6,4 | — | 6,1 | 6 | 6 | 6,7 | 50 | 53 | 56,3 | 59,5 | 52 | 49 |

| KM1 | 1:20,047 | 12,065 | 12,2 | 9,4 | M6 | 9 | 8,7 | 9 | 9,7 | 53,5 | 57 | 62 | 65,5 | 56 | 52 | |

| KM2 | 1:20,020 | 17,780 | 18 | 14,6 | M10 | 14 | 13,5 | 14 | 14,9 | 64 | 69 | 75 | 80 | 67 | 62 | |

| KM3 | 1:19,922 | 23,825 | 24,1 | 19,8 | M12 | 19,1 | 18,5 | 19 | 20,2 | 80,1 | 86 | 94 | 99 | 84 | 78 | |

| KM4 | 1:19,254 | 31,267 | 31,6 | 25,9 | M16 | 25,2 | 25,2 | 24 | 26,5 | 102,5 | 109 | 117,5 | 124 | 107 | 98 | |

| KM5 | 1:19,002 | 44,399 | 44,7 | 37,6 | M20 | 36,5 | 35,7 | 35,7 | 38,2 | 129,5 | 136 | 149,5 | 156 | 135 | 125 | |

| KM6 | 1:19,180 | 63,348 | 63,8 | 53,9 | M24 | 52,4 | 51 | 51 | 54,6 | 182 | 190 | 210 | 218 | 188 | 177 | |

| KM7 | 1:19,231 | 83,058 | — | 285.75 | 294.1 | |||||||||||

| Metric | № 80 | 1:20 | 80 | 80,4 | 70,2 | M30 | 69 | 67 | 67 | 71,5 | 196 | 204 | 220 | 228 | 202 | 186 |

| № 100 | 1:20 | 100 | 100,5 | 88,4 | M36 | 87 | 85 | 85 | 90 | 232 | 242 | 260 | 270 | 240 | 220 | |

| № 120 | 1:20 | 120 | 120,6 | 106,6 | M36 | 105 | 102 | 102 | 108,5 | 268 | 280 | 300 | 312 | 276 | 254 | |

| № 160 | 1:20 | 160 | 160,8 | 143 | M48 | 141 | 138 | 138 | 145,5 | 340 | 356 | 380 | 396 | 350 | 321 | |

| № 200 | 1:20 | 200 | 201 | 179,4 | M48 | 177 | 174 | 174 | 182,5 | 412 | 432 | 460 | 480 | 424 | 388 |

Shortened Morse tapers

For many applications, the length of the Morse cone turned out to be excessive. Therefore, nine standard sizes of shortened Morse cones were invented, obtained by removing the thicker part of the Morse cone. The number in the short cone designation is the diameter of the new thick part of the cone in mm. Russian standard for shortened cones GOST 9953-82 “Shortened tool cones. Main dimensions."

- B7

- shortened to 14 mm

KM0

. - B10

,

B12

- shortened to 18 and 22 mm, respectively,

KM1

. - B16

,

B18

- shortened to 24 and 32 mm, respectively,

KM2

. - B22

,

B24

- shortened to 45 and 55 mm, respectively,

KM3

. - B32

- shortened to 57 mm

KM4

. - B45

- shortened to 71 mm

KM5

.

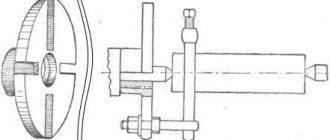

Morse taper is one of the most common means for securing a tool on a machine. This instrument received its name in honor of the famous engineer Stephen Morse, who lived in the 19th century. Today, fractional numbers are used to correctly select the size of this product. There are several standardized values, differing in angles of inclination and sizes.

The area of application of the Morse cone is mechanical engineering. With its help you can quickly and very accurately secure the cutting tool. To do this, the Morse taper is mounted in the machine in a special hole or chuck, and a drill, for example, is inserted into it. This fastening method guarantees the most accurate centering and subsequent processing. It can also be used to supply cutting fluid to the workpiece or cutting tool.

Standard sizes of cones according to DIN 2080 and GOST 25827-93 standards, version 1

Due to the absence of a belt with a groove designed for the manipulator to grip the tool magazine and the inability to install a post for automatic clamping, it can be used on machines with manual tool change and fixation with a long ramrod (pull rod) through the internal hole of the spindle.

| N cone | D | D1 | d1, H7 | d2, a10 | L h12 | l | l1 | a±0.2 | l2, min | l3,min | l4, min | l5, min | M | hmax | b H12 |

| 30 | 31,75 | 50,0 | 13,0 | 17,4 | 68,4 | 48,4 | 3,0 | 1,6 | 8,0 | 5,5 | 24,0 | 34,0 | M12 | 16,2 | 16,1 |

| 40 | 44,45 | 63,0 | 17,0 | 25,3 | 93,4 | 65,4 | 5,0 | 1,6 | 10,0 | 8,2 | 32,0 | 43,0 | M16 | 22,5 | 16,1 |

| 45 | 57,15 | 80,0 | 21,0 | 32,4 | 106,8 | 82,8 | 6,0 | 3,2 | 12,0 | 10,0 | 40,0 | 53,0 | M20 | 29,0 | 19,3 |

| 50 | 69,85 | 97,5 | 25,0 | 39,6 | 126,8 | 101,8 | 8,0 | 3,2 | 12,0 | 11,5 | 47,0 | 62,0 | M24 | 35,3 | 25,7 |

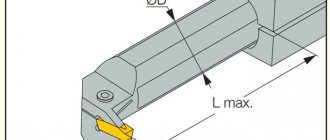

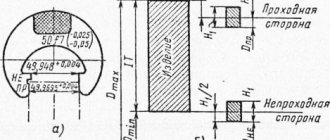

Dimensions and elements of the Morse cone

The distinguishing feature of one Morse taper from another is its size. There are several types of them and, in accordance with GOST, each has a specific number and abbreviation. To measure it, you need to use a calibration, or best of all, a special table that will allow you to calculate dimensions down to the micron. Depending on the machine on which the part will be processed, you should choose, for example, a cutter, a drill, and then the type of invention of Stephen Morse.

With the development of the engineering industry, a need arose to expand the model range of Morse cones. For this purpose, a metric cone was developed, which did not have any special design differences from its predecessor. Its taper was 1:20, with an angle of 2°51'51″ and a slope of 1°25'56″. Metric tapers have made it possible to create a large selection of tools for various machines and operations. They are classified into two categories: large and small. Large ones are designated, for example, No. 120, 200, and the numbers correspond to the largest diameter of the metric cone.

A tool taper is a conical shank of some cutting tool and a conical hole in the spindle or headstock of the same diameter. Its function is to quickly change cutting tools and maintain high precision when centering and clamping.

It is used mainly in CNC machines because it eliminates a number of disadvantages of a conventional Morse taper.

Advantages:

- jamming of shanks in the spindle is much less;

- smaller sizes;

- improved axial stop;

- ease of fastening;

- automatic change of cutting tool.

Nowadays, Morse cones are manufactured in accordance with the international ISO and DIN standards. In Russia, the standardization system combines into one class both simple Morse cones, as well as metric and instrumental ones. Information about them can be obtained from GOST 25557-82. The situation with a single GOST has developed due to the fact that Morse cones have been very popular in our country since the times of the USSR, and in parallel with this, many new ones have appeared.

Download GOST 25557-82

Morse tapers are divided into 8 categories. Abroad these are MT0, MT1, MT2, MT3, MT4, MT5, MT6, MT7. In Germany, the numbering is the same, but the letter designation is MK. In our country and in the post-Soviet space KM0, KM1, KM2, KM3, KM4, KM5, KM6 and No. 80.

As time has shown, some foreign-made Morse cones are inconvenient to use due to their large length. For this case, a series of shortened products has been developed, having 9 sizes.

The best varieties of cones today

These days, tool Morse tapers from HSK, Capto and Kennametal are especially popular due to their quality. Good resistance to temperature changes and compliance with stringent requirements in the machine tool industry have allowed Morse tapers of these brands to become market leaders.

HSK are hollow instruments with a taper of 1:10. They are designated by a letter of the Latin alphabet and a number indicating the larger diameter of the flange. The main feature of such products is quick tool replacement, which is very important in CNC machines.

Capto tool tapers comply with the international ISO standard and are high quality products. The products are expensive due to the complexity of manufacturing, but high precision will minimize production defects when using these tools on machines. The design feature does not allow them to turn during operation of the machine; self-jamming occurs. The rigidity of the connection of Capto products is their main advantage over other competitors

Kennametal products are less common, but still do their job very well.

The products of B&S, Jacobs and Jarno are distributed mainly in the USA, as they do not have confirmation of international standards and are created, respectively, for the American market, where they are in great demand.

Bridgerport Machines has developed the R8 model for collet clamps on its equipment. But then the invention was finalized and released onto the international market. The effectiveness of this remedy caused a sensation at one time and all sorts of analogues began to appear. Today the company produces only one type of such mechanism.

The 7:24 tool taper is widely used in CNC machines, where tool change occurs automatically. Being instrumental, it has a number of advantages over conventional ones and that is why it is so popular in the machine tool industry. There are many varieties of it. Many countries have developed their own standards for it and therefore 7:24 models from different manufacturers do not replace each other.

The 1:50 cone is also widely used in the mechanical engineering industry if it is necessary to additionally fasten two products with a threaded connection. To do this, the 1:50 model has special pins that must be inserted into the workpieces, having previously drilled holes in the appropriate places.

Standard cone sizes MAS 403 BT

Tapered shanks of the Japanese standard JIS B6339, which have no domestic analogues. They are used mainly on machines and equipment manufactured in the Asian region.

| N cone | D | d1, h8 | d2 | d3, H8 | M | L ±0.2 | lmax | l1 | l2, +0.5 | l3,min | h, -0.2 | b, H12 |

| 30 | 31,75 | 46,0 | 38,0 | 13,0 | M12 | 48,4 | 2,0 | 20,0 | 7,0 | 24,0 | 16,3 | 16,1 |

| 40 | 44,45 | 63,0 | 53,0 | 17,0 | M16 | 65,4 | 2,0 | 25,0 | 9,0 | 30,0 | 22,6 | 16,1 |

| 45 | 57,15 | 85,0 | 73,0 | 21,0 | M20 | 82,8 | 3,0 | 30,0 | 11,0 | 38,0 | 29,1 | 19,3 |

| 50 | 69,85 | 100,0 | 85,0 | 25,0 | M24 | 101,8 | 3,0 | 35,0 | 13,0 | 45,0 | 35,4 | 25,7 |

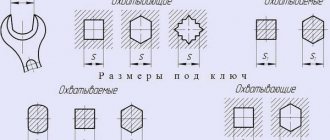

Basic information about shanks and their designation

There are several types of instrument cones. It may contain threads, a foot or do without them.

A thread can be cut at its end, which is made to secure the tool to the spindle using a pin. This is a special rod that prevents the tool from falling out. It can also be used to remove the product if it accidentally gets stuck in the spindle.

If the shank is made with a foot, then it holds the tool in the spindle due to the fact that it is secured in a special groove. The foot has two purposes: with its help it is easier to remove the product from the spindle, and it also creates a rigid fixation and there will be no turning.

You can also find a design with several grooves and holes. They have different depths and sizes. Their task is to supply cutting fluid to the cutting tool.

Tool shanks come in different designs and are designated by letter codes. Below is their transcript:

- BI – internal, there is a groove;

- BE – external, there is a foot;

- AI – internal, there is a hole along the axis;

- AE – external, there is a hole along the axis with a thread;

- BIK – internal, there is a groove and a hole for feeding;

- VEK – external, there is a foot and a hole for coolant supply;

- AIK – internal, contains holes along the axis and for coolant supply;

- AEK – external, contains an axial hole with a thread and a hole for coolant supply.

External and internal correspond to their names. Depending on the tool used, you should choose an external or internal version.

Shortened Morse tapers

In some situations, the dimensions of the Morse cone are too large and in this case you should use shortened versions.

The names below indicate that the cone has been shortened:

- B7 - up to 14 mm;

- B10 - up to 18 mm;

- B12 - up to 22 mm;

- B16 - up to 24 mm;

- B18 - up to 32 mm;

- B22 - up to 45 mm;

- B24 - up to 55 mm;

- B32 - up to 57 mm;

- B45 - up to 71 mm;

The number in the name informs about the size of the diameter of the new part of the cone. Detailed data can be taken from the relevant GOST.

INTERSTATE STANDARD

Official publication

INTERSTATE COUNCIL FOR STANDARDIZATION. METROLOGY AND CERTIFICATION Minsk

Preface

1 DEVELOPED by Gosstandart of Russia

INTRODUCED by the Technical Secretariat of the Interstate Council for Standardization, Metrology and Certification

2 ADOPTED by the Interstate Council for Standardization,

3. The standard complies with the international standard ISO 297-88 regarding shank dimensions for 7:24 taper tools and is fully compliant with ISO 7388-1-83

Standard sizes of cones determined by GOST 25827-93 version 3

A standard size that has no foreign analogues, designed for machines manufactured before 01/01/1994, including those equipped with automatic clamping and a tool magazine with a manipulator.

| N cone | D | D1, ±0.15 | D2, -0.5 | d1, H7 | d2, a10 | M | L H12 | l | l1 | a±0.1 | l2, ±0.1 | l3, +0.5 | l4, min | l5, min | h -0.3 | b H12 | b1, -0.3 |

| 30 | 31,75 | 50,0 | 46 | 13,0 | 17,4 | M12 | 68,4 | 48,4 | 3,0 | 1,6 | 8,0 | 5,5 | 24,0 | 34,0 | 16,2 | 16,1 | 15,5 |

| 40 | 44,45 | 63,0 | 58,0 | 17,0 | 25,3 | M16 | 93,4 | 65,4 | 5,0 | 1,6 | 10,0 | 8,2 | 32,0 | 43,0 | 22,5 | 16,1 | 18,5 |

| 45 | 57,15 | 80,0 | 74,0 | 21,0 | 32,4 | M20 | 106,8 | 82,8 | 6,0 | 3,2 | 12,0 | 10,0 | 40,0 | 53,0 | 29,0 | 19,3 | 24,0 |

| 50 | 69,85 | 100,0 | 94,0 | 25,0 | 39,6 | M24 | 126,8 | 101,8 | 8,0 | 3,2 | 12,0 | 11,5 | 47,0 | 62,0 | 35,3 | 25,7 | 30,0 |