Every office employee who works with documents is often faced with the need to staple papers. In this case, many people use a stapler. This is the most popular and convenient way. Do you know how to use a paper stapler, what is a tabletop stapler? When did this stationery item appear? How to determine the size of staples for a stapler? About all this and more - prepared material.

What is a stapler for?

Those who work with papers can easily answer this question. A stationery stapler is a device for fastening several sheets of paper. You can, of course, use regular paper clips. But they will not give long-term results. One extra movement, and the papers will scatter in different directions. How does a stationery stapler with a spring work? And what can you fill it with?

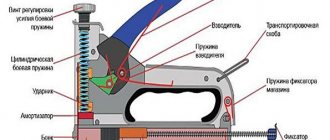

The structure of a stationery stapler includes two main elements:

- shop. This is where you insert the staples into the stapler;

- impact-return device.

You will find out later what kinds of staples there are for a stapler. For now, let's turn to history and go back several centuries.

Marking of staples for a stapler and features of choice

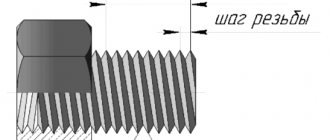

In brackets with fractions, such as 24/6, the value 24 determines the number of these products per inch. The lower the number per inch, the thicker the wire from which the staple is made.

The second digit in the fraction is the length of the leg in mm. When choosing an element for fastening, you must first know in advance the thickness of the papers that need to be punched. To do this, you should press it down a little and take a margin of 3-4 mm for the hem.

The “Kantskorally” store, located at st. Rishelievskaya, 40. For more details, please call: +38.

Who invented the stapler

The first device for stapling documents was developed in the 18th century. It was invented for the collection of King Louis XV. Back then, a stapler was more of a rarity than something unusual. There was no need to use it.

But a century later this device was patented. This was done by a man named John McGill. He changed the stapler somewhat: he changed its material (the new device was made of brass) and increased the speed of stitching, after which the device gained incredible popularity.

Types of staples

It is worth noting that staples differ not only in their performance indicators. In fact, their main classification depends on the type of stapler for which they are intended. The fact is that different purposes require products of different thicknesses and strengths. Obviously, paper staples will break if you try to use them on a wooden board. That is why there are several main types of staplers:

- ordinary and powerful stationery;

- building;

- electric.

There are also narrower categories of staplers for staplers that are used in special production, but the main ones belong to one of the listed types.

Types and sizes of office staplers and staples

There are several types of such devices:

- Quite compact and bright pocket devices. They cost quite a bit. You can't expect much from them. Their capabilities end at ten sheets. They are used as needed: on the road or in the bank. Pocket staplers load wire staples for office purposes;

- more bulky and convenient desktop devices. They bind more than 10 pages. Used in small companies, offices, schools;

- specialized models. They differ significantly in their design. The size of the staples for specialized office staplers is significantly larger than that of previous devices. They are longer and sharper. These devices cut up to 250 sheets. It is clear that they are used in printing houses, as well as large companies.

All these varieties belong to the mechanical type of staplers. But there are also automatic models on sale that run on batteries or mains. All that is required of a person in this case is to bring the documents to a specially designed hole.

It would not be superfluous to mention a device that sews sheets together with paper tape. The invention belongs to Christian Berger. A ribbon is cut from the material to be sewn.

Workers at construction sites know firsthand about such a device as a construction stapler. It also uses a fastening material. The size of staples for a construction stapler is much larger than for a stationery stapler. They act as a kind of nails.

Now let's look at the types and types of staples for a stapler. The following varieties are distinguished:

- The first type is staples for a stationery stapler, which are often size 10. However, you can find others. How to choose staples for a stapler? Nothing could be simpler. Before you buy staples for a stapler, you need to find out what size is written on the packaging of the device;

- the second type is a consumable material for industrial devices. They are thicker and more durable.

The best stationery mini staplers

Mini staplers are small in size and are suitable for stapling 10-20 sheets. Most often, their body is made of bright plastic. There are many products for children in the form of toys in this category.

Kw-Trio Pollex No. 10

The vertical stapler Kw-Trio Pollex is made in gray color, has an ergonomic shape and a reliable mechanism. The handles have black inserts that prevent slipping. Case material: plastic. The maximum number of sheets to be stapled is 15 pieces, while 100 No. 10 staples are placed in the gutter.

Advantages:

- high-quality assembly;

- metal mechanism;

- comfortable handles;

- Possibility of storage in vertical and horizontal position.

Flaws:

- price.

Kw-Trio Pollex No. 10 bends staples in two directions and, with proper use, works reliably for many years.

Attache Master

The Attache brand has released a stapler that staples 20 sheets with a density of 80 g/sq.m. The white plastic case has blue corrugated linings, which prevent fingers from slipping, so the device is comfortable to hold in your hands. The stapler is compatible with staples No. 24/6 (70 pieces fit here) and 26/6 (100 pieces). There is a container for storing paper clips.

Advantages:

- ergonomic shape;

- paper laying depth 45 mm;

- strong bond;

- long operation.

Flaws:

- no stapler.

Attache Master works silently, quickly and efficiently. The absence of a destapler should not be considered a serious disadvantage - a separate mechanical destapler still copes with its task better.

Artfox Set “Fairy Tale Life!”

The children's stapler is made of bright glossy plastic, and on its top handle there is a funny Baby Girl, the sight of which can lift your spirits and brighten up your school days. The design simultaneously fastens up to 20 sheets. Sold with a set of #10 staples in a clear top box.

Advantages:

- original design;

- open and closed stitching method;

- smooth operation of the mechanism;

- sharpened staples.

Flaws:

- the drawing is quickly erased;

- not the cheapest option.

The set fastens paper securely and neatly. A good gift for a schoolgirl.

Mini stapler No. 24/6, 26/6 Berlingo Universal (up to 20 l)

The black plastic desktop stapler punches up to 20 sheets and performs open and closed stapling. For work, staples No. 24 and 26 are used. The product is supplied in a cardboard box.

Advantages:

- matte durable plastic;

- presence of an anti-stapler;

- functionality;

- piercing depth 25 mm;

- inexpensive.

Flaws:

- There are no rubber pads.

Berlingo Universal has a discreet design and is suitable for home and office use.

Staff No. 10 black (224625)

The Staff device punches 10 sheets of paper at a time. The body is made of black plastic and contains a metal staple channel and a spring inside. There is a small protrusion at the back for unbending and removing staples from the paper. Product length 15 cm.

Advantages:

- compact dimensions;

- nice design;

- non-slip surface;

- presence of a destapler;

- very cheap.

Flaws:

- the spring quickly stretches and jumps off the hooks.

Staff No. 10 is good for stitching thin sheets of sheets. It is usually used by schoolchildren and students when stitching together abstracts.

Stapling Types

There are several methods for fastening sheets:

- closed. This is the type of fastening that most people who work in an office are familiar with. The stapler bends the edges of the staples inward. This method is considered the most reliable;

- open. Here everything happens quite the opposite. The edges of the staples extend and bend outward. With this method of fastening, sheets of paper can be easily separated;

- special, involving the use of a stapler with straight staples. When is such a device used? For example, if you need to attach a document to a special board made of soft material.

Advantages and disadvantages

A stapler is a tool that performs tasks better than a standard stapler.

- You get more leverage. Instead of pressing, you squeeze the tool with your hand.

- More access. You can place a paperclip anywhere, because it fastens where another stapler cannot reach.

- Better security. The player can seal a cardboard box with high quality.

The stapler plier for working in weight provides reliable fastening of materials.

The most underrated benefit is the connection that users get from the sight of a stapler. The grip can also be a disadvantage if the handle is too far from the base for the user. Fast, high-quality connections allow people to move quickly from task to task, something that any type of stapler or plier cannot provide.

The office stapler is broken: how to fix it

In case of breakdowns, you need to act according to the situation. If we are talking about small devices (pocket or tabletop), it is best to say goodbye to them right away. However, you can carry out simple DIY repairs. Someone will think about how to open and disassemble a paper stapler. Others will act decisively:

- Remove the housing box.

- They will pull the magazine out of the chute.

- Remove consumables stuck at the outlet. A thin screwdriver or tweezers will help them with this.

- The spring mechanism will be returned.

- The housing will be installed.

- Fix the lower and upper parts, connecting them to each other.

general information

Often the staples are shaped like the letter “P”. Most people are used to using them to bind paper. However, they are also used in the process of upholstery of furniture and walls, when fastening drywall, in the production of packaging, and so on. The main advantages of staples for a stapler are their invisibility and reliability. For convenience, the tips of the products are most often pointed. Thanks to this, they easily penetrate the surface.

Staples are most often sold in blocks. This makes “loading” the stapler much easier. In the first models of the device they had to be placed one at a time. However, now glue is used for fastening. The strips are inserted into a special box of the device and pushed out one at a time when pressed. The mechanism of each stapler is designed for a specific size and shape of staples, which must be taken into account when purchasing.

How to choose a stapler

First, you need to decide how often you will use the device. If the application is active, then you can opt for more reliable metal models. If not, then plastic options will do.

Secondly, you need to take into account the power of the device. The higher it is, the more pages the stapler can sew.

Finally, when choosing a device, it is important to remember that certain models cannot work under weight. Otherwise, all the staples will fall out of them.

540 total views, 1 views today

780200cookie-checkHow to choose a stationery stapler?no

Choosing a stapler

The type of materials you plan to fasten also plays a role. Bonding tapes and other fragile materials is different from bonding paper or upholstery. Staplers are heavy-duty pliers that have pneumatic or electrical components installed for stapling in warehouse and industrial settings. Think about your needs to select a tool that will meet the toughest requirements needed to achieve results.

Also look for an all-metal construction if you plan to use this type of stapler on a regular basis. If you work in the dry cleaning sector, as a florist, or set up retail displays, then the accuracy and ergonomics of all-metal structures will be higher than in comparison with plastic structures.

All metal construction

This type of pliers is suitable for film fastening and use in simple conditions. Resistant to chemicals. They are available with galvanized and stainless steel brackets.

Medium Duty Pliers

Pliers for medium-duty applications such as dry cleaning, clothing labeling and flower packaging. Staples 2-20 sheets of carbon paper. Galvanized and stainless steel staples are used.

Wave pliers

Wave-shaped pliers. This lightweight stapler is ideal for laundries, dry cleaners, florists, POS terminals, factories and offices. It has a steel structure, chrome finish, and galvanized and stainless steel brackets.

Light duty pliers

Pliers for lightweight work such as paper, plastic and canvas. Staples 2-45 sheets of carbon paper.

Player for lighter applications

Player for free applications. Assembling small cardboard boxes, plastic, paper, canvas.

Anvil pliers

Anvil bag pliers are designed for heavy-duty applications such as packing bags of chicken and packing iced products. Stainless steel staples are used.

Staple shapes

Despite the fact that many are accustomed to seeing U-shaped staples, there are other options that are used much less frequently. In general, according to this criterion, only 3 types of products can be distinguished:

- U-shaped – rectangular, they are the most popular and versatile;

- U-shaped – made in the shape of an arc, most often used for fastening wires and cables;

- T-shaped - the least common, they allow you to make the most hidden fastening that does not carry a special load.

In addition to the basic shape, staples can differ in the type of sharpening of the tips. The sharper they are, the easier they are to use. The backs may also differ: there are narrow, wide and flat. The first are suitable for inconspicuous fastenings, the second - for more reliable work (plasterboard, chipboard), and the third - for non-woven materials.

How to insert staples into a stapler

For those who don't interact with a variety of staplers often, the question of exactly how to place staples for the job may be far from obvious. It all depends on the type of device.

Stationery stapler

Most of these devices have a special cover that must be opened. There is a spring there that is manually retracted. Next, the strip of staples is installed in the compartment that appears. After this, you can lower the mechanism so that it firmly secures the strip in the stapler. To check how correctly the staples are selected and installed, just staple a couple of sheets of paper together.

Electric stapler

This option is also called automatic. Here, first of all, you need to disconnect the device from the network or remove the batteries. Next you need to press the “rev” button. After this, a special slot for staples slides out. Having placed the fasteners in it, you can close the device, connect it and check it.

Construction stapler

Another extremely popular stapler, which is actively used during finishing work.

Threading staples is in many ways similar to the stationery option. At the bottom of the gadget you need to remove the spring. Next, the strip is inserted into the compartment and fixed. The main thing is to press the spring all the way. After this, you can check the device and continue using it for its intended purpose. By choosing the right staples for your stapler, you can easily use it for many years, just periodically updating the strip. The main thing is to take into account the size of the staples, their type, shape and the material from which they are made. In this case, the work will be productive and safe.

Prices for staples for staplers

As a rule, the cost of staples is quite small - about 15-30 rubles per thousand pieces of size “10” (office staplers). Staples in sizes “24” or “26” cost a little more - 30-60 rubles per thousand pieces. Specialized staples designed for a specific stapler model are more expensive. As a rule, the price is regulated by the manufacturer, and there is often a large markup for the brand.

As for staples for construction staplers, due to the use of more expensive materials in their manufacture, they are more expensive than office staples. Thus, the most common size “53” costs on average about 300 rubles per thousand pieces. Other sizes, as well as specialized brackets, cost more.

Staples

Staples are small U-shaped wire products that are used to “stitch” papers together.

Depending on their purpose, they vary in length, width, and also in the metal from which they are made. To help them stitch papers better, the ends of the staple legs are always pointed.

In early models, the staples had to be inserted one at a time. However, in the twentieth century, the Boston Wire Sticther Co. I came up with a way to fasten staples for a stapler with glue. The types and sizes of staples no longer mattered. Fastened with glue, they were easily tucked into the device, simplifying its use. Since then, all staples have been sold as glued strips that can be easily inserted into a stapler.

Staples for construction stapler

Unlike a stationery stapler, in a construction stapler the most common staple size is “53” (width 11.4 mm, length 4-14 mm). They are suitable for most construction equipment, regardless of their subtypes. By the way, many construction staplers, due to their universal design, can use several types of staples at once.

For more durable “stitching” of wooden and other surfaces, staples numbered “36”, “140”, “300” and “500” are used. Since the length of the legs for all these numbers can be very different, you need to read the accompanying documentation very carefully.

Staple sizes

Despite the classification described above, for many, the size of the staples is a significant indicator. It’s not surprising, because for different staplers they are made in a special format. This takes into account the thickness of the wire, as well as its shape. There are several most common types:

- Width 10 mm is an option that is used for office purposes. Most often it can be seen in offices, where it is used to fasten sheets of paper;

- Width 24 mm is another format for a stationery stapler. However, this option allows you to combine a larger amount of material;

- The 53 mm type is the most popular. Thickness is 0.7 mm;

- Type 140 mm – fairly large staples. They are often used in a professional environment.

In general, the size of the staples affects the strength of the attachment. There are other variations that are less popular but are also used for different purposes. For example, type 4 (C) staples for a construction stapler, which are suitable for both pneumatic tools and electrical devices.

Materials for staples

It is customary to use metals in the production of staples. Due to the variety of resources, you can vary the cost of the finished product, strength and other characteristics. In most cases, 4 main metals are used for manufacturing:

1. Aluminum is the most economical option. It is rarely used on hard surfaces and areas that must withstand high loads. If too much force is applied during application, these staples will become deformed. Their main advantage is resistance to rust;

2. Copper staples are also often used when working with non-rigid materials. They also do not rust, but due to their high cost, they are not nearly as common as aluminum ones. Very often they are used for fastenings under wallpaper or plaster;

3. Steel – more durable and practical. They may or may not be hardened, which affects the final cost. Unfortunately, such staples are prone to rusting;

4. Galvanized – the most stable. Most of the branded staples are made from this metal. Due to their reliability, they provide long-term fastening.

Regardless of material, staples may or may not be sharpened. The former are better suited for a manual stapler. They allow you to work without pressure. The second option is most practical in automated production, where electrical gadgets are used.

What is a stapler and what is its purpose?

A device for fastening (“stitching”) papers is a stationery stapler. This small device is designed to “stitch” several sheets of paper using a thin steel wire (bent in the form of a staple).

The first stapler appeared in the eighteenth century in France with its ruler, Louis the Fifteenth. However, back then staplers were more of an interesting curiosity than an important device.

But John McGill in the mid-nineteenth century (when science, as well as bureaucracy, began to actively develop) saw prospects in the production of staplers and, having slightly modified the model of the time of Louis the Fifteenth, patented this device. Soon, John McGill's brass stapler, capable of reliably and, most importantly, quickly fastening sheets of paper, became an incredibly popular device.