A furniture stapler is a fairly universal tool with which you can not only perform furniture upholstery procedures, but also a number of other construction operations.

Today, there are several types of similar equipment, differing in their operating principles:

- pneumatic,

- electric,

- manual.

Pneumatic staplers are used in industry, and electric and manual staplers are used in everyday life. Models belonging to the latter type are the most common in the furniture industry due to their mobility and ease of use. Let’s use this example to look at the principle of operation, operation and repair of furniture staplers.

However, before moving on to this procedure, I would like to say a few words about staples and their varieties.

Changing staples in a furniture stapler

It is difficult to imagine a person who has never encountered the mechanism of a stapler, even a simple stationery one. But the mechanism of the stationery model and the furniture model is the same. The process of changing brackets is similar in principle and takes a short time. The correct sequence of actions will allow you to change consumables without delays and increase the productivity of furniture upholstery.

To change and install new ones yourself, you should first read the instructions, but if you don’t have them when purchasing them, then the following tips for changing will come in handy:

Changing staples in a furniture stapler

The first step is to get the mechanism that is responsible for holding the staples in the gun. This must be done carefully.

- Next, you need to prepare new staples and also carefully place them, point down, into the special slot intended for them.

- This very mechanism needs to be put back. A characteristic click will indicate that everything is done correctly and the mechanism is ready for use.

To make sure it works, press the stapler tightly and fasten it. A click will mean that you can release the trigger mechanism that reproduces the pistol and evaluate your work.

That's all you need to know about furniture staplers, staples and how they work together.

An indispensable device for performing everyday tasks is a stapler. It is intended for joining plastic panels, furniture fabric and other surfaces made of plastic or wood. During the operation of such a device, it becomes necessary to insert staples into the stapler.

The problem of issuing a pair of staples at once

How to repair a stapler yourself if it starts producing a pair of staples at once? This problem is more serious. Due to improper use or over time, the firing pin of the impact mechanism may become deformed. If the metal from which the striking part of the mechanism is made was of poor quality, which applies to almost all cheap and Chinese models, its striker can either flatten or bend slightly, as a result of which, with the next blow, it will catch not one, but a pair of staples at once. How to fix the stapler in this case and is it even possible in principle? You can correct the situation, but you will have to disassemble the entire stapler. You can read about the procedure in the next section.

Design and principle of operation of a construction stapler

The furniture stapler is widely used by builders and furniture makers, as well as representatives of other fields of activity. Based on the type of energy used to fire a shot during operation, the following types of takers are distinguished:

The first two types are intended for domestic use, while the last type of tool is considered professional and is used mainly when performing large-scale work. The operating principle of mechanical and electric staple guns is based on pushing out fasteners by the force of a cocked (compressed) spring. After pressing the trigger, it unclenches, which causes the striker to move. He strikes the staple (nail or pin), driving it into the surface of the material.

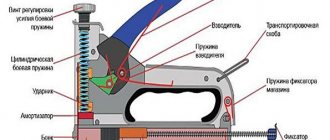

Mechanical stapler design

Manual (mechanical) staplers differ from their analogues in their simpler design. They consist of the following components and parts:

- cocking handle;

- a safety bracket that protects against accidental shots when transporting the tool;

- impact springs;

- shock absorber;

- drummer;

- striker;

- impact force regulator, providing the ability to work with material of varying degrees of hardness (different densities);

- housings;

- charging spring;

- store for fasteners;

- rammer (with spring and lock);

- tip that allows you to accurately drive fasteners.

The diagram of the staple gun device is shown in the photograph below.

The impact mechanism is the main unit of the stapler, cocked by the force of the worker’s muscles. It can be equipped with two types of springs:

- twisted;

- spring (plate).

Manufacturers indicate in the operating instructions for products the type of spring installed.

The twisted spring mechanism shown in the photo above is equipped with cheap models. They can be easily distinguished by the adjusting screw located on the tool body on the opposite side of the staple outlet hole. But it is also possible that the wing will be missing, then you will need to refer to the instructions to determine the type of spring installed.

Leaf springs are more powerful, but more expensive than their coiled counterparts. At the same time, the impact of a tool equipped with them during operation is less. They also have a long service life and are easier to cock. The leaf spring mechanism is installed on models intended for professional use.

To make it easier to work with the tool, the handle is covered with rubber pads, and the magazine is made with a transparent insert (which makes it easy to control the presence of staples or nails).

Design features of electric and pneumatic staplers

The device of a network-type electric stapler is shown in the photo below.

The numbers in the photograph correspond to the following structural elements:

- trigger;

- fuse;

- handle with special coating;

- power cord;

- on/off switch;

- shock force regulator;

- pusher mechanism;

- shop.

Inside the tool there are electric drive and impact mechanisms. In this case, the electric motor is designed to charge the spring.

Battery models do not have a power cord: batteries are installed instead.

The design of a pneumatic furniture stapler is more complex than its mechanical counterparts. Pneumatic tools consist of the following structural elements:

- housings;

- a cylinder with a piston located inside it;

- starting systems (trigger mechanism);

- magazine for fasteners with a pusher;

- impact mechanism;

- an inlet fitting designed to connect a high-pressure hose to the tool;

- regulator of penetration depth of fasteners (impact force);

- air distribution unit.

Pneumatic type scrapers are powered by the energy of compressed air supplied by a compressor or from a cylinder. After pressing the trigger, the gas passes through the air distribution unit. Next, the compressed air enters the cylinder, causing the piston to move. The latter transfers energy to the striker striking the fastener. After impact, the staple or nail is driven into the surface of the material.

Rules for safe use of the tool

When working with a construction stapler, it is imperative to follow safety regulations. The main requirements boil down to the following points.

- When replacing staples, you need to block the tool with a fuse from sudden, unexpected activation.

- It is prohibited to point the tool at your hand or other part of your own body, as well as at other people or animals.

- When transporting or storing the stapler, it is necessary to secure its handle with a safety lock.

- Only a person in a normal psychological state (not under the influence of alcohol, psychotropic substances or drugs) is allowed to work with a staple gun.

- The workplace should be well lit and kept clean.

- It is necessary to constantly use personal protective equipment such as glasses so that nothing accidentally flies into the eye. To prevent the bracket from flying off when fired, you need to monitor the presence of metal inclusions on the working surface, bypassing or removing them in a timely manner.

- If the fastener gets stuck, it must be carefully removed.

- When working with small workpieces, they must be held motionless using a vice or clamps; it is prohibited to hold them with your hands.

- Your body position should always be stable and as comfortable as possible, and your shoes should have non-slip soles.

Instructions for safe work with electric and pneumatic staplers contain additional points:

- corded power tools must not be used inside hazardous areas;

- Only switched off equipment is allowed to be connected to the outlet;

- the power cord with plug and the body of the model being used must be intact;

- It is prohibited to use an electric staple gun in the rain or indoors with high levels of humidity;

- unauthorized persons must be kept at a distance of more than 2 m;

- the pneumatic tool used, the high-pressure hose attached to it, as well as other parts of the system must be free of mechanical damage;

- During work, it is necessary to ensure that the power cord is located behind the tool so that it does not interfere.

There is nothing complicated when using mechanical, pneumatic, or electric types of construction staplers. It is only necessary to use suitable fasteners (specified in the operating instructions) for the job, and before doing so, adjust the impact mechanism for the specific material. At the same time, constant adherence to safety precautions will prevent injury. Attention and accuracy are one of the main guarantees of high-quality performance of any work.

In construction, furniture production and minor repair work, a furniture stapler is often used. The device has several varieties and, when used correctly, significantly reduces the time required to connect certain surfaces to each other.

Types of staplers

First you need to decide what type of stapler you need. These devices are classified according to the type of driving force.

Mechanical

They are operated using hand strength, have low productivity, and a small number of staples that can be “filled” into it. When working with hard materials, this tool is quite complicated and requires considerable effort.

However, mechanical tackers have relatively small dimensions and light weight, which makes it possible to work in awkward positions. In addition, many are attracted by their low price, although there are also models with a fairly high price tag.

Electrical

In such tools, the staple flies out when the trigger is pressed, but the mechanism is driven by electricity. There are models that run on batteries, and others on mains power.

Of course, the productivity of such staplers is much higher than that of mechanical ones, but their prices are much higher, especially for battery-powered types. The dimensions are also larger.

Important! For models that operate from the mains, the cord may interfere with operation, and for battery-powered types, the bulky handle and weight are inconvenient. But physical effort is reduced to a minimum.

Pneumatic

Here the driving force is compressed air, under the influence of which nails or staples fly out of the magazine. Such devices have high productivity and a fairly large magazine - you can refill a furniture stapler with a large amount of consumables at once.

However, the disadvantage of pneumatic models is that they operate from a compressor, which makes a very loud noise. It is very difficult to move with such a unit, so this type of tackler is more appropriate for professional use in a specific place.

Important! If you need a construction stapler only for one-time work - only during the construction or finishing of a house, then it is better to choose a mechanical or electrical model.

How to choose a quality pneumatic stapler?

First you need to decide on the range of planned actions. The conditions in which the tool will be used, the amount of consumables and the condition of the working surface determine the parameters that you need to rely on when choosing. For furniture production, universal models are suitable, which maintain a balance of efficiency in performing work and ergonomic qualities.

Super universal stapler Stanley Fatmax TR75.

If you plan to use the unit at home, it is better to choose an entry-level pneumatic model. Such equipment allows targeted activity with small hardware. If you plan to work with textiles, such a tool will be quite sufficient.

For plywood you will need a pneumatic nailer.

Use of mechanical staplers

Typically, a simple mechanical device is used in everyday life. In another way it is called a construction stapler. If you need a tool for one-time use (upholstering a greenhouse), then it will be quite enough. It can be made of plastic or metal. Plastic is cheap, but breaks quickly. Metal is more reliable and a little more expensive. Which one is more suitable, you need to decide for yourself.

What if the choice fell on a mechanical construction stapler? How to use? Very simple.

Tips for using a mechanical stapler:

- It is better if the model has a screw or adjustment wheel. This way you can select the force with which the bracket will be pressed. It is important not to forget to change the adjustment, because different materials require different forces. So, if it is hard chipboard, then you need to increase it. If the surface is soft, then it needs to be loosened. With the right force, the fastener will go completely into the material and will not stick out.

- We apply the filled gun to the surface. Press the lever (force will be required). Did you hear a characteristic sound? The fastener went in.

- When using a metal stapler, you should press down on the top with your thumb to reduce kickback and distribute the load. The staples will go in easier.

- Do not rush to hammer in the fasteners. Experiment with a rough draft. This will make it easier to adjust the force, and the product will not be damaged.

- Prepare markings on the surface to work with and mark the distance for driving in charges in advance. The fasteners will look organic on the surface, and the material will adhere better.

- If work with the stapler is completed, you need to put it on the safety lock. The staples will not fly out and injure you. The main and difficult question when using a gun: how to fill the stapler with staples? This is not difficult to do. First you need to lock the lever. You need to remove the spring from the back surface of the gun. Next, load the brackets with the ends down and install the bar back until it clicks. It is recommended to refuel the gun while wearing special glasses. The charging method may differ slightly depending on the model, so you need to read the instructions for the unit.

Characteristics and description of the Cherriet F1 radish hybrid, cultivation and care

Safe work techniques

Using a mechanical stapler.

By following safety precautions when using the device, you will avoid unnecessary injury. And the device will last longer:

- Before replacing staples, you need to put the tool on safety. This way he won't shoot by accident.

- Do not point the stapler at yourself or other people or animals.

- When transporting or storing the device, always switch the safety switch on.

- The tool can only be used in a sober mind. Persons in a state of intoxication are prohibited from handling a stapler.

- The work place should be well lit.

- Care must be taken to ensure that staples hit metal surfaces to avoid rebound. It is important to use special glasses to prevent the charge from flying into the eye.

- If the fastener is stuck in the product and is not completely clogged, you must carefully remove it.

- If small parts are used in the work, they need to be clamped in a vice. Driving staples into small surfaces directly in your hand is very dangerous.

- During work, the body position should be natural, clothing should be comfortable, and the sole should not slip.

When working with an electric or pneumatic stapler, you must follow the safety rules described for mechanical tools. More important:

- An electric stapler cannot be used indoors if there is a risk of explosion;

- you need to make sure that the switch on the device is off before plugging the cable into the outlet;

- the device body, electrical cable and plug must be undamaged;

- The power tool cannot be used outdoors during rain and snow, or indoors in high humidity;

- there should be no people or animals in the work area;

- all components of pneumatic tools must be in good working order and not damaged;

- During operation, the power cable must not come into the worker's area.

Mechanical, electric or pneumatic staplers are easy to use. But it is important to use the tool correctly. You need to charge it with fasteners with the markings indicated for your model. It is also necessary to adjust the mechanism for the required force of driving in staples. The main thing: follow safety rules when using. Careful handling and careful use are the key to productive work with any stapler.

Video “Master class on replacing staples in a stapler”:

open the box of staples, take a batch of staples, open the stapler, insert the staples, pointy ends down.

I don’t know if the procedure for inserting staples is the same in all staplers, but I just looked at my stapler and can write this:

- Open the stapler

- Pull the spring device that held the brackets in position downwards,

- Insert the brackets into the space provided (so that you get the letter P standing on a support, and not upside down),

- Slowly return the spring to its place and it will rest against the brackets.

- Close the stapler.

A construction stapler is a multifunctional mechanism. It is used when it is necessary to connect identical or different not particularly hard materials to each other, for example, plastic, wood, film, insulation, plywood. This tool is called differently: tacker, staple gun, staple gun, nailer, staple gun. The individual elements are fastened to each other using staples, pins or small nails. To know how to properly work with a construction stapler, you need to understand its design, the types of fasteners suitable for it, and the method of setting up and replacing staples.

The sequence of adjusting the stapler

Setting up a staple gun is needed in the following cases:

- after purchasing the tool before starting work;

- if the stapler stops completely driving in the fasteners;

- when starting to work with a material of a different density than the previous one.

If the stapler stops driving in the fasteners completely, this is due to gradual wear of the spring of the impact mechanism or its loosening. For some time, the adjustment will help, but after that you will need to purchase a new stapler.

You should take into account the dimensions of the fasteners for which the tacker is designed: if the size of the staples exceeds what is allowed according to the operating instructions, then adjustment has nothing to do with it, you just need to select the appropriate consumables.

Mechanical staple guns with a coil spring have a screw that regulates the degree of compression . It is shown in the photo below with a red arrow.

If you tighten the adjusting screw clockwise, the spring will compress more strongly and its potential energy will increase. The result will be a blow of greater force. The ejected staple will go deeper into the surface of the material. Turning the adjuster counterclockwise will loosen the spring. The blow will also become weaker. By rotating the screw, you can adjust the stapler to work with material of varying hardness (density).

For mechanical models of staple guns with a spring (leaf) spring of the impact mechanism, the regulator is located under the handle. By rotating it in different directions, the force of the shot is adjusted. It is necessary to reconfigure the impact mechanism every time you start working with a different material. After adjusting the spring compression, it is recommended to test the tool's performance on a workpiece that is no longer needed.

The adjustment process ends when the fastener with the entire length of the legs enters the material without piercing it with the “back”. It is recommended to practice by rotating the adjuster from minimum to maximum spring compression.

The problem with staples that keep getting stuck

This problem stems from the same area as in the previous case. Even though the striker of the impact mechanism fits into the slot, if it is even slightly bent, staples will constantly get stuck between it and the guide wall of the casing. At first, it will work normally every other time, and then it will become impossible for it to work at all due to the fact that the staples that become clogged over and over again will deform it more and more. In these cases, it can be stated that the stapler is broken, and how to fix it should be described in more detail.

First of all, you should prepare the necessary tools. What you will need to completely disassemble the stapler:

- a regular screwdriver;

- metal file;

- pliers;

- hammer;

- vice (required).

When everything is prepared, you can start disassembling. There is nothing complicated about this and you shouldn’t be afraid that you won’t be able to assemble it later. You simply won't be able to do it any other way. For repair you need:

- Open the magazine and remove the remaining staples.

- Turn out the adjusting screw completely.

- Remove the released spring through the hole at the top.

- Now disassemble the body. The casing parts are held in place by pins. They have molded caps on one side and locking washers on the other. They must be pulled out so that each pin can freely come out of its hole.

For repairs, it will be enough to remove two pins from the impact mechanism side.

It happens that the stop on the impact mechanism against which the spring rests may break off. In this case, only welding will help, and it is not a fact that the tool will last for a long time in this case. As a result, the welded stop will still fall off and you will have to buy a new stapler.

When the tool is completely assembled, we check it, at the same time adjusting the spring. If everything is fine, you are great. If not, it means that something was “missed” somewhere. You will have to disassemble everything and check the evenness of the parts of the impact mechanism more carefully. Therefore, it is better to do everything efficiently the first time and check it ten times.

How many shells will fit into a stapler?

There is a wide range of staplers with different working holder sizes. Staples can be purchased in small rows that are separated into sections by hand. 1 stapler can freely accommodate 1-1.5 rows, which contain more than 20 staples.

When choosing brackets, builders and furniture makers are guided by their depth. This figure varies from 4 to 14 mm depending on the type of work being performed.

So, to upholster furniture items with fabric surfaces, you need to purchase a bracket with a depth of 8 mm. Fixing thicker structures requires choosing staples with greater depth.

The following types of staples are available in the market:

- 53 - is in greatest demand and has a width of 11.4 mm and a thickness of 0.7 mm. The fastening depth is 4-14 mm.

- 140 - characterized by a width of 10.6 mm and a thickness of 1.2 mm. The depth indicator is equal to the previous variety.

- 36 - the marking indicates brackets with a semicircular shape; they are in demand when laying cables.

- 300 - are a special type of stapler nails.

At the selection stage, you should also pay attention to the material of manufacture of fasteners.

Simple steel products are in demand for processing wooden structures. But if you are working with particle board or plywood, it is better to choose models made of hardened steel. They have an extended service life and cannot be bent.

How to use it correctly

Despite the apparent simplicity of design, working with a furniture stapler requires compliance with a number of rules. Today, several of the most popular and very easy-to-use modifications of the tool are produced (pneumatic and manual types, electric models), but the technology for their use is in most cases common.

The main stages of working with a furniture stapler:

- Move the spring and fill the tool with staples through a special groove.

- Return the spring to its original place and check that the tool is ready for use.

- Press the tool firmly onto the location chosen for fixing the bracket.

- Press the special lever or trigger button.

The success of the “shot” fired is determined by the characteristic sound and the presence of a staple embedded in the upholstery material.

Video: stapler_stapler.AVI

A furniture stapler, or, as they also like to call it, a strobe shooter, is a very necessary thing. But sometimes, even when recently purchased, it begins to work incorrectly and either does not drive the staples into the tree completely, or they completely get stuck in the tool. In most cases, this can be “cured” by simple adjustments or is associated with improper use of the tool. But there are situations when the stapler has already exhausted its service life to such an extent that the parts in it have simply worn out or have worn out over time. How to fix a stapler so that it works again as before, and is it even possible to do this in principle?

Operation of electrical appliances

Most often, electric staplers for furniture are used for reupholstering interior items and for other large-scale repair work. They differ from mechanical ones by having more massive charges. Their service life is longer. And it’s easier to use electric ones. This furniture stapler costs several times more than mechanical models.

People often ask a question about a furniture stapler. How to choose? There are many options here. Electric staplers differ in the following parameters:

- Number of shots. 20-30 per minute is the standard speed. There are also faster staplers - about 50 beats per minute.

- Source of energy. Units with an electrical cord will not be useful everywhere. The wire may be very short. If there is no access to an outlet, the gun will not work. A type of stapler with a battery is more useful here. But such models are much heavier. You need to pay attention to this if you plan to work long hours.

- A very important point: when purchasing a tool, you need to look at its operating characteristics. How long an electrical appliance can be used without interruption. The fact is that the engine of the device heats up. And the staples clog badly. If this happens, you need to stop the device and wait for it to cool down.

- Safety. It is better if the pistol has protection against accidental shots. The design of the stapler can be constructed in such a way that the staple flies out only when it touches the surface.

- Devices are also distinguished by the presence and absence of different operating modes.

- Price. Directly depends on the manufacturer. If the quality of the pistol is important, then it is better to choose German models.

How to insert staples into an electrically powered furniture stapler? The scheme is simple. Just find the button on the back of the gun and pull out the sliding bar. Then load the staples with the ends down and push the chute. It is important to follow safety precautions.

The problem of incomplete driving of staples

This problem can be solved by simply setting up the tool. If the stapler does not jam staples, repairs will not be necessary. Just tighten the spring adjustment screw. The tighter the screw is screwed in, the more tension the spring will be under and the next time it is lowered it will push the bracket to the end.

If the problem is not in the settings and the stapler was working normally before and suddenly stopped, most likely the problem is that one of the next staples was jammed and stuck in the slot. Over and over again, the striking mechanism hits it, but it is stuck firmly, thereby preventing the magazine clamping device from moving the next staple to the “starting” position. Here you need to open the magazine and remove the jammed staple. With the next shot everything will fall into place.

Classification

There are different types of furniture staplers.

Manual

This category also includes manually operated mechanical devices.

These devices hammer the staples in with forceful blows. Compared to manual analogues, the performance of this model is much higher. This tool is convenient for performing the following work:

- Fastening insulating material.

- Installation of roofing felt.

This tool is used for installing cables with a voltage load of 50 V. The maximum cable diameter is 7.5 mm. These staplers are used when performing the following work:

- Cable fixation.

- Laying an electrical network.

- Installation of communication lines.

Classic model

This hand-operated tool has become a true classic. After the release lever is pressed, the staple is driven into the material. A special category is hybrid models, with which you can perform several types of described operations.

They have only one drawback: a relatively high price.

Professional or household

Like all other tools, construction staplers are conventionally divided into professional and household. The difference in price is very significant - many times over. And this is justified. It's a matter of functionality, number of settings, operating modes and working resource. Household models have a short working life, as they are mainly made of plastic. Professional models are made of steel, often stainless steel. They have plastic elements, but these are metal handle covers to soften recoil. It is clear that they will work longer, and they are usually easier to work with - staples fit easier, jam less often, etc.

When choosing a manual construction stapler, you need to pay attention to the body, the height of the handle

There is also an intermediate class - semi-professional. They fall between these two categories in price and quality. Often it is in this group that you should look for equipment for home use. It works fine and doesn't cost much.

see also

Comments 9

Sometimes I also lubricate the stapler. Stayer companies. Still alive. I probably hit 10,000 staples with them at most.

I would throw it away if the new one works like that)) I have the same type, but I’ve never had any problems, I haven’t smeared anything, I haven’t taken it apart

It is advisable to lubricate. Works easier

again dust sticks to the lubricant, here you also need moderate lubrication and not static lubrication))

Yes, there are few places where dust can get in. And there are not such small parts that dust can cause harm. I think so. And everything doesn’t last forever. After lubrication it is more convenient to work. And the reach force is greater) Please lubricate the entire tool. As an option, Runway silicone lubricant dries leaving a slippery layer. But not so durable...

Yes, the gates too, only lubricating with silicone and VD is allowed, but as for the dust, as long as I’ve been living, I don’t understand where the money goes and where the dust comes from)) I don’t use it often for periods, until I had enough strength without lubrication)) maybe I’ll try the thread when

It's not for long. It’s easier to buy a normal stapler, with a leaf spring. They last quite a long time, and these cheap ones are designed for 500 staples.

I’ve been using it for about 5 years now, if not 7. Everything is fine, but like the whole instrument I have to lubricate it periodically

It's not for long. It’s easier to buy a normal stapler, with a leaf spring. They last quite a long time, and these cheap ones are designed for 500 staples.

Come on

Important nuances

When purchasing a paper stapler, it is important to consider how actively you will use it. If you plan to use it often, then pay attention to metal options. They are considered more reliable and will last longer. In other cases, ordinary plastic devices will do.

Their operating principle is absolutely the same. It is also important to take into account that staplers differ in power. This indicator determines how many sheets your device can fasten at a time. By the way, it is also important to choose the right staples for a stationery stapler. It is advisable to know not only their size, but also the manufacturer.

Calendula - medicinal properties and contraindications

In addition, you need to know that there are devices that only work when resting on a table or other flat surface. If you try to fasten papers by weight with such a stapler, the staples will fall out or become deformed.

Additional options

It seems to many that a stationery stapler is a fairly simple device that cannot be improved in any way. But manufacturers are making it more convenient to use. So, when purchasing, pay attention to the fact that there is a plastic footrest or rubberized inserts at the bottom. They will protect your table from scratches.

Another important and convenient addition is the presence of a built-in destapler. This is a special device with which you can quickly straighten the staples. It will come in handy in situations where you need to separate previously fastened sheets. It is inconvenient to pick out staples with scissors, much less with fingernails, and it looks unsightly.

Stapling Types

Not everyone knows that office staplers differ depending on how they fasten sheets. Most office workers are familiar with the common closed-type stitching options. This type of stationery stapler bends the edges of the staples inward. This is considered the most reliable way to bind paper.

It is also the most common. There is also an open type. In this case, the staples are bent outward. This method is preferable to use in cases where only temporary stitching of sheets is necessary. Papers fastened in this way can be easily separated, and the marks are practically invisible.

Sometimes in offices they use a special stationery stapler with straight staples. It is necessary in situations where it is necessary to attach paper (some kind of announcement or document) to a special board with a soft surface. It can be made, for example, from cork.

Wrong option

The mistake many people make is that when the stapler runs out of staples, they pull back the two-sided tabs of the frame lock, open it and try to insert the next clip of staples through the front part on the impact mechanism side. As a result, with an awkward movement, the spring mechanism continually throws the clip back, and it flies many meters away, after which you have to search for it for a long time. Often the clip can fly into the eye of the unlucky “stapler operator”. Here is a video that shows what not to do, although the operator himself is not aware of it.

What to do if a bracket gets stuck

When using a construction stapler, a problem such as breakage of the staple inside the receiver often arises. Fasteners often become bent or stuck in the outlet, causing many problems. To restore functionality, you will need to completely remove the magazine with staples. Professional models have a removable receiver, so repairs will not take much time.

First of all, you should open the metal plate and take out the spring. Next, in the middle of the stapler you need to find an iron part and tightly clasp it with your fingers. This will allow you to remove the entire magazine and remove the jammed bracket.

Reassembling the tool does not require much effort: the removed magazine is put back in its original place, after which a characteristic click should sound. Next, all that remains is to return the spring to the groove.

If you are using a power tool, be sure to adjust the special screw when using the rough material to check. During this stage you need to rotate it from minimum to maximum. If the bracket is well secured from the first shot, proceed to work on the “finishing” part. In other cases, the procedure will need to be repeated.

A furniture stapler is a universal construction device that is suitable not only for upholstery activities, but also for more complex work. If you use this tool correctly, it will serve you for a long time and with high quality.

Replacing the matrix for compact storage of stapled sheets of paper

The matrix is often a stapler where the ends of the staples rest and bend under force. Moreover, they can bend in various ways. The most common is when the ends of the paper clips form semicircular parts.

In view of this, when storing stitched sheets in folders, there is an irrational use of space. Things are different when the ends of the paper clips are bent flat.

Possible mistakes

There are several of the most common, frequently encountered errors and problems that accompany the operation of a furniture stapler. The tool may fire multiple staples at once, or not at all, and may damage upholstery material. Errors are due to the following reasons:

- incorrect pre-adjustment of the adjusting screw when performing work with traditional mechanical models of the device;

- neglect of the rule of advance marking of places for installing staples, which allows for high-quality and uniform tension of upholstery material;

- lack of fixation of the upholstery with a free hand in order to prevent the material from moving during operation with a stapler.

It is important to control the number of staples inside the “magazine” of the tool, and also be sure to secure the handle with a safety lock immediately after finishing work. This will prevent spontaneous or accidental shooting.

It is strictly forbidden to work with a faulty tool. If necessary, the problem is diagnosed, and the firing pin that has exhausted its life is also periodically replaced.

general information

If you have long been interested in the question of which stapler is better to choose, then it will not hurt you to first find out how this tool for fastening papers works.

Principle of operation

Its design includes a metal groove for inserting staples. To move them forward, a special spring or plate is provided. The latter option is considered more practical, since the spring begins to stretch over time and at one point may come off the hooks on which it is attached.

Thanks to the plate, the staple-moving tongue will operate smoothly. Its main task is to ensure that the clip of staples is constantly located at the edge. The push rod is usually made of metal or plastic. And it’s best if this is the first option, which is characterized by increased reliability.

Loading the stapler

Before work, the staples must be placed in the internal mechanism, after which, when you sharply press the device, staples will shoot out of it and fasten the sheets. When all the clips are used up, you just need to insert a new one to continue working.

Typically, full-load stapler models require one new plate of clamped staples to be inserted. However, there are models in which half the clip is enough to replace the spent staples. It's easy to understand how pocket and office staplers work and how many staples they require. You can easily figure out how to change the plates, for which you don’t even need to look for a diagram of the stationery stapler. You just need to lift the top cover and insert a new clip into the groove.

Office supply stores also offer front-loading staplers. These models have a special button on the body, when pressed, the spring of the mechanism is released and the chute moves forward.

We invite you to familiarize yourself with Floor installation in a country bath

Owners of professional devices may experience certain difficulties in replacing staples. Among them there are models that allow you to load 7 types of staples. But they have one feature - they allow users to choose the bonding depth at their discretion.

Special mechanism for installing new blocks with staples

This approach to organizing the device design is the most attractive:

- no effort is required to reach the staple compartment;

- Injuries when installing new staple blocks are eliminated.

The idea is to press the button on the back of the stapler. It has specially selected colors and has a rubberized surface. At the same time, it is located in such a way that it is impossible to press it accidentally.

A tray pops out from the front end of the stationery, where you will need to insert a new block of paper clips.

As far as can be noted, the procedure for inserting new paper clips takes a matter of seconds. However, most stapler models have a less advanced mechanism.

To get to the tray you have to open the top of the stapler. If closing (already with paper clips inside) is not done carefully, you can accidentally puncture your finger.

Many people forget

Before work, adjust the adjusting screw according to the material of the surface you are going to work with.

If it is hard plywood, strong penetration of the material will be required, therefore, it is worth setting a high force. If it is a loose surface, the force must be reduced so as not to break through the fabric, or for example the PVC panel that you are shooting.

During operation, it is recommended to press the lever with one hand and press the adjusting screw with the thumb of the other hand. Then the recoil will be minimal and the load will be distributed evenly in the stapler. You will be able to nail the brackets much better.

Not just parentheses

Some staplers can work not only with staples, but also with studs of various shapes. The designations of what the stapler works with are indicated on its body or in the instructions.

I tuck the nails into the stapler in the same way as with staples, but you need to be careful after pulling out the spring. A row of nails must be loaded along one of the outer edges of the letter “P”, and not inside this very letter!

If you want it to produce two nails side by side when working with a stapler, load the second row along the second outer edge. Next, the spring is inserted and the stapler is closed.

Source: narodnyeokna.ru