Corrugated or smooth reinforcement is often used in the manufacture of reinforcing frames for foundations and other reinforced concrete structures.

Moreover, for the manufacture of metal frames, both straight and bent reinforcement bars are used.

If there are no problems with straight rods - I measured and cut them, then with bent rods you have to tinker. Of course, you can bend the reinforcement with your bare hands, but that’s if you do it too much.

In general, for these purposes, various machines and devices are used at home (popularly they are also called armagibs or simply benders).

In today’s article, we’ll look at several ways to make a homemade bending machine for reinforcement with your own hands.

We would like to immediately draw your attention to the fact that you cannot do without welding and a grinder.

Therefore, if you decide to make a bending device with your own hands, this tool must be at hand. And, of course, you need to know how to use it.

The correct reinforcement bender for yew trees

If you do not need a simple manual machine for bending reinforcement, but a universal device for performing various tasks, then pay attention to this design.

The idea and production of a homemade device belongs to the author of the YouTube channel “IGOR ANDREYCHUK”.

The practicality and functionality of a homemade device can be explained very simply - by using different equipment, you can perform different operations with metal.

The machine can not only bend reinforcement at right angles, but also make decorative curls and twist round steel bars.

The capabilities of this device can be seen in the photo below.

Bar winding

Making a curl

Let's now look at the main stages of manufacturing and assembling a homemade bending device.

Step one - we make the housing bearing.

To do this we need a bearing of a suitable size and a piece of pipe. We select a pipe of such diameter that the bearing fits freely into it, but the gap should be small.

Cut a piece of the required width from the round pipe. Using a grinder with a cutting disc, we make a cut in the wall of the ring.

We insert the bearing inside the ring and tighten the edges with a clamp. Then we scald it.

Step two - we make a seat in the bearing for installing the equipment.

From a metal corner 30x30 mm we cut two identical pieces. We apply them to a 30x30 mm profile pipe and scald them. We grind the corners with a grinder.

We insert the corrugated pipe with the corners inside the bearing, and weld the corners to the inner race. Then we remove the profile pipe and scald the upper part.

Step three - we make a handle with seats for the stop.

To make the handle of a bending machine, you can use a rectangular profile pipe. Cut a piece of the required length. The seats for the emphasis can be made from a round pipe.

We select a pipe of a suitable diameter, and then cut off six small pieces (barrels or bushings) from it. Then we weld them together.

The professional pipe handle must be attached by welding to the outer race of the bearing.

A previously made block of six bushings is welded to the side of the handle. Then the standard procedure is performed - cleaning the welds and the metal itself, and painting.

Step four - making a stop for the workpieces.

It's very easy to make. You will need a bolt, bearings and a nut. We insert the bolt into one of the seats on the handle, put bearings on it, and secure it with a nut.

Step five - preparing

a homemade bending device for work.

We install the equipment required for the job into the bearing (they are manufactured separately for specific needs). We clamp the lower part of the equipment in a bench vice.

Then, at the required distance from the equipment, we install a stop for the workpieces.

To bend the reinforcement you will need a lever handle. It can be made from rods of corrugated fittings, to the ends of which sections of corrugated pipe must be welded. We hammer the handle into the profile, welded to the outer race of the bearing.

You can also clamp the device itself in a yew. In this case, the lever handle will be inserted into a special attachment, which is installed on top of the equipment.

How to make a reinforcement bender with your own hands is shown in all details in the video below.

Reinforcement bender

Overall, the design turned out to be practical and functional. And the costs of time and materials for its production are quite adequate.

Reinforcement bending - process features

At any construction site today you can see various equipment, many tools and devices, and almost every one of them has a machine for bending reinforcement. This is no coincidence: the most effective technology for strengthening fragile concrete structures, protecting them from destructive loads in compression, tension and bending, is reinforcement, which is performed using metal rods - reinforcement. Without a high-quality reinforcement frame, it is almost impossible to build reliable concrete walls and foundations.

Professional equipment capable of bending reinforcement of a very decent diameter looks like this.

It would seem much easier to reinforce corner concrete structures and adjacent wall areas using straight reinforcing bars. However, in this case, the concrete structure will be greatly weakened and may delaminate. In addition, this is a gross violation of building codes. In any corner concrete structures, it is necessary to use only bending, with an overlap of at least 80 cm on each side. A machine or a simple device for bending metal rods is also useful if you need to quickly produce connecting elements of various types - hooks, claws, etc.

And this is a simple homemade solution, mounted on a floor slab right on the construction site.

When bending steel bars used for reinforcement, it is very important to know how to bend foundation reinforcement so that it does not lose its strength characteristics. To comply with this requirement, it is necessary to perform such an operation only mechanically, using special machines for cutting and bending reinforcement. In this case, it is important to ensure that the bend angle is not sharp, and that the radius of curvature at the bend is from 10 to 15 diameters of the rod itself. It should be remembered that a steel reinforcing bar bends without losing its strength characteristics up to an angle of 90 degrees, then the strength indicators begin to decrease.

If you don’t have the time or desire to deal with homemade products, then purchasing a similar ready-made bender would be a good way out.

When bending steel reinforcing bars with your own hands, two mistakes are often made:

- a notch is made at the bend site using a grinder or other tool;

- The section of the reinforcement where the bend will be located is heated using a gas burner or blowtorch.

After such procedures are completed, some primitive means for bending is used: a heavy hammer, a sledgehammer, a piece of pipe, a vice, etc. These bending methods lead to a significant weakening of the reinforcement, which can cause the destruction of concrete structures. In such cases, you should always remember that you need to bend the reinforcing bars without violating their integrity and only if they are in a cold state.

In general, everything here is expensive and serious - full automation and many settings. For home craftsmen, this video is provided for informational purposes only. Since spending 130-180 thousand rubles on such a unit for non-professional use does not make any sense.

Do-it-yourself bending machine (rebar bender)

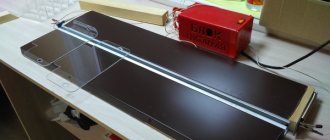

If your work requires a homemade desktop machine for bending reinforcement, we suggest adopting the idea of the author of the YouTube channel Fawa Bros.

This device can be used to bend corrugated and smooth reinforcement, as well as square bars.

Step one is making the base of the structure.

We will use a channel as a base. We cut the workpiece 35 cm long.

We install housing bearings on top of the channel, and use a marker to mark the locations for drilling holes.

After this, we drill holes and secure the bearings with bolts and nuts.

Step two is making a homemade bending mechanism.

On a lathe you need to turn a shaft with metal blanks at the ends. If you don't have a lathe, you can do it differently.

We cut two blanks of the same length from the steel round timber.

We drill blind holes at the ends of the workpieces. We insert pieces of a round rod of suitable diameter into the holes and scald them. Then in the blanks themselves you need to cut grooves for the reinforcement and square rod.

We insert two parts of the shaft into the holes in the housing bearings installed on the frame, and then weld them together.

We weld a long handle-lever made of a round rod to the central part of the shaft. A travel stop needs to be welded to it.

Step three - make an axle with support rollers

.

On the opposite side of the housing bearings, we weld an axle made of a round rod to the frame. We put on it two support rollers made of thick-walled round pipe.

To prevent the rollers from jumping off the axis during the bending of the reinforcing bar, washers must be welded along the edges of the rod.

The author solved this problem differently. First, he welded pieces of a metal strip with holes to the base (for fastening to the work table), then, along the edges of the axis, he welded pieces of a square rod that rest against the mounts.

Step four - installing a homemade handle stop.

You need to drill a hole in the base and weld a nut on the bottom. Then we screw a bolt into the nut, which will act as a stop to adjust the bend angle. We clean and paint the homemade product.

The completed structure can be mounted both on the table and on the floor in the workshop if you first drill holes in it and install mounting pins.

Instructions on how to assemble a compact machine for bending reinforcement with your own hands can be seen in the video below.

DIY tool | Make A Powerful Metal Bender for Construction Steels

The design turned out to be quite convenient for everyday use, and most importantly, reliable. The only difficulty may arise in the manufacture of the shaft.

Rod driven machines

The characteristic features of the plastic deformation technology, which is implemented on such equipment, are the sequential implementation of cutting transitions and subsequent bending, since stamping is carried out from a continuous material. Therefore, the number of transitions on such machines is at least two (some models also provide for editing and calibration of cut rod blanks). Non-automated equipment (for example, a reinforcement bending machine SGA50) is more often used for bending reinforcement with a diameter of over 12...16 mm. Specialized machines are used to bend wire reinforcement.

We will consider machines for cutting and bending reinforcement using the example of bending and cutting machines SB6-12 (PRC), manufactured under license from the German company Schelle. The unit structure includes the following components:

- Reception cassette.

- Workpiece feeding mechanism (roller type).

- Drive of the cutting mechanism.

- Cutting slide.

- Adjustable stops and clamps.

- Pneumatic compressor.

- Bend sliders.

- Electric motor.

- Computer control panel with built-in display.

- Dropper.

The machine for bending reinforcement works as follows. First, the operator enters a program for bending the workpiece, after which the computer sets the required length of the cut of the original workpiece, as well as the stroke of the bending slider, taking into account the springing of the material and the geometric configuration of the finished product. When the feed mechanism is turned on, the bar is simultaneously straightened. When feeding all the way, the cutting mechanism drive is turned on, the measured workpiece is cut off and advanced by the end part of the material to the bending position, where it is fixed. At the same time, the compressor creates the pressure necessary to move the bending slider until the material completely compresses the matrix, the profile of which corresponds to the shape of the final part. When the slider moves in reverse, the ejector removes the product from the processing zone, after which the operator removes the finished part into a container.

Read also: Range of equal flange steel

The SB6 model performs flat bending, while the SB12 machines are also capable of spatial bending of the material. The equipment can also operate in fully automatic mode, then the operator’s only function is to thread the next bar into the cassette.

Manual benders with cutting and straightening functions can also operate in a similar manner.

Fully automated machines (for example, AlbaDesa made in Italy) are considered a further development of this type of equipment. Here, a coil is used as a range of source material, and the stamping process is carried out continuously. Productivity increases, and the overall dimensions of the equipment, on the contrary, decrease (the coil unwinder is more compact than the cassette).

In the practice of producing bent reinforcement products, it is sometimes impractical to purchase automated equipment. The bending machine for fittings is very compact, simple and has a significantly lower cost. The limitation of this technology is the need for preliminary cutting of workpieces “to size”.

A typical representative of this technology is the domestic machines for bending reinforcement SGA-1E. It is designed to perform various bar bending operations, including single and double angle bending, hook bending, circular bending, etc.

These rebar bending machines include:

- Welded frame type frame.

- Electric motor.

- Tool plate.

- Drive with reduction worm gear.

- Control cams.

- A bending disk equipped with fixing and working fingers (analogous to a punch).

- A fixed thrust pin (analogous to a matrix) fixed to the tool plate.

- Electronic control unit, which completely automates the deformation cycle.

The machine works like this. Cams are used to set the required configuration of the part after stamping. The measured workpiece is placed and fixed in the die cavity, after which the drive is turned on and the bending disk deforms the part of the workpiece that is located between the fingers. When the bending disk is reversed (carried out when the required bending angle is reached, which is monitored by a rotation angle sensor), the working finger releases the rod. The disk stops, after which the finished part is removed from the processing zone.

On the SGA-1 bending machine, it is possible to change the profile of the working rollers (for example, to square), which makes the described equipment quite universal. A manual machine for bending reinforcement has a similar operating principle. Thus, all bending machines for the production of fittings are rotary equipment.

Reinforcement bender for home workshop

We bring to your attention another version of a homemade desktop device for bending reinforcement.

This idea was shared by the author of the YouTube channel Kwando Technic.

A square profile pipe measuring 50x50 mm is used as the machine bed. Cut a piece of it 80 cm long.

We also prepare two bearings and a piece of round pipe of a suitable diameter in order to then make a housing bearing.

At the end of the profile pipe we make a seat for installing a housing bearing.

Next, we manufacture the housing bearing itself. You will need to weld a lever from a square corrugated pipe to it.

In order to secure the frame to the desktop, it is necessary to weld metal plates with drilled mounting holes to its lower part.

On one side of the frame, the author welds metal plates to the mounting “feet”, between which a guide made of a round pipe will be attached.

At the next stage, we weld a piece of a corner to the frame, to which the workpiece stop is attached (we also make it from a corner, but we just need to cut the grooves for the bolts).

We install the guide in its place, having first put a pair of movable sliders on it. We weld the end stops to them.

Next, we proceed to assembling the reinforcement bending machine. We attach a housing bearing with a handle to the frame, and weld a pin to the handle onto which the thrust bearings are placed.

You can familiarize yourself with step-by-step instructions on how to make a desktop machine for bending reinforcement with your own hands, and also see the principle of operation of the device in the author’s video.

Homemade Metal Bending Tool | Making A Powerful Metal Bender

Compared to previous options, the design seems a little confused. But overall, it is quite functional.

Equipment for bending reinforcing wire

Reinforcing wire is supplied exclusively in coils. It is required much more, since the shape of the bend and the diameters of the source material can vary within the widest range. Therefore, to produce such products, domestic multi-slide universal bending machines of the A72 series are used. Such equipment is a vertical rotary type machine, and consists of:

- Drive motor.

- V-belt transmission.

- Switching systems (clutches + brakes).

- Main shaft.

- A rotating frame with a punch of the required configuration.

- Cutting knife.

- Block of matrices with clamps.

- Ejector.

After filling the coil into the cutting matrix up to the pre-set stop, the machine drive is turned on. After this, the cut workpiece is fed into the rotation zone of the rotors, which sequentially bend the semi-finished product to the required configuration. At the last stamping transition, the ejector is triggered, and the finished part is removed from the deformation zone, and the next workpiece is fed there.

The use of such machines is justified in case of mass production, since readjustment of sliders takes a lot of time, and each standard size of a part requires its own “punch-die” pair.

The technical characteristics of the type of equipment under consideration are summarized in the table. The parameters of multi-slide bending machines comply with the requirements of TU2-041.

Analyzing the data in the table, it should be noted that this equipment is quite energy-intensive, and therefore its load factor in production conditions should be maximized.

G42 reinforcement bending machines have similar characteristics. The market also offers imported models, in particular, GW40 reinforcement bending machines, Zitrek SB40b machines (made in the Czech Republic + China) and the like. It is important that Zitrek, when selling its equipment, also offers devices for bending reinforcement, which expands the technological capabilities of the equipment.

Not a single serious construction project today can be completed without the use of such an important element as reinforcement, which is largely responsible for the load-bearing characteristics of structures. That is why bending of reinforcement must be carried out professionally and in compliance with all generally accepted requirements.

Bending reinforcement 90 degrees using a special press. Home craftsmen don’t have such equipment, so we’ll make our own machine!

Bending machine from scrap metal scraps

You can make a simple reinforcement bender with your own hands even from unnecessary scraps of metal that are lying around in scrap metal.

A version of this bender design was shared by the author of the YouTube channel Fawa Bros. We will take this as a basis.

The first step will be to manufacture the moving part of the structure.

We cut out a blank of the required shape from sheet metal. Then you need to drill a hole and attach by welding a section of a pin onto which a thrust roller made of a round pipe is placed. Screw the nut onto the stud.

We weld the bearing to the bottom of the workpiece.

A metal plate of rectangular or square shape is suitable for the base - whichever you prefer.

We drill mounting holes in it in the corners, and another one closer to the central part.

We install a previously made part with a bearing on the plate, and fix it with a steel round timber, in the upper part of which there is a groove so that workpieces can be inserted.

The lower part of the round steel will need to be welded to the base of the reinforcement bender.

Next, we weld a piece of profile pipe to the moving part, onto which the lever handle will be placed.

We weld a piece of a square rod to the metal plate, on top of which we need to weld an elongated coupling. We screw a bolt into it, which in this case serves as a travel limiter for the moving part.

At the last stage, all that remains is to make the handle and install it.

The handle additionally has a movable stop, with which you can adjust the bending length of the workpiece.

How to make a compact device for bending reinforcement with your own hands is shown in all details in the author's video.

DIY Tool | Make A The Simplest Metal Bender | Homemade Metal Bending Tool

As in previous cases, the homemade product turned out to be simple and easy to use. The square plate is attached to the table using bolts, and you can immediately start working.

Powerful do-it-yourself reinforcement bender

This homemade product allows you to work with both corrugated and smooth fittings, as well as with corrugated pipes. Therefore, you can call it a pipe bender or a universal bender for the home workshop.

The author of the YouTube channel Kwando Technic shared how to make this device.

Necessary materials:

- channel;

- round pipe;

- Metal sheet;

- corner;

- steel round timber.

First we make the frame. For this we will use a channel. We decide on the length of the bed and cut the workpiece to the required length (80-90 cm will be enough).

We make homemade housing bearings and weld them to the frame. We install the steel shaft.

Additionally, the craftsman cuts off a piece of square rod and welds it in front of the housing bearings. It turned out to be a kind of small emphasis - just in case.

We cut out two narrow strips from sheet metal. We bend them like clamps and weld them to the frame and housing bearings.

At the next stage, we need to weld a shelf from a corner on the side of the bed, and attach a support roller next to it. We weld a fork to the end of the shaft for bending the workpieces.

Two handles must be welded on the opposite side of the shaft.

At the end, all that remains is to make a limiting stop to limit the stroke of the handle. To do this, cut off a piece of the corner, then weld it to the frame. First, drill a hole in the corner and weld the nut. We screw the bolt into the nut.

To attach the homemade product to a table or floor in the workshop, “feet” with holes need to be welded to the bottom of the frame. The final touch is sanding and painting.

You can watch how to make a device that bends reinforcement and corrugated pipe in the video on our website.

DIY tool | Homemade Powerful Metal Bender for Construction Steels

Range of fittings used

This type of rolled steel, in accordance with the requirements of GOST 5781, is supplied in a hot-rolled state. With a cross-sectional diameter of up to 27 mm, this can be rods and wire; above 27 mm - only rod. Reinforcing profiles with a square cross section are much less common. The steel reinforcement profile is special, with surface notches of various types and intensity.

The choice of steel grades intended for bending reinforcement is also limited. Depending on the operating conditions, the reinforcement is divided into 4 classes, and each corresponds to certain steel grades:

- For fittings of class A-I (A240) - carbon steel of ordinary quality, type St.3 according to GOST 380 (range of profiles from 6 to 40 mm);

- For fittings of class A-II (A300) - carbon steel of ordinary quality, type St.5 according to GOST 380 (range of profiles from 6 to 80 mm);

- For reinforcement of class Ac-II (Ac300) - low-carbon high-quality construction steel type 10GT or 18G2S according to GOST 27772 (range of profiles from 10 to 40 mm);

- For reinforcement of class A-III (A400) - medium-carbon high-quality construction steel types 32G2R, 35GS according to GOST 27772 (range of profiles from 6 to 40 mm).

The choice of class depends on the operational loads to which the reinforced concrete structure of the structure is subjected, since only the metal component absorbs all operating stresses. The laying of corner reinforcement elements is almost always required, since the stresses that arise in the corners of walls, foundations, etc. are especially high.

The ductility of all of the above grades of hot rolling steel is in the range of 65...70%, which makes it possible to use cold plastic deformation processes for their processing. In particular, even the most durable reinforcing steels of class A400 allow bending without cracking at angles up to 90 0 (without taking into account the natural springback of the material). At the same time, the strengthening of steels is relatively small.

In addition to rods, the production of reinforcement requires binding wire. Its diameter usually does not exceed 3...4 mm. Unlike rods, tying wire always has a strictly round profile and is made of soft plastic steel grades St.3 or (for more critical reinforced concrete structures) from steel 08kp according to GOST 1050.

Thus, the choice of the appropriate type of bending equipment is determined by the physical and mechanical characteristics of the material and the required productivity.