SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

In winter, any owner of a summer house or private house is faced with the need to clear snow from the yard, paths, driveway to the house, and also the roof. Using special equipment, which many companies produce, this can be done easier and faster. But there is another option: a DIY snowblower. Anyone who is familiar with the operating principle of snow blowers and has certain technical skills can assemble the device themselves.

It is possible to build a snowblower that can effectively cope with cleaning the local area yourself.

Drawings and diagrams

To assemble snow blowers, you can use drawings that are easy to find on the Internet, or start developing your own version based on local conditions.

There are four types of snowblowers:

- Bulldozer. Wheels with a blade mounted at the front.

- Auger. In it, snow is gradually captured by rotating belts and moved to a pipe through which it is thrown out.

- Fan-blade. Using special blades, the sticky snowflakes are directed to the fan, lifted by the blades to the pipe and flew out.

- In air-fan . It works like a vacuum cleaner. The snow mass is drawn in by a strong stream of air and thrown out into the street.

In cities, all these types of cleaning equipment are used, but in rural areas it is difficult to make the air-fan type, since a very powerful engine is needed to suck up snow. Therefore, the article discusses the creation of only the first three options.

Required tools and materials

Before choosing materials and making the device, you should remember that the chainsaw engine has little power. You should not use the unit to clear ice or heavily frozen snow to avoid damage.

First you need to think about what to make the cleaner from and what devices to use. It is not difficult to guess that different types of work will require different materials. They will be indicated in the instructions for the manufacture of a particular design.

What tools should you use:

- welding machine;

- hammer, pliers, screwdriver;

- different keys;

- file;

- grinder and drill;

- hacksaw;

- vice.

Principle of operation

The power unit starts up and rotates the auger, which, in most cases, has a spiral shape. In rotary snow blowers, the guide elements are straight.

Thanks to him, the snow is raked and thrown to the side. Moreover, this operating principle is relevant for all models, regardless of cost. As the price increases, headlights, heated grips and other extras are added.

Snow blower with blade

The easiest thing is to assemble a motorized snow blower from an already finished product, slightly altering it. But you can do it differently and do it yourself.

In the first case, the basis of this unit is a conventional industrial-style manual cleaner with two or four wheels. In the second, all the parts are obtained or made by hand.

Materials for assembling a snow blower

- metal sheets 2, 3 or 4 mm;

- pipes with a caliber of 50-70 mm;

- bearings (local);

- frame squares;

- wheels;

- axles;

- washing machine tank, boiler or pan;

- sprockets or gears;

- chains or belts;

- bolts, nuts;

- electrodes.

Snow blowers from industrial designs

The unit is made from mobile rather than hand-held devices. There are two options for such devices. The first of them has a stationary axis, and the second has a rotating axis. Both devices (or the rotating rod) have a fixed blade.

It is better to choose an option with one or two axles that rotate, and the wheels are rigidly fixed to them. Then minimal modification will be required.

Step-by-step instruction:

- One or two wheels are removed (front ones if the snowplow is biaxial).

- A sprocket, for example, from a motorcycle, is welded (or otherwise strengthened) onto the freed axle. It is advisable to install it closer to the hub of one of the wheels.

- The structure is being put back together.

- A plate is screwed to the handle (if the option is single-axis) or to the frame. A chainsaw is attached to it so that the chain draped over the welded sprocket is properly tensioned.

If the axle is welded tightly, you need to do the following:

- Remove the wheels.

- Choose an axle or a thick rod for them.

- Grind the hubs or cups so that the wheels “sit” tightly.

- Weld metal corners with holes for the new axle to the frame.

- Strengthen the driven sprocket (from a motorcycle, for example).

- Assemble the structure - insert the axle into the corners (you don’t have to cut off the old one if it doesn’t interfere) and install the wheels.

- Attach the chainsaw to the frame or handle.

When operating such a unit, you will not need to waste a lot of energy. The saw motor will create the required force.

Homemade bulldozer type cleaner

This option repeats the previous two. The difference is that most of the parts and components are made independently.

To make it you need to get the wheels. You can borrow them from an old bicycle. Or remove one or two complete wheelsets from a wheelbarrow or any end-of-life vehicle. Then select an axis for them on which they will be permanently mounted.

The whole job is as follows:

- A single or biaxial frame is welded from ordinary or profile pipes.

- Corners with holes are welded to it.

- An axle with a pre-fixed sprocket is inserted into them.

- The wheels are being put on.

- Weld stationary pipes or a rotating mechanism for the blade.

- Install the plate with a chainsaw.

Making a homemade blade

This part of the purifier is made of metal sheets, a barrel, a large-diameter pipe or some kind of tank (from an electric heater, for example).

The main dimensions are selected independently depending on the power of the chainsaw. It is not recommended to make a blade more than a meter long, since the engine may not be able to withstand such a load.

When making a dump from sheets, they are pre-lined. Then the parts are cut out and welded together. This snowblower assembly can have any shape.

When making a blade from a cylindrical blank, it is cut as shown in the figure. If the unit is made from a pipe, then sides are installed on the sides. At the bottom (for rigidity) a knife made of a long, pointed strip of metal is riveted.

Types of snow removal equipment for the home with your own hands

Snow removal machines are designed for mechanical removal of snow cover in the required area. Their functions include collecting snow mass and throwing it back to the collection point. The engine that powers the car can be electric or gasoline. And the snow removal equipment itself is divided into self-propelled (with tracked or wheel drive), manually controlled, single-stage and two-stage.

To independently assemble such garden equipment, you can use a chainsaw engine, an electric motor or a walk-behind tractor, as well as various improvised materials that everyone probably has on their farm. Before you make a snow blower with your own hands, you should familiarize yourself with the types of such equipment and choose an acceptable option for yourself.

The choice of snow blower design depends on many factors, one of which is the area of the area that is supposed to be processed.

Electric snow blowers can clear small areas near your home, such as porches or narrow walkways. Such a unit is not suitable for clearing large areas of snow cover. In addition, its operation is not effective if there is ice or significant snowdrifts. On the other hand, such equipment is quite compact, easy to operate and convenient to store.

Gasoline-powered self-propelled snowblowers do an excellent job of removing large amounts of snow from large areas. Moving independently, these vehicles have excellent maneuverability and a long ejection range. The equipment is quite large in size, but does not require any physical effort during operation.

Before you make a manual snow blower with your own hands, you need to keep in mind that non-self-propelled models are designed for cleaning small areas of freshly fallen snow up to 25-30 cm thick. They are mainly used for daily cleaning of sidewalks, garden paths and flat roofs. Such devices are quite maneuverable, however, when removing a dense layer, it will be difficult to control the equipment, since you will have to push not only the device, but also the thickness of the snow in front of it.

DIY snow blower with a chainsaw engine

Helpful advice! When assembling a non-self-propelled snow blower for your home with your own hands, you should use the lightest possible parts, since the equipment will work due to human efforts.

Screw option

A device with a blade has drawbacks, and the main one is the waste of time and effort to remove the layer of snow picked up by the blade. Often it is left right next to the road, creating high snowdrifts, which is not always acceptable.

The version of the snow blower with an auger will allow you to get rid of even roadside sediment, because its design provides for the throwing of the captured mass over a distance of several meters. This will help clear the yard or street completely, leaving the piles next to the fence.

This option is welded or screwed from the front to a frame with wheels, which can be removed from an old wheelbarrow, for example.

Another design is a wheelless version, controlled by a tube. The body is mounted on a frame made of angles, from the bottom of which skis are screwed.

Main components and materials of both options:

- box - welded from sheets of metal;

- central shaft - is a ¾-2 inch pipe;

- gripper (scapula) - iron plates or pieces of channel;

- supporting elements;

- auger - made of rings or tape;

- motorcycle sprocket;

- ski made of plates or pipes;

- frame made of corners;

- bearings;

- a pipe for throwing out snow - you can take it from the stove.

Screw assembly sequence:

- 4 rings and 6 support plates are cut from roofing sheets or other metal.

- Six strips are placed on the shaft and welded to it at an angle of 90°. Then the sprocket is strengthened and the bearings are pressed in.

- Two blades made of plates are inserted between the middle guides. They are welded to the shaft and to the supporting elements. If pieces of channel bars are used as gripper blades, they are rotated 180° relative to each other.

- The rings are cut, bent and welded so that two intersecting spirals are obtained.

You can straighten them in two ways:

- Clamp the middle part in a vice, grab one edge with pliers and pull it to the side. Do the same with the other end.

- Weld one edge to the support element at the blade and stretch it.

If the rings are made of thick material and it is difficult to grasp them with pliers, then you can use two clamping devices, such as a vice.

After making the auger, a sheet of metal is laid out and the box is welded. A hole is cut out in its middle part for a pipe to throw out snow. You can make it yourself or use one already prepared from an iron stove. Some craftsmen use plastic ones.

Then a rectangular hole is cut in the body opposite the sprocket to allow the chain to pass through. The box is installed on a frame with runners or wheels and the chainsaw is strengthened.

How to make an ice screw from a trimmer?

Making a motor drill from a trimmer consists of two stages - assembling the gearbox and creating the auger. Each of them must be treated with great responsibility, since the serviceability and efficiency of homemade equipment depends on this.

Selecting the type and assembling a gearbox for a motor drill

The first stage of making a motor drill from a trimmer is to select and assemble a reliable gearbox. All gearboxes are divided into several types. Depending on the initial direction of movement of the working part, the following types of gearboxes are distinguished:

- mechanisms in which the built-in output shaft moves in the direction of the clock hand;

- gearboxes in which the output shaft moves counterclockwise;

- reverse type mechanisms;

It is best to equip a homemade drill from a trimmer with a reversible gearbox. It will make it possible to freely remove the working part of the drill if it becomes jammed in the ground or ice.

To manufacture a reversible gearbox you will need to prepare:

- serviceable worm shaft;

- durable body;

- 2 pairs of bearings and bevel gears;

- output metal shaft.

In addition to the preliminary preparation of the elements, the motor drill manufacturer will need a diagram. It must indicate the exact dimensions of all parts and mechanisms used.

After studying the diagram, you can begin manufacturing the gearbox.

The procedure should look like this:

- First, you will need to connect the output shaft of the motor and the worm shaft of the motor drill being used;

- Next you need to install a flexible or rigid coupling. The first option is suitable for an engine that creates strong vibrations. In this case, the flexible coupling will effectively dampen vibrations created by the engine crankshaft and the working body of the motor drill;

- Next you will need to connect the worm shaft and the 2-row gear. The lower part of the latter must be previously equipped with straight teeth;

- During the manufacture of the gearbox, a hole must be left between its parts for unhindered application of lubricant;

- In the end, all that remains is to adjust the angular velocity of the mechanism. To do this, you will need to select and match gears with the appropriate sizes.

As a result of the actions performed, the manufacturer will receive a reliable 1-speed gearbox with the simplest possible design. The mechanism will stably transfer force from the trimmer’s internal combustion engine shaft to the shaft of the working body of the motor drill under any operating conditions.

Making your own screw

To assemble an ice screw from a walk-behind mower, the manufacturer will definitely need an auger mechanism. It has the shape of a screw and is used in a device for cutting earth or ice with subsequent preparation of holes. To make a simple screw, the manufacturer will need to study the drawings of the mechanism. Compliance with them will make it possible to assemble an effective and durable unit that can successfully withstand heavy loads.

In addition to studying the drawings, you will also need to prepare the following elements:

- a sharpened metal blade curved in the shape of a screw;

- metal core;

- steel tip.

If the motor drill will be used to make holes in hard rocky soils, the metal for assembling the auger will need to be pre-hardened. This will prevent the metal from deforming during drilling.

Fan unit

An industrial version of this type (Blizzard) has long been used on the farm by many people. But you can assemble it yourself.

This snow blower is very reliable and does a great job.

It consists of a small number of parts:

- The knives perform two functions: they cut the snow and direct them to the fan.

- A rotor with blades captures layers of stuck together snowflakes, spins them and pushes them out at high speed through a hole in the body.

- The pipe serves as a guide for the flow of thrown snow.

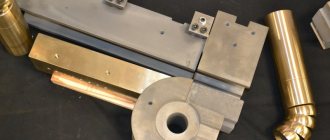

To manufacture such a unit, the following materials are required:

- sheet iron 1-3 mm for the body and blades and 5-10 mm thick for the blades;

- shaft for rotor;

- star;

- squares for the ski option or wheelset;

- pipes for making handles.

The procedure for manufacturing the structure

First, they make a body with knives. To do this you need:

- Determine the diameter of the fan and calculate the circumference using the well-known formula L=πD.

- To the resulting value, add an allowance of 1 cm if using a welding machine and 2 cm when connecting the edges with bolts or rivets.

- Then you need to cut a strip of length L+ (1 or 2 cm) of the required width (for example, 10-15 cm) from the sheet.

- Bend the workpiece on a mandrel and weld it. Or drill holes in the overlap area and connect in another way.

- Draw on a sheet of paper a circle with diameter D for the back wall of the case and triangular-shaped knives with a rounding at one corner.

- Weld all the workpieces in place.

Execution of a rotating assembly:

- A 20-30 cm long shaft is placed on the bearing so that 5-6 cm peeks out on one side. To manufacture it, the services of a turner may be required. If the farm has the necessary part with a bearing, then you can use it.

- Determine the center of the circle (back wall) and drill it with a drill whose caliber is 3-5 mm larger than the diameter of the shaft.

- Measure the external dimensions of the bearing and cut out a cup for it from iron. It should have tabs in order to drill them and secure this part with screws.

- A glass is placed on the bearing, and a pipe of suitable diameter is pressed onto the shaft or mounted and clamped with screws.

- Blades are welded to it - plates made of thick iron.

- The rotating assembly is fixed from the inside of the housing so that 5-6 cm remains outside.

- An asterisk is welded onto this “tail”.

At the very end, a drawing of the pipe is made and a blank is cut out, which is bent and welded. A hole is made on top of the body (in the center or slightly to the side). Then the pipe is strengthened. It is advisable to make its top rotating so that you can direct the flow of snow where needed.

The entire structure is mounted on a frame (front) with skis or wheels. The chainsaw is strengthened, as in the previous ones.

Precautionary measures

The main danger is the puppy, which is capable of not only wrapping clothes around itself, but also hitting or even injuring an arm or leg. When clearing snow, a number of rules should be followed:

- Wear warm clothes and non-slip shoes.

- Wear ear protection, gloves and goggles.

- Do not direct the flow of snow towards people or cars.

- If the snow blower is electric, then do not forget about the cable.

You should also remember the dangers when refueling the unit, because mistakes made can lead to a fire or explosion of the fuel.

A snow blower can work not only in winter, but also in other seasons. The fan version (if placed with the opening facing up) can be used for threshing corn. Or supplement it with pipes and use it as a forced ventilation device.