If you need to make a large diameter hole in a tree, you will have to use special devices, each of which has its own characteristics. We will consider all possible options and tell you about their main advantages and disadvantages so that you can choose the best option in accordance with the specifics of the work in a given situation.

In the photo: equipment for wood differs from equipment for concrete and ceramics

Drilling square holes. Watts drill. Reuleaux triangle.

When performing various plumbing and repair work, sometimes it becomes necessary to make a square hole in a metal workpiece. If to obtain round holes a standard set of tools is used, which every master has at hand, then for a square profile you need a specific tool.

Of course, without having the appropriate tool, you can get a square hole by drilling a round one, followed by manual processing to a square profile. But this method is low-productivity, labor-intensive and does not allow obtaining the exact shape and dimensions of the required profile.

To obtain a high-quality profile, a square hole is most often drilled using a Watts drill, the operation of which is based on the peculiarities of the movement of a geometric figure called the Reuleaux triangle. From a technical point of view, it is more correct to call such a drill a milling cutter. It will not be possible to use a Watts drill directly with a drill; you will need an additional special adapter spindle, which will provide the necessary trajectory of the tool.

Peculiarities

In terms of its design, the device for drilling square holes is more like a cutter than a drill. However, domestic craftsmen are more accustomed to calling it a drill, and manufacturers also call the product that way.

According to the kinematics in accordance with which this device moves, it is obvious that the cut of the material being processed occurs exclusively through the side surface, or rather, 4 such surfaces. This method is typical not for a drill, but for a cutter. But rotational movements are not enough to drill a high-quality and even square hole. The cutter must not only rotate, but also make rocking movements - also around its axis.

It is also important that rotation and swaying should be directed in mutually opposite directions.

At what speed the drill-cutter will rotate can only be determined based on the characteristics of the electric drill or other tool that you plan to use. However, it must be borne in mind that drilling a square hole will not occur very quickly, and the work productivity will be low.

One Reuleaux triangle is not enough to obtain a square hole - the drill must have grooves along which chips, which are waste from drilling, will be removed. It is for this reason that 3 semi-elliptical circles are cut out on the working surface of the drill.

Due to this, the moment of inertia of the cutter is reduced, the load on the spindle is reduced, and the cutting ability of the nozzle is increased.

Drill or cutter?

The majority of the technical community believes that it is still a milling cutter. However, manufacturers stubbornly continue to call this tool a drill for square holes, a Watts drill, or a drill whose profile corresponds to the Reuleaux triangle.

Which is more correct? If we turn to the kinematics of movement of such a cutting tool (for clarity, you can use the diagram shown in Fig. 1), you will find that metal removal will be carried out only by the side surface, and there will be not one cutting plane, like a conventional drill, but four, which more typical for cutters.

However, a single rotating motion will not be enough to obtain a square hole. Simple mathematical calculations (not given in this article) show: in order for a “drill” for a square hole to perform its function, during operation it must describe not only the basic rotational movement of the cutting edge, but also the rocking movement of the drill/cutter around a certain axis. Both movements must be made in mutually opposite directions.

Read also: Mass of a spring pendulum formula

Figure 1 – Reuleaux Triangle: a) – construction; b) rotation sequence to obtain a square-shaped hole.

The angular velocity of both rotations is determined quite simply. If we take the rotation frequency of the drill shaft (or hammer drill) as the parameter f, then a speed of 0.625f is sufficient for oscillatory rotations of the spindle around its own axis. In this case, the spindle axis is, as it were, clamped between the working shaft and the drive wheel, causing the drill/cutter to oscillate in the clamping device with a residual speed

(1 – 0.625)f = 0.375f.

The resulting rotation speed of the cutter can be more accurately determined using the technical characteristics of the drill/hammer, but it is clear that it will be much lower than that for which the tool was originally designed. Therefore, obtaining a square hole will occur with less productivity.

Square hole drill

A non-obvious and fascinating stray - Mortising Chisel Woodwork Square Hole Drill Bit. More specifically, a drill-device for square holes in wood.

Suitable for drilling holes and grooves in wood materials.

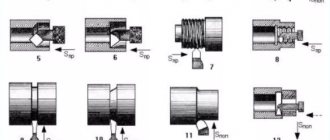

Now we will talk about a device for creating square-shaped holes and grooves by drilling. The device consists of two parts: a wood drill and a square cutter - the outer shell of the drill. The cutter has a hole for chips. There are two sizes of sets for square holes to choose from in the lot: 10 and 16 mm. In general, in the vastness of Ali and Ebay, I came across a huge number of similar sets, branded (expensive) and not so much. The meaning is the same for everyone - the drill removes excess wood , and the cutter shirt seems to squeeze out the excess into a square shape. The edges of the shirt are pointed, the cut wood shavings go inside and are removed with a drill out through the hole . To work on a vertical drilling machine, you will need a small device-press holder, which holds the cutter jacket while simultaneously ensuring rotation of the chuck and drill. An example of gradual “punching” of a hole; marks from the jacket and from the drill itself are clearly visible. There are a lot of options for such holders, purchased ones are quite expensive, but it is quite possible to make them yourself. Common features - attachment to a fixed spindle sleeve, lowering together with the drilling head. The mount simultaneously holds the cutter, and the chuck with the drill rotates inside. Gradually, as the head is lowered, a square hole . Now about the drills themselves. I have already said that there are two sizes in the lot to choose from: 10 mm (above in the photo) and 16 mm (below). Packed in a simple plastic case, the sets are in oil. In the photo there is a “small” set - 10 mm. The drill is the longest, so it can be clamped in the chuck for the fixture. But the “shirt” is not very long, about 13 cm. The drill is slightly different in shape from the usual drills, including those for wood. Its shape is more like a drill (for concrete). This shape enhances the flow of chips to the top. The shape of the drill tip fits the notch on the jacket (conical). In general, these places rub, you can lightly lubricate them before use. The corners of the shirt are sharpened, made with arches - the corners are pressed in first, then sharp arches cut off the plane. On one side there is a narrow hole for the chips to exit. Complete set. The same is true for the 16 mm kit. 16 mm drill bit The shape of the tip is the same - conical. The edges of the drill are sharp, the wood gnaws only on its way, but the corners are small, it removes a little bit at a time, and drills cleanly. Shirt. Sharp corners are clearly visible. The edges are also sharp. The diameter of the clamping part (in the holder) is 19 mm.

An example of a drilling kit installed in a holder on a machine. Preparing the workplace Setting the drilling height

Maintenance - slight lubrication of rubbing parts.

READ Drilling Holes In Concrete Diameters

You can make a clamping device yourself from scrap materials.

To begin with, I just check the drill - it drills well, the feed needs to be small. The hole is even. An example of the resulting holes. The only thing I will note is that for the first time you need some skill; I pinched the shirt a little higher than necessary, resulting in a slightly uneven hole . Same thing for 16mm. The drill is separate - the quality of the holes is clearly visible. Trying on a shirt Insert a drill, height and try. Well, I’m a little shifted again. The grooves are made by sequentially selecting material between the holes. The main thing is not to rush anywhere. There should be something like this with the proper skill.

A little history with geometry

Back in the 15th century, the legendary Leonardo da Vinci, while studying the properties of geometric figures, drew attention to the so-called geometric objects with equal thickness. There are an infinite number of such figures, but the simplest - besides a circle - is a rounded triangle, which can be formed as follows. An equilateral triangle is drawn, each of the corners of which is connected by an arc of a circle drawn from the center of the opposite side. The peculiarity of such a triangle will be that all its sides will have a constant width, which is equal to the length of the side of the original equilateral triangle.

L. Euler drew practical benefit from this fact, who three centuries later demonstrated the rotation of such a rounded triangle: first around its own axis, and then with some eccentricity, since the cardan mechanism was already known to science and technology of that time.

The German engineer F. Relo went even further in the practical use of this figure, who drew attention to the fact that the trajectory of the corners of a moving triangle with certain methods of its rotation is very close to a square. Only directly at the corners of the square does the outer surface describe an arc, however, of a small radius. In modern technical literature, such a triangle is called the Reuleaux triangle, although this figure actually no longer has any angles.

A few more decades will pass, and the Englishman G. Watts will come up with a device that can provide a guaranteed square trajectory for a metal-cutting tool. The technical solution for the Watts drill was patented in 1916, and a year later mass production of such tools began.

Operating principle and design of the Reuleaux triangle

The Reuleaux triangle is a flat geometric figure. It is formed by connecting the vertices of an equilateral triangle with circular arcs drawn from each vertex of the same triangle.

The peculiarity of the Reuleaux triangle is that when performing a rocking motion, its vertices describe the trajectory of an almost perfect square.

The only drawback of this rotation of the Reuleaux triangle is that small roundings remain in the corners of the square.

If it is necessary to obtain a square hole with internal angles of 90 degrees, it will have to be modified. This can be done manually using files and rasps or on a slotting machine.

Features of drilling square holes in wood

In furniture production, parts are often connected using a tongue-and-groove system. This connection assumes the presence of square grooves in the supplied parts. To make holes in wood, use a special square wood drill. It is a set of slotting tools. It consists of an internal wood drill and a chisel that fits onto it. Typically, the drill diameter ranges from 6 to 18 millimeters. The shank usually has a diameter of 19 millimeters. Such kits can be installed on slotting and drilling machines.

Criteria for choosing a quality option

Below we will look at the main types of devices for cutting holes in wood, but for now we will outline the criteria that any option must meet, regardless of its modification:

| Reliable manufacturing material | Of course, it is unlikely that you can determine this criterion by eye, so it is best to ask the seller for a quality certificate for the product. Unreliable counterfeit versions from China most often do not have any documents. |

| High quality performance | Examine the product carefully: the surface must be smooth without flaws or defects, the cutting part must be carefully sharpened. If you purchase a long wood drill, check whether it is level; this can be done by eye or by rolling it over a flat surface - any irregularities will be immediately visible on it. |

| Good packaging | Low-quality fakes are most often packaged haphazardly, moreover, there are mistakes in the words. No well-known brand will allow itself unsightly packaging, remember this. |

| Price | Price is also an indicator of quality; as a rule, the most budget options do not last long, especially when it comes to large-sized drills and fixtures. After all, they are subjected to very high loads during operation. |

Advice! To be guaranteed to purchase a quality product, be it an electric jigsaw for wood or a circular saw, you need to contact official representatives of a particular brand or buy products from well-known stores that care about their reputation and do not sell cheap fakes.

Cheap core drill sets are so unreliable that they may only last for a single use

Basic tool for sawing wood

In this article we will look at the basic tool for sawing wood, and the features of cutting a rectangular hole in the center of a wooden board. The lesson will be useful to new builders who are taking their first steps in mastering the interesting world of construction.

The main tool for sawing wood in an apartment

We will look at the main tool for sawing wood using the example of a specific task: how you can cut inside a large flat board, chipboard, or sheet of plywood. To understand the process, I have prepared several visual pictures.

So, we have before us a flat wooden surface, inside of which we need to cut a rectangular hole to the given dimensions:

There are many options for cutting wood: hand saw, wood saw, jigsaw, jigsaw. To pass the saw into the center of the board, you must first drill it with a thin drill along the marked lines. Take the most ordinary drill and drill many holes in the board, along the marked line, next to each other:

When the holes are close to each other they actually form a gap. How many holes should I drill? And just enough so that a hand saw or other tool can be pulled into the resulting gap to start cutting:

Now you can calmly, along the line, make cuts in one direction and the other. We sawed through one side, we move on to the next, where we have drilled holes.

Thus, you will cut out the required part inside the board or plywood.

If you have on hand not a hand saw, but a jigsaw, that’s great. You can use it. You just need to remember that the jigsaw saw, which will run along the plywood along the drawn line, should not touch anything underneath the board, otherwise it will simply break if it hits any obstacle:

In practice, you will often encounter similar problems. For example, a long time ago I needed to cut a rectangular hole in the parquet in order to get to the concrete floor, from where I was supposed to build a niche. A lack of understanding about which tools could be used and which ones could not almost led to a fire. Read about it here.

Specifications of Square Hole Drill

The profile of the drill for making square holes corresponds to a specially shaped triangle, which was named after its inventor Reuleaux. Distinctive feature: metal removal is carried out by the side, it has 3 cutting planes. At the same time, during the operation, the tool describes the main and swinging movements. They are performed in opposite directions (the triangle rotates around a moving axis). The peculiarity of the tool: it draws a figure representing the intersection of identical circles. As a result, its vertices draw a square. In this case, the axis of rotation moves along a certain trajectory, and does not stand still.

Like any drill, the product structurally consists of a working part and a shank, with which it is attached to a chuck, spindle or special fixture of a tool or machine. The profile of the working part has ellipsoidal grooves for removing chips during the drilling process. Thanks to their presence, the load on the clamping device is reduced, the cutting ability of edges is increased and the level of inertia is reduced. The use of coolant during the operation significantly increases the service life of the cutting tool. Some models of square drills may have grooves for the passage of fluid.

- material with which they can work (metal, wood);

- material of manufacture (alloy steel, carbon steel, high-speed steel, alloy);

- manufacturing method (solid, composite);

- designs (with and without an overhead frame, adapter);

- tail section designs (cylindrical, conical, hexagonal);

- execution series (short, medium, long);

- accuracy class (normal, increased);

- diameter;

- length of the working part.

In terms of length and diameter, domestic products must comply with the requirements of GOST 886-77, 4010-77 and 10902-77, imported analogues must comply with current foreign standards. Markings are applied to the shank of each drill that makes a square profile in materials of different densities. The diameter of the drill, the material from which it is made, and even the logo or name of the company are indicated. Drills with diameters of 9, 16, 23, 28 and 33 mm and lengths of 50, 60, 75, 85 and 90 mm are available.

Geometric parameters

The main geometric parameters include the following indicators:

- diameter indicated in mm;

- total length, mm;

- length of the working part, mm;

- sharpening angle in degrees.

In addition, when choosing a square drill, pay attention to the shank, which must match the tool spindle or a set of devices for fastening it. Drilling square holes must be done after preliminary marking and punching the center of the future hole. It is recommended to start drilling at low rotation speeds, and then switch to the speed indicated in the data sheet of the machine or tool.

How to make a square hole in metal

Surely you have already heard and seen about the method of drilling square holes using a Watts drill. In this video, the author shows a different method based on the use of a special tool. What to do if you need to drill a hole, but the diameter of the drill is smaller than needed? Roman also has drilling and milling machines and a hand router Laser cutting - Fantastic worlds made of wood Vladimir Fomin Yes, of course it’s cool!

Search data for your request:

Schemes, reference books, datasheets: Discussions, articles, manuals:

Wait for the search to complete in all databases. Upon completion, a link will appear to access the found materials.

WATCH THE VIDEO ON THE TOPIC: How to make square holes in metal with a simple device

Classification of drills for square openings

The name "square drill" comes from the shape of the hole the bit is capable of drilling. Externally, such drills have the shape of a triangle (tip), but with their help it is possible to obtain square-shaped openings. The nozzles in question are classified according to a number of the following characteristics:

- Type of working material - it can be wood, metal or plastic

- The material from which the nozzle is made. Depending on the material in which it is necessary to obtain a square opening, the nozzles are made of alloy, carbon or high-speed steel

- Type of production of nozzles - they come in two types: solid and composite type. Composite attachments have a hinged (cardan) shank, through which the load on the tool chuck is reduced. Today, cardan attachments are extremely rare

- Shape of the shank - depending on this parameter, you can use attachments on drills, drilling machines and other types of equipment. Watts drills are available with cylindrical, conical and hex shanks. Mills with tapered shanks are installed directly into the drill chuck, while cylindrical and hexagonal bits require the use of a special chuck for fastening

- Drill length - they come in long, medium and short

- Accuracy class - normal and increased

- Diameter - depends on what size square you need to get in the end

- The length of the working part is another important parameter, which is responsible for the ability to drill corresponding holes with different degrees of depth

- Design - cutters for square holes come with an overlay frame, as well as an adapter or without it

Domestic-made square drills are produced in compliance with the standards GOST 886-77, GOST 4010-77 and GOST 10902-77. However, foreign-made drills, which are manufactured in compliance with relevant standards, are very popular. The marking is indicated on the tail of the cutter, where information such as diameter, material of manufacture and company name is presented.