Drilling, countersinking and reaming

TO

category:

Drilling metal

Drilling, countersinking and reaming

Next: Metal Milling

Drilling, countersinking and reaming are carried out on various types of drilling machines, aggregate boring machines, as well as turning machines. In addition, these operations can be performed using hand and mechanical drills.

Drilling. Drilling is a machining operation to produce holes in a solid material. Drills of various designs are used as cutting tools for drilling. The main movement when drilling is rotational, the feed movement is translational. On general purpose drilling machines and boring machines, the main movement is the drill; on lathes and special drilling machines for deep drilling, the drill has only translational motion, and the workpiece has rotational motion; this determines higher processing accuracy.

Rice. 1. Twist drill

During drill operation, the transverse edge does not cut, but presses the metal of the workpiece. It was found that about 65% of the feed force occurs at the transverse edge.

Rice. 2. Double sharpening of twist drill

To facilitate the working conditions of the drill, the transverse edge is sharpened. For the same purpose, drills working on cast iron and steel are double sharpened with an angle of 2 ft! = 75-80°. The width b of the rear surface of the second sharpening is made within 0.18-0.22 of the drill diameter. As a result of double sharpening, the width of the chip increases at the expense of the thickness, the leading angle decreases, and therefore the durability of the drill increases.

Centering drills are used for drilling center holes when centering workpieces. These drills are made combined and double-sided for better use of tool steel.

Feather drills are made in the form of blades. They are rarely used, mainly when drilling holes in hard forgings and castings.

Drills with carbide inserts are manufactured with a diameter of 3 to 50 mm and are used for drilling bleached cast iron, hard steels, etc.

Deep holes are defined as holes having a length five times or more greater than their diameter.

Drills for deep drilling are manufactured with a diameter of 6 to 100 mm. Drilling holes with such drills is carried out on special drilling machines, and in most cases, only the feed movement is communicated to the drill, and the main movement (rotational) is transmitted to the workpiece.

Rice. 3. Center drill

Rice. 4. Feather drill

Rice. 5. Drill with carbide insert

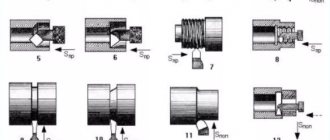

In Fig. 6 shows a gun drill made from a round rod. The cutting edge of the drill is formed by the front surface and the rear surface (unilateral cutting).

Rice. 6. Gun drill

Rice. 7. Gun drill

Rice. 8. Countersinking scheme

In addition to gun drills, the following are used for drilling deep holes: a) gun drills for drilling holes of small diameter and great depth. These drills are hollow inside (to supply coolant) and have a groove to drain the liquid along with the chips; b) single- and double-cut drills for drilling deep holes of medium and large diameters; c) heads for circular drilling of deep holes of large diameter. Qi.nozny drilling of metal with diameters over 100 mm is unprofitable, therefore, in such cases, hollow drilling heads with cutters fixed in them are used.

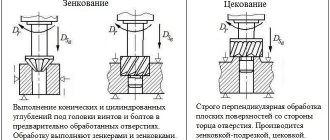

Countersinking. Countersinking is a machining operation by cutting the walls or inlet of a hole; countersinking is carried out using holes obtained during casting or forging (black) or pre-drilled holes. The purpose of countersinking is to obtain more accurate dimensions of holes and the position of their axes, shaped processing of the end (input) part of the hole to obtain recesses for screw heads, etc.

The cutting process during countersinking is similar to the simultaneous operation of several boring cutters, which in this case can be considered countersink teeth.

There are four main types of countersinks: for expanding holes, for producing cylindrical recesses of holes, for producing conical recesses for holes, for cleaning end surfaces.

Countersinks for expanding holes are made three-pronged (for holes up to 30 mm) and four-pronged (for holes up to 100 mm). In Fig. 9, a shows a three-tooth countersink with a conical shank for mounting in the machine spindle, and in Fig. 281, b - four-tooth mounted countersink. In order to increase productivity, countersinks are equipped with plates made of hard alloys.

In addition to solid countersinks, countersinks with inserted knives made of high-speed steel or reinforced carbide alloys are also produced. The advantage of such countersinks is the saving of high-speed steel and the ability to regulate the processing diameter. Mounted countersinks with insert knives can have 6 teeth -

Processing with countersinks ensures correction of the axis with holes, increases accuracy to 4-5 classes and surface cleanliness to 4-6 classes:

Countersinks for producing cylindrical recesses (Fig. 281, c) have a guide pin, which is manufactured integrally with the countersink body or (in other designs) made replaceable.

Countersinks for producing conical recesses - countersinks (Fig. 281, d) - most often have an angle 2cf> = 60o, less often 75, 90 and 120°. The number of teeth in countersinks ranges from 6 to 12.

Countersinks for cleaning end surfaces (Fig. 281, d) have teeth only at the end. The number of teeth of these countersinks, depending on their diameter, can be 2, 4 or 6.

In addition to those described, there are also combined countersinks for producing stepped holes. These countersinks allow complex processing to be carried out on a simple machine, thereby reducing the cost of processing.

Rice. 9. Countersinks

Deployment. Reaming is a machining operation that involves cutting the walls of holes in order to obtain high precision and surface finish. When unfolding, a layer of metal of a few tenths of a millimeter is removed from the walls of pre-processed holes (by drilling and countersinking or just drilling); holes are obtained within the 1-3 accuracy classes and 6-9 cleanliness classes. To obtain accurate and clean holes, sequential rough and finishing reaming is used.

Rice. 10. Sweeps

According to the shape of the hole being machined, reamers are divided into cylindrical and conical.

Reamers, just like countersinks, are made with tail and attachment ones.

The working part 1 of the cylindrical reamer consists of a cutting part 2 of the calibrating part and a rear cone. The number of reamer teeth is taken even (six or more) to achieve an accurate measurement of the reamer diameter. To avoid obtaining a faceted hole, the distribution of teeth around the circumference is made uneven, but taking into account that it is possible to measure the diameter along the tape (variation in steps of 1-4°).

According to the method of application, reamers are divided into machine and manual; by design - solid and prefabricated with insert knives. To increase durability, the cutting part of the teeth is reinforced with hard alloy plates.

Hole making: types of operations and tools used

Hole processing is a whole series of technological operations, the purpose of which is to bring the geometric parameters, as well as the degree of roughness of the inner surface of pre-made holes, to the required values.

The holes that are processed using such technological operations can be previously obtained in solid material not only by drilling, but also by casting, punching and other methods. Processing a drilled hole with a cylindrical countersink

The specific method and tool for processing holes are selected in accordance with the characteristics of the desired result. There are three methods for processing holes - drilling, reaming and countersinking. In turn, these methods are divided into additional technological operations, which include drilling, counterboring and countersinking.

To understand the features of each of the above methods, it is worth considering them in more detail.

The tip of the drill can be different and depends on the material being processed. For processing soft materials it should be from 80 to 90°, for steel and cast iron 116-118°, for very hard metals 130-140°.

Sharpening drills. During operation, the drills wear out along the front and rear surfaces, a chamfer is created, and the corners are rounded (Fig. 1, a). Blunt drills are sharpened on sharpening machines. Control of the main elements of the cutting part is carried out using templates (Fig. 1, b).

Rice. 0. Twist drill: 1 - working part of the drill, 2 - neck, 3 - shank, 4 - foot, 5 - groove, 6 - feather, 7 - guide chamfer (ribbon), 8 - back sharpening surface, 9 - cutting edges, 10 - jumper, 11 - cutting part

Manual drilling is carried out with hand drills, electric drills and pneumatic drills.

A hand drill (Fig. 2) consists of a spindle on which the chuck is located, a bevel gear (consisting of a large and small gear), a fixed handle, a movable handle and a breastplate. The drill is inserted into the chuck and secured in it. When drilling, the mechanic holds the drill with his left hand by the fixed handle, and with his right hand he rotates the movable handle, leaning his chest on the breastplate.

Rice. 1. Wear pattern (a) and template for monitoring the main elements (b) of the drill

An electric drill (Fig. 3) consists of an electric motor located in the drill body, a gear and a spindle with a chuck in which the drill is clamped. There are light electric drills - for drilling holes with a diameter of up to 15 mm in the shape of a pistol; medium type - for drilling holes with a diameter of 15-20 mm with a closed handle at the end; heavy type - for drilling holes with a diameter of up to 32 mm with two side handles and a chest stop.

Rice. 2. Hand drill: 1 - chuck, 2 - gear, 3 - movable handle, 4 - breastplate, b - fixed handle

A pneumatic drill (Fig. 4) is manufactured with piston and rotary type pneumatic motors. A pneumatic drill is easy to use, as it has small dimensions and weight. Drilling machines are used to mechanize the drilling process.

Rice. 3. Electric drill: 1 - handle, 2 - body, 3 - spindle

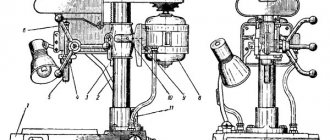

Drilling machines are divided into tabletop drilling machines, vertical drilling machines and radial drilling machines. Tabletop drilling machines are designed for drilling holes of small diameter (up to 12-15 mm). Radial drilling

machines are used for drilling holes in large parts. They make it possible to machine a hole anywhere in the part within the annular area.

The most common are universal vertical drilling machines (Fig. 5). The workpiece or part to be processed is placed on a table that can be raised and lowered using a screw. The handle secures the table to the frame at the required height. The drill is installed and secured in the spindle. The spindle is driven by an electric motor through a gearbox, and automatic feeding is carried out by a feedbox. Vertical movement of the spindle is carried out manually using a flywheel.

Rice. 4. Pneumatic drill: 1 - spindle, 2 - body, 3 - nipple

Drilling technique. Drilling is carried out according to the markings, according to the jig, using universal prefabricated devices (USP).

When drilling, a hole is marked according to the markings, it is punched around the circumference and in the center, and the workpiece is secured in a vice or other device. Drilling along the markings is usually carried out in two steps. First, drill a hole to a depth of a quarter of the diameter. If the resulting hole (not through) coincides with the marked one, then continue drilling, otherwise correct the installation of the drill and only then continue drilling.

When drilling a hole for a thread, it is necessary to use reference manuals to select the drill diameter in accordance with the type of thread, as well as taking into account the mechanical properties of the material being processed.

When processing a large number of identical parts, jigs are used. They consist of a body where the part is placed and oriented in a certain position, and a jig plate with holes and jig bushings pressed into them to guide the drill.

In addition to conductors, universal prefabricated devices (USF) are used, consisting of normalized elements (plates with T-shaped slots, installation parts - pins, disks, keys, linings, guides, clamping and fastening parts). They are used to assemble devices for a specific operation. At the end of the work, the devices are disassembled and their parts are used again. USP significantly reduces processing costs and provides high accuracy.

Countersinking is the name given to the subsequent (after drilling) processing of holes, which consists of removing burrs, chamfering and obtaining a conical or cylindrical recess at the inlet part of the hole. Countersinking is carried out with countersinks.

According to the shape of the cutting part, countersinks are divided into cylindrical and conical (Fig. 6, a, b). Conical countersinks are used for processing conical recesses for screw heads, countersunk rivets, and valves. Conical countersinks are available with apex angles of 60, 75, 90 and 120°.

Cylindrical countersinks are used to process cylindrical recesses for fasteners and boss planes. A cylindrical countersink has a guide pin that fits into the hole being machined and ensures the correct direction of the countersink. Countersinks are made of high-speed steel and with carbide plates.

Rice. 5. Single-spindle vertical drilling machine: 1 - screw, 2 - table, 3 - spindle, 4 - flywheel, 5 - feed box, 6 - gearbox, 7 - electric motor, 8 - handle, 9 - bed

Countersinking is an operation to increase the size or change the shape of a hole obtained by drilling, stamping or casting. When countersinking, an accuracy of 3-5th class is obtained.

Countersinking of holes is performed with a countersink. In appearance, a countersink resembles a drill and consists of the same basic elements, but has more cutting edges (3-4) and spiral grooves. According to their design, countersinks are divided into solid (Fig. 7, a), mounted (Fig. 7, b) with soldered plates, and prefabricated with insert knives (Fig. 7, c). Materials for countersinks: high-speed steels R9, R18, R9K5, R9KYu, hard alloy plates of grades VK6, VK8, VK6M, VK8V, T5K10, T15K6. Countersinking is performed on drilling machines or using electric and pneumatic drills.

Reaming is the final processing of holes after drilling, countersinking or boring to give them high accuracy and low roughness. Reaming achieves 2-3rd accuracy classes and roughness classes.

Reaming the holes is done by reaming.

According to the shape of the hole being machined, reamers are divided into cylindrical and conical, according to the method of application - into manual and machine ones, and according to the method of fastening - into tail and attachment ones.

Manual reamers (Fig. 58) consist of a working part and a shank. The shank is cylindrical with a square at the end for a knob. The working part is divided into cutting and calibrating. The cutting part has a conical shape with a intake cone angle of <р = 1°; at the end, to protect the teeth from chipping, a chamfer is made at an angle of 45°.

To ensure that the reamer fits freely into the hole, the diameter of the intake part is made smaller than the diameter of the pre-treated hole. The calibrating part directs the reamer into the hole and calibrates it; at the intake cone it has a cylindrical shape, closer to the shank it has a reverse cone to reduce friction.

Rice. 6. Countersinks: a - cylindrical, b - conical

Rice. 7. Countersinks: a - solid, b - mounted, c - with insert knives

The number of reamer teeth is even - 6, 8, 10, 12; They are performed with uneven steps, which ensures better processing.

Machine reamers differ from manual reamers in the shorter length of the working part and the long neck (for reaming deep holes). Their intake cone is short with an angle cp = 5° for processing brittle materials and cp = 15° for viscous materials. Reamers equipped with hard alloys have an angle f = 35–45°.

Conical reamers are used to machine a pre-drilled cylindrical hole into a cone or calibrate a conical hole made in another way.

Manual reamers are made from steel U12A, 9ХС, Р9 and Р18, machine reamers are made from steel Р9, Р18, РК8; they are equipped with hard alloys VK2, VK4, VK6, VK8, T15K6. The working part is thermally treated.

Rice. 8. Basic elements of manual cylindrical reamer

On the reamers, the nominal diameter is marked (on prefabricated ones - maximum diameters), accuracy number or fit for the completed reamer, grade of steel or hard alloy. Conical reamers are marked with the nominal diameter or cone number, taper, and steel grade.

Manual deployment. When reaming manually, the tool is rotated using cranks. To machine deep holes, extenders are put on the reamer. Small workpieces or parts are secured in a vice, while large ones are processed without securing.

Machine reaming is performed on drilling machines, as well as using power tools.

It is better to perform reaming immediately after drilling, without re-clamping the parts. This ensures alignment of the holes. When working on machines, swinging mandrels are used; they allow the reamer to self-align along the axis of the pre-processed hole and eliminate the influence of machine inaccuracies on the accuracy of the hole.

Drilling

To process holes, they must first be obtained, for which various technologies can be used. The most common of these technologies is drilling, performed using a cutting tool called a drill.

Main parts of a twist drill

Using drills installed in special devices or equipment, both through and blind holes can be produced in solid material. Depending on the devices and equipment used, drilling can be:

- manual, performed using mechanical drilling devices or electric and pneumatic drills;

- machine tools, carried out using specialized drilling equipment.

The physics of drilling holes

The use of manual drilling devices is advisable in cases where holes, the diameter of which does not exceed 12 mm, need to be obtained in workpieces made of materials of small and medium hardness. Such materials include, in particular:

- structural steels;

- non-ferrous metals and alloys;

- alloys made of polymer materials.

If it is necessary to make a hole of a larger diameter in the workpiece, and also to achieve high productivity of this process, it is best to use special drilling machines, which can be desktop or stationary. The latter, in turn, are divided into vertical and radial drilling.

Reaming, a type of drilling operation, is performed in order to increase the diameter of a hole previously made in a workpiece. Drilling is also performed using drills whose diameter corresponds to the required characteristics of the finished hole.

The physics of drilling holes

This method of processing holes is undesirable for those that were created by casting or through plastic deformation of the material. This is due to the fact that sections of their inner surface are characterized by different hardness, which causes uneven distribution of loads on the drill axis and, accordingly, leads to its displacement. The formation of a layer of scale on the inner surface of a hole created by casting, as well as the concentration of internal stresses in the structure of a part made by forging or stamping, can cause the drill not only to move from the required trajectory when drilling such workpieces, but also to break.

When performing drilling and reaming, it is possible to obtain surfaces whose roughness will reach Rz 80, while the accuracy of the parameters of the hole being formed will correspond to the tenth grade.

Hole machining equipment

Topic 3.

Drilling, countersinking, reaming, threading.

Drilling

Drilling is a metalworking operation, which is a type of metal cutting using a tool called a drill, which makes rotational and translational movements.

Drilling is a very common operation, both in various machine-building plants and in plumbing and mechanical workshops, especially during installation and assembly work.

Drilling is used to obtain holes with a low degree of accuracy, and to obtain holes for threading.

Drilling is used:

— to obtain non-critical holes of low accuracy and significant roughness, for example, for fastening bolts, rivets, studs, etc.;

— for obtaining holes for threading, reaming and countersinking.

Drills come in various types (Fig. 3.1 a-i) and are made of high-speed, alloy and carbon steels, and are also equipped with carbide inserts.

The drill has two cutting edges. For processing metals of different hardness, drills with different helical flute angles are used. For drilling steel, drills with a flute angle of 18...30 degrees are used, for drilling light and tough metals - 40...45 degrees, when processing aluminum, duralumin and electron - 45 degrees.

The shanks of twist drills can be conical or cylindrical.

Conical shanks have drills with a diameter of 6...80mm. These shanks are formed by a Morse taper. The drill neck connecting the working part with the shank has a smaller diameter than the diameter of the working part.

Drills are equipped with carbide inserts, with helical, straight and oblique grooves, as well as with holes for the supply of coolant, carbide monoliths, combined, centering and feather drills. These drills are made from tool carbon steels U10, U12, U10A and U12A, and more often from high-speed steel R6M5.

Rice. 3.1. Work performed on drilling machines: a - drilling holes; b - drilling; c - countersinking; g - boring; d - countersinking; e - deployment; g - ironing; h - cutting internal threads; and—counting

Hole machining

After making holes in a solid material, they are processed to increase the size and reduce the roughness of the surfaces, as well as processing of previously obtained holes (for example, by casting, punching, etc.). Hole processing is performed in several ways, depending on what parameters of accuracy and surface roughness of the hole are specified in the drawing. In accordance with the chosen processing method, the tool for its implementation is also selected.

When processing holes, there are three main types of operations:

drilling, countersinking, reaming and their varieties:

drilling, countersinking, counterbore.

Drilling

- this is an operation to form through and deaf

holes in solid material, made using a cutting tool

tool - drill. There are manual drilling - with manual pneumatic and electric drilling devices (drills) and drilling on drilling machines. Manual drilling devices are used to produce holes with a diameter of up to 12 mm in materials of low and medium hardness (plastics, non-ferrous metals, structural steels, etc.). To drill and process holes of larger diameter, increase labor productivity and quality of processing, desktop drilling and stationary machines are used - vertical drilling and radial drilling.

One of the types of drilling is reaming - increasing the diameter of a previously drilled hole. Drills are used as tools for drilling holes, as well as for drilling. It is not recommended to drill holes made in a workpiece by casting, forging or stamping. Such holes have different hardness along the hole surface due to scale formed during casting, as well as

due to the uneven concentration of internal stresses in the metal on different parts of the surface of holes produced by forging or stamping. The presence of places with uneven and increased surface hardness leads to changes in the radial loads on the drill during the processing of the hole, which leads to a displacement of its axis and also causes drill breakage. Processing holes by drilling and reaming allows you to obtain dimensional accuracy of the machined hole up to 10th grade and the roughness of the machined surface

to Rz

80.

Countersinking

is an operation associated with the processing of pre-drilled, stamped, cast or other methods of holes in order to give them a more regular geometric shape (elimination of deviations from roundness and other defects), as well as to achieve higher accuracy compared to drilling ( up to 8th quality) and lower roughness (up to

Ra

1.25). Countersinking is carried out either on tabletop drilling machines (for small hole diameters) or on stationary drilling equipment installed on the foundation. Manual drilling equipment is not used for countersinking, since it cannot provide the required accuracy and surface roughness. Types of countersinking include countersinking and countersinking.

Basic rules for countersinking holes:

• drilling and countersinking of holes must be done with one installation of the part (workpiece) on the machine, i.e. changing only the processing tool;

• when countersinking unprocessed holes in body parts, special attention should be paid to the reliability of installation and the strength of the part;

• it is necessary to strictly observe the amount of allowance for countersinking, guided by the corresponding table;

• countersinking should be carried out in the same modes as drilling;

• it is necessary to comply with the same labor protection rules as when drilling.

Countersinking -

This is the processing at the top of drilled holes of cylindrical or conical recesses for the heads of screws and rivets, as well as chamfers. The operation is performed using a special tool - a countersink.

Basic rules for countersinking holes:

• it is necessary to follow the correct sequence of countersinking holes: first drill a hole, and then countersink it;

• drilling a hole and countersinking it should be done from one installation of the workpiece (part), changing only the tool;

• countersinking should be performed with manual feed of the countersink and low spindle speed (no more than 100 rpm) using emulsion, the depth of countersinking should be checked with a caliper or a machine ruler;

• when countersinking holes with a cylindrical countersink, when the diameter of the trunnion is greater than the diameter of the hole, it is necessary to first drill a hole along the diameter of the trunnion, and then countersink the hole. The final operation is drilling the hole to a given size.

Countering

- this is an operation for cleaning the end surfaces when processing bosses for washers, nuts, and retaining rings. The operation is performed using a special tool - a counterbore, which is installed on special mandrels.

Deployment -

This is an operation for processing previously drilled holes with a high degree of accuracy (up to 6th grade) and low roughness (up to

Ra

0.63). Reaming processing is carried out after preliminary drilling, reaming and countersinking of holes using reamers, which are divided into roughing and finishing, manual and machine. Deployment is carried out both manually and on machines, usually stationary. The design of the tool is selected depending on

the processing method used.

Basic rules for drilling holes:

• it is necessary to strictly observe the amount of allowance for deployment, guided by the corresponding table;

• manual deployment should be performed in two steps: first rough, and then finishing;

• in the process of reaming a hole in a steel workpiece, it is necessary

generously lubricate the surface to be treated with emulsion or mineral oil; cast iron workpieces should be rolled out dry;

• manual reaming should be carried out only clockwise to avoid scoring the hole walls with chips;

• during processing, the reamer should be periodically cleared of chips;

• the accuracy of processing of reamed holes should be checked with gauges: cylindrical - go-through and non-go-through; conical - according to the maximum risks on the caliber. The expanded conical hole can be checked with a “pencil” control pin;

•drilling and reaming holes on a drilling machine using a machine reamer must be done from one installation of the workpiece, changing only the processing tool.

Hole machining equipment

Manual equipment

The following types of hole machining equipment are distinguished:

manual; manual mechanized; stationary.

Manual equipment is equipment that uses human muscular energy as a drive; This includes hand drills and ratchets.

Electric drills (Fig. 3.2) of the light type are used for drilling holes with a diameter of up to 10 mm, the medium type - with a diameter of up to 15 mm, and the heavy type - with a diameter of up to 32 mm. When working, light and medium-sized electric drills are held in the hands. Heavy-duty electric drills require additional devices for fastening and holding them during operation. Such devices are various hanging

devices on springs and cables (Fig. 3.3), screw devices

with a stop (Fig. 3.4), as well as a special chest stop mounted on a drill, which allows you to use a person’s muscular energy.

Electric drilling machine with angle attachment (Fig. 3.5)

Designed for drilling holes in hard-to-reach places. A tube 5 is installed on the body 6 of the machine, which is secured with a nut 4. A head 3 is connected to the tube, located at an angle of 90° to the tube and the body. Inside head 3 there is a spindle on which a three-jaw chuck 2 with drill 1 is installed. The spindle is connected to an electric motor located in housing 6 using a roller 8 and a bevel gear, which is located in head 3. The electric machine is turned on by button 7. Head installed

on a drilling machine, can also have an inclination to the body axis of 45 °.

Fig.3.2. Electric drills: a -

light type;

6 -

medium type;

c

- heavy mud

Rice. 3.3. Devices for holding heavy-duty electric drills: a

- on a spring;

b -

on cables

Rice. 3.4. Screw device with stop

Rice. 3.5. Electric drilling machine with angle attachment: a -

machine with 90° head;

b

- machine with head 45

1 -

drill;

2

– three-jaw chuck;

3 -

head;

4

— fastening nut;

5

- tube;

6

— body;

7 — shutdown button; 8

- roller

Pneumatic drills (Fig. 3.6) are available in two versions:

light type (Fig. 3.6, a) and heavy type (Fig. 3.6, b). Due to the fact that pneumatic drills are driven from a centralized compressed air network or an individual compressor, they allow you to perform work of a very different nature in various conditions, including in hard-to-reach places.

Rice. 3.6. Pneumatic drills: a-light type, b-heavy type

The most interesting designs have drilling machines models

D-2 and USM-25.

Rice. 3.7. Manual drilling pneumatic machine D-2: 1 - chuck; 2 - nozzle; 3 - rotor; 4 — button; 5 - nipple; 6 – handle

Rice. 3.8. Manual pneumatic drilling machine USM-25: I - drill; 2 - three-jaw chuck; 3 - head; 4 — body; 5 — start button; 6 – nut

The manual pneumatic drilling machine D-2 (Fig. 3.7) has a spindle speed of 2500 rpm with an air pressure in the network of 0.5 MPa and a mass of 1.8 kg. The pneumatic machine has a handle 6, a rotor 3, a nozzle 2, a cartridge 1, a button 4 and a nipple 5. It comes with a set of angular and jig nozzles that are fixed in the machine body, which allows processing in hard-to-reach places.

Manual pneumatic drilling machine USM-25 (Fig. 3.8) widely

used in metalworking, assembly and repair workshops

works. It consists of a body 4 onto which a head 3 is screwed. A pneumatic reducer is installed inside the body and head with a spindle located on it at an angle of 90° with a three-jaw chuck 2 with a drill 1. The air hose is secured to the threaded nipple of the body with a nut 6. Air supply to the gearbox machine is carried out by pressing button 5.

Stationary drilling equipment

Stationary equipment is equipment that is permanently installed.

place, while the workpiece being processed is delivered to it. Stationary equipment includes tabletop, vertical

and radial machines.

Tabletop drilling machines (Fig. 3.10) are distinguished by a large

variety of designs, but the principle of their operation and

The scope of application is approximately the same. As an example

consider a high-speed tabletop drilling machine with high

precision with micrometric tool feed, designed

for drilling holes with a diameter of 0.3 to 4.0 mm.

Rice. 3.10. Bench Drilling Machine:

a - general view; b - drive unit; 1 - table; 2, 8, 10 — handles; 3 - three-jaw chuck;

4 - spindle; 5 - clamp; (5-limb; 7-casing; 9 - electric motor; 11 - head; 12 - column; 13,15,24 - ball bearings; 14 - cup; 1 6,2 2 - pulleys; 17 - adapter sleeve; - coupling; 19 - flange; 20 - screw; 21 - thrust washer; 23 - gear; 25 - vernier

Vertical drilling machines are the main and most

a common type of drilling machine used for machining holes in relatively small parts. These machines allow you to perform the following types of work: drilling, reaming, countersinking, countersinking, counterbore and reaming.

The range of these operations can be significantly expanded by using a special

tool.

Rice. 3.11. Vertical drilling machine mod. 2N118: 1

- foundation slab;

2 -

table;

3 -

spindle;

4 –

feed box;

5

— gearbox;

b

- electric motor;

7 — drilling head; 8 —

handle;

9 –

column

Radial drilling machines, like vertical drilling machines,

designed for processing holes by drilling, reaming,

countersinking, countersinking and reaming. Using

With special tools, their technological capabilities can be significantly expanded.

The fundamental difference between radial drilling machines and vertical drilling machines is that during processing the spindle can move relative to the workpiece in different directions. This ensures the processing of heavy parts, the installation and alignment of which on the machine table requires considerable time. This design feature of radial drilling machines makes it possible to process heavy body parts with a large number of holes located in the same plane. Radial drilling machines are universal and are used, as a rule, in small-scale production.

The most common types of radial-

drilling machines.

Rice. 3.12. Radial drilling machine: a - general purpose; b - with a movable column; c - on a special trolley; g – portable

A general-purpose radial drilling machine (Fig. 3.12, a) has a vertically located spindle that can move

in three directions: around the column, along the radii of the circle determined by the extension of the sleeve, and vertically along its axis. The workpiece is installed on the machine table.

Radial drilling machine

with a movable column (Fig. 3.12, b), which can move along the guides of the frame. The machine is designed for processing heavy, large-sized workpieces.

A radial drilling machine (Fig. 3.12, c) can be mounted on a special trolley that moves along a railway track.

Such machines are used in car repair plants.

A portable radial drilling machine (Fig. 3.12, d) is used for processing holes in large-sized body parts; it is installed directly on the workpiece being processed.

Rice. 3.13. Radial drilling machine mod. 2A554: I - foundation slab; 2 - base; 3 - sleeve; 4 — lifting mechanism; 5 – spindle head; b - control panel; 7 – table

Basic rules for working on a drilling machine

1. Drilling should be done only with a properly sharpened drill; if necessary, the drill must be re-sharpened or refilled. Sharpening control must be carried out using a template (Fig. 3.14, a) or a special protractor (Fig. 3.14, b).

2. It is necessary to firmly fix the drill with a cylindrical shank

in the chuck: the end of the drill should be rested against the bottom of the chuck, and then secure it by alternately inserting the key into all sockets of the chuck.

3. It is necessary to firmly fix the drill with a tapered shank

(chuck with drill) in the machine spindle.

4. To ensure strong and safe fastening of the workpiece

details needed:

• fix large body workpieces on the machine table;

• prismatic blanks of medium size (length 100… 120 mm,

width 50... 60 mm, height 30... 40 mm) secure in a machine vice;

• fasten small workpieces (length 70... 80 mm, thickness 1... 5 mm)

in a hand vise;

• install and secure cylindrical workpieces on prisms.

5. At the drilling site on the part, you need to make a deep (1.0 ... 1.5 mm) core recess.

6. Drilling holes of large diameters (over 10 mm) is necessary

perform in two stages: first with a drill with a diameter of 5 ... 6 mm, and then with a drill of the required diameter.

7. It is necessary to correctly determine the cutting speed depending on

from the material being processed and rationally adjust the machine to the spindle speed.

8. The correct drilling sequence should be observed when feeding the drill manually:

• align the tip of the drill with the core recess on the workpiece;

• turn on the machine;

• drill the hole to full depth;

• when the drill comes out of the hole, release the pressure.

9. It is necessary to correctly determine the automatic feed value and set the machine to this value.

10. The correct sequence for processing through holes when automatically feeding the drill should be observed:

• align the tip of the drill with the core recess on the part;

• turn on the machine;

• drill a hole to a depth of 3 ... 5 mm using a manual

submission;

• without removing the drill from the hole, turn on the automatic feed;

• drill the hole to full depth.

11. When drilling holes on the jig, you must observe

the following rules:

• the workpiece must be firmly fixed in the jig or

conductor on the workpiece;

• the diameter of the drill must exactly match the diameter of the hole

in the conductor bushing.

12. When drilling steel parts, lubricants should be used -

cooling liquid.

Rice. 3.14. Template for controlling the sharpening of drills: a -

sample;

b -

control of the angle at the apex

13. Cast iron parts must be drilled without cooling the drill.

14. After completion of work, compliance should be checked

drilled holes (diameter, depth) and center-to-center distances

drawing requirements.

Drilling safety rules:

• it is prohibited to drill a loose or weakly secured workpiece;

• hair should be tucked under a hat;

• it is necessary to carefully fasten the cuffs on the sleeves;

• do not press hard on the drill feed lever, especially when drilling small-diameter holes;

• do not bend close to the drilling site to avoid chips getting into your eyes;

• it is forbidden to blow away chips.

Thread cutting.

Thread elements

Each thread is characterized by certain numerical parameters

— elements (Fig. 3.80), which are pitch, profile angle, profile height, outer, inner and middle diameters.

Thread pitch P is the distance in millimeters between the tops of two adjacent thread turns, measured in the direction of its axis.

Rice. 3.15. Thread elements:

a - triangular; 6 - rectangular; c - trapezoidal; g - trapezoidal thrust; d - round; a is the profile angle; P - thread pitch; d is the outer diameter of the thread; d1, - internal thread diameter; d2 - average thread diameter

Profile height t is the distance from the top of the thread to the base of the profile, measured in the direction perpendicular to the thread axis.

The base of the thread is the section of the thread profile located at the shortest distance from its axis.

Profile angle a is the angle between the straight sections of the sides of the thread profile.

The outer diameter of the thread d is the largest diameter measured along the tops of the thread perpendicular to its axis.

The internal thread diameter dx is the smallest distance between

opposite thread roots, measured perpendicular

its axis.

The average thread diameter d2 is the diameter of a conditional circle drawn in the middle of the thread profile between the bottom of the recess (the base of the thread) and the top of the protrusion perpendicular to the thread axis.

Thread types and systems

The thread profile (see Fig. 3.16) depends on the shape of the working part of the tool used to produce the thread. According to their purpose, threads are divided into fastening and special. Fastening threads include triangular, and special threads include rectangular, trapezoidal, thrust and round. Fastening threads are cylindrical and conical, allowing for a tight connection.

Rice. 3.16. Thread profiles: a

- triangular;

c

- trapezoidal;

c

- rectangular;

g

- trapezoidal thrust;

d) - round; / - top; 2

- depression;

3

- thread

In mechanical engineering, three thread systems are accepted: metric, inch and pipe.

Rice. 3.17. Metric thread (dimensions in millimeters): dcp

- average thread diameter;

e –

normalized gap;

d1

- internal thread diameter; S—thread pitch; l0 – theoretical profile height; l1, is the distance between the tops of the bolt and nut turns; l2 – distance from the top of the turn to the bottom of the cavity

Rice. 3.18. Inch thread (dimensions in millimeters): da

— outer diameter of the thread;

d –

internal diameter of the bolt thread;

d1 - internal diameter of the nut thread; dcp

– average thread diameter;

S—thread pitch; l0 - profile height; e -

normalized gap

Rice. 3.19. Pipe thread (dimensions in millimeters): d0

— outer diameter of the thread;

d1, - internal thread diameter; l0—profile height; r

is the radius of the depression; S - thread pitch

Rice. 3.20. Thread control: a, 6

— pedometer template;

c –

caliper

Internal Threading Tools

For cutting internal threads both manually and using

Various mechanized equipment use a special tool - a tap.

Taps are distinguished by various design solutions, which depend on the nature and processing conditions, as well as on the material of the workpiece being processed. However, the design principle is the same for all taps.

The tap (Fig. 3.21) is a hardened screw on which several straight or helical grooves are cut, forming the cutting edges of the tool. The grooves also provide placement of chips formed during cutting; along them, chips can be removed from the cutting zone.

The tap consists of two parts - a working part and a shank, at the end of which there is a square (for hand taps). The working part of the tap includes: a cutting (taking) part, which ensures the removal of the main part of the processing allowance; a calibrating part that performs final processing of the thread; chip flutes; feathers (thread turns separated by chip grooves) and a core, which provides the tap with sufficient strength and rigidity for processing. Tail section

The tap is used to secure it in the driver used to make

working and idle movements of the tap.

Rice. 3.21. Tap:

A -

design:

I

- thread (turn);

2

- square;

3 -

shank;

4 -

groove;

5 -

cutting

feather; b —

geometric parameters:

1 -

front surface;

2 -

cutting edge;

3

—

backed surface; 4 —

back surface;

5

— cutting feather;

a -

rear angle; (3 -

cutting angle; 8 — sharpening angle; y - front angle; V -

with helical flute:

1 —

groove;

g

- cutting through threads;

d

- cutting blind threads: w - angle

helical groove inclination

To cut internal threads with taps manually use

device - a crank, which is installed on the square end of the tail part of the tap and imparts a rotational movement to it.

Knobs (Fig. 3.22) come in various designs, which have their own advantages and disadvantages. The simplest is a knob with three square holes of different sizes.

Rice. 3.22. Collars:

A

— sliding:

1 —

frame;

2 - coupling; 3

- handle;

4 -

movable cracker; 5 - stationary

cracker; A

- side of a square hole;

6

- safety:

1 -

body;

2 -

bushing; 3

- spring;

c

- end; g - with ratchet

The universal knob (Fig. 3.22, a) is a frame 1 with two crackers: movable 4 and fixed 5, forming a square hole. One of the handles 3 ends with a screw that moves the movable block 4 and secures the square of the tap shank. Reliability of fastening is ensured by coupling 2 with a hole for a stopper. To protect the tap from breakage, wrenches are used

with switching cams (Fig. 3.22, b). In these gates, body 1 and sleeve 2 have oblique cams that interlock with each other. When the force transmitted by the handle exceeds the force of spring 3, the housing cams disengage with the bushing cams. In this case, the body continues to rotate, but the tap remains motionless. The socket wrench (Fig. 3.22, c) resembles in its design a socket wrench with limited torque. Such wrenches are used when cutting threads in hard-to-reach places, as they allow you to work with one hand.

Ratchet drivers (Fig. 3.22, d) are used for cutting threads in holes located in hard-to-reach places, when the driver can only be turned a small angle at one time. These wrenches can be single-sided or double-sided, that is, with handles on both sides of the head.

External Threading Tools

A special tool is used to cut external threads

- dies. Fundamentally, the design of their cutting apparatus is similar to the design of a tap for cutting internal threads. However, if the tap is a screw with grooves cut along it, then the die is a nut with cut grooves that form the cutting edges of the tool.

The working part of the die (Fig. 3.23) consists of two parts - intake and calibrating. The intake part is conical with an angle of 40... 60; it is located on both sides of the die, and its length is 1.5... 2 turns. The calibrating part usually consists of 3...5 turns.

For metalworking (manual) cutting of external threads,

dies of various designs: round, which are sometimes called

handles, sliding (cluppies) and special ones for cutting pipes.

Round dies (holes) (see Fig. 3.23) are a threaded

ring with several grooves for the formation of cutting edges and removal of chips when cutting threads. Round dies are made solid and split, springy. The threads on the rods using dies are cut manually using cranks or on drilling and lathe machines using special mandrels. Split dies

due to their springing properties, they allow you to adjust the average thread diameter.

Rice. 3.23. Round die: 1

- fence part;

2 – calibrating part; 3

- chip

Groove

Round dies are made from tool alloy steels

grades 9ХС' and ХВСГ or high-speed steel.

Rice. 3.24. Square (sliding) die: 1 - die; 2 – die

A square (sliding) die (Fig. 3.24) consists of two halves, fixed in a special frame with handles - a clamp, the corner protrusions of which fit into the grooves of the die, holding its halves. One of the die halves can be moved to set the die to the required average thread diameter. The die is secured with screws. Currently, thread cutting using such dies is carried out very rarely, since they do not provide sufficient

thread accuracy. Collars for round dies (Fig. 3.25) are a round frame with a recess, in the hole of which a round

die. The die in the hole is kept from turning by means of three locking screws, the conical shanks of which fit into recesses made on the generatrix of the die body. The fourth screw allows you to adjust the average diameter of the thread.

Rice. 3.25. Driver for round dies

When cutting threads, lubricating and cooling fluids (coolants) serve to facilitate the working conditions of the tool, reduce the roughness of the machined surface, and, consequently, to improve the quality of the thread obtained during thread cutting. The choice of coolant depends on the material of the workpiece being processed. For example, emulsion is most often used to cool steel (structural, tool and alloy), cast iron, copper and aluminum. In addition, kerosene is used to cool cast iron and aluminum. Threading in copper, brass and bronze can be done without cooling.

Rules for processing external and internal threaded surfaces

1. Thread cutting must be done with plenty of lubrication

dies or taps with machine oil.

2. When cutting threads, you should periodically cut off the resulting

chips by reversing the tap or die 1/2 turn.

3. After cutting a thread on a rod or in a hole, it is necessary to control its quality: by external inspection - avoiding scuffing and torn threads; thread gauge (or standard bolt, nut) - through

part of the gauge (bolt, nut) is screwed on by hand; rolling in the bolt-nut pair is not allowed.

Table 3.1

Typical defects when cutting threads, the reasons for their occurrence

and methods of prevention

Rules for cutting external threads

1. Before cutting threads, you should check the diameter of the rod (bolt, stud, screw); it should be 0.1 ... 0.2 mm less than the nominal thread diameter.

2. It is necessary to file the chamfer at the top of the rod (if it is not on the workpiece). When filing a chamfer, you need to ensure its concentricity relative to the axis of the rod, as well as its diameter, which should not exceed the internal diameter of the thread along the end surface. In addition, the angle of inclination of the chamfer relative to the axis of the rod should not exceed 60°.

3. The rod should be fixed firmly and perpendicularly in the vice

sponges. The perpendicularity of the rod must be checked

along the square.

4. It is necessary to strictly monitor the perpendicularity of the end of the die to the axis of the rod when cutting into the die.

5. Before rolling threads on a rod, it is necessary to

check its diameter; it should be equal to the average diameter of the thread being cut.

6. When cutting threads on gas and water pipes, special attention should be paid to maintaining the length of the cut part for couplings and bends.

When cutting internal threads, the following must be observed:

rules.

1. Before cutting a thread, you should check: the diameter of the hole matches the size of the thread being cut. It must match the thread table data; hole depth for cutting blind threads. She must

correspond to the size indicated on the drawing.

2. When inserting a tap, it is necessary to ensure that its axis is perpendicular to the upper plane of the workpiece in which the thread is being cut.

3. When cutting threads, you should use the entire set of taps: the first - rough; the second is semi-finish; the third is finishing.

4. When cutting a thread in a blind hole, it is necessary to periodically

clear it of chips.

5. Particular care should be taken when cutting small diameter threads (5 mm or less) to avoid breakage of the tap.

6. When cutting threads with a machine tap on a machine, you must

secure it in the safety cartridge.

Typical defects when cutting threads, the reasons for their occurrence and methods of prevention are given in table. 3.1.

Countersinking

With the help of countersinking, performed using a special cutting tool, the following tasks related to the processing of holes produced by casting, stamping, forging or through other technological operations are solved:

- bringing the shape and geometric parameters of the existing hole into accordance with the required values;

- increasing the accuracy of the parameters of a pre-drilled hole up to the eighth grade;

- processing of cylindrical holes to reduce the degree of roughness of their internal surface, which, when using such a technological operation, can reach a value of Ra 1.25.

When countersinking, less cutting force is applied than when drilling, and the hole is more accurate in shape and size

If it is necessary to subject a hole of small diameter to such processing, it can be performed on tabletop drilling machines. Countersinking of large diameter holes, as well as processing of deep holes, is carried out using stationary equipment installed on a special foundation.

Manual drilling equipment is not used for countersinking, since its technical characteristics do not provide the required accuracy and surface roughness of the hole being machined. Varieties of countersinking are technological operations such as counterbore and countersinking, which use various tools to process holes.

Conical countersinks for metal

Experts give the following recommendations for those who plan to perform countersinking.

- Countersinking should be carried out during the same installation of the part on the machine in which the hole was drilled, and only the type of tool used changes from the processing parameters.

- In cases where an unprocessed hole in body-type parts is subjected to countersinking, it is necessary to control the reliability of their fixation on the machine table.

- When choosing the amount of allowance for countersinking, you need to focus on special tables.

- The modes in which countersinking is performed must be the same as when drilling.

- When countersinking, the same occupational health and safety rules must be observed as when drilling on plumbing equipment.

Topic 9. HOLE MACHINING presentation for a lesson on the topic

Slide 1

Discipline “Technology for performing plumbing work” College of ISTD (branch) NCFU in Pyatigorsk Oleg Yuryevich Goncharov, college teacher

Slide 2

Topic 9. HOLE PROCESSING 1. The essence of the processes of drilling, countersinking, countersinking, counterbore and reaming. 2. Tools and devices used when processing holes. Drills, wear and sharpening forms of drills. Basic rules for sharpening drills. Countersinks, countersinks, counterbores, reamers. Devices for installing tools. Devices for installation and fastening of workpieces. Machine vice. Conductors for securing workpieces. Devices for limiting drilling depth. 3. Hole processing equipment. Manual equipment. Basic rules for drilling with a hand drill. Basic rules for drilling with a hand-held electric drill. Stationary equipment for drilling. Basic rules for working on a drilling machine. Drilling safety rules. 4. Cutting modes and allowances when processing holes. Typical defects when processing holes, the reasons for their occurrence and methods of prevention. Study questions:

Slide 3

1. The essence of the processes of drilling, countersinking, countersinking, counterbore and reaming. When processing holes, there are three main types of operations: drilling, countersinking, reaming and their varieties: drilling, countersinking, counterbore. Drilling is an operation for the formation of through and blind holes in solid material, performed using a cutting tool - a drill. There are manual drilling - with manual pneumatic and electric drilling devices (drills) and drilling on drilling machines. One of the types of drilling is reaming - increasing the diameter of a previously drilled hole.

Slide 4

Continuation of question 1 Countersinking is an operation associated with the processing of pre-drilled, stamped, cast or other methods of holes in order to give them a more regular geometric shape (elimination of deviations from roundness and other defects), as well as to achieve a higher, compared to drilling, accuracy (up to 8th grade) and lower roughness (up to Ra 1.25). Types of countersinking include countersinking and countersinking. Basic rules for countersinking holes: - drilling and countersinking holes must be done with one installation of the part (workpiece) on the machine, i.e., changing only the processing tool; - when countersinking unprocessed holes in body parts, special attention should be paid to the reliability of installation and the strength of fastening of the part;

Slide 5

Continuation of question 1 - it is necessary to strictly observe the amount of allowance for countersinking, guided by the corresponding table; - countersinking should be done in the same modes as drilling; - it is necessary to follow the same labor protection rules as when drilling. Countersinking is the processing of cylindrical or conical recesses for the heads of screws and rivets, as well as chamfers, on the top of drilled holes. The operation is performed using a special tool - a countersink. Basic rules for countersinking holes: it is necessary to follow the correct sequence of countersinking holes: first drill a hole, and then countersink it; - drilling a hole and countersinking it should be done from one installation of the workpiece (part), changing only the tool;

Slide 6

Continuation of question 1 - countersinking should be performed with manual feed of the countersink and low spindle speed (no more than 100 rpm) using an emulsion, the depth of countersinking should be checked with a caliper or a machine ruler; - when countersinking holes with a cylindrical countersink, when the diameter of the trunnion is greater than the diameter of the hole, it is necessary to first drill a hole along the diameter of the trunnion, and then countersink the hole. The final operation is drilling the hole to a given size. Countering is an operation for cleaning the end surfaces when processing bosses for washers, nuts, and retaining rings. The operation is carried out using a special tool - a counterbore, which is installed on special mandrels.

Slide 7

Continuation of 1 question Reaming is an operation for processing previously drilled holes with a high degree of accuracy (up to 6th grade) and low roughness (up to Ra 0.63). Basic rules for reaming holes: - it is necessary to strictly observe the amount of allowance for reaming, guided by the corresponding table; -manual deployment should be performed in two stages: first rough and then finishing; in the process of reaming a hole in a steel workpiece, it is necessary to generously lubricate the surface to be treated with emulsion or mineral oil; cast iron workpieces should be reamed dry; - manual reaming should be carried out only clockwise to avoid scoring the walls of the hole with chips; -during the processing process, the reamer should be periodically cleared of chips;

Slide 8

Continuation of question 1 - the accuracy of processing of reamed holes should be checked with gauges: cylindrical - go-through and non-go-through; conical - according to the maximum risks on the caliber. The expanded conical hole can be checked with a “pencil” control pin; -drilling and reaming of holes on a drilling machine using a machine reamer must be done from one installation of the workpiece, changing only the processing tool.

Slide 9

2. Tools and devices used when processing holes Fig. 2.1. Twist drill: a - drill design; b - design of the working part; c — design of the cutting part; 2φ — apex angle; ώ - angle of inclination of the helical groove; α - main clearance angle; γ- front angle; ψ is the angle of inclination of the transverse cutting edge. Drills are used when processing holes in solid material. The design differs between spiral, centering, feather, gun drills with external or internal chip removal and annular (trepanning heads) drills.

Slide 13

Continuation of question 2 Fig. 2.2. Centering drills: a - without safety cone; b - with a safety cone Centering drills (Fig. 2.2) are designed for making center holes; they are made from high-speed tool steels of grades P9 and P12. Based on their design, they distinguish between center drills without a safety cone (Fig. 3.27, o) and with a safety cone (Fig. 3.27, b).

Slide 15

Continuation of question 2 Fig. 2.3. Feather drills: a - with a cylindrical shank; b - with a conical shank; c - with coolant supply Feather drills (Fig. 2.3) have a flat working part and straight grooves for removing chips.

Slide 16

Continuation of question 2 Fig. 2.4. Gun drills: a - with a spike made of high-speed steel; b - reinforced with hard alloy plates; c - with internal coolant drain Gun drills (Fig. 2.4) are used for drilling deep and extra-deep holes.

Slide 17

Continuation of question 2 Fig. 2.5. Annular drills: a - two-cutters: 1 - body; 2,3 - replaceable cutters; 4,5,6 - guide plates; b - three-incisor; c - multi-incisor: 1 - incisors; 2 - body; L is the length of the working part. Annular drills (Fig. 2.5) are used to reduce cutting forces and equipment power consumption, increase the productivity of processing solid holes with a diameter of more than 50 mm, as well as reduce the volume of chips and subsequent use of the central rod formed along the axis of the hole being machined.

Slide 18

Continuation of question 2 Fig. 2.6. Wear of drills: a - along the back surface; b, c, d - along the ribbon; d - carbide drills; h 1 - wear along the axis; h 3 - wear of the backed part; h 2 - wear of the ribbon; L - linear wear of the corner; φ 1 - angular wear of the drill Wear and sharpening shapes of drills In spiral drills, wear occurs mainly along the rear surface of the angle at the intersection of the intake cone with the drill strips (Fig. 2.6, a)

Slide 20

Continuation of question 2 Fig. 2.7. Sharpening shape: a - single; b - single with a jumper point; c - single with a point of the jumper and ribbon; g - double with a point of the jumper; d - double with a point of the jumper and ribbon; 2φ — apex angle; l 0 — width of additional sharpening; 2φ 0 - additional sharpening angle

Slide 21

Continuation of 2 questions Basic rules for sharpening drills 1. It is necessary to adjust the position of the tool rest of the sharpening machine so that there is a gap of at least 2 mm between it and the periphery of the sharpening wheel. You should check the presence and serviceability of the sharpening machine screen. 2. The following requirements for sharpening drills must be observed: - sharpening should be done using the periphery of the grinding wheel; - in the left hand there should be the cutting part of the drill with the cutting edges up, in the right hand - the shank of the drill; -the left hand should rest on the tool rest of the machine. 3.When sharpening, you should periodically check that the drill is sharpened correctly using a special template (Fig. 2.8):

Slide 22

Continuation of question 2 Fig. 2.8. Template for controlling the sharpening of drills: a - control of the angle at the tip; b — control of the angle of inclination of the ribbon; c - control of the angle of inclination of the transverse cutting edge; ψ - angle of inclination of the transverse cutting edge, the length of the cutting edges must be the same; the sharpening angle at the tip of the drill must correspond to the template; the angles between the edges and the side surface of the drill must be the same; The sharpening angles of the edges must be equal and correspond to the template.

Slide 23

Continuation of question 2 4. It is necessary to tuck the cutting edges of the drill on the block. 5. It is necessary to test drill the hole with a sharpened drill: - the chips from both cutting edges must be of the same thickness (check visually); - the diameter of the drilled hole must exactly match the diameter of the drill; - the hole should not shift by more than 0.2 mm (checking is carried out using control marks).

Slide 24

Continuation of question 2 6. The following safety requirements must be observed: -sharpening small-diameter drills must be done on a fine-grained wheel; - it is prohibited to sharpen drills on a sharpening machine without a tool rest and with or without a faulty protective casing; It is strictly forbidden to sharpen drills “in weight”, that is, without using a tool; - it is necessary, especially when sharpening large-diameter drills, to lower the protective screen; in the absence of a screen, sharpen drills using safety glasses to avoid getting abrasive dust into the eyes.

Slide 25

Continuation of question 2 Fig. 2.9. Countersink: a - design; b - geometric parameters of the working part: ώ - angle of inclination of the ribbon; φ is the main plan angle; φ 0 — angle of the intake cone; γ — front angle; a - rear angle; t - depth of cut Countersinks, countersinks, counterbores, reamers Countersinks (Fig. 2.9, a) are designed for processing holes in workpieces obtained by casting, stamping or pre-drilling.

Slide 26

Continuation of question 2 Fig. 2.10. Mounted countersink: 1 - cutting plates; 2 - body; 3 - thrust By design, countersinks are mounted and solid and can have a different direction of the spiral angle (right, left, straight).

Slide 27

Continuation of question 2 Fig. 2.13. Wear of countersinks: h l - wear length; h з - wear width; hy - wear at corners Fig. 2.12. Countersink with internal coolant supply

Slide 28

Continuation of question 2 Fig. 2.14. Countersinks and counterbores: a, b - cylindrical; c, d - conical; d, f - mounted pins; 2φ - apex angle Countersinks and counterbores (Fig. 2.14) for processing the supporting surfaces for mounting screws, unlike countersinks, have cutting teeth at the end and guide pins, which provide the desired direction of the countersinks and counterbores during processing.

Slide 29

Continuation of question 2 Fig. 2.15 Development: a - structure; b - design of the fence part; c - geometric parameters of the cutting and calibrating parts; d - cutting diagram; φ is the angle of the intake cone; 2φ — apex angle; α—rear angle; γ — front angle; D - reamer diameter Reamers (Fig. 2.15) are made solid and mounted with a conical and cylindrical shank, equipped with insert knives, soldered carbide plates or made of high-speed steel. Reamers, unlike drills and countersinks, have a larger number of cutting edges

Slide 30

Continuation of question 2 Fig. 2.17. Reamers equipped with hard alloy plates: a, b - solid; c, d- mounted Fig. 2.16. Conical reamers

Slide 35

Continuation of question 2 Fig. 2.18. Three-jaw drill chuck: a - general view; b - design: 1 - cams; 2 - nut; 3 — clip; 4 - key Devices for installing tools

Slide 36

Continuation of question 2 Fig. 2.18. Double jaw drill chuck Fig. 2.19. Collet drill chuck: 1- shank; 2 - cylindrical part; 3 - split bushing; 4 – ring

Slide 37

Continuation of question 2 Fig. 2.20. Adapter conical bushings Fig. 2.21. Quick-change drill chuck: a - chuck design: 1 - conical hole; 2 — ring groove; 3 - ring; 4 - balls; 5 — replaceable bushing; 6 — body; b - replaceable bushing

Slide 38

Continuation of question 2 Fig. 2.22. Self-aligning drill chuck: 1 - body; 2 - spring; 3 - leash; 4 - bearing; 5 - retaining ring; 6 — mandrel; 7-clutch Fig. 2.23. Swinging mandrel for reamers: 1 - shank; 2 — thrust bearing; 3 - ball; 4 — body; 5 - pin; 6 - swinging part

Slide 39

Continuation of question 2 Fig. 2.24. Wedges for removing tools: a- flat; b - radius; c - eccentric key

Slide 40

Continuation of question 2 Fig. 2.25. Clamps (a), prisms (b) and squares (c): 1 - workpiece; 2 — screw Devices for installation and fastening of workpieces

Slide 41

Continuation of question 2 Fig. 2.26. Squares: a - hard; b - adjustable

Slide 42

Continuation of question 2 Fig. 2.27. Machine screw vice: 1 - screw; 2 - movable sponge; 3 - fixed sponge; 4 - base; 5 – handle Machine vice

Slide 43

Continuation of question 2 Fig. 2.28. High-speed machine vice: 1 - body; 2 - rotating part; 3 - fixed sponge; 4 - setscrew; 5 - movable sponge; 6 — handle; 7 - eccentric shaft; 8 - double cam; 9 - base

Slide 44

Continuation of question 2 Fig. 2.29. Pneumatic machine vice: 1 - pneumatic cylinder; 2 - movable sponge; 3 — multi-arm lever; 4 — piston rod; 5 - check valve; 6 - handle

Slide 45

Continuation of question 2 Fig. 2.30. Conductor bushings: a - permanent; b - quick-change jigs for securing workpieces To secure workpieces and ensure the correct positioning of the tool relative to the axis of the hole being machined, special devices are used - jigs.

Slide 46

Continuation of question 2 Fig. 2.31. Installation supports: a - pins: I, II and HI - flat, spherical and notched heads, respectively; b — plates: I and II — flat and notched, respectively; L and B are the length and width of the plate, respectively; c - adjustable screw support

Slide 47

Continuation of question 2 Fig. 2.32. Overhead jig: 1,2 - fixing fingers; 3 — conductor bushings; 4 - conductor plate; 5 - base surface of the workpiece; b - machined holes

Slide 48

Continuation of question 2 Fig. 2.33. Tiltable conductor: 1 - folding bar; 2 - bushing; 3, 8 — conductor bushings; 4 - movable prism; 5 - bolt; 6- cracker; 7 - blank

Slide 49

Continuation of question 2 Fig. 2.34. Rotary jig: 1 - dividing disk; 2 - key; 3, 5 - nuts; 4 - workpiece; b - split washer; 7 - spindle; 8 - spring; 9 — latch

Slide 50

Continuation of question 2 Fig. 2.35. A set of universal prefabricated devices: a - basic parts; b - guide elements; c - installation elements; g - assembly device Devices for limiting drilling depth

Slide 51

3. Hole processing equipment Fig. 3.1. Hand drill: 1 - chuck; 2.3 - gear transmission; 4 — movable handle; 5 — bib rest; b - fixed handle Manual equipment The following types of equipment for processing holes are distinguished: manual; manual mechanized; stationary.

Slide 53

Continued 3 questions Basic rules for drilling with a hand drill 1. It is necessary to firmly secure the workpiece in a vice, and the drill in the drill chuck. 2. The handle must be firmly attached to the drill shaft. 3. By moving the handle to different shafts of the drill gearbox, you should rationally adjust the rotation speed of the drill depending on its diameter. 4. When drilling, the drill should not be skewed; in addition, it is necessary to ensure that the drill is perpendicular to the drilling plane. 5. When drilling, the drill handle should be rotated evenly, smoothly, without jerking. The pressure on the drill stop should be applied evenly and constantly throughout the drilling process. 6. At the end of drilling, when the drill comes out of the material, you need to loosen the pressure on the drill stop and reduce the rotation speed of the drill.

Slide 54

Continuation of 3 questions Fig. 3.3. Ratchet: 1 - drill; 2 - clamping chuck; 3 — ratchet (ratchet wheel); 4 - nut; 5 - center; 6 - clamp; 7 — bracket; 8 — handle; 9 - pawl To facilitate the drilling process and increase its productivity, use a lever to press the drill stop (Fig. 3.2). Rice. 3.2. Leverage application

Slide 55

Continuation of 3 questions Fig. 3.4. Electric drills: a - light type; b - medium type; c - heavy type

Slide 56

Continuation of 3 questions Fig. 3.5. Devices for holding heavy electric drills: a - on a spring; b - on cables

Slide 57

Continuation of 3 questions Fig. 3.6. Screw device with stop Fig. 3.7. Electric drilling machine with an angular attachment: a - machine with a 90° head; b - machine with a 45° head; 1 - drill; 2 - three-jaw chuck; 3 - head; 4 — fastening nut; 5 - tube; b - body; 7- shutdown button; 8 - roller

Slide 58

Continuation of 3 questions Fig. 3.8. Pneumatic drills: a - light type; b - heavy type

Slide 59

Continued 3 questions Basic rules for drilling with a hand-held electric drill 1. Before starting work, you must check the serviceability of the electrical wire and plug. 2. Before starting drilling, you need to check the operation of the drill at idle speed, and also make sure that there is no beating of the drill. If necessary, the drill should either be replaced or refastened. 3. When drilling holes in workpieces made of high-strength steels, use a cutting fluid. 4. Stop the rotation of the electric drill only after removing the drill from the hole.

Slide 60

Continuation of 3 questions Fig. 3.9. Manual drilling pneumatic machine D-2: 1 - chuck; 2 - nozzle; 3 - rotor; 4 — button; 5 - nipple; 6 - handle Fig. 3.10. Manual drilling pneumatic machine USM-25: 1 - drill; 2 - three-jaw chuck; 3 - head; 4 — body; 5 — start button; 6-nut

Slide 61

Continuation of 3 questions Fig. 3.11. Tabletop drilling machine: a - general view; b - drive unit; 1 - table; 2,8,10 - handles; 3 - three-jaw chuck; 4 - spindle; 5 - clamp; 6 - limb; 7 - casing; 9 - electric motor; 11 - head; 1 2-column; 13,15,24 - ball bearings; 14 - glass; 16, 22 pulleys; 1 7-way bushing; 18 - coupling; 19 - flange; 20 - screw; 21 — thrust washer; 23 - gear; 25 — vernier

Slide 63

Continuation of 3 questions Fig. 3.12. Vertical drilling machine MOD.2N118: 1 - foundation slab; 2 - table; 3 - spindle; 4 — feed box; 5 — gearbox; 6 - electric motor; 7- drilling head; 8 — handle; 9 - column

Slide 64

Continuation of 3 questions Fig. 3.13. Radial drilling machine: a - general purpose; b - with a movable column; c - on a special trolley; g - portable

Slide 65

Continuation of 3 questions Fig. 3.14. Radial drilling machine mod. 2A554: 1-base slab; 2 - base. 3 - sleeve; 4-lifting mechanism; 5- spindle head; b - control panel; 7 - table

Slide 67

Continued 3 questions Basic rules for working on a drilling machine 1. Drilling should be done only with a properly sharpened drill; if necessary, the drill must be re-sharpened or refilled. Sharpening control must be carried out using a template (Fig. 3.76, a) or a special protractor (Fig. 3.76, b). Rice. 3.15. Template for controlling the sharpening of drills: a - template; b - control of the angle at the apex

Slide 68

Continuation of question 3 2. It is necessary to securely secure the drill with a cylindrical shank in the chuck: the end of the drill should be rested against the bottom of the chuck, and then secure it by inserting the key one by one into all sockets of the chuck. 3. It is necessary to firmly fix the drill with a tapered shank (chuck with drill) in the machine spindle. 4. To ensure strong and safe fastening of the workpiece, it is necessary to: - secure large body workpieces on the machine table; - prismatic workpieces of medium size (length 100... 120 mm, width 50;..60 mm, height 30...40 mm) are secured in a machine vice; -small workpieces (length 70... 80 mm, thickness 1... 5 mm) are secured in a hand vise; - install and fix cylindrical workpieces on prisms.

Slide 69

Continuation of question 3 5. At the drilling site on the part, you need to make a deep (1.0 ... 1.5 mm) core recess. 6. Drilling holes of large diameters (over 10 mm) must be done in two stages: first with a drill with a diameter of 5... 6 mm, and then with a drill of the required diameter. 7. It is necessary to correctly determine the cutting speed depending on the material being processed and rationally adjust the machine to the spindle speed. 8. The correct drilling sequence should be observed when feeding the drill manually: - align the tip of the drill with the core recess on the workpiece; - turn on the machine; -drill the hole to full depth; - when the drill comes out of the hole, release the pressure.

Slide 70

Continuation of question 3 9. It is necessary to correctly determine the automatic feed value and adjust the machine to this value. 10. The correct sequence of processing through holes should be observed when automatically feeding the drill: - align the tip of the drill with the core recess on the part; - turn on the machine; -drill a hole to a depth of 3... 5 mm using manual feed; -without removing the drill from the hole, turn on the automatic feed; -drill the hole to full depth. 11.When drilling holes on the jig, the following rules must be observed:

Slide 71

Continuation of question 3 - the workpiece must be firmly fixed in the jig or the jig on the workpiece; - the diameter of the drill must exactly match the diameter of the hole in the jig bushing. 12. When drilling steel parts, coolant should be used; 13. Cast iron parts must be drilled without cooling the drill. 14. After finishing the work, you should check the compliance of the drilled holes (diameter, depth) and center-to-center distances with the requirements of the drawing.

Slide 75

Continuation of question 3 Safety rules when drilling: - it is prohibited to drill a loose or weakly secured workpiece; -hair should be tucked under a headdress; - it is necessary to carefully fasten the cuffs on the sleeves; - do not press hard on the drill feed lever, especially when drilling small-diameter holes; - do not lean close to the drilling site to avoid chips getting into your eyes; - It is prohibited to blow away chips.

Slide 76

4. Cutting modes and allowances when processing holes Cutting modes when drilling The main elements of cutting when drilling are speed and depth of cut, feed, thickness and width of chips (Fig. 3.16). Rice. 3.16. Cutting elements when drilling: S - feed; D - hole diameter; t—cutting depth; b – cut width; a - cut thickness Allowance is a layer of material to be removed during processing. The size of this layer depends on the requirements for the treated surface and the type of treatment. When drilling, the machining allowance is half the diameter of the drill.

Slide 77