Typically, any metal part, complex or simple, has holes. There are different ways to obtain them. If the part has been stamped, the holes in it are also stamped. The same thing happens during casting. You can make holes on a finished product if you use a drill. What all methods of producing holes have in common is that they all have inaccuracies and require improvement. Here, the next stage will be the countersinking process - a technological operation to improve the geometric parameters of finished through or blind holes.

To carry out countersinking, special tools and equipment are required. This tool is for the most part very similar to a regular drill, but it has characteristic differences. Its working area allows you to give the channel strictly identical geometric parameters along its entire length.

Countersinking is a precise operation. Therefore, it cannot be carried out manually using a conventional electric drill - a special machine is required.

Countersinking

The work is performed on lathes (to produce holes from the end side), drilling, CNC milling and boring machines (to change the size of the hole).

The selection of tools is made based on the location of the hole and material, the depth and size of the hole, and the method of fastening. The processing speed in countersinking is identical to the drilling speed. For light steel, the angle of inclination is 15-20 degrees, for medium-light alloys - 8-10 degrees. High-alloy steels and cast iron are processed at an angle of 0-5 degrees, according to GOST 12479-71. The use of automatic equipment allows us to achieve high precision of the processed surface. When performing work, you must adhere to the following safety rules: the surface of the countersink must be well sharpened and free of burrs and cracks

When attaching the shank, you need to pay attention to the smoothness of the surface as fasteners.

This processing is similar to a drilling operation. Only in the case of countersinking does the final version come out more accurate, the surface cleanliness improves in the process, and any errors are eliminated. Next, reaming is usually performed - a type of finishing.

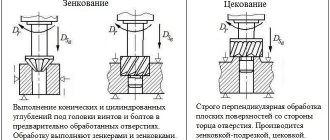

Countersinking is the secondary processing of ready-made holes for installing bolt heads, rivets, and screws into them.

TOOLING - BEARING CENTER

There are three main methods for making a helical flute in a drill: ground profile, milled profile and screw rolled. In production, the cheapest method is screw rolling, which consequently sacrifices quality. This does not bother domestic companies and they massively purchase these drills from China. Moreover, they are made from the cheapest steel 4241 (less than 3% tungsten W) and are marked P6M5. In principle, they are quite suitable for woodworking.

Drill sharpening

If you work with wood, you don't need to sharpen the drill for years. It's a different story with metal drills. They are made of high-speed steel and the hardness of the working surface reaches HRC 62-64. The most common steel grades are P9, P6M5, P18 and P6M5K5. A special place is occupied by carbide drills made of VK8 and VK6M alloys, which are manufactured both monolithic and with brazed plates. A significant number of types of drills also determines different approaches to their sharpening and regrinding.

The type of material being processed also plays an important role, on which the angle of the drill depends. For drilling structural, alloyed and similar steels it is usually 2φ118°, and for softer steels 2φ135°.

When sharpening and regrinding, not only the cutting angle φ must be obtained, but also the rear angles α 8-18° necessary for cutting and the back of the head. This will prevent the rear surface from rubbing against the bottom of the hole. The quality of sharpening is assessed by the axial runout of the edges δ, which depends on the error in the circumferential pitch of the grooves Δ and the eccentricity of the core ω. The non-straightness of the cutting edges should not exceed 2 δ.

The runout can be easily checked with a dial gauge indicator, which is mounted on a stand.

When processing brittle materials, wear occurs along the back surface and corners, and when processing viscous materials, wear occurs along the strip. In addition to wear and tear, polyps can form on the ribbons. The main task is the consolidated placement of the chips formed during the drilling process in the drill flute. Various sharpening methods are used, among which the most common are screw, compound screw and two-plane for drills with brazed carbide plates. To extend the service life of the drill, a sharpening of the jumper is often used, since it essentially does not cut, but scrapes. Reducing the length of the bridge reduces heating and premature chipping of cutting edges.

Sharpening is carried out using abrasive wheels, both straight profile made of normal 25A electrocorundum, and cup-shaped CG wheels. Finishing is carried out with wheels made of green silicon carbide 64C. Sharpening of carbide drills is carried out with diamond discs of disc and cup shape 12A2. Diamond pencils are used to edit circles. When sharpening, it is advisable to use gloves and safety glasses to avoid injury.

When sharpening, do not allow the drill to overheat, as cracks may appear and the carbide plates may peel off. In order to avoid this, it is necessary to periodically cool the drill with liquid. For cooling, you can use ordinary water, but cutting fluid (coolant) is much more effective, which should not be forgotten during the drilling process. Selecting a drill for thread cutting

Terminology

A countersink is a multi-bladed cutting tool used for making holes in metal parts. After processing, conical/cylindrical type recesses are obtained, you can create a reference plane near the holes, and chamfer the center hole.

Countersinking of holes is the secondary preparation of finished holes for placing hardware heads - bolts, screws, rivets

A countersink is a cutting tool with a multi-bladed surface. Used in machining cylindrical/conical holes in workpieces to expand the diameter, improve surface characteristics and accuracy. This type of processing is called countersinking. This is a semi-finish cutting process.

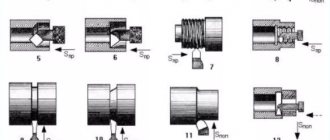

A - drilling with a drill B - boring on a lathe C - countersinking with a countersink D - reaming with a reamer E, F - counterbore with a counterbore G - countersinking with a countersink H - thread cutting with a tap

Countering holes is the process of reworking the top of an opening in order, for example, to remove burrs from the edge of a hole or to create recesses to hide the head of a rivet or screw and level it with the surface of the part. The tool used for this task is called a countersink.

Basic definitions

A countersink is a special cutting tool that allows you to make canonical or cylindrical holes. It is used to process finished holes in order to chamfer the center hole.

A countersink is a tool consisting of a certain number of blades designed for cutting. Designed to improve the quality of the hole and expand existing holes, creating holes of cylindrical or canonical shape. Machining holes using a countersink is called countersinking. Countersinking refers to semi-finishing metal processing.

You can come across the wrong concept when they say that a countersink and a countersink are the same thing. Using a countersink, the technical quality of the hole is improved. And it is not intended for making recesses.

Countersinking holes is the removal of chips or irregularities from a drilled hole. Countering holes is the process of deepening a canonically shaped hole in order to hide the head of a bolt or self-tapping screw. You can also come across the definition of hiding a self-tapping screw in a pattai.

Countersinking a hole

Countersinking of holes - processing of drilled holes for the heads or heads of bolts, screws, hardware.

Countersink. Purpose and types of tools

A countersink is a tool designed for semi-finishing metal. Externally, it is a metal shaft with cutting surfaces, reminiscent of a drill. It is created specifically for the metalworking industry. Produced in accordance with GOST 12489-71, GOST 3231-71 or TU 2-035-923-83 in accordance with the type of device.

Countersinks are divided into:

By type of fastening in the machine chuck:

- tail;

- mounted

By design features:

- solid;

- prefabricated;

- welded;

- with and without carbide inserts.

By geometric shape:

- cylindrical;

- conical;

- reverse.

In the direction of the ribbons and grooves:

- right rotation;

- left rotation.

Solid shank countersinks are most similar to drills, but differ in the presence of more cutting edges. In their cross section there are from 3 to 6 such sharp teeth. For production, high-speed tool steels R9, R18 are used, as well as alloy plates with increased hardness and wear resistance VK4, VK6, VK8, T15K6. The permissible cutting speed for models with carbide inserts is higher, which increases their efficiency.

There are strictly 4 teeth in diameter. The nozzle itself is sometimes equipped with removable working blades made of hard alloys. The cutters are fixed with wedges and can be replaced as needed.

A conical countersink is similar to a drill; the working part of the tool tapers towards its end. Used for processing inclined circular surfaces. Manufactured from alloy steel and metal-ceramics.

The ribbons of the countersink drill can be twisted in different directions; accordingly, the profiles of right and left rotation are distinguished. Left-hand rotation countersinks are used in semi-automatic lathes that feed material from the right side.

The choice of type of countersink is directly determined by the size of the hole in the workpiece and its material. With a diameter of up to 12 mm, they work with solid countersinks, starting from 20 mm - with countersink attachments and tools with inserted alloy blades. When it is necessary to make smoother and larger holes, combined models are installed in the machine, where there can be up to eight sharp teeth, and these countersinks are optionally combined with drills, reamers and other drilling and cutting tools.

What is a countersink, systematization

A cutting tool for metal (countersink) allows you to countersink an opening in a part up to accuracy group 5. It is widely used for semi-finishing parts before mechanical reaming. According to its structure, it is divided into types:

- holistic;

- nozzles;

- tail;

- connected.

Externally, metal-cutting devices look like a simple small drill, but have an increased number of cutting edges. The correct dimensions of the opening of the workpiece being processed is determined by the gauge. The tools are fastened in the unit's chuck with the support of the shank.

To cultivate openings with a diameter of up to 10 cm, attachments with 4 points are used. Their main feature is fastening through a mandrel. The presence of a chamfer on the teeth of the element made it possible to achieve correct adjustment of the cut.

The principle of metal countersinking

To understand how the countersinking process occurs, you need to have an idea of the design of the tool that performs this operation. This device is called a countersink. The simplest tail countersink is shaped like a regular drill, but it has significant differences. The difference between a drill and a countersink is that the latter has a larger number of side cutting edges that run in a spiral. Thanks to them, a thin layer of metal in the channel is removed when the countersink passes through it. In the process of passing along the working area, the countersink is imparted a translational-rotational movement. The process of improving the accuracy class of a hole by countersinking is as follows:

- In accordance with the diameter that needs to be obtained after the operation, the diameter of the countersink is selected. It must be larger than the initial one (the diameter of the tool depends on several factors) and correspond to the final diameter during finishing or intermediate during further development.

- This selected countersink is secured in the chuck of a machine (drilling, lathe) using a shank.

- The workpiece is fixed with a channel strictly opposite the countersink so that their axes perfectly coincide.

- Turn on the machine and set certain rotation speeds of the tool. They are strictly regulated and depend on the type of cutting element, metal and hole diameter.

- This tool is brought into the work area at a speed that is also not chosen by chance. Sometimes a coolant is also supplied to the processing area when the process requires it.

Geometric parameters

To choose the right countersink for a specific task, you need to know what metal it will work with and what parameters the main elements of the countersink have. For all-metal cylindrical elements, the following standards are provided for geometric parameters when processing specific materials:

- For parts made of structural steel with holes up to 40.0 mm in diameter, the latter are processed with a tool with a working part diameter of 40 to 10 mm and a number of cutting edges of 3–4 units. If the diameter reaches 80 mm, then the cutter should be in the range of 32–80 mm.

- For parts made of metal that has been hardened, the holes are machined with 4- and 3-blade countersinks with a cross-sectional size from 50 to 14 mm.

- For parts made of cast iron or non-ferrous metal, the countersinking operation for blind holes is carried out with a stylus tool.

This is interesting: Is stainless steel magnetic or not: how to determine stainless steel

Recommendations for the application of conical elements to the type of metal that must correspond to a certain geometric shape of the cone (meaning angle) are as follows:

- An angle of 20 to 15 degrees can be used when processing soft grades of steel and alloys is necessary.

- An angle of 10 to 8 degrees is suitable for work, which involves countersinking metals with medium hardness or parts for steel castings.

- An angle of 5 degrees and below is suitable for countersinking workpieces made of cast iron or high-alloy steel.

When finishing a product is carried out using a countersink, the diameter of the diameter of the tool must coincide with the diameter that should be obtained in the end!

Design features

If we look at the countersink, we can highlight some of its parts

- Cutting part. This is the main part that performs the countersinking process. Consists of several cutting edges located at an angle from the center to the sides.

- Shank. Using a shank, the countersink is secured in the tool or machine in which the work will be performed. The shank can be tapered or cylindrical.

- The part between the shank and the cutting part has a particularly thin shape in one place. This part acts as a fuse. If the countersink gets stuck, in order to avoid serious consequences, it is in this part of the countersink that it breaks.

The structure of a countersink One of the varieties of a countersink has welded blades on the working part, which makes it possible to process hard metal alloys.

Rules for working with a countersink

When performing work on a lathe or drilling machine with a countersink, you need to remember and follow a number of simple rules. Before starting work, check the condition of the chuck on the machine. After all, if the cartridge is in a faulty condition, it will not be possible to secure the countersink well, and thus you will not be able to get a high-quality machined hole. Countersinking of holes is carried out in accordance with the following rules:

- To perform the work, the countersink must be strictly in the center of the hole being machined.

- When processing hard metals such as cast iron, you need to take breaks from work and use special solutions to remove heat. In everyday life, technical oil is used for such purposes.

- When operating, do not exceed the speed specified by the manufacturer. Failure to comply with this rule will result in rapid wear of the cutting edges due to heating.

- Select the correct countersink diameter for the hole being machined. If you choose the wrong size, the processing will not be of high quality, namely incorrect centering, uneven edges.

Problems when working with the tool

Like all tools, our subject of discussion can break at the most inopportune moment. This applies not only to the cutting component itself, but also to the element that is used as a power tool. It happens that when using a countersink, the hole turns out to be broken. The reason for this may be an incorrectly sharpened cutting tool. There may be two ways to correct the situation: sharpen it or install a new one.

Another problem that experts face is that part of the hole surface remains untreated. There may be two reasons: the cutter allowance is too small, this can be corrected by increasing the allowance, or the workpiece in the chuck is skewed, here you need to carefully inspect the workpiece and check the hole for runout. The most common problem is inadequate quality of the treated surface. There can be 4 reasons for this situation: a large allowance (eliminate by reducing it), a dull tool (replace it with another), chips on the ribbons (clean the cutting tool from chips more often), too much feed (reduce it).

These are the main problems encountered when working with a countersink. But there are also related situations that can be avoided with proper operation of the device. Therefore, you should first study the instructions that come with it. After all, it is there that you can find answers to most questions regarding operation. Thus, the described tool can process both parts and surfaces. The main specialists who use it are turners, finishers and those whose professions are directly related to the processing of parts.

Features of countersinking

This procedure is similar to drilling, because it is also performed with a hole already made. The only difference is that countersinking is characterized by the highest accuracy. At the same time, various kinds of shortcomings and defects that appear during drilling, casting or stamping are eliminated. In addition, indicators such as accuracy and surface finish are improved, and a high level of alignment is obtained.

It often happens that when creating a hole with a drill, there is a deviation from the center point. This is due to insufficient rigidity of the cutting tool. A countersink is characterized by greater rigidity than an ordinary drill, since it has more teeth.

A more high-precision operation is considered to be reaming, which is already a finishing processing process.

Countersinking is often confused with countersinking, for which a completely different device is provided - a countersink. This tool has a different design and is intended for other technological operations.

A countersink is used to remove chamfers from holes, as well as to create conical recesses. There are also cylindrical countersinks, but these devices are called counterbores.

https://youtube.com/watch?v=f_A28_RQTSM

How does a countersink differ from a countersink?

Often a countersink is confused with a countersink. Countersink and countersink - belong to the class of cutting tools, with 3 or more cutting edges. Both tools are used for conical and cylindrical holes. But the countersink expands the hole, at the same time grinding it and adjusting it to the specified parameters. And the countersink only polishes the hole from burrs at the finishing stage.

This is interesting: Schematic diagram of a welding inverter: let’s look into the details

Applications and types of countersinks

A countersink is a multi-bladed, multi-toothed cutting tool used for finishing pre-made round holes in parts and workpieces made of different materials (pictured). Processing by this method is used to increase the diameter and obtain a better surface of the hole by cutting.

This process is called countersinking. The cutting method is similar to the drilling procedure: the same rotation of the countersinking equipment around its axis and simultaneous translational movement of the tool along the axis are observed.

Countersink with carbide inserts

We developed a countersink for the metalworking industry to process drilled, slotted or stamped holes. A countersink for metal, the requirements for the characteristics of which are regulated by GOST 12489-71, is used when performing intermediate or final processing. In this regard, there are two types of tools:

- for subsequent deployment with allowance;

- to obtain a high-precision hole - with quality H11 (tolerance 4–5 accuracy classes).

GOST 12489-71 Solid countersinks. Design and dimensions Download

When using a boring tool, the diameter increases, surface accuracy and hole cleanliness improve. Countersinking is intended mainly for:

- achieving a smoother, cleaner hole surface before reaming or tapping;

- calibrating the hole for a bolt, stud or any other fastener.

Countersinks are used, the requirements for which are determined by GOST 12489-71, also when processing end surfaces and when performing certain operations that give the hole the desired profile (for example, expanding the recess in the upper part of the hole intended for bolt heads).

Countersinks are divided into several types according to the method of their fastening into the machine:

- mounted;

- shank (with a metric taper or with a Morse taper - types of shank for mounting in a machine).

Diamond countersink

By design, countersinks are of the following types:

- prefabricated;

- solid;

- welded;

- with carbide plates.

A solid countersink is similar to a drill, so its second name is a countersink drill. It has more spiral flutes and cutting edges (3 to 6 teeth) than a simple drill. The cutting part of the tool, as stipulated by GOST 12489-71, is made of high-speed steel P18, P9 or made with carbide inserts (BK4, BK6, BK8 for processing cast iron, T15K6 for processing steel). Tools equipped with carbide inserts have greater productivity (higher cutting speed) than those made of high-speed steel.

Spiral tail countersinks

This is interesting: Sharpening an ax with your own hands - angles, devices

Cone countersink design

This device is intended for passing cone-shaped openings of small depth. The main feature in the design of the element is the presence of straight teeth and an absolutely flat outer base. The number of cutting elements, in accordance with calibration, can vary from 6 to 12 units.

Countersinking holes is considered a manual procedure, carried out through a turning unit on which the countersink is mounted. The workpiece is clamped in the machine's grip, and its correct location in the recess is checked. The axial centers of the electric spindle and the rear assembly of the machine must be at the same level. This reduces the risk of the technically movable sleeve (quill) flying out. The tip of the tool is inserted into the hole to be finished manually.

To obtain an opening of the required diameter after the countersinking operation, an allowance of 2-3 mm is made during drilling. The exact allowance values depend on the calibration of the recess in the workpiece being processed. It is more difficult to implement the countersinking process for forged and dense products. To simplify your task, you should bore the countersunk hole by 5-9 mm in advance.

Countersinking can be done in cutting order. In this situation, the tool feed is doubled than when drilling, but the travel speed remains the same. The cutting recess with a countersink is laid at approximately 50 percent of the allowance for the diameter. Countersinking of holes with a tool is carried out using cooling materials. The mechanism made of hard alloys does not require the introduction of auxiliary coolant.

When processing openings, a countersink guarantees high accuracy, but defects cannot be avoided at all. The most common processing defects are:

Increased opening diameter. The main reason for the occurrence of such a defect is considered to be the use of a device with incorrect sharpening. Reduced diameter of the recess. It happens that the wrong tools were chosen for the job or a damaged countersink was used. Defiant purity. This defect can be caused by a number of reasons.

Usually, a decrease in cleanliness lies in poor sharpening of the device. In practice, the cause of the defect can also be excessive viscosity of the product material.

Therefore, the element sticks to the tool belts. Damage is also caused by the error of the turner, who made an incorrect feed and acceleration of the cut. Partial processing of the opening. This reason usually occurs as a result of incorrect fixation of the part or an incorrect countersink allowance saved after drilling.

Areas of application for countersinks

Countersinking and countersinking, despite the fact that they are used for processing pre-prepared holes, have a number of fundamental differences. The main purpose of countersinking is to form conical or cylindrical recesses in the upper part of a pre-prepared hole, which are necessary to hide the heads of the fasteners used.

Conical countersink with Morse shank type 8, cutting part material - HSS steel (analogous to P6M5)

Based on the degree of cleanliness of the recess formed during the countersinking process, such a technological operation is classified as semi-finishing. As a rule, it is performed before drilling holes in workpieces made of various materials. The equipment used for countersinking can be drilling, turning, milling and boring machines. A distinctive feature of this technological operation is that it is performed at low speeds, performed by a countersink or the workpiece being processed.

According to their design, countersinks are distinguished:

- conical (GOST 14953-80);

- cylindrical type.

Types of Conical Countersinks

A separate category of countersinks consists of cutters, which are made of carbide materials and are used primarily for grinding and roughing work. Another type of countersinks that are used for machining and chamfering holes located in hard-to-reach places are reverse-type tools. Specialists who often work with countersinks of this type prefer to have at their disposal entire sets of them, which allow them to process holes with various geometric parameters.

Roller cutter is a type of countersink used for cutting valves of an internal combustion engine

Conical countersinks produced in accordance with GOST 14953-80 have a standard design, the constituent elements of which are a shank and a working part with a front end sharpened to a cone. The cone angle, which is formed by the side surfaces of the front part of such a countersink, can be 60, 75, 90 or 120°. GOST 14953-80 also regulates the number of teeth on the working part, which depends on its diameter.

Thus, countersinks of various diameters (12–60 mm) may contain from six to twelve cutting teeth. Depending on the length of the tool used for processing, which is also regulated by the provisions of the regulatory document, a trunnion can be used to support it on the machine, ensuring the alignment of the surface being formed.

Types of Standard Conical Countersinks

Cylindrical countersinks, in contrast to conical tools (manufactured according to the requirements specified by GOST 14953-80), are specifically used for cutting chamfers for metal products. The working part of such a countersink, which usually has a wear-resistant coating, resembles a drill, but differs from it in a large number of cutting teeth. Depending on the diameter of the working part, it can have from 4 to 10 cutting teeth. To reliably fix the position of such a tool during its operation, there is a special guide pin at its end - solid or removable. The most convenient and practical to use are countersinks with removable trunnions. In addition, for greater efficiency of the processing performed, an additional cutting attachment can be installed on the countersink.

In order to process several holes to the same depth using one countersink, the tool is equipped with a special holder with a limiter, which can be stationary or rotating. In this case, the cutting tool is mounted in a holder, and its working part protrudes from its stop by an amount equal to the depth of the hole being machined.

These chamfers on the holes were made with a conical countersink

Various metals and alloys can be used as materials for the manufacture of countersinks, in particular:

- carbon tool steels;

- alloyed high-speed steel alloys;

- carbide materials.

For processing holes made in soft metals, as well as in materials such as wood or plastic, countersinks made of steel alloys are used. If it is necessary to process holes made in products made of harder metals, then carbide countersinks are used for this. The latter are able to withstand significant loads arising when processing metals with high hardness.

GOST 14953-S. 13

mm

| Table 4 |

| Dimensions in mm Table 5 |

| * Size on small diameter. |

| Dimensions in mm Table 6 | ||||

| GOST 14953-80 S. 15 | D | d | L | / |

| 2353-0083 | 5,0 | 2,00 | 45 | 3,0 |

| 2353-0084 | 6,3 | 2,50 | 50 | 3,7 |

| 2353-0085 | 8,0 | 3,15 | 4,7 | |

| 2353-0086 | 10,0 | 4,00 | 56 | 6,0 |

| 2353-0087 | 12,5 | 5,00 | 63 | 7,4 |

| 2353-0088 | 16,0 | 6,30 | 71 | 9,5 |

An example of a symbol for a countersink type 2, diameter D = 5 mm:

Countersink 2353-0083 GOST 14953-80 Type 3

Countersink designation | Applicability | d | D | D\ | L | / |

| 2357-0001 | 0,80 | 5,0 | 1,55 | 35,5 | 0,82 | |

| 2357-0002 | 1,00 | 6,3 | 2,00 | 1,13 | ||

| 2357-0003 | 1,25 | 7,1 | 2,40 | 40,0 | 1,21 | |

| 2357-0004 | 1,60 | 8,0 | 3,10 | 45,0 | 1,52 | |

| 2357-0005 | 2,00 | 10,0 | 4,00 | 2,20 | ||

| 2357-0006 | 2,50 | 12,5 | 5,00 | 50,0 | 2,60 | |

| 2357-0007 | 3,15 | 14,0 | 6,40 | 3,30 | ||

| 2357-0008 | 4,00 | 16,0 | 7,90 | 56,0 | 4,20 | |

| 2357-0009 | 5,00 | 20,0 | 10,00 | 63,0 | 5,20 | |

| 2357-0010 | 6,30 | 25,0 | 12,50 | 71,0 | 6,50 |

An example of a symbol for a countersink type 3, diameter D = 5 mm:

Countersink 2357-0001 GOST 14953-80

| mm Table 4 |

| An example of a symbol for a countersink type 4, diameter D = 6.3 mm: Countersink 2353-0089 GOST 14953-80 Table 5 mm |

| Continuation of the table. 5 |

| An example of a symbol for a countersink type 6, diameter D - 10 mm: Countersink 2353-0108 GOST 14953-80 |

The principle of metal countersinking

To understand how the countersinking process occurs, you need to have an idea of the design of the tool that performs this operation. This device is called a countersink. The simplest tail countersink is shaped like a regular drill, but it has significant differences. The difference between a drill and a countersink is that the latter has a larger number of side cutting edges that run in a spiral. Thanks to them, a thin layer of metal in the channel is removed when the countersink passes through it. In the process of passing along the working area, the countersink is imparted a translational-rotational movement. The process of improving the accuracy class of a hole by countersinking is as follows:

- In accordance with the diameter that needs to be obtained after the operation, the diameter of the countersink is selected. It must be larger than the initial one (the diameter of the tool depends on several factors) and correspond to the final diameter during finishing or intermediate during further development.

- This selected countersink is secured in the chuck of a machine (drilling, lathe) using a shank.

- The workpiece is fixed with a channel strictly opposite the countersink so that their axes perfectly coincide.

- Turn on the machine and set certain rotation speeds of the tool. They are strictly regulated and depend on the type of cutting element, metal and hole diameter.

- This tool is brought into the work area at a speed that is also not chosen by chance. Sometimes a coolant is also supplied to the processing area when the process requires it.

Countersinking Equipment

In principle, not only for this operation, but also for both, which appear in the review, an ordinary hand-held device is also suitable.

That is, a drill, and some even use a screwdriver. Of course, doing this is strictly not recommended. Even if there is, in principle, enough power for successful completion, there will clearly be a serious loss in accuracy. Whatever expert undertakes such an undertaking, he will not be able to 100% accurately align the center and axis simply by holding the device with his hands. This means that deviations are inevitable. The logical option would be a lathe. It is used in almost all cases. Sometimes it is replaced by a special processing center, multifunctional equipment. The essence does not change from this.

The tool itself that is needed is a countersink. It consists of two components. The first is the cutter. The type of processing depends on its shape and location. So, there are cylindrical and conical options, which we talked about above, reverse and others. What is reverse countersinking of holes is easy to understand. This is the usual cleaning of the groove with a special nozzle. The second part is the tail. It is needed for fixation in the machine chuck.

Tools are produced from hard alloys of carbon and alloy steel. After all, the edge will have to work with a different resource. And among the materials in which it is necessary to make a recess there are often very hard ones, like cast iron. Accordingly, if the cutters are not higher in level of hardness, then at serious speeds they may simply break off or wear off prematurely. Which will lead to economic costs for the enterprise.

Purpose of countersinking and scope of application

Countersinking holes is a necessary operation in mechanical engineering and machine tool building. Here, the accuracy of the parts must correspond to microns, and this primarily concerns the drilled channels. Holes in metal that do not have a clear cylindrical shape or a strict diameter along the length in critical structures can cause additional play and, as a result, lead to rapid wear of bearing units and destruction of the structure as a whole. Countersinking significantly increases their accuracy, bringing them to the fourth and fifth class.

The process of countersinking in metal workpieces allows you to achieve the following results:

- After processing, the pre-drilled channel acquires a strict cylinder shape along its entire length - this moment facilitates the clear passage of threaded connections, shafts, spindles, rods through it without unnecessary stress and backlash.

- The channel receives strict geometric parameters regarding the diameters at each specific point of the channel. As a result, there is less play and wear of the hole itself, if it is part of the assembly where mechanical transmission occurs, as well as less wear of the transmission mechanism.

- The channel cleanliness is significantly improved. Reduced roughness contributes to less chip formation, which can arise from vibration and friction, greater strength, reliability, wear resistance of the channel and the entire structure as a whole.

If the previously obtained hole has an accuracy class of no higher than third, then it is necessary to carry out countersinking and reaming.

Countersink designation in the drawing

In production, countersinking of holes is carried out according to the drawing. The countersink in the drawing is displayed in uppercase and capital Latin letters and Arabic numerals. The meaning of the letters and numbers is as follows:

- d1 – indicates the main diameter of the channel;

- d2 – for countersinking diameter;

- L1 – displays the length of the cylindrical channel;

- L3 is the countersinking depth;

- L4 – indicates the depth of the chamfer;

- j is the size of the central countersinking angle;

- α (alpha) – chamfer angle size.

Countersink for metal: features and technology of countersinking – Turner Master

Among the metalworking tools used to create holes, countersinks and countersinks deserve special importance. With their help, openings are made with specified characteristics, for example, stability of important geometric parameters, roughness, narrowing of a cylindrical hole. Let's look at what a countersink and a countersink are.

The principle of countersinking metal products

When processing an opening created in a part during its casting, it is recommended to bore it several millimeters deep at once so that the countersink selects the correct initial direction.

During the period of work when processing steel workpieces, it is recommended to use emulsion cooling compounds. The procedure for countersinking non-ferrous metals and cast iron does not require additional coolant. A very important stage is the correct selection of tools for carrying out the work.

In this regard, attention is focused on the following aspects:

- The type of tools is selected in accordance with the harvesting materials and the nature of cultivation. The factors of hole location and the number of processes are taken into account.

- Countersinks and a device for countersinking are selected depending on the specified parameters: the size of the recess, diameter, accuracy of work.

- The design of a metal-cutting tool is determined based on the method of its fastening on the machine.

The choice of countersink is made according to reference literature or using the normative act of the GOST 12489-71 standard:

- Blanks made from structural steel with openings up to 40 mm in diameter are processed with a countersink made from high-speed iron, including 3-4 teeth and a diameter of 10-40 mm. In holes up to 80 mm, nozzles with a diameter of 32-80 mm are used.

- For hardened iron, when boring, equipment is provided with plates made of hard alloys, with a diameter of 14-50 mm and 3-4 teeth.

- For boring blind openings of cast iron products and non-ferrous metal parts, a feather countersink is used.

A necessary condition for the countersinking procedure is the observance of allowances. As a result, the diameter of the selected tooling must coincide with the final diameter of the opening after processing.

If, after countersinking, the opening is to be expanded, then the diameter of the device is reduced by 0.15-0.3 mm.

If rough boring or drilling for countersinking is planned, then the edge allowance should be maintained from 0.5 to 2 mm.

Countersinks for metal: description, types and tips for use

Quite often, home craftsmen are faced with the need to make a metal part with high-quality holes. However, it is not always possible to achieve good quality or high accuracy. In such cases, you should use a special tool - a metal countersink.

The difference between countersinking and related operations

We have already found out that this stage occurs after drilling and before deployment.

But the initial stage is not always drilling. Sometimes the first stage is considered to be casting or stamping. In this version there may be even more defects. Various sagging, layering of metals, beveled walls, serious rough protrusions and the like. Accordingly, it will definitely not be possible to finish the surface for a final look in one stage. It is worth understanding that deployment is already a finishing process; it cannot cope with serious defects. Doesn't fit the shape. Countersinking will almost always raise the accuracy class to level 5. If the work is done using high-precision equipment, and it is also performed by professionals, then class is achievable. But unlike drilling, the process is longer. You will have to perform almost twice as many tool movements.

The most important difference from drilling and reaming can also be the level of permissible roughness after processing and quality, that is, the degree of compliance of the resulting part with the original parameters in the drawing or diagram. The first stage - drilling usually leaves a “whisker” of 20 microns, and the degree of accuracy can reach up to 12. After grinding with a countersink, the surface will be cleaned to 2-3 microns, and the quality will increase to 9. Finishing brings the hardware to full readiness. The roughness drops to a threshold value of less than 1 micron, and the degree of accuracy is around 6.

That is, the differences are clearly visible. This includes the degree of quality, duration, and sequence. But if you compare a countersink and a countersink, the difference will be even more obvious. After all, these are, in principle, actions from different spheres.

Countersink. Finishing holes

In many cases, a pre-drilled hole (especially using a hand drill) is not of high quality: in addition to end burrs, there may also be axis non-perpendicularity. Therefore, after drilling, the next transition is often used - countersinking; for this operation we need a countersink.