Countersinking and countersinking

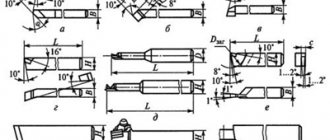

When performing countersinking, a special tool is used - a countersink. In this case, only the upper part of the hole is processed. This technological operation is used in cases where in this part of the hole it is necessary to form a recess for the heads of fasteners or simply chamfer it.

What is the difference between countersinking and countersinking?

When performing countersinking, certain rules are also followed.

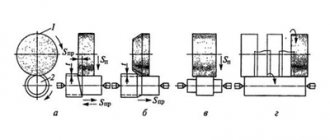

- This operation is performed only after the hole in the part is completely drilled.

- Drilling and countersinking are performed in one installation of the part on the machine.

- For countersinking, set low spindle speeds (no more than 100 rpm) and use manual tool feed.

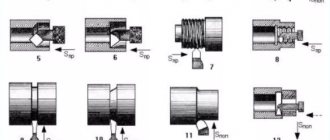

- In cases where countersinking is carried out with a cylindrical tool whose trunnion diameter is greater than the diameter of the hole being machined, the work is performed in the following sequence: first, a hole is drilled, the diameter of which is equal to the diameter of the trunnion, countersinking is performed, then the main hole is drilled to a given size.

The purpose of this type of processing, such as counterbore, is to clean the surfaces of the part that will come into contact with nuts, bolt heads, washers and retaining rings. This operation is also performed on machines and using a counterbore, for installation of which mandrels are used on the equipment.

Countersinking

A countersink is used to process holes that are pre-stamped, cast or drilled. Countersinking can be both preliminary (before deployment) and final processing. In addition to machining holes, countersinks are sometimes used to process the end surfaces of workpieces.

To increase the accuracy of countersinking (especially when processing cast or stamped deep holes), it is recommended to first bore (with a cutter) the hole to a diameter equal to the diameter of the countersink, to a depth approximately equal to half the length of the working part of the countersink.

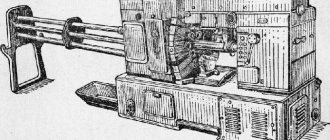

Countersinks, like drills, are installed on lathes most often in the tailstock or turret.