Drilling large holes is not a problem if you choose the right tool. For example, such work may be necessary to secure a channel or metal corner. The easiest way is to use an electric drill, but getting a hole with a diameter of, for example, 15 mm requires a lot of effort. To drill a large diameter hole in metal, special devices and core drilling technology are used.

How to make a hole in metal without a drill - Metalworker's Guide

Metal processing is carried out not only in industrial conditions. When performing repair work on a car, manufacturing structures on a personal plot, or carrying out home renovations, it is necessary to drill holes in the metal. At home, a hand drill is most often used. This versatile tool requires some skill in working with hard work. You can purchase or make your own machine for drilling holes in metal, but this is not a cheap pleasure.

Selection of drills for drilling metal

Drills are needed to make holes in metal. They are rods made from an alloy that must be harder than the workpiece material. Such devices are made from steel with the designation HSS - grades P18, P6M5, P9 (high-speed steel) or use hard alloys specially created for working with hard-alloy, hardened parts. Their brands are VK and T5K10.

Drills consist of three main parts:

- edges that are designed to penetrate holes and remove a thin layer of the material being processed;

- spiral cutting, designed for removing chips from the hole;

- shank used to secure the drill bit in the tool.

First, let's take a closer look at the cutting edges. They are bevels converging at the top, forming a jumper. The angle of convergence of the bevels, called the main one, varies and depends on the selected processing mode of the workpiece and its material.

The angle is standardized:

- for stainless and hard steel the angle should be from 135° to 140°;

- for structural steel – 135°;

- for aluminum, brass and bronze – from 115° to 120°;

- for copper – 100°;

- for cast iron - clearance angle is 120°, and the edge sharpening angle is 90°.

The drill has two edges, which are sharpened at an angle from 20° to 35°. They determine the sharpness of the instrument. The edge angle is called the back angle. The drill touches the workpiece surface in accordance with this parameter. At the same time, there will be free space behind it. This shape makes it easy to remove and throw away chips from the work site. The angle can be different, sometimes it is up to 90°. Increasing its value is necessary for processing fragile workpieces made of materials such as brass, cast iron, and bronze.

Spiral cutting is grooves that help remove chips. Each of them has its own edge. Their planes are always parallel to the axis of rotation of the drill. This edge is called “ribbon”. Its task is to clean the walls of the hole being made with the centering of the drill.

How to drill in hardened steel? — Machine tools, welding, metalworking

To improve the basic characteristics of the metal, it is often hardened. This technology involves increasing the hardness of the product due to strong heating of the metal and its rapid cooling.

In some cases, after heat treatment it is necessary to perform drilling. By increasing this characteristic, drilling hardened metal becomes more difficult.

Let's take a closer look at all the features of drilling hardened steel.

Read also: How to make a BJD doll with your own hands

How to drill through hardened steel

Drilling a hole in hardened steel

The widespread question of how to drill hardened steel can be associated with the fact that when using conventional technology, the tool quickly becomes dull and becomes unusable

That is why you need to pay attention to the features of drilling hardened alloy. Among the features of the technology, we note the following points:

Nuances when drilling

The technology in question has a fairly large number of features that need to be taken into account. Drilling of hardened metal is carried out taking into account the following points:

- Before carrying out work, pay attention to the hardness of the surface. This parameter is used to select the most suitable drill. Hardness can be determined using a variety of technologies.

- During drilling, a large amount of heat is generated. This is why rapid wear of the cutting edge occurs. In this regard, in many cases, cooling liquid is supplied to the cutting zone.

- When cutting difficult-to-cut material, it is necessary to sharpen the cutting edge from time to time. For this, a conventional sharpening machine or a special tool is used. Only diamond-coated wheels are suitable as an abrasive.

Steel Drilling Tool

There are a variety of methods for cutting hardened steel. Some of them significantly simplify the processing. Only by taking into account all the nuances can the quality of the resulting hole be improved.

How to drill with a drill?

Drilling metal with a drill requires following some recommendations:

- To make a hole you will need an electric drill, a core punch, a hammer, machine oil and safety glasses.

- Initially make markings.

- Wear safety glasses.

- When the pressure on the drill is low, you need to select the low speed position and start working.

- Don’t forget to water the area being treated with coolant.

If you follow the technology and use high-quality tools, you can make holes of different diameters and depths. To drill straight holes or accurately select the depth, you can use a device called a “depth stop.” It is attached to an electric drill and adjusted to the desired depth.

Technology and methodology for drilling stainless steel

The first and most important thing to remember: drill stainless steel only using cooling lubricant and special drills. As for the thickness of the material being processed, the technology provides the following:

- Stainless steel, the thickness of which is within 1–2 millimeters, can be drilled with ordinary metal drills. In this case, the sharpening angle of the tool should correspond to 120 degrees, and the revolutions of the electric drill should not exceed 100 per minute.

- It is better to drill a millimeter-thick or thinner layer of stainless steel using step-type equipment. It provides a smooth channel with no burrs or burrs on the edge.

- It is best to produce holes in stainless steel with a thickness of more than 6 mm using specialized cutters in two stages. First, you need to drill the metal with thin equipment with a diameter of 2–3 mm, and then bring it to the desired diameter with a finishing drill.

If stainless steel shavings begin to acquire dark shades and become small, this indicates that the cutting edges are dull and overheating. It is impossible to work in this mode.

How to drill metal products correctly

One of the most important parameters when drilling a hole is the sharpness of the drill. If you purchased one of the cheapest drills, it may turn out to be dull and made of soft metal, which will not allow you to make even a couple of holes.

How quickly the drill tip will shear and dull depends on the drilling speed, the hardness of the metal, the force applied to the drill, and cooling.

- When drilling large holes, you must first make holes of a smaller diameter. This way the process will be much faster, and the drills will not become dull so quickly.

- To accurately center the hole, you need to use a core punch and punch the center of the hole before drilling.

- To cool the working part of the drill, you need to use machine oil. Simply lower the working part of the drill into a container of oil. Repeat this operation periodically. You can use soapy water for cooling (by reducing friction).

- When drilling deep holes, periodically remove the drill and clear it of chips.

How to drill sheet metal

When working with sheet metal, there should not be any particular difficulties, even when drilling large-diameter holes. The only thing is that you need to place a wooden block under the drilling site, it will help remove the chips. When you feel like you've almost drilled through the metal sheet, reducing the pressure on the drill will also help reduce the likelihood of burrs.

How to make holes in pipes correctly

The main problem when drilling holes in round pipes is the difficulty of perpendicular drilling. This means that the hole from which drilling began does not correspond to the exit hole. To solve this problem, you need to use a drilling machine, or special guides, which you can make yourself or purchase ready-made.

How to drill aluminum

Anyone who has worked with aluminum parts knows that it is a soft metal. The main problem when drilling aluminum is excessive shavings wrapping around the drill bit. Because of this, the drill stops drilling and gets stuck in the metal. To avoid this, you need to remove the drill from the hole more often and remove the chips.

How to drill stainless steel (stainless steel)

Stainless steel is an alloy steel, which is not an easy task to drill. To make drilling comfortable, it is advisable to choose drills with a cobalt tip. You need to drill stainless steel at minimum speed, namely 100-200 rpm. Such speeds provide the required cutting speed for stainless steel and good quality. If your tool does not have a rotation speed control, you should press the button periodically for a second or two, which will prevent the drill from accelerating quickly.

If you need to make a hole of a large diameter, you need to use metal crowns, which make it possible to drill only along the outer diameter of the hole.

Drilling mode

To drill metal correctly, you need to select the desired rotation speed of the drill. The force applied to the drill also plays an important role. It is guided along its axis and ensures the depth of the cutting tool with each revolution. The correctly selected mode is easily determined by the chips. If the effort and speed are not exceeded, then it is long and beautiful.

There are simple rules for correctly selecting a drilling mode. The harder the metal that needs to be processed, the lower the number of revolutions the drill should have. This principle also works when selecting the diameter of the drill. The thicker the drill, the lower the cutting speed.

Dependence of drill rotation speed on its diameter:

- 5 mm – from 1200 to 1500 rpm;

- 10 mm – 700 rpm;

- 15 mm – no more than 400 rpm.

You also need to monitor the force applied to the drill. The deeper the immersion into the metal, the less pressure on the tool is necessary. Ideally, the pressure on the drill should gradually decrease during the drilling process.

What and how to drill deep and large holes in metal parts

Drilling large holes is not a problem if you choose the right tool. For example, such work may be necessary to secure a channel or metal corner. The easiest way is to use an electric drill, but getting a hole with a diameter of, for example, 15 mm requires a lot of effort. To drill a large diameter hole in metal, special devices and core drilling technology are used.

- Features of creation

- Drill accessories

- Feature of deep holes

- Features of large diameter holes

- Hassle-free drilling

- Cone drill

- Metal crown

- Hole press

Drill selection

Twist drills, which are represented by a vertical rod with two grooves, have become quite widespread. Due to the specific arrangement of the grooves, a cutting edge is formed. Among the features of the choice, we note the following points:

- The pobedite drill bit has become quite widespread. It can be used to work with various hardened alloys. However, a surface with too high hardness cannot be processed with such a tool.

- The choice is also made based on diameter. It is worth considering that it is quite difficult to obtain a large diameter hole. The larger diameter version is much more expensive due to the use of a large amount of material in its manufacture.

- Attention is also paid to the sharpening angle, the purpose of the product and the type of material used in manufacturing. For example, cobalt versions are characterized by higher resistance to high temperatures.

- It is recommended to pay attention to products exclusively from well-known manufacturers. This is due to the fact that Chinese versions are manufactured using low-quality materials. However, such an offer is much cheaper and can be used for short-term or one-time work.

- When choosing a drill, you can be guided by the markings. It can be used to determine which materials were used in production. The diameter of the hole that can be obtained when using the tool is also indicated.

Drill for hardened steel

In a specialized store you can find almost everything you need to carry out the work. However, the fairly high cost of the product and some other factors determine that some decide to make a drill themselves from scrap materials. Similar work can be done if you have the required tools.

Working with some types of metal

- When drilling into thick aluminum pieces, chips often clog the drill channels, making it more difficult to rotate. Therefore, when working with such material, remove the drill from the recess more often and remove the chips. Well, don’t forget to pour plenty of oil on it.

- If you need to drill black cast iron, then you do not need to add any lubricating and cooling substances, since it drills very well even dry

- Unlike black cast iron, white cast iron has increased strength, which means strong drills and lubricants are required to process it.

These are the basic rules for drilling metal with a drill. I hope I was able to bridge this gap in your knowledge. Good luck with your homework and see you soon!

Final Recommendations for Drilling in Metal

In conclusion, it is important to note the need to comply with safety regulations, as well as to prevent defects and accelerated wear of tools. Let's give some useful tips:

- Before starting drilling, always check that all parts of the tool and workpiece are secure.

- Clothing should be comfortable and not have parts that could get caught in the rotating parts of the machine. The use of safety glasses is mandatory.

- Contact with the workpiece should only occur when the drill is rotating. Otherwise, it will quickly become dull.

- The reverse movement of the drill when removing it from the hole should occur with the drill turned on at low speed.

Features of large diameter holes

This procedure is more complex than deep drilling. Cutting work is carried out either using a crown or using a cone drill. Crowns for metal are similar to products for concrete and drywall. The only difference is the material used to create the cutting edge.

Drilling can also be carried out with standard products in several stages. To do this, first use a nozzle of small diameter. Then a larger tool is selected.

The most convenient way is to use cone drills. Such devices allow you to drill a large hole in one go. To do this, the tool is simply recessed into the material.

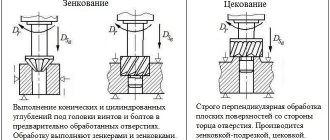

Drilling and reaming technology

Drilling according to markings

Rice. 1. Drilling holes according to the markings:

a – marking and punching the center of the hole; b – marking and punching of the control circle; c – moving the drill away from the center of the hole; d – correction of the drill direction; 1 – mark from the center punch; 2 – groove from a pre-drilled hole; 3 – machined hole

This type of processing of workpieces is carried out in several stages:

When pre-drilling, drill a small hole (0.25d). Next, the spindle with the drill is retracted to check the prepared hole with the original markings.

If the result of preliminary drilling is satisfactory (Fig. 1, b), final processing is carried out, for which work continues until the cutting tool leaves the part.

If a bevel occurs and the hole being drilled goes away (Fig. 1, c), an adjustment is made using a cross-section tool - grooves are cut in the direction where the hole needs to be moved (Fig. 1, d).

Thanks to the guides for the drill, the direction is set in the desired direction to correct the bevel.

Drilling a hole in hardened steel

The widespread question of how to drill through hardened steel can be associated with the fact that when using conventional technology, the tool quickly becomes dull and becomes unusable. That is why you need to pay attention to the features of drilling hardened alloy. Among the features of the technology, we note the following points:

- It is necessary to properly prepare the hardened workpiece.

- In some cases, a special tool is required.

- Coolant is being used.

If necessary, you can make a drill for hardened steel with your own hands, which requires certain equipment and skills. However, in most cases, a purchased version is used, since it will cope better with the task when cutting hardened steel.

Hardened steel drilling process

Useful drilling techniques

A variety of technologies can be used to work with hardened steel. The most common technologies are characterized by the following features:

- Surface treatment with acid. This technology is characterized by long-term use, since it takes quite a lot of time to reduce the surface hardness. Sulfuric, perchloric or other acid can be used for etching. The procedure involves creating a lip that will contain the substance used in the cutting zone. After prolonged exposure, the metal becomes softer, and it will be possible to drill using the conventional version.

- You can use a welding machine to achieve your goal. When exposed to high temperatures, the metal becomes softer, which greatly simplifies the procedure.

- Most often, a special drill is used. There are versions on sale that can be used for processing hardened steel. In their manufacture, metal with increased resistance to wear and high temperatures is used. However, the complexity of manufacturing and some other points determine that the cost of a special tool is quite high.

In addition, to achieve this goal, a punch is often purchased. It can be used to make a small hole, which will simplify further drilling.

Power and speed when working with metal

An important factor is the choice of tool, namely a hammer drill, drill or screwdriver, which will be used to make holes in the metal. If you use a drill with a power of up to 700W, you will not be able to make a large hole right away. A hand drill with a power of up to 700W is best used for drilling holes with a diameter of up to 10-13mm.

It is important to choose the correct speed of the drill or screwdriver. After all, at high speeds, your drill will simply burn out. This way you will ruin it.

You need to drill metal at low or medium speeds, not exceeding 500-1000 revolutions.

The larger the diameter of the drill you are working with, the lower the speed you need to choose.

How to drill through stainless steel. Tips for choosing a drill for stainless steel

Parts and objects made from stainless steel are widely used in industry and everyday life. Stainless steel is popular due to its anti-corrosion properties. Corrosion resistance significantly extends the service life of engineering parts, structural metal structures, plumbing elements and household items. In addition, most grades of stainless steel are distinguished by high hardness, strength and, at the same time, toughness of the material. These properties have a positive effect on the performance characteristics of elements made from them, but make them difficult to process.

Often when working with stainless steel parts, it becomes necessary to make holes in them. Drilling holes in stainless steel is somewhat more difficult than in ordinary unalloyed or lightly alloyed steels. In the article below we will discuss how to drill a hole in stainless steel.

Devices to facilitate the process

Cutting fluid is used in many types of metal cutting. Most often it is used for deep drilling to reduce friction forces and stabilize the temperature of the working tool. A high-quality liquid does not cause surface corrosion, is safe for humans, does not have an unpleasant odor and removes heat well.

The following is used as a lubricant for drilling metal at home:

- Technical Vaseline – for soft materials.

- Soap solution - for aluminum.

- Turpentine with alcohol - for silumin.

- A mixture of oils - for tool and alloy steels.

Some craftsmen prefer to use a universal composition, which includes laundry soap (200 g) and motor oil (20 g). The components are mixed and boiled until a homogeneous emulsion is obtained.

The use of industrially produced cutting fluids makes it possible to increase the speed of drilling various types of metal. For example, when processing stainless steel, productivity increases by 30%. For cast iron this parameter increases to 40%.

Which drill is better to use

- Any tool that contains cobalt in its alloy. The higher the percentage of this component, the better. Cobalt products differ from ordinary ones in a yellowish tint. Do not confuse the cobalt alloy with the application of this metal only to the outer part of the drill by electroplating. In the latter case, it will not be possible to drill through stainless steel.

- Expensive specialized tool. Such pobedit drills can drill through stainless steel, not just concrete. They have a certain sharpening angle.

- For thin stainless steel, you can use a feather-shaped drill bit for ceramic tiles. This is not the best option, but it will help to drill the workpiece once.

How and with what to drill deep holes

Drilling deep holes in metal is very difficult. As working equipment, experts recommend using machines in which the drill is a stationary element and the workpiece is rotated. During the work process, it is necessary to use coolant. Drilling lubricant will dissipate heat and allow for greater productivity.

It is necessary to ensure timely removal of drilling by-products. They can clog the channels and lead to drill breakage. A small workpiece can simply be turned over - the chips will fall out of the hole under the influence of gravity. For massive parts there are special devices with magnetic tips.

For home work, it is better to purchase drill guides. This is a convenient support mechanism that holds the tool in place, allowing you to drill holes with high precision.

If there is no guide, you must carefully monitor the perpendicularity of the drill location. The slightest deviation can break the tool or damage the workpiece.

How to make the right hole

To drill a hole in metal, you first need to securely secure the workpiece. If the part has good mass, it is often enough to simply place it on a flat surface. Its own weight will not allow it to “slither” from side to side.

Parts of small dimensions and light mass must be clamped in a vice. If you first mark the future center of the hole according to the applied markings, then this notch will allow you to confidently start when working. The drill installed in it will no longer move to the side.

Through hole

From the lips of some masters you can hear the word “passage”. Because the drill completely penetrates the workpiece in its movement. In fact, this is the easiest operation. But special attention needs to be paid to the final stage.

When leaving the workpiece, the drill can not only damage the surface of the workbench, but also break itself from the impact. To avoid this, you need to do the following. Either place the part above the through hole in the workbench, or place a wooden spacer under it.

Through hole in a metal workpiece Source onarzedziach.pl

Also, a sharp exit from the part creates a hart (burr) on its reverse side. To prevent this from happening, it is necessary to reduce the drill speed at the final stage to the very minimum. This technique will help if you need to make a through hole in the metal, when the part cannot be dismantled and clamped in a vice. That is, drilling occurs at its location.

Blind hole

To ensure that the drill does not go right through the part, but stops at the required depth, two methods are used. A special stop is attached to the drill, positioning it at a given distance from the cutting edge. The device usually has the form of a sleeve.

Or the drill has a movable pin in the chuck area. It is clamped with a screw so that its end creates an emphasis on the workpiece. Not allowing the drill to penetrate deeper than the measured distance.

Drill with stop Source icover.ru

If a machine is used to drill a blind hole in metal, it usually has a ruler. Knowing the required depth, the operator stops the mechanism at the right moment. There are machines in which such an operation is fully automated. And the most serious inconvenience in such work is that it is periodically necessary to remove chips from the hole.

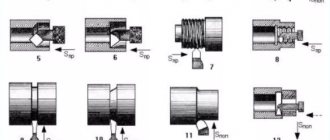

Drill accessories

There are several accessories for drills that can make the process easier and make a large hole smooth:

- Drilling jig. This device is a housing in which there are several guide bushings for drills of different diameters. The material used to create the bushings is harder than drill bits, so you don't have to worry about the tool moving to the side while drilling and widening the hole.

- Drill guide. This product allows you to fix the tool in such a way that it does not deviate to the side during drilling. If such a product is not available, the tool may move to the side, resulting in an uneven edge. It can also be mounted at an angle. But when drilling metal products, this is usually not required.

- Drill stand. A DIY product like this can be an inexpensive replacement for a drilling machine, as it allows you to carry out work more comfortably. When using a stand, a fixed tool moves along the bar using a lever. In this case, displacement is completely eliminated, since the workpiece being drilled is securely held due to the presence of a clamp.

Using these products, you can greatly facilitate the process of drilling metal products.

Hassle-free drilling

During work, you can use a small section nozzle, as well as a used grinding wheel for an angle grinder. It is important to remember that it should have a smaller diameter than the hole being created.

Before carrying out work, a circle for the hole is marked on the workpiece, and the second circle will be smaller than the first by a distance equal to the diameter of the drill used. After this, 2 holes are marked in opposite places of the circle. It is necessary to retreat 3 mm from them and mark the places for drilling. Thus, drilling occurs along the entire drawn circle. If additional work is necessary, some areas will have to be processed with a chisel. This will create jagged edges that will then need to be filed down. It is important to ensure that during work the circumference does not increase, i.e. do not expand the planned diameter.

Cone drill

The described types of drills are made from tool steel. The shanks of such products can be hexagonal or cylindrical. The cutting edge removes all burrs, so the edge is smooth. The end of the drill head has a sharpened point that allows pre-drilling of the material.

Using these products you can:

- create cuts with a diameter of up to 30 mm;

- forget about jagged edges;

- carry out boring of various diameters without changing the nozzle.

Thanks to step drills, you can create cuts of various diameters in sheet steel up to 4 mm thick. Unlike a simple cone drill, when using such products, the drilled diameter is fixed.

The disadvantages include:

- the need to use tools with low speeds and high torque;

- sensitivity even to small distortions.

Despite these disadvantages, this attachment allows you to conveniently work with metal plates, quickly drilling circles of the required diameter.

Metal crown

Metal processing is a complex process, so such work is usually carried out using specialized equipment. To carry out work at home, you can use core drills.

Such products allow you to make the edges round and centered. In this case, a standard drill is used for drilling. The products consist of several parts:

- crown;

- centering attachment;

- product shank;

- screws that are necessary for fastening.

When using a core drill, the speed of work increases up to 10 times. Another advantage is the ability to accurately drill in the range from 1.2 to 15 cm.

In this case, there is no need to perform alignment during drilling. It is also worth noting that such drills have higher wear resistance compared to twist drills.

Before starting work, a centering drill is installed in the center of the circle, after which drilling is carried out. After this, the drill is retracted and the work is carried out with a crown.

Metal crown

Large holes in metal, plastic, wood, etc. with a diameter of 19 to 102 mm. Conveniently done using a bimetallic crown from Hilti.

The bits performed very well when drilling a large number of holes for fittings in metal cable boxes (metal thickness 2 mm).

A clear advantage is that the crown is collapsible. If the centering drill becomes dull or breaks, the cost of replacement is about 250 rubles.

But for each diameter you will have to use a separate crown, the price of which (depending on the diameter) is from 400 to 1200 rubles. Add 1000 rubles here. to the adapter.

Marking metal before drilling

Before you start drilling metal using different methods, be sure to mark the hole. Using a punch, mark the place on the surface of the product where the slot will be made. In addition to the center punch, a marker can be used. However, this is less convenient, since you will have to constantly monitor the location of the drill at the selected point. The punch makes a small depression at the drilling site. To do this, it is hit with a hammer. The resulting outline will be convenient for further work.

VT-metall offers services:

Precision can be increased by pre-drilling. Notches are made on the surface of the workpiece with a chisel, designed to guide the tool towards the hole.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

If it is necessary to produce several holes in workpieces, a template is used. Thus, several sheets of metal are drilled at once, which are connected with a clamp.

A jig is used to make precise holes that must be angled. This is a small strip with templates for holes located on it. Such devices are used in various industries.

Currently, several types of conductors are used, for example:

- universal;

- fastened;

- turning;

- sliding;

- overhead.

Pereosnastka.ru

Features of drilling small holes

TO

category:

Miniature technology

Features of drilling small holes

Currently, the minimum size of holes produced by drilling is 0.05 mm. The production of smaller holes by drilling is limited by the possibility of producing sufficiently high-quality and durable drills and the lack of precision, highly sensitive drilling equipment.

In addition, as studies have shown, holes with a diameter of 0.03 mm obtained by drilling, as a rule, do not have a clearly defined contour. The resulting chips and burrs become comparable to the hole. Removing chips is difficult.

Therefore, to obtain holes smaller than 0.05 mm, laser, electron beam and other methods are more effective.

Undoubtedly, drilling holes with dimensions close to the minimum limit value has its own characteristics compared to drilling holes with a diameter of about 1 mm and requires not only special tools and equipment, but also much greater caution.

The industry produces standard twist drills, the minimum diameter of which is 0.1 mm. To obtain smaller hole sizes, special drills are made.

The small size of drills for drilling holes with a diameter of 0.05-1 mm, their limited rigidity and strength determine the specific features of the drilling process.

The main feature is the sharper influence of a number of factors, such as the runout of the drill and machine spindle, the condition and quality of the surface of the product, the amount of drill overhang, the nature and uniformity of feed.

Worsening of any of these factors can result in drill bit failure or inaccurate holes.

Therefore, it is very important to study the influence of each of these factors on the drilling process, surface quality, processing accuracy and durability of drills.

Before starting drilling, it is necessary to ensure the correct installation of the drills in the collet or chuck, limit the spindle runout and the non-perpendicularity of its axis to the working surface of the table within 0.005 mm.

The runout of the cutting edges of the drill should be minimal and not exceed 0.015 mm. It is generally accepted that the installation of drills in the chuck is considered correct if, when the spindle rotates at a speed of less than 1.5 thousand.

rpm, when visually examined through a magnifying glass with 4-10x magnification, the drill appears in the form of a solid rod without chip flutes.

For a more accurate quantitative assessment of the runout of small-sized drills when installing them in a chuck and measuring wear, a special device is used.

It consists of a plate, a stereoscopic microscope head (MBS-2) mounted on it, and a bracket for attaching and moving an optical prism designed to rotate the image of the drill under study by 90°. Changing the image magnification from 4.8 to 56x is done by turning the nut.

The division value of the measuring eyepieces at maximum magnification is 0.015 mm. The eyepieces can be rotated in the tubes to set the scale to a position convenient for measurement. The light source is located in the sleeve, which, together with the bracket, is installed on the optical head housing.

Precise focusing of the image is achieved by moving the prism. If processing conditions require measuring the vertex angle, the prism can be additionally rotated to the appropriate angle and secured with a screw. If necessary, drill wear can be recorded on photographic film.

Rice. 1. Graph of the dependence of the “breaking” feed on the drill overhang value

At large values of drill overhang L and drilling depths h, the bending strength of drills decreases sharply. In Fig. Figure 32 shows the dependence of the “breaking” feed 5L0M on the overhang value at various drilling depths (for drills d = 0.5 mm and V = 3.1 m/min).

The overhang of small-sized drills has a significant impact on the processing performance and durability of small-sized drills. At large ratios Lid, under the influence of the cutting force, the longitudinal stability of the drills is lost, as a result of which their rectilinear shape is lost, which is preserved when drilling with an overhang of up to 10d.

Therefore, in all cases it is advisable to carry out processing with minimal (in relation to free chip exit) overhang.

If, according to technological conditions, the reach length is regulated, then the efficiency of using small-sized drills can be significantly increased by using a tool with a reduced length of the working part, which is quite acceptable, since the depth of holes with a diameter of up to 1 mm does not exceed (with rare exceptions) Ad.

It should be borne in mind that when drilling, holes are broken due to inevitable beats of the drill. Therefore, when drilling precise holes, the diameter of the drill should be selected taking into account the layout of the hole and taking into account the allowance for subsequent calibration. The latter is produced using calibrating punches or balls, first in advance, and then “to size”.

Drilling using conventional three-jaw chucks for fastening drills does not always provide the required accuracy and requires additional time for alignment. The use of cartridges at high rotation speeds (over 10 thousand/min) causes significant vibrations.

In this regard, for fastening small diameters, clamping collets are used, which have less mass and imbalance.

Equipment types

Drilling begins with preparing tools for work. You can make holes using a screwdriver, drill or a special drilling machine.

To make a hole, you need to select the appropriate equipment. For metal workpieces, you need to choose specialized equipment that is suitable specifically for this material. This is due to the fact that equipment for wood, concrete or ceramic tiles have different sharpening and shape. Tooling for metal products is marked with the letters HSS.

The working part of the tool is coated with titanium nitride coating, which increases their strength and wear resistance. For hard steels, a different tooling is used, which is designated P18. The strength of the tool increases when cobalt is added to its composition. An example of marking is P6M5K5.

To drill alloy steel, drills with a tip made of carbide are used. With their help, you can drill any metal workpieces, however, due to the high price, this is not cost-effective.

When the hole is made, you can select a drill for the thread. Its diameter will depend on the previously used equipment. To make holes of different diameters in thin metal sheets, you can use cone drills.

Is it possible to drill with a drill in concrete?

Situations often arise when it is difficult to find a tool for drilling metal products at a construction site, but there is equipment for working with concrete. You cannot make holes of large diameter or in thick metal sheets with concrete drills. Otherwise, you may break the equipment or damage the surface being processed.

How to drill with a step drill?

On sale you can find stepped structures for creating holes in metal of various diameters. Several drills of different diameters are fixed on one axis. They are designed to create holes of various sizes in thin sheet metal. When working, do not rush or put too much pressure on the drill handle.

Is it possible to drill with a Pobedit drill?

Any master of finishing work will tell you that drilling metal with Pobedit equipment is unacceptable. Pobedite drills are designed for hard and, at the same time, brittle materials. These include natural stone, brick, concrete. When it hits metal, the drill will hit the surface and damage it, but there will be no hole.

Pobedit drills

How to drill large diameter holes?

Drilling large holes in metal requires the use of appropriate equipment. You can do the work in several ways:

- Crown for metal surfaces. It is a circle of the required diameter with sharpened edges. There is a drill in the center that pierces the metal. Next, at low engine speeds, the bit makes a hole of the selected diameter. During work, it is necessary to use forced cooling of the sharp edges of the crown and the surface being treated.

- Multi-stage operation. This implies the use of several metal drills of different diameters. Work begins with equipment of the smallest diameter and increases as drilling progresses.

- Cone-shaped equipment (stepped). Designed for working with thin sheet metal.

Builders recommend using crowns. However, when working with them, it is necessary not to increase the speed and ensure that all the teeth running around the circumference are intact.

How to avoid dulling a tool?

The tool becomes dull because it overheats during use. To maintain sharpness, drilling should be done at low speed. There is no need to press the power button all the way down. When drilling thick workpieces, you need to use coolants or pastes.

If there is no cooling lubricant, machine oil can be used instead. Coolant keeps the tool from overheating and reduces friction.

Ultrasonic hole drilling

The ultrasonic method is effective for processing holes in fragile materials (glass, ceramics, etc.) and has a relatively low productivity. The principle of the process is to “prick out” particles of the material being processed with abrasive grains, which experience the impact of a tool vibrating at an ultrasonic frequency. A feature of the technological scheme of ultrasonic processing in piercing operations is the need for forced supply of an abrasive suspension to the processing zone. To avoid chipping when the tool exits the workpiece, it is advisable to glue it to glass spacers. Ultrasonic processing can produce holes with a diameter of 0.2 mm, as well as holes of complex shapes.