Carefully! Electric current | 08/09/2015

Almost any man uses a power tool as needed - to cut something, grind something, drill something.

One of the most popular electrical mechanisms for performing various jobs is an angle grinder (angle grinder) .

Scope of application. Professional and household grinders

The grinder is a tool of universal use - this machine is capable of performing a large range of operations.

True, for their different types it is necessary to change the working “organs” themselves - the nozzles. Then the grinder cuts, grinds, cleans stone, metal, wood and other materials. In everyday life, this tool is not used every day, but if necessary, you cannot do without it - the age of manual labor is a thing of the past. An angle grinder saves you time and effort.

Depending on the mode of use and the power of the engine and other components, grinders are distinguished:

- household use;

- industrial use.

Household "grinders" are mainly low-power devices of "elegant" convenient sizes. They will not survive in the industrial sector, since they are demanding of their operating mode - we work for about 15 minutes and rest for the same amount. Otherwise - overheating and...

Industrial angle grinders are tools capable of working productively for a long time without interruption or overheating. In the case of grinders, these qualities of a professional tool are put on the scale with two other parameters: weight and cost. They also increase their values in the "professional" category.

When choosing a tool, you should focus on the ease of working with it and its effective work capabilities. The price factor is also not an unimportant detail. Professional equipment, of course, breaks down less often, but its repair is more expensive.

Why is an angle grinder called an angle grinder?

An angle grinder is also popularly called an angle grinder. To understand where this name came from, you need to dig a little into history.

In the Soviet Union, the word “Bulgarian” appeared in everyday life in the late sixties of the last century. At that time, far from us, the Bulgarians bought a license from the Bosch company to produce angle grinders. Since the goods of capitalist countries were unavailable in the USSR, this instrument of Bulgarian production appeared in the fatherland. At that time, Bulgaria was a country of the socialist community, and our trade relations with this state were well established. Therefore, in the USSR, first of all, angle grinding machines of this country appeared, hence the name. The instrument from Bulgaria began to be called the “grinder”.

Signs of classification

Any electromechanical tool is characterized by many parameters, among which the power of the device is never in last place. Let's start with her!

Power

The power of an angle grinder determines its interrelated parameters: capabilities (performance), size, weight. Existing models of angle grinders fit into the power range from 0.5 kW to 2.7 kW.

Common “household” representatives of this tool are capable of developing from 800 to 1000 W of effective power, sufficient to perform most operations in a household environment. For long-term “industrial” or heavy home work (cutting concrete, brick, etc.), you should choose an angle grinder with a power of 1.5 kW or more.

But this parameter is interconnected power, but not the main characteristic of an angle grinder. The determining technological parameter is the maximum diameter of the installed disk.

Disc diameter

For angle grinders, discs with a diameter of 115, 125, 150, 180 or 230 mm are used. It is practically capable of cutting only the part of the disk that protrudes beyond the body of the angle grinder.

Therefore, when choosing a 115 mm disc, you will be able to cut through a material thickness of no more than 25-30 mm. During the use of the disk, this parameter decreases, since the disk wears out (erased), and given the number of revolutions and performance of such units, this happens quite quickly - a couple of minutes and the disk “disappears”.

When choosing a tool, you must initially analyze its future tasks and choose the correct disk diameter:

- 115 mm – convenient for grinding, suitable for cutting only “small” parts. The tool for such disks has low power and, accordingly, a “convenient” weight for work;

- 125 mm is a popular size. A grinder for such a disc is ideal for home use. And all types of grinding and cutting discs are maximally adapted to this diameter;

- 150 mm is a kind of middle ground between the 125th and 180th disk. You can take it for your home, but for greater convenience, if you have financial capabilities, it is better to choose two separate tools;

- 180 mm – inconvenient for small work, optimal for construction and industrial use. Capable of cutting both pipes and bricks;

- 230 mm is the maximum size of the “grinder” circle. Such an angle grinder will be ideal for large-scale construction work and is ineffective in terms of ergonomics when performing small-scale work.

In principle, you should begin choosing an angle grinder by determining the required disk diameter, and then “add” its power to the analysis. If a 600 W grinder is suitable for one-time work with a circle of 125 mm, then for long-term work with the same circle it is advisable to choose a tool of 1-1.5 kW. A more powerful angle grinder will “tire” less under load and, accordingly, its operating cycles will be longer and its “life” period will be longer.

The following types of disks are used when working with angle grinders:

- metal cutting;

- stone cutting;

- on stone for dry work;

- on stone for wet cutting;

- combined diamond wheel for cutting tiles;

- petal type discs;

- holder for discs with Velcro;

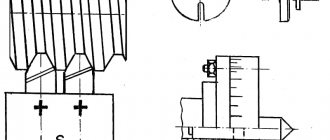

- metal wire brushes for cleaning disk or cup form factor.

Number of rotations of the grinder spindle

When choosing an angle grinder, you are unlikely to pay attention to the number of revolutions of its spindle. This, of course, is an important parameter in the operation of the tool, but it is already optimized by the manufacturer for a specific model of angle grinder.

Interesting from a practical point of view is the possibility of smoothly adjusting the speed. Powerful grinders can have this function, but more on that below.

For general information: the rotation speed of the grinder disk ranges from 2800 rpm to 6600 rpm. Some models of grinders for discs up to 125 mm have a rotation speed of up to 11,000 rpm.

Ergonomics and ensuring safe operation

Since the grinder is still a hand tool, its ease of use is determined by the “organs” of interaction with a person.

Ease of handling and reliable protection

For convenient operation and reliable holding of the tool in your hands, the grinder should be equipped with practical handles. Thoughtful options also play an anti-vibration role.

The provided options for right-handed and left-handed installation of handles will allow left-handers and traditional right-handers to operate the tool equally comfortably.

When choosing an angle grinder, you must also take into account its weight. An angle grinder with a power of 0.6-0.8 kW weighs about 1.4-2 kg and usually has one handle. This type of tool is best suited for grinding. A “kilowatt” of grinder power will create a load on your hands of 1.9-2.3 kg. And “giants” of 2-3 kW will not have less than 3.5 kg.

The presence of a protective cover on the grinder is mandatory! Without it, you will be playing Russian roulette with your life. The fact is that the discs for the grinder are quite thin, but they rotate at enormous speed. A poor-quality disc or its defect can lead to rupture and scattering of fragments, which will inevitably lead to injury. Therefore, the presence of the casing is not discussed.

When working on stone, brick or plaster, it makes sense to purchase a casing that allows you to connect a vacuum cleaner hose. Such casings are suitable for 230 mm discs and may also have a guide ruler for uniform cutting of scratches.

Changing discs on an angle grinder

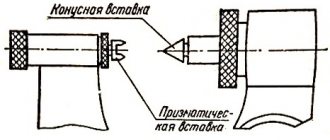

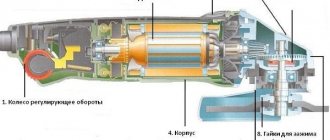

The ease of maintenance of the tool determines the additional time spent on “recharging” - changing the disk. The grinder has a spindle locking device for this purpose. By pressing the stop button, the driven gear is blocked, and the nut is unscrewed using a wrench.

There are lug nut options that allow you to operate them without a wrench. Such a composite nut is clamped by hand, and when the lower part of the nut rests on the surface of the disk, it is further tightened by rotating its upper part by hand. Such systems are especially relevant when frequently changing disks on an instrument.

The nut of a standard angle grinder is self-tightening, which makes unscrewing it more difficult than tightening it.

Types of angle grinders and their purpose

An angle grinder is a tool necessary for carrying out construction or repair work. This tool is convenient to use when material needs to be cut, cleaned, or sanded. Of course, all this work can be done using hand tools, but then you will have to spend a lot of time.

The “grinder” is considered a fairly universal tool; it can be used to perform various types of work:

- Clean weld seams;

- Cut metal (for example, a drainpipe);

- Grind various surfaces;

- Cut concrete or stone (using a special abrasive wheel);

- Work with ceramic tiles.

The scope of application of angle grinders is wide; it would be difficult to list all the work performed with its help. Angler grinders are divided into two types according to their intended purpose: professional and household. Unlike household grinders, professional machines can work in a more difficult mode, withstanding long-term loads. True, such a tool is more expensive - higher quality materials are used for its manufacture. The electric motor of a professional angle grinder is capable of operating almost continuously for several hours without overheating.

Angle grinders also differ in size. Large grinders allow you to use cutting wheels of larger diameter; a small angle grinder can only accommodate a small disc. Each angle grinder size has its own advantages when carrying out certain work, and a large angle grinder will not always be convenient to use. The large tool is convenient to use when you need to:

- Make a deep cut (for example, cut a large diameter pipe);

- Cut through a thick layer of material;

- Treat hard materials (concrete, stone).

Small grinders are convenient for performing various grinding and polishing work. First of all, the angle grinder was intended for this purpose - it’s not for nothing that the name of the tool contains the word “grinding”.

Functional and protective automation

The convenience and safety of working with the tool is facilitated by additional functional “bells and whistles” of the tool.

Smooth start

An angle grinder equipped with a soft start system suffers less from short-term critical overloads at the moment of start. It is especially important to equip powerful grinders with such a system, which have a significant mass of parts and the disc itself. Then, when turned on, the angle grinder smoothly picks up speed, does not twitch in your hands, and the windings and brushes of the motor do not experience strong surges in current.

Speed adjustment

The angle grinder engine speed control system allows you to select the spindle speed for any task: cutting, grinding, cleaning, etc. These are additional conveniences designed to optimize the operating modes of the tool.

Speed stabilization

The system for stabilizing the spindle speed when the load on the disk changes significantly facilitates the processing of massive, labor-intensive parts.

Protection against disc wedge

Jamming of a disc in a slot in the material is a very dangerous phenomenon, especially for powerful angle grinders. The tool will simply break out of your hands with unpredictable consequences. To avoid this, the professional tool is equipped with an anti-jamming system for the cutting disc. In the case of a “wedge”, the tool will simply instantly de-energize.

Secondary fuse

If the power supply to the tool was interrupted while it was working (someone, for example, pulled the plug out of the socket), then when the power supply is restored, the angle grinder can be protected by a safety system from spontaneous restart.

Brush protection

A branded tool can be equipped with a safety system for shutting off the motor brushes when the supply voltage is lost. Restarting the rotating commutator of a powerful engine threatens to burn out the contact group. A system can also be provided to turn off the brushes when they are significantly worn.

Balancing system

When working with powerful grinders, the disc is produced unevenly, and certain vibrations of the tool occur, which do not have any positive effect on the quality of work. To eliminate them, well-known tool manufacturers use a balancing system designed to dampen these vibrations.

Dust protection

Not all angle grinders have reliable dust protection, which makes them unsuitable for cutting stone, brick or plaster. When choosing a tool, it is necessary to clarify this point if it is necessary to perform “dusty” work.

Bulgarian

Grinder - angle grinder.

It is specially designed for cutting hard metals and stone, roughing, stripping, grinding surfaces, etc. The working tool of a grinder is an abrasive disc for cutting or grinding a certain type of material. Each specific disc is designed for a strictly specific type of material. Otherwise, you could lose a disc or, worse, get seriously injured.

The diameter of the disc determines the functionality of the grinder: the larger the diameter, the deeper the cut.

Main characteristics:

Spindle rotation speed at idle speed. The key point when calculating the optimal spindle speed is the fact that the linear speed of the cutting tool surface at the point of contact with the workpiece surface should be close to 80 m/s (relative to this workpiece). For this reason, the rotation speed of large diameter disks is lower than that of smaller ones. After all, the higher the diameter of the disk, the greater the circumference, and the longer the working surface of the tool will be in contact with the surface being processed per spindle revolution.

Power consumption is an equally important characteristic of grinders. This indicator is closely related to the maximum diameter of the working tool. After all, a disk with large dimensions has a lot of weight and experiences more significant loads. In addition, a powerful tool is more durable, it does not heat up so quickly and has a long service life. Therefore, professional angle grinders, designed for long-term operation, are more powerful than their non-professional counterparts.

"Soft start" system. Thanks to the presence of this system, when the tool is turned on, there is no significant current surge, which makes it possible to connect it to a household power supply.

A system for maintaining a constant speed - regardless of the force applied, the working tool was in optimal operating mode.

Self-switching brushes - this system is equipped with expensive models. During its operation, if there is a short-term disconnection of the supply voltage, and then the voltage appears again, the angle grinder will not start working independently. To continue working, you will need to turn it off (using the on/off button) and then turn it on again.

Automatic disk balancing system. During operation, the disc, as a rule, wears unevenly, because of this, the grinder begins to vibrate and complicate the grinding process. Automatic disk balancing is used to avoid this inconvenience. The principle of its operation is similar to the principle of operation of the vibration stabilization system of some washing machines (which uses a bearing with missing balls).

Protective cover - to increase operational safety, can be rearranged if desired.

Accessories:

Grinding discs for grinders are very economical to use. They have a wide range of processing metal, plastic, wood and stone.

Grinding and cutting wheels. With their help, you can easily, quickly and economically separate workpieces and carry out grinding. When working with a grinding wheel, the cutting angle should lie between 35 and 45 degrees. Well, in the case when the workpiece being processed requires a flatter position of the angle grinder, the grinding wheel must be ground down from time to time in order to again obtain a grinding edge on the workpiece. It is not recommended to use cutting wheels when working on the wide sides of metal workpieces or when cutting oscillating workpieces.

Diamond cutting wheels. They are intended for a strictly defined type of material. Thus, discs for granite are intended for very hard material, but they can get stuck in viscous material. Asphalt discs will become dull in granite, and the concrete varieties are not suitable for limestone.

Sanding belts. Paper sanding pads on a sanding pad with adhesive joint are used for heavy sanding work. They are suitable for processing various materials: wood, varnish, metal and stone.

General rules for choosing a cutting wheel:

1. Before purchasing, check that the circle is not deformed. There should be no cracks or chips on its surface.

2. It is preferable that the specified maximum value of the rotation speed of the wheel be no less than the rotation speed of the grinder.

3. Remember that the reinforcing element is not always included in the design of the abrasive wheel. Its presence can be judged by the markings. For example, in Russian it means “bakelite bond with a reinforcing element.” If “U” is missing, it is not recommended to install such a circle on an angle grinder.

The efficiency of working with an abrasive wheel largely depends on the size and hardness of the particles: the larger the particles and the harder the abrasive itself, the faster the material can be cut.

Abrasive grain size designations

according to Russian and international ISO standards

| GOST 3647-80 (ed. 1994), for any abrasive tool | ISO 8486-1.2:1996 (E), excluding abrasive paper | ISO 6344-1.2:1998 (E), only for abrasive paper | |||

| Designation | Main particle size µm | Designation | Main particle size, microns | Designation | Main particle size, microns |

| — | — | F 4 | 4750 | — | — |

| — | — | F 5 | 4000 | — | — |

| — | — | F 6 | 3350 | — | — |

| — | — | F 7 | 2800 | — | — |

| — | — | F 8 | 2360 | — | — |

| 200 | 2000 | F 10 | 2000 | — | — |

| 160 | 1600 | F 12 | 1700 | R 12 | 1700 |

| — | — | F 14 | 1400 | — | — |

| 125 | 1250 | F 16 | 1180 | R 16 | 1180 |

| 100 | 1000 | F 20 | 1000 | R 20 | 850 |

| — | — | F 22 | 850 | — | — |

| 80 | 800 | F 24 | 710 | R 24 | 710 |

| 63 | 630 | F 30 | 600 | R 30 | 600 |

| 50 | 500 | F 36 | 500 | R 36 | 500 |

| — | — | F 40 | 425 | R 40 | 355 |

| 40 | 400 | F 46 | 355 | — | — |

| 32 | 320 | F 54 | 300 | R 50 | 300 |

| 25 | 250 | F 60 | 250 | R 60 | 250 |

| 20 | 200 | F 70 | 212 | — | — |

| 16 | 160 | F 80 | 180 | R 80 | 180 |

| — | — | F 90 | 150 | — | — |

| 12 | 120 | F 100 | 125 | R 100 | 150 |

www.stroyka74.ru

Types of tools:

Cordless tool.

- if there is no possibility of connecting to the network;

- to eliminate the inconvenience of “transporting” a power cord behind a tool (for example, when working at height).

Cordless angle grinders are classified in the same way as network options. One more parameter is added to their parameters - the time of continuous operation from one set of batteries. And this is their huge disadvantage - short operating time from one battery. Increasing its capacity will lead to an unjustified increase in the weight and cost of the instrument. Therefore, you should choose a cordless angle grinder in cases of urgent need or if there is a sufficient number of replaceable batteries.

An alternative to using a cordless angle grinder can be to use a diesel or gasoline portable electric generator of appropriate power (the significant starting currents of the angle grinder should be taken into account) to connect a corded power tool to it.

Pneumatic grinders

The pneumatic angle grinder is capable of operating for a long time without overheating under severe load conditions. They are most widespread in the metalworking industry, but can also be used in repair, construction and other fields of activity.

Its distinctive feature is the absence of an electrical network cable and the possibility of complete isolation from the compressor or air line. This tool can be used safely in conditions of high humidity. Pneumatic grinders also have a higher spindle speed.

Gasoline cutters

A gasoline cutter is, of course, not an angle grinder and is not intended for home use. But this professional tool allows you to perform some similar operations for separating solid materials, is capable of long-term autonomous operation, and has quite a lot of power.

A few points to make the right choice

All the tool parameters listed above may have helped you navigate the functional equipment of angle grinders, but did not bring clarity and specificity to the selection process. All grinders are initially similar, and you can evaluate the correctness of your choice only during long-term use of the tool. But, nevertheless, let’s try to specify the selection algorithm:

- The required diameter of the disk is determined - 125 mm is best for home use.

- Based on the operating mode, the power is determined.

- Determine the need and availability of additional functions.

- Evaluate the comfort of the case and the location of the handles.

- The terms and duration of the warranty are important.

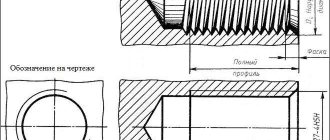

Cutting disc parameters

Cutting discs (circles) are determined by two main parameters:

- Size,

- Purpose by type of material.

There are five main diameters of cutting wheels: 230, 180, 150, 125 and 115 mm, but professional discs can be 300 mm or larger. Accordingly, larger diameter wheels are suitable for larger angle grinders. Cutting discs also have different thicknesses, and it can be from 1 to 4 mm.

The circles differ in their purpose - in the type of material that you will have to deal with when working. There are discs for metal, stone, wood, reinforced concrete. The circles themselves can be made of different materials and have different shapes.