Electrical equipment of tabletop drilling machine 2M112

- The electrical equipment of the 2M112 drilling machine is designed for power supply from a three-phase alternating current network with a voltage of 380V, 50 Hz.

- If necessary, the 2M112 machine with electrical equipment can be made upon special order for a voltage of 220V, 50 Hz.

- The starting and protective equipment is mounted in the plate of the 2M112 table-top drilling machine.

Protection of tabletop drilling machine 2M112

- The electrical equipment of the 2M112 machine is protected from short circuits and overloads by a single-pole circuit breaker.

- To prevent self-starting of electric motors, zero protection is applied using contacts of magnetic starters K1 and K2.

Schematic diagram of the tabletop drilling machine 2M112

Specification of purchased electrical equipment

| Designation according to the diagram | Name | Qty |

| QFI | Automatic switch VA47-2916A | 1 |

| KM1, KM2 | Magnetic contactor KMI 11210 | 2 |

| M | Electric motor: | 1 |

| SB1 | Button KE021 red. | 1 |

| SB2 | Button KE011 black | 1 |

| SB3 | Button KE011 black | 1 |

Instructions for connecting and servicing electrical equipment of the 2M112 drilling machine

- The 2M112 tabletop drilling machine must be connected to the general grounding system of the workshop using a special bolt located on the machine plate. Grounding of the machine and operation of its electrical equipment must be carried out in accordance with the requirements of the “Rules for technical operation and safety of maintenance of electrical installations of industrial enterprises.”

- When servicing, adjusting and repairing the electrical equipment of the 2M112 machine, you must follow the established safety rules for electrical installation work. Access to the contact parts of electrical machines and devices is permitted only after the machine is disconnected from the network by a circuit breaker.

- It is recommended to first do a test run of the 2M112 drilling machine at idle speed at all speeds sequentially, starting with the lowest spindle speed. During the first period after starting the machine, it is not recommended to work at maximum spindle speed.

- To ensure long-term and trouble-free operation of the 2M112 drilling machine, it is necessary to regularly:

- clean the electric motor, starting and protective equipment from dust,

- clean contacts from carbon deposits,

- tighten connections of wires to equipment as necessary.

Compliance with the above rules will ensure long-term uninterrupted operation of the 2M112 drilling machine and the safety of operating personnel

Initial launch of tabletop drilling machine 2M112

- Before the initial start-up of the 2M112 machine, all instructions set out in the sections “Machine Electrical Equipment” and “Lubrication System” related to the initial start-up must be followed.

- Then a test run is done at idle at all speeds sequentially, starting with the lowest spindle speed. After making sure that all the mechanisms of the machine are working properly, you can begin to operate it.

- During the first period after launching the 2M112 tabletop drilling machine, it is not recommended to work at maximum spindle speed.

How does the kinematic diagram of the machine work?

The electric motor of the drilling machine rotates a five-speed pulley fixed on its shaft, the torque from which is transmitted through a V-belt to the pulley of the spindle assembly. The vertical movement of the sleeve and, accordingly, the spindle assembly is carried out due to the rack and gear fixed on it, which is rigidly connected to the corresponding control handle.

The trunk of the NS-12 drilling machine moves in the vertical direction also due to the rack and pinion transmission, the operation of which was described above. The shoe, mounted on the base plate, has a special clamp, after loosening which you can rotate the column together with the trunk around its axis.

To ensure operator safety, a cast or extended welded casing is mounted on the drill press belt drive.

Drilling machine 2SS1M: characteristics

The 2SS1M desktop drilling machine can successfully handle drilling and milling a small batch of workpieces. The unit performs drilling operations in steel workpieces, milling non-metals and turning wood.

The unit is designed for domestic use and work in single production.

The machine is equipped with a three-jaw lathe chuck and a clamp with a mounting kit.

Three-jaw lathe chuck

As an option, a device is included that allows turning.

Main technical characteristics of the machine

The characteristics of the unit are quite standard:

| No. | Parameter name | Meaning |

| 1 | Maximum drilling diameter in steel, mm | 6 |

| 2 | Maximum drilling size, mm | 13 |

| 3 | Maximum distance from the table mirror to the end of the spindle, mm | 250 |

| 4 | Marking the distance from the base to the end of the spindle, mm | 370 |

| 5 | Amount of rotation of the desktop, degrees | 360 |

| 6 | Maximum quill shift, mm | 70 |

| 7 | Spindle reach from the stand, mm | 150 |

| 8 | Table size, Length × Width, mm | 200×200 |

| 9 | Base size, Length × Width, mm | 200×200 |

| 10 | Cone in spindle | Morse B16 |

| 11 | Maximum diameter of a wooden workpiece for turning, mm | 70 |

| 12 | Number of spindle speed steps | 3 |

| 13 | Rotation speed according to drilling diameter, rpm | |

| up to 5 mm | 1.6 thousand | |

| from 5 to 7.5 mm | 1 thousand | |

| from 7.5 to 13 mm | 600 | |

| 14 | Machine dimensions, Length × Width × Height, mm | 620×240×700 |

| 15 | Equipment weight, kg | 52,5 |

Device Description

The 2SS1M drilling machine is a vertical design for desktop installation with a massive base in the form of a plate.

Drilling machine device

The slab support includes:

- Cylindrical stand - it contains a movable work table and a traverse.

- To secure the table, a clamping mechanism with a handle is provided.

- Above the working area of the table there is a quill mounted in a traverse.

- The quill has the ability to move in a vertical plane along a rack and pinion transmission. The quill is lowered by rotating the manual feed handle.

- An electric motor is installed in the opposite part of the traverse of the 2SS1M machine.

- The three-stage pulley of the electric motor and the quill are connected by a belt drive.

Preparing the machine for operation

The specialist needs to know the operating instructions for the unit:

- The machine is secured to a workbench or work table using holes in the base.

- A drill of the required diameter is clamped in a spindle with a chuck.

- The handle moves the quill to its highest position.

- The workpiece is placed on the table and secured with clamps or other equipment.

- By moving the table, you need to establish a gap of at least 5 mm between the top plane of the part and the top of the tool.

The movement of the tool during processing is controlled by the dial ruler. The division value of the reading device is 1 mm, the mark corresponds to the amount of movement of the tool on the part. Before starting processing, you should connect the zero of the dial with the mark on the machine by rotating the dial counterclockwise.

The principle of operation of the electrical circuit

The 2SS1M machine is powered from a 220 V mains voltage. The type of current is alternating, single-phase, and the current frequency is 50 Hz.

After connecting to the network and being completely ready for work, press the start button on the control panel. After electricity is supplied, the inching contact for turning on the starting winding is triggered, and the working winding of the electric motor is started.

When the button is turned off, the terminals on the contactor open, and the starting circuit of the electric motor is turned off.

The equipment is stopped by the red stop button. It is also necessary in an emergency and when stopping the engine unnecessarily. The button prevents damage to the machine drive and injury to the machine operator.

The 2SS1M drilling machine has an electric motor with a rated power of 0.18 kW.

Electric motor with a power of 0.18 kW

Engine speed 1420 rpm. The motor has a class II product with double insulation.

Recommendations for processing

Experts who work with the unit advise craftsmen to adhere to several rules:

- The choice of processing modes is made taking into account the hardness and type of material. High-hardness workpieces are processed at low speeds.

- Large parts are installed on the floor or stand. The traverse is deployed to the desired position.

- Milling of grooves is carried out with a fixed quill. The workpiece is placed along the stop and fed manually.

During the turning operation, a comb is installed in the quill instead of a chuck. A rotating center is fixed into the hole in the worktable. The part being processed is located between them. Processing is carried out with cutters with the installation of a special device.

Specification of components of the drilling machine NS-12

- Plate

- Column

- Trunk (spindle head)

- Spindle sleeve (quill)

- Spindle

- Spindle quill feed handle

- Rack

- Electric motor

- Electric motor plate (sub-motor plate)

- Belt tensioner stopper

- Shoe (bracket for fastening the column to the plate)

Brief description of the design and operation of the NS-12 desktop drilling machine

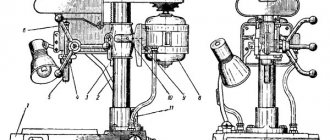

The machine consists of the following main parts: plate 1; column 2; trunk with spindle group 3; electrical equipment 8.

On the stove

shoe 11 is fixed, in the hole of which column 2 is installed. Column

secured by tightening the shoe.

Along the perimeter of the plate there is a trench for collecting coolant. At the bottom of the chute there is a drain hole with a plug. When connecting the machine to a centralized supply of emulsion, instead of a plug, a nipple with a rubber hose can be wrapped.

A step-down transformer and a package switch housing (for local lighting) are mounted inside the plate, and a push-button station is installed outside (for the machine’s electric motor).

On the column

a rack 3 is fixed (Fig. 4) (m = 2), in mesh with which there is a gear mounted in the trunk, rigidly fixed to the handle 4 (see diagram of the location of the controls). When turning handles 3, 4 (Fig. 6), the trunk moves along the column. After installing the trunk to the required height, handle 3 clamps the trunk.

On the trunk

spindle group 5, electric motor 8 with plate and tensioner 10 for the V-belt are fixed.

Spindle

, unloaded from the pulley, is installed in sleeve 4 (quills) on precision angular contact bearings.

Sleeve

moves when turning handle 6 (Fig. 1).

The transmission of rotation from the pulley to the spindle is carried out using two parallel keys.

Five speed spindle pulley

secured by a bushing on two radial bearings.

Electric motor

fixed on the under-engine plate, the guides of which freely fit into the corresponding bores in the trunk. After the belt is thrown onto the corresponding pulley stage, this plate is pulled away from the trunk to the normal belt tension and in this position is fixed with clamping screws.

Location of controls for the NS-12 drilling machine

Device

One of the important advantages of the drilling machine is its simple and reliable design. It has gone through several modernizations, but has retained a number of important components.

The modern 2M112 machine is a massive steel column with a work table at the bottom and a horizontal bracket at the top. A vertically moving spindle head is mounted on the bracket at the front, and a drive motor is installed at the rear.

The power unit shaft is connected to the spindle module by a drive belt (V-belt drive), and the entire drive is protected by a cast metal casing. The motor shaft is equipped with a pulley with five stages of belt installation (splines), which allows you to adjust the spindle rotation speed when working with parts made of different materials.

The spindle head is a tool movable head with a rotating spindle (quill). It is equipped with mechanisms for fixing on the bracket and moving along the bracket (back and forth), as well as mechanisms for spindle feed (up and down) and tension of the drive belt (adjusts the distance between the transmitting and receiving pulleys), which are controlled using handles.

To adjust the position of the work table, which is a massive thrust plate made of tool steel with T-shaped slots, a mechanism with a handle is also used. To precisely control the movement of the spindle head and the drilling depth, a clamp with a flat measuring notch is installed on the tool head.

The spindle is mounted in a special sleeve with two ball bearings, and its clamping device (Morse taper) is adjusted by a rotating head with a lock, which makes it possible to quickly install and change drills of different sizes to drill holes of the required depth and diameter.

To illuminate the working area of the machine, an electric lamp is attached to the body. The electric drive is started by the start button, which is located on the body of the machine column.

In addition, when working with the machine, you can use additional equipment: a support stand (for face machining of parts with a diameter of up to 120 mm), a cross table for ultra-precise drilling, a replaceable turret, a vice for securely fastening parts on the work table and a cooling unit for long-term drilling superhard materials.

Machine design

This model is designed for forming holes in small workpieces made of various materials: steel, wood, polymers. If you have a tap, the thread can be cut. It has found application in repair shops and is widely popular among home craftsmen.

The design consists of a work table, which serves as a base. On its surface there are polished T-shaped grooves for fixing the workpiece. A vertical column is installed on the frame, in the upper part of which electrical equipment, a spindle head and shafts for switching the number of revolutions are mounted.

The passport describes in detail the design features of the NS-12 desktop machine. They are as follows:

- use of cast iron bodies. This ensures long term maintenance-free operation of the equipment;

- convenient system for changing the spindle speed. For this purpose, pulleys of various diameters are installed on the headstock and electric motor shafts. The drive is carried out using a belt drive;

- Precision processing provides a report of the drilling depth on a stop or on a flat scale.

The original belt tension system makes it possible to change gears. But to do this you need to wait until the electric motor stops completely. To drive the spindle head on the NS-12A machine, you can install flat and toothed belts.

When working on the equipment, it is mandatory to install a protective casing on the shaft with spindle pulleys. This will prevent dangerous situations from occurring.

Classification of spindles by type, size and diameter

There are various bases for classification. The first, and perhaps the main one, is what equipment the unit is intended for. Of course, different machines and electrical equipment require different instruments.

The second principle of differentiation is size. The devices come in different sizes, designed for industrial use and private use. In this regard, a variety of consumable parts are needed - larger and smaller. If you want to replace the spindle on your own machine, then when purchasing you must indicate the number of your equipment, name and year of manufacture (there may be different modifications).

Well, the last, but not intended, classification is by type. Shafts can be:

- Collector. This is a device that includes a high-speed collet roller. The main areas of use are milling machines, as well as engraving operations.

- Specialized for high speeds. They allow you to achieve significant metal processing speeds, therefore increasing productivity. But since good quality can only be achieved with great precision, high-speed models are used mainly only on CNC equipment. You can buy such machines on the website.

- Design with built-in cooling. The cooling system can be supplied through a part or liquid, or cold air. This increases the cutting speed and the degree of surface roughness, and friction becomes less, so wear also comes later.

There is another classification - by manufacturer. Of course, European production is more preferable than Chinese. In Europe, porcelain bearings are often used, which provide very positive performance.

Local lighting

The machine is equipped with the necessary equipment for connecting local lighting. The installation location is selected depending on the installation location.

Most often, craftsmen choose a workbench or a monolithic table as a place to install the NS-12A drilling machine. Then the mounting bracket with the local lighting transformer is installed near the machine on the same base. When placing equipment near a wall, it is convenient to place the mount on it.

The presented drilling machine model is considered reliable equipment with a clear control algorithm. The model is highly maintainable and does not require large maintenance costs.

A popular and budget model will be an ideal assistant in the following rooms:

- auto repair shop;

- mini-workshop;

- educational laboratory of the technical school.

Advantages and disadvantages of the device

The fact that the model 2M112 tabletop drilling machine, the design of which was developed more than thirty years ago, can still be found in the equipment of many manufacturing enterprises and home workshops, indicates that specialists value this equipment for its characteristics and advantages.

The popularity of the 2M112 vertical drilling machine is also evidenced by the fact that even after a complete breakdown (which happens extremely rarely), users try to find a unit of a similar model, rather than purchasing cheap and low-quality devices from Chinese manufacturers or expensive European equipment.

In the electrical panel of the machine (combined with the control panel) everything is simple and minimalistic

Among the most significant advantages that the drilling machine model 2M112 has, it is necessary to highlight the following.

- Thanks to its long service life, the machine is characterized by exceptionally high endurance and is able to be successfully operated even in the most severe conditions.

- Due to the simplicity of the design, the device does not require complex care and special maintenance. Even disassembling such equipment yourself does not cause any particular difficulties.

- On the modern market you can easily find any spare parts and components for the 2M112 machine, so there are no difficulties with the repair of such equipment.

- The power of the electric motor with which this machine is equipped is quite enough to satisfy the needs of both a home craftsman and a small manufacturing enterprise.

- A significant characteristic of the 2M112 machine is its affordable price, which is optimally combined with its reliability, efficiency and ease of use.

Connection diagram of the machine to a 220 volt power supply network

The vertical drilling machine of the model in question is not without its shortcomings, which are not mentioned in the passport. The main disadvantage of this equipment is that it is already obsolete. Modern devices of this category, the production of which uses new technological approaches and innovative kinematic schemes, surpass the 2M112 in processing accuracy, efficiency and productivity.

The kinematic diagram of the machine consists of a minimum number of parts

Schematic diagram of 2M112

pros

The technical characteristics of the 2M112 drilling machine, the repair of which is very simple, were developed several decades ago. However, this unit remains popular to this day. This is due to its reliability, ease of execution and high processing accuracy, as well as its affordable price.

To repair or replace elements on the domestic market, it is easy to select domestic or Chinese analogues. The advantages of the unit are the following parameters:

- High working life, endurance, ability to operate in various climatic zones.

- Ease of maintenance and operation of equipment, including unit repair.

- Maintainability and availability of spare parts.

- The power of the electric motor is enough not only for schools and private households, but also for small production workshops.

Of course, along with reliability and practicality, the main advantage of this machine is its reasonable price.

Machine characteristics and documentation

The main characteristic of any drilling machine is the maximum diameter of the hole drilled with it. Using the machine model 2M112, according to the passport, it is possible to produce holes in the workpieces with a diameter of up to 12 mm. Holes of this diameter are quite sufficient to carry out drilling work in a home workshop, but in production conditions, larger diameter drills are installed on these machines.

Machine Specifications

Data sheet for tabletop drilling machine 2M112:Download

The chuck of the 2M112 drilling machine, according to the passport, can rotate at a speed of 450–4500 rpm, and the rotation speed of this unit can be adjusted in 5 steps. The machine is equipped with a B-18 class spindle, the distance from the end of which to the surface of the work table can vary in the range of 0–400 mm.

The dimensions of the work table, on the surface of which there are three T-shaped grooves for fixing the workpiece or a machine vice, are 250x250 mm.

The surface of the machine's work table allows the clamping fixtures to be fixed

To expand the functionality, the drilling machine can be installed on a special stand, which allows the equipment to be used for drilling holes in the ends of parts whose length reaches 1000 mm. An electric motor with a power of 550 W is used as the main drive device on the 2M112 machine.

Despite its small dimensions and not too high power, the tabletop drilling machine of this model can be subjected to long-term and intensive use. Such worthy characteristics are ensured by the simple but effective design of the device.

In a home workshop, the 2M112 machine can be placed on a homemade metal stand

Design features

The 2M112 drilling machine, whose technical characteristics allow it to process plastic, metal and wood, has a fairly simple design. The unit design provides the ability to adjust the rotation speed of the working chuck in five ranges. This option is provided by changing the position on the pulleys of the corresponding gear. The drilling depth during operation of the machine is adjusted using a flat scale or stops.

Simplicity of design is the main advantage of the device, since it is reliable and easy to use. Compact dimensions and low weight make it possible to transport the unit to any suitable location. The equipment in question can be mounted on the surface of a mechanic’s workbench, drilling column or cabinet.

NS-12A tabletop drilling machine. Purpose and scope

The machine is designed for drilling holes and cutting threads in small parts made of cast iron, steel, non-ferrous alloys and non-metallic materials in industrial enterprises, repair shops and household workshops.

Main parameters of the drilling machine NS-12a:

- Maximum drilling diameter: Ø 12

mm - Maximum drilling depth: 100

mm - Maximum height of workpiece: 400

mm - Distance from spindle axis to column (spindle overhang): 200

mm - Spindle speed: 450, 710, 1400, 2500, 4500

rpm - Electric motor power: 0.65

kW - Machine weight: 120

kg

Spindle unit

drilling machine NS-12 - the most complex and precise unit in the machine. The spindle assembly is mounted in the spindle head. Main parts of the spindle assembly:

- Spindle

- a shaft that rotates on 2 angular contact bearings inside the spindle sleeve; - The spindle sleeve (quill)

is a cylinder that is mounted in the spindle head and has the ability to move axially within 100 mm.

The upper part of the spindle has splines to receive rotation from the take-up pulley, the lower part has a Morse taper for attaching the drill chuck.

The spindle of the NS-12a machine receives five rotation speeds from five-stage drive pulleys, which provides a choice of cutting speeds in the range of 450, 710, 1400, 2500, 4500 rpm.

Spindle end

— external Morse cone KM2, designation B18 according to GOST 9953 (Shortened tool cones) — shortened cone: D = 17.780 mm, cone length 37.0 mm.

The shortened cone B18 corresponds to a three-jaw drill chuck of the 16th standard size in accordance with GOST 8522 (Three-jaw drill chucks) with a clamping range from 3 to 16 mm.

An example of a symbol for a 3-jaw drill chuck, size 16, with a connecting conical hole B18:

Cartridge 16-B18 GOST 8522-79

Morse cone instrumental shortened

Tool taper - Morse taper is one of the most widely used tool mounts. It was proposed by Stephen A. Morse around 1864.

Morse taper is divided into eight sizes

- from KM0 to KM7 (in English: MT0-MT7, in German: MK0-MK7).

Morse taper standards: GOST 25557 (Tool cones. Main dimensions), ISO 296, DIN 228. Cones made according to inch and metric standards are interchangeable in everything except the shank thread.

For many applications, the length of the Morse taper has proven to be excessive. Therefore, a standard was introduced for nine standard sizes of shortened Morse cones (B7, B10, B12, B16, B18, B22, B24, B32, B45), these dimensions were obtained by removing the thicker part of the cone. The number in the designation of a short cone is the diameter of the thick part of the cone in mm.

Russian standard for shortened cones GOST 9953

Tool cones are shortened.

Russian standard for drill chucks GOST 8522

Three-jaw drill chucks.

- B7

- Morse cone

KM0

, D = 7.067 mm; - B10

- Morse cone

KM1

, D = 10.094 mm.

Cartridge 4-B10

(0.5÷4 mm); - B12

- Morse cone

KM1

, D = 12.065 mm.

Cartridge 6-B12

(0.5÷6 mm), Cartridge

8-B12

(1÷8 mm); - B16

- Morse cone

KM2

, D = 15.733 mm.

Cartridge 10-B16

(1÷10 mm), Cartridge

13-B16

(1÷13 mm); - B18

- Morse cone

KM2

, D = 17.780 mm.

Cartridge 16-B18

(3÷16 mm); - B22

- Morse cone

KM3

, D = 21.793 mm.

Cartridge 20-B22

(5÷20 mm); - B24

- Morse cone

KM3

, D = 23.825 mm; - B32

- Morse cone

KM4

, D = 31.267 mm; - B45

- Morse cone

KM5

, D = 44.399 mm.

Where D

- diameter of the cone in the main plane.

The simplicity of the design ensures ease of control, reliability and durability of the machines.

The drilling depth is measured using a flat scale or stop.

Five-speed drive pulleys allow five spindle rotation speeds, which provides free choice of cutting speeds.

The original design of the belt drive tension allows you to quickly change the position of the belt on the pulleys to obtain the desired cutting speed.

NS-12A machines allow you to perform the following operations:

- drilling

- countersinking

- deployment

- reaming

- thread cutting

Photo of drilling machine NS-12a

Soviet lathes for metal and wood

- This unit is one of the most popular brands, which has found application in many workshops. Even educational institutions use the IT-1M lathe to develop the skills of their students. This model first appeared at the Ivanovo machine tool enterprise, where employees

- To carry out high-quality turning work, certain skills are required. The TV-6 lathe is used to teach the basics of the lathe profession, which determines its wide distribution in various training organizations. Despite the fact that the equipment appeared on sale in

- On sale you can find a fairly large number of machines that are installed at home to carry out a wide variety of work. For a long period, the Universal 2 lathe was very popular. Design features determine that such

- The TSh-3 lathe allows for three processing operations: drilling holes, turning tools, and grinding surfaces. The abbreviation ТШ, present in the name of the machine, indicates that it is both a sharpening and grinding machine. The unit has its own characteristic features,

- To produce high-precision parts, special turning equipment is used. The 1E61M screw-cutting lathe and models 1E61PM, 1E61Mt have become quite widespread. Explanation of the marking indicates that the machines in question belong to the turning-screw-cutting group, while the height of the centers

- The 1M63N screw-cutting lathe is designed for all types of processing of workpiece rotation surfaces, including making cones and cutting threads of most accepted standards with one or more passes. Unlike its predecessor brand 1M63, the screw-cutting lathe 1M63N has

- Turret lathe 1341 belongs to the turning group equipment. Using a turret lathe with a set of tools allows you to perform a range of works: turning external and internal surfaces, grooves; drilling; processing with a countersink to obtain precise dimensions and ledges; when using reamers

- Previously, the equipment of the Ryazan plant 1M65 was widely used - a screw-cutting lathe. Model 1N65 is the next modification with improved main components and expanded capabilities for manufacturing complex contours of a part. According to the data specified in the passport, the diameter of the workpiece can

- The 1M63 screw-cutting lathe was developed and began to be produced in the mid-50s. This equipment at that time had unique technical characteristics; the 1M63 machine made it possible to process high-quality workpieces from various metals. Scope of application by Buyers

- In the middle of the last century, there was a surge in the development of models of domestically produced metal-cutting equipment. This trend is aimed at import replacement of this product category. The shortage was in the category of lathes. Design bureaus placed emphasis on this, and a turning machine appeared

stankiexpert.ru

Operating rules

The drill model 2a112 requires compliance with a number of rules before starting work and when performing operations on it.

A preliminary check of the strength of the drill fastening is required. During the work process, a smooth approach of the drill to the workpiece is necessary. The transmission is engaged until the drill comes into contact with the workpiece. The feed rate decreases as the drill exits the hole formed in the part.

Removing short chips that wrap around the drill is done with a hook. Long chips are removed only after the machine stops. Maintenance of the device includes:

- changing the oil in the gearbox after 90 hours of operation;

- removal of coal dust from the electric motor after 90 hours of operation;

- complete cleaning of the unit after each start-up;

- after disassembling and assembling the device, it must be checked for electrical safety;

- Constant inspection of brushes and their replacement if the height is less than 8 mm.

Flaws

Like any technology, the device in question has a number of disadvantages. Among them, users note the following points:

- Obsolescence of the device.

- The unit is inferior in accuracy and quality of processing to modern models from other manufacturers.

- Reduced recoil efficiency and efficiency during intensive work.

- In addition, this machine is inferior in some respects to modern models, including compactness and reliability, along with ease of maintenance.

Help with the restoration of 2N112 – Drilling machines

I’m not completely sure that this is 2M112, but still. :rolleyes:

In general, I bought a “working” machine from an ad on the Internet, but in reality, everything turned out to be a little different. However, I’m not the first...

The already battered engine nameplate was also painted over. We managed to wipe off the paint and somehow see the initial symbols of the model - AMX74, rpm - 1370, efficiency yes Δ/Y 220/380. I already knew the latter, because... I have already managed to reconnect the windings and connect the motor to the frequency converter. The connection showed squeaking bearings. You can probably lubricate it, but I’d rather change it. The engine power remains a mystery to me.

A couple of questions arose:

1. Does it make sense to weld the spindle head clamp? Not only is it cast iron (you need to find a track welder), but you also have to weld it over a thin body... Will the welding seam hold up when tightened?

2. Do I understand correctly that the console on which the engine is mounted is skewed because in the gap between the dovetails there must be some kind of slats (wedges?) filling it? What material is best to make it from?

3. I saw in neighboring topics that on such machines a thrust bearing is installed between the lifting ring and the SB. Is this by design or homemade? Can anyone tell me the bearing number...

Thanks to everyone who takes the trouble to help with the answers.

Machine control principle

Before putting the machine into operation, you need to make sure that grounding is present.

Operating the machine is quite simple:

- to turn it on, you must press the “Start” button on the push-button starter panel;

- switching on is accompanied by the start of the electric motor;

- the machine is ready for work, and to stop work, press the “Stop” button. The power will turn off and the engine will stop. If necessary, local lighting is turned on by turning the toggle switch of the package switch.

Transportation.

To transport the unpacked machine, a steel rod Ø 6-17 mm is used, which is passed through the hole provided in the body.

When gripping the machine with ropes by the rod, care must be taken not to damage the lining of the machine. In this case, the spindle head of the machine must be moved to its lowest position and securely fastened.

When transporting to the installation site and when lowering onto the foundation, the machine should not be subjected to strong shocks.

Before installation, the machine must be thoroughly cleaned of the anti-corrosion coatings applied to the machine’s open and covered surfaces with casings and shields, and to avoid corrosion, coated with a thin layer of I-ZOA oil GOST 20799-88.

Installation diagram of the 2M112 machine

Cleaning is first done with a wooden spatula, and the remaining lubricant from the outer surfaces is removed with clean napkins moistened with gasoline B-70 GOST 511-82. When re-opening the machine, comply with the safety requirements in accordance with GOST 9.014-78.

Technical characteristics of the 2SS1M machine

| Parameter name | 2m112 | NS12A | 2SS1M |

| Basic machine parameters | |||

| Largest drilling diameter, mm | 12 | 12 | 6 |

| Maximum drilling diameter, mm | 13 | ||

| The smallest and largest distance from the end of the spindle to the table (base) | 0…400 | 20..420 | 0..370 |

| The smallest and largest distance from the end of the spindle to the table | No | No | 0..250 |

| Distance from the axis of the vertical spindle to the rack guides (overhang), mm | 190 | 185 | 150 |

| Desktop | |||

| Width of the working surface of the table (base), mm | 250 | 360 x 360 | 200 x 200 |

| Width of the working surface of the table, mm | No | No | 200 x 200 |

| Desktop rotation angle, degrees | No | No | 360° |

| Number of T-slots | 3 | 3 | 1 |

| Spindle | |||

| Maximum movement of the spindle head, mm | 300 | ||

| Spindle sleeve stroke, mm | 100 | 100 | 70 |

| Spindle speed, rpm | 450, 800, 1400, 2500, 4500 | 450, 710, 1400, 2500, 4500 | 600, 1000, 1600 |

| Number of spindle speeds | 5 | 5 | 3 |

| Spindle taper | Morse B18 | Morse B18 | Morse B16 |

| Drive unit | |||

| Main motion drive electric motor, kW (rpm) | 0,55 | 0,65 | 0,18 (1420) |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 795 x 370 x 950 | 770 x 465 x 700 | 600 x 240 x 700 |

| Machine weight, kg | 120 | 121 | 53 |

Related Links

Design of the NS-12A machine

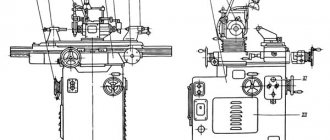

The main design elements of a tabletop drilling machine are:

- base;

- Column;

- trunk with spindle group;

- electric drive;

- controls.

The cast iron base serves as a support base, and inside the massive plate there are electric drive elements, including a switch housing that provides lighting for the work area and a step-down transformer.

A push-button station for turning on the equipment is located on the front panel of the base. At the top of the base there is a work table for installation and securing fixtures and parts.

Along the perimeter contour there is a trench for accumulating coolant used during processing. The gutter has a drain hole closed with a screw plug. In the case of supply from the central line, a nipple with a rubber hose is connected to the hole.

The column is fixed to the base plate with a special shoe and tightened with bolts. When it is necessary to rotate the column around its axis, the bolts are released, the stand together with the upper part is installed in the required position and fixed.

The trunk consists of a cast iron body in which a spindle assembly, a movement mechanism, a belt tensioner and a local lighting lamp are mounted.

An electric motor is suspended from the rear of the body on a sub-motor plate.

It will be able to move longitudinally along the guides. Motor mobility is necessary to reduce the tension of the drive belt when adjusting the spindle speed. When the belt is placed in the pulley groove, the motor returns to its place and the required tension is ensured.

The raising and lowering of the trunk along the column is ensured by a rack and pinion transmission. The transmission rack is firmly fixed to the column, and the drive gear is located in the trunk. Vertical movement is controlled manually through a handle that has a rigid connection with the gear. The second lever is located near the column and fixes the position on the column; this occurs at the required height above the table.

The spindle is installed on the cantilever part of the trunk in the machine quill, movable in the vertical direction.

The movement of the quill, which transmits the feed movement to the spindle, is carried out by a handle located on the side of the trunk. The spindle of the NS-12A drilling machine is placed in supports with precision angular contact bearings; they ensure precision movement and smooth running. The control pulley is made in the form of a five-stage design and is mounted in supports with radial bearings.

You can control the drilling depth of blind holes using a special hard stop and a flat scale on the body.

Electrical equipment and electrical circuit of the drilling machine 2M112

Power supply of the drilling machine 2m112 ~380 or ~220 Volts.

Machines manufactured for industrial enterprises and educational institutions have a supply voltage of ~380 V, for mobile workshops - ~220 V. Local lighting has a safe voltage of ~24 V.

All electrical equipment of the machine: switches, transformer, fuses are placed under the work table plate.

Technical characteristics of the electric drive

- Type of spindle drive electric motor - AIR714U3 or 4A71A4U3

- Electric motor – asynchronous three-phase, with a squirrel-cage rotor, height of the axis of rotation 71 mm, weight 8.4 kg

- Spindle drive electric motor power – 0.55 kW

- Spindle drive electric motor speed – 1370 rpm

Initial start-up and instructions for installation and operation

When installing, you must first connect the machine (cooling unit) to the general grounding system using a special bolt located on the machine plate (on the machine of the cooling unit tank).

The supply wires are inserted by the customer through the hole located on the back of the machine plate (on the casing of the cooling unit control panel).

The OSZR (coolant) device is connected autonomously to the supply circuit.

The machine (cooling unit) is connected to the power supply using switch Q1.

First, it is necessary to test run the machine at idle, at all speeds sequentially, starting with the lowest spindle speed. During the first period after starting the machine, it is not recommended to work at maximum spindle speed.

Protection

The stack's electrical equipment is protected from short circuits and overloads by fuses F1, F2, F3.

To prevent self-starting of the electric motor, zero protection is applied using contacts of magnetic starters K1 and K2.

Instructions for servicing the electrical equipment of the machine

Electrical equipment was installed using wires of the following colors:

- power circuits - black

- control circuits - red

To ensure long-term and trouble-free operation of the machine, it is necessary to regularly clean the electric motor, starting and protective equipment from dust, and contacts from carbon deposits; Tighten connections between drives and equipment as necessary.

Electrical diagram of a drilling machine 2m112 at 380V

List of elements for the electrical diagram

- Q1 – Switch PKU3-154I-2037U3 TU 16-526.047-74

- S1 – Switch KE201U3 used. 5 red “P” TU 16-642.015-84

- S2, S3 – Switch KE181U3 used. 2 black “P” TU 16-642.015-84

- E1 – Lamp NKP03-60-0.04UH4 TU 16.876.184-86. Lamp M 024-40 GOST 1182-77

- Ml – Engine AIR 71 A4U3, 380 V, 50 Hz TU 16-525.564-84 or 4A71A4U3 GOST 19523-81

- F1, F2, F3 – Fuse PRS-6U3-P with fuse link PVD1-6U3 TU 16-522.112-74

- K1, K2 – Starter PME-041U4 (380 V, 50 Hz) OST 16.0.536.001-72

- T, Q2, F4 – Device OSZR-0.04-83UHL3 TU 16-6/1 041-84 (coolant)

It is possible to replace components without compromising the quality of the machine.

Electrical diagram of a drilling machine 2m112 at 220V

Control panel for drilling machine 2m112

Installation of the electrical circuit of a drilling machine 2m112

Equipment design elements

The design of the NS-12 drilling machine includes the following elements:

- base plate;

- column;

- a trunk on which the spindle group of equipment is mounted;

- electrical equipment.

The column, which is installed on the base plate, is secured to it using a special shoe. Along the perimeter of the base plate there is a special chute for collecting coolant. The liquid drains from the gutter through the lower hole, which is closed with a screw plug. If the coolant is supplied from a centralized network, a nipple is screwed into the drain hole, to which a rubber hose is connected.

The inside of the massive base plate is used to house a step-down transformer and a package switch housing, which is responsible for lighting the processing area. A push-button station is mounted on the front of the plate, with the help of which the main electric motor of the machine is turned on.

The vertical movement of the trunk along the column is carried out due to a rack and pinion transmission, consisting of a rack mounted on the column and a gear mounted in the trunk. This movement is controlled using a handle rigidly connected to the gear. Among the controls of the drilling machine there is another handle, with the help of which the trunk is fixed at the required height.

The spindle assembly is mounted on the trunk; there is also a plate with an electric motor mounted on it and a mechanism for tensioning the drive belts. The spindle itself is installed in the sleeve (quills) of the machine, which can move in the vertical direction.

The movement of the sleeve, which imparts the feed movement to the spindle, is controlled by means of a handle located on the side of the trunk. Smooth and precise rotation of the spindle is ensured by its installation in supports with precision angular contact bearings. The spindle pulley of the drilling machine, which is a five-stage design, is also mounted on two supports with radial bearings.

The machine's electric motor is mounted on a special plate and can move along its guides. This design allows for quick loosening of the drive belt at the moment when it needs to be transferred to another pulley, as well as its rapid tension when it is necessary to begin processing.

Tabletop drilling machine 2M112: technical characteristics

A feature of the unit in question is the ability to adjust the diameter of the drilled hole. According to the operating instructions, the machine can make nests with a diameter of up to 12 mm. This range is quite enough for work in home workshops. Industrial analogues have an increased diameter of the holes produced.

Below are the technical characteristics of the 2M112 drilling machine:

- The maximum drilling diameter is 12 mm.

- The difference in distance from the spindle axis to the stand is from 0 to 400 mm.

- The overhang of the guide element is 190 mm.

- Working surface width – 250 mm.

- Number of grooves – 3 pieces.

- The spindle sleeve stroke is 100 mm.

- Number of speeds – 5.

- Maximum speed – up to 4500 rotations per minute.

- Drive type – electric motor with a power of 0.55 kW.

- Length/width/height – 0.79/0.37/0.95 m.

- Weight – 120 kg.

What does the electrical diagram of the device include?

This characteristic of the machine of this model, such as ease of use and repair, is determined, among other things, by the simplicity of the electrical circuit. The elements of the electrical circuit of the NS-12 drilling machine, which are responsible for controlling the equipment, are the “Start” button, when pressed, the drive motor is started, and the “Stop” button, with which the electric motor is turned off.

The characteristics of the drilling machine include the presence of local lighting, which is turned on when the handle of the corresponding batch switch is turned. The operation of the local lighting system requires the use of a step-down transformer, which is mounted in close proximity to the machine.

What is a tabletop drilling machine 2m112

Drilling machines 2M112 are household-grade machines with an electric drive, designed to perform a wide range of vertical drilling operations:

- drilling and reaming round holes in workpieces and parts;

- drilling of cylindrical holes (countersinking and reaming);

- cutting internal threads in parts.

The equipment is universal and can drill holes in parts and workpieces made of steel, iron, cast iron, non-ferrous metal alloys, durable plastic and any type of wood.

The machine is designed for use in small metalworking and woodworking enterprises, repair shops, vocational schools and home workshops. The price for the tabletop drilling machine 2M112 is favorable. The equipment has excellent performance characteristics.

Description

The technical characteristics of the 2M112 drilling machine allow it to be classified as equipment of the middle category of vertical drilling type. Its production began in 1980. During serial production, the unit gained recognition and popularity. It is especially in demand in private workshops and small manufacturing enterprises. The main purpose of the machine in question is to train young specialists in schools and technical educational institutions.

Thanks to its functionality, the unit can be used for the following purposes:

- Drilling holes of various diameters.

- Drilling workpieces.

- Reaming and countersinking of parts.

- Making internal threads.

Device and control

Main components of the unit:

- Working column for moving the headstock with the spindle.

- Clamping device.

- Drive with electric motor.

- Spindle head lifting unit.

- The base is in the form of a table top.

- Protective cover for the mechanism drive.

- Spindle type headstock.

- Tensioner unit to control the elasticity of belts.

- Bracket for fixing the base of the column.

The technical characteristics and features of the 2M112 drilling machine determine the presence in the design of the following monitoring and control elements:

- Mechanical spindle feed handle.

- Handle for tensioning belts.

- Special adjustable spindle head clamp on the work column.

- Control buttons that electrically start and stop the motor drive.

- The handle for fastening the under-engine platform.

The manufacturer of the equipment in question provided for the installation of the main parts in a cast iron casing, which ensured reliable protection of the components from mechanical deformation. For greater comfort when working with the machine, a lighting system is provided for the processing working area.

Purpose of the machine model NS-12

Model NS-12 belongs to the category of desktop equipment. This suggests that it is suitable for processing small-sized parts. The appropriate dimensions and low productivity of the machine make it possible to use it in repair shops of manufacturing enterprises and small workshops, specialized classes of technical and general educational institutions. You can often find such a device in home workshops.

The long service life, ease of use, maintenance and repair of the NS-12 machine are ensured by the simplicity of its design. When drilling blind holes on such a machine, their depth can be adjusted using a flat scale or a special stop.

The use of a multi-stage belt drive in a drilling machine allows for five different rotation speeds of the spindle assembly. What is important is that the belt can be switched to a pulley of a different diameter simply and quickly thanks to a special belt tensioning mechanism.

The technical capabilities of the drilling machine model NS-12 allow you to perform various types of processing of workpieces made of cast iron, steel, non-ferrous metals and non-metallic materials:

- drilling and reaming holes;

- deployment;

- countersinking;

- internal thread cutting.