Material selection

Having decided on a place for a workbench and drawn a drawing, the question of choosing materials for the product logically arises. Much here will depend on what is more accessible to you - metal or wood. As a base, you can use a wooden beam or a 40 mm board, or you can make a frame from a metal corner, from a profile pipe or from an aluminum profile. For the countertop, you can use chipboard, MDF, but you can also build it from scrap materials, for example, from the same pallets or pallets.

Working with metal often involves treating with oils or other chemical liquids that are well absorbed into wood, so to prevent saturation of the countertop and possible fire, you need to equip a mechanic's corner. Plywood or perforated metal strip is perfect for an apron. We will also need self-tapping screws, screws, studs, glue and other small consumables.

Base

The base of the structure when placed permanently is best made from a wooden beam with a size of no less than 150*50, so the workbench can easily withstand a static load of up to 200 kg/cm and a dynamic load of up to 750 kg/cm. Among other things, wood is more ductile than metal and perfectly absorbs vibration. Of course, such legs must be made of dry hardwood or softwood and treated with impregnation.

If for some reason you don’t want to make a wooden base, you can weld it from metal. This has its pros and cons, for example, you can make adjustable supports - this is a plus. It is impossible, without losing the ability to bear a dynamic load, to make an opening for the legs in the frame - this is already a minus. Boxes for such a base are made of galvanized metal.

What to make the countertop from?

The workbench top must be durable. The best option would be a glued panel made of dry boards with a thickness of at least 25 mm. However, chipboard or MDF sheets covered with steel sheet or hardboard are also suitable. Instead of purchased boards, you can also use waste materials at hand, such as timber from pallets (pallets). The table can also be divided into two sections: one made of wood, and the second made of a rectangular metal pipe (instead of a thick metal plate). The boards will need to be treated with drying oil and a fire retardant to prevent fire.

Protective screen

Making a tabletop protective screen is very simple - just cover the entire tabletop or part of it with metal.

Such a screen allows you to significantly increase the usable area, because thanks to the holes you can make a good storage system for tools or various small items, leaving shelves and drawers for larger things.

Optional equipment

A universal workbench should be equipped not only with a vice, but also with clamps and various clamps. In addition, various equipment is additionally installed, for example, a jigsaw, a milling machine, additional power and lighting points, grinding equipment, and a dust extraction system.

Material used

To make a workbench for your garage with your own hands, two materials are used: wood and metal. The difference between these designs will be reliability and resistance to various force and mechanical influences. In this regard, a metal workbench will significantly outperform a wooden one. There are other points worth mentioning:

It is difficult to make a metal structure with your own hands, because it will require welding work, and you also need to have skills in working with metal. Processing an iron blank is also quite difficult. Therefore, to make a desktop of this type with your own hands, you will need special equipment and specific knowledge. A tree is a completely different matter. To make a wooden workbench for your garage with your own hands, you will only need a standard set of household tools - an angle grinder, a screwdriver, an electric jigsaw, a hammer, etc.

You can even use only a hand saw, but in this case the work will be a little more complicated. If we take into account the operational and technical aspects of a desktop made of one material or another, then it is necessary to highlight the large weight of the metal product and the rather low strength of the wooden workbench. The ideal option would be to combine these two materials in one product, for example, make a workbench from wood and cover its tabletop with a thin layer of iron

In this case, even the use of a vice and other similar devices will not harm it.

Thus, combining materials is an ideal solution for making a workbench for the garage with your own hands. However, if the desktop will not be used too often, but from time to time, then it is best to get by with a completely wooden structure.

Preparatory work

When equipping a garage with your own hands, it is very important to choose the right place where the workbench will be installed. The best option would be a part of the garage where there is good lighting and electrical outlets.

It is also necessary to take into account such a moment as the direction of natural light. The light should come from the left side or straight ahead. In this case, the working surface will always be illuminated.

The length of the tabletop should be such that it can easily accommodate tools and large parts required for work. Its width should not be more than 50 - 60 cm. This allows you to easily reach the opposite edge. One side can be equipped to work with an electric cutting tool: a circular saw, jigsaw, etc. For this purpose, fix the board so that it protrudes beyond the edge of the workbench by 200 - 300 mm.

Also, before you make a workbench in the garage with your own hands, you need to clarify one more parameter - its height. The ease of carrying out the work depends on how correctly it is determined. To determine the height, you need to stand up straight, bend your elbows and mentally lean on an imaginary table. The distance between the floor and bent arms will be the ideal height for the future design.

Required tools and materials

To make a workbench in the garage, you will need the following tools:

- a grinder with a grinding disc and a circle for cutting metal;

- level;

- screwdriver;

- drill;

- welding machine and electrodes;

- roulette;

- jigsaw for cutting plywood.

Materials:

- corner 4 mm thick;

- steel strip 4 mm thick;

- steel sheet required for the manufacture of holders for drawers with a thickness of 2 mm;

- plywood for making the back and side walls of the table and drawers, 15 mm thick;

- screws;

- anchor bolts;

- square pipe 2 mm thick;

- steel sheet that will be used for the countertop, 2 mm thick;

- wooden boards for tabletops 50 mm thick;

- guides for table drawers;

- metal screws;

- paint for metal and wood.

A structure made from these materials will be reliable and very durable. Boards will be used for niches and shelves, and steel strips will be needed to create edges on the table surface.

Ways to minimize the cost of organizing a garage

You can minimize the cost of arranging a garage by making your own racks, shelves, and storage systems. Advice from experienced car owners will help reduce costs:

- Heating and cooling a room can be done using the same device: an air conditioner.

- Proper installation of natural ventilation will help you avoid buying a fan for a forced ventilation device. For this purpose, one pipe built into the wall is placed at a distance of 20-30 cm above the floor, and the second - on the opposite wall at a distance of 30-40 cm from the ceiling.

- The best insulation for walls and ceilings is polystyrene foam. Unlike mineral wool, it does not absorb moisture and does not lose its thermal insulation properties.

- The most inexpensive method of interior finishing is plastering followed by whitewashing with water-based emulsion.

- For wall cladding, you can make your own gypsum tiles with a “brick” or “natural stone” surface.

- Instead of expensive store-bought storage systems with many drawers, you can sew (or order from a studio) fabrics with numerous pockets.

Which material to choose

The material of the workbench is determined by the purpose of the device. If the table is needed for simple work, and heavy loads will not be placed on it, then wood will do just fine. To make a workbench, a 50x100 mm timber is suitable, from which the frame is assembled, fastening it with bolts or self-tapping screws. To make the structure stronger, wooden spacers are used between the legs at the top and bottom. The lower spacers are mounted at a level of 15 cm from the floor.

For the countertop, it is better to use planed hardwood boards, such as oak. In the absence of such, moisture-resistant plywood will do. Its thickness must be at least 40 mm.

Despite the ease of making a workbench from wood, it still has some disadvantages:

- not designed for heavy loads;

- it is problematic to install several tools, for example, a drilling machine, a vice, etc.;

- fragility of the material;

- wood absorbs oil and other substances, metal shavings get stuck in it;

- there is a risk of fire.

A metal workbench is devoid of the listed disadvantages. This table has:

- high reliability;

- small in size;

- sustainability;

- possibility of reliable fastening of tools;

- ease of care;

- safety in case of fire.

However, in terms of financial and time costs, such a table is inferior to a wooden structure.

Bed: metal or wood?

A stationary wooden workbench has advantages over one on a steel frame not only in lower cost and labor intensity. Wood, firstly, is not plastic. A workbench on a wooden base can be broken, but if the wood used is seasoned and treated, it will never bend. Secondly, wood perfectly dampens vibrations. The foundations of your buildings are not reinforced vibration-absorbing ones, like workshops in a factory? And the overall strength and stability of the home workbench frame will be fully ensured by commercial coniferous wood of ordinary quality.

Wooden workbench frames

The design of a wooden workbench frame made from 120x40 boards is shown on the left in Fig. Permissible static load – 150 kgf; dynamic vertically downward for 1 s – 600 kgf. Corner posts (legs) are assembled on 6x70 self-tapping screws in a zigzag (snake) pattern with a distance from the edge of 30 mm and a pitch of 100-120 mm. Double-sided fastening; the snakes on both sides of the package are made in mirror image. Intermediate support beams are fastened with steel angles on self-tapping screws; the edge ones - with pairs of self-tapping screws at the tenons of the posts and, on the outside, with corners.

If timber 150x50 or (180...200)x60 is available, the design can be simplified, as shown in the center in Fig. The load-bearing capacity will increase to 200/750 kgf. And from timber 150x150, 150x75 and (180...200)x60 you can build a frame capable of bearing 450 kgf in statics and 1200 in dynamics, on the right in Fig.

Note: any of these beds is suitable for both carpentry and metalworking workbenches. Under the joinery, a box-shaped lid is placed on it (see below), and under the fitter, a tray from a 60x60x4 angle with welded 4-mm strips above the intermediate beams is placed. A wooden cushion is placed in the tray and covered with steel, also see below.

If there is no welding

An all-wood workbench, without the need for welding work for its manufacture, can be made according to the following scheme. rice. The “trick” here is the tabletop, glued together from 75x50 lumber and fastened with ties. If the beam is oak, then the permissible load is 400/1300 kgf. Corner posts – timber 150x150; the rest is timber 150x75.

All-wood workbench design

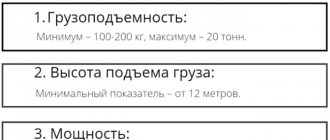

It happens the other way around: metal is more accessible than wood, and welding is available. Then the workbench table for a load of 100/300 kgf can be assembled according to the drawing on the left in Fig. Materials – corner 35x35x3 and 20x20x2. Boxes are made of galvanized steel. Disadvantage - it is impossible to make an opening at the bottom for the legs; the structure will lose its ability to bear dynamic loads.

Metal workbench frames

For a load of 200/600, a more convenient metal workbench according to the diagram at the top right, made of corrugated pipe 50x50 (corner posts), 30x30 (other vertical parts) and a corner 30x30x3, is suitable. The plank cushion of both workbenches is laid only across (bottom right) from tongue-and-groove boards (120...150)x40.

Shelf – steel 2 mm. The shelf is attached to the pillow with 4x(30...35) self-tapping screws, a pair at each edge of each board, and along the outer boards - in increments of (60...70) mm. Only in this design will the workbench show the specified load-bearing capacity.

These workbenches are already universal: for carpentry, the lid is turned over with the wooden side up or adjusted as described below. A bench vise is mounted on a wooden pad, but is not secured with a clamp. A collet anchor for an M10-M14 bolt is driven into the vice pad from below, and a through hole is drilled in the cover for it. A 60x2 washer is placed under the bolt head. This solution is convenient because it is possible to use inexpensive non-rotating vices.

Types of workbenches

There are carpentry and metal workbenches. The former are used for working with wood, the latter are intended for metals and other complex materials. There are options for dividing according to other criteria, for example, into single-seat and multi-seat, but they are not so important.

Next, we will consider the manufacture of an outdoor workbench. Its specificity is that it should not be placed in a workshop, but directly in the fresh air - for example, on a plot. Often such workbenches are placed on wheels so that they can be rolled into a dry place in bad weather, or they have a folding table top. The examples will examine the creation of a single-seat carpentry workbench.

Folding carpentry workbench

You can make a variety of designs for your workshop table with your own hands. The previously presented step-by-step instructions allow you to get a rather massive structure, the installation of which will require a lot of free space. If desired, you can also create a structure that will fold and unfold if necessary.

The folding carpentry workbench for the workshop is characterized as follows:

- When connecting all elements, bolts and other detachable elements are used. Due to this, you can quickly disassemble the structure. Welding is practically not used in this case. The use of bolts and screws significantly reduces the rigidity of the structure. Therefore, folding workbenches are used when performing minor work.

- As a rule, lightweight materials are used to increase the mobility of the workbench. An example is various thin-walled profiles. It is best to choose a metal that does not react to exposure to high humidity. That is why the workbench will last quite a long time.

- Some schemes provide for the creation of movable elements that significantly increase the functionality of the device. An example is the case when the tabletop should be placed at a certain angle to the load-bearing element. Due to this, a fairly large number of guides are placed.

These points should be taken into account when creating a homemade folding workbench.

In conclusion, we note that a purchased workbench has a fairly high cost. That is why many decide to make the structure with their own hands. Of course, this will require metal and other elements that can only be purchased.

What material is better to make a workbench for the garage with your own hands?

There are several options for making a desktop. According to the type of material used for manufacturing, workbenches are:

- wooden;

- metal;

- combined.

Combination workbenches use a wooden base and a metal sheet to reinforce the worktop. In addition, the design contains metal combs, as well as threaded screws. Combined devices include metal tables with drawers and tool shelves made of wood.

Advantages and disadvantages of a wooden workbench in the garage

The choice of material for making a table is primarily determined by its purpose. A wooden workbench in a garage is usually installed in cases where you need to quickly organize a workspace to perform simple operations. To create the frame part, you can use boards measuring 4x8 cm or timber measuring 5x10 cm. The rectangular base is assembled taking into account standard dimensions, and its components are fixed with nails or self-tapping screws.

A wooden workbench is installed in cases where it is necessary to quickly organize a workplace

To strengthen the structure, wooden spacers are installed in the upper and lower parts between the legs. The lower ones, which are located at a height of 15 cm from the floor, can be used as a basis for a shelf. To assemble the tabletop, a planed tongue-and-groove board made of oak or beech is suitable. You can also use a couple of sheets of moisture-resistant plywood 1.8 cm thick, which are glued together and sheathed along the edges.

To create a workbench in your garage out of wood with your own hands, you don’t need much effort or skill in handling a welding machine. The set of tools is minimal (electric jigsaw and drill), and the process itself takes much less time than manufacturing a metal structure.

On the other hand, a wooden table has many disadvantages:

- not able to withstand significant power loads;

- the working surface is not intended for the installation of several tools, which does not allow the simultaneous use of a heavy bench vice and sharpening or drilling;

- the wooden frame is short-lived;

- wood reacts poorly to humidity and contact with various paints, oils and other substances;

- there is a risk of fire.

The disadvantage of a wooden workbench is its inability to withstand large force loads

Advantages and disadvantages of a metal workbench for a garage

To assemble a welding table with your own hands, you will need special equipment and skills in handling it. The workbench elements are connected by welding. Not every craftsman can produce a high-quality metal structure. In addition, the table turns out to be very heavy, and the material itself, unlike wood, is not cheap.

Related article:

On the other hand, workbenches in a metal garage have many advantages that many car owners will appreciate:

- compactness with a high degree of reliability;

- ability to withstand severe mechanical loads;

- increased weight of the structure, making it more stable;

- a large selection of modifications (the design can be folding, mobile, shortened or with a folding tabletop);

- strength and reliability of all connections;

- fire safety;

- durability and ease of maintenance;

- the absence of sharp corners makes the tabletop safe;

- the working surface allows you to install two sets of vices;

- due to the high strength of the material, the table can be used for cutting and sawing, as well as grinding and turning metal and wooden parts;

- the space under the tabletop can be used to install shelves, organizers, grids and tool boxes;

- metal shavings do not damage the surface.

Types of workbench

There are several types of workbench. Each of them has some characteristic features. In turn, they are divided into:

Locksmith. It is intended for metal work. The tabletop of this product is made of a high-strength metal alloy. This is necessary for safety. While working on iron, sparks may be present.

In addition, the use of lubricants may leave marks on the wooden surface. The iron base does not require special care.

Carpentry. Its surface is made of solid wood. A carpenter's workbench is used for woodworking. These products do not have high strength and versatility, unlike metalwork.

The universal table has a metal and wooden tabletop in its design. The drawing of the workbench shows the structure of the carpentry work area.

Workbench: this is the main element of the woodworker's workshop

In any workshop where they work with wood, there is always a carpentry workbench. Regardless of how the material is processed (manually or using a power tool), the presence of this element allows not only to properly organize the workspace, but also to make it more convenient and comfortable. All this ultimately affects the result. In such conditions, the productivity of the master and the quality of his work increase.

Any carpenter cannot do his work without a workbench.

A workbench is a work table that is used for processing wooden products manually or mechanically. Its design and ergonomic capabilities are designed in such a way that it is convenient for the master to fix parts in different positions to perform various tasks.

The workbench allows you to perform the following operations:

- assembly of wooden structures;

- production of wood parts;

- processing of workpieces with varnishing compounds and other means.

A carpentry workbench is a table on which a craftsman processes wood products. Note! A traditional carpenter's workbench is designed for working with lumber whose length does not exceed 3-3.5 m. To work with longer workpieces, you will have to use a carpenter's workbench.

What is a workbench

The workbench is the basis of all plumbing work. It is believed that the birthplace of the workbench is Germany. It is a multifunctional table for performing metalworking, electrical, technical work and metal or wood processing. It is equipped with a large number of racks, cabinets and shelves.

Workbench layout.

A vice and other tools necessary for work are installed on it. During the work, you can use any other power tool. Places and attachments for drawings and other technological documentation are also often provided.

Among its other advantages, I would like to note functionality, durability and reliability. The workbench is able to withstand enormous loads and remain intact and undamaged afterward. This is not just a table, but a whole mini workshop with the ability to store tools, parts and workpieces.

The more shelves, cabinets and drawers, the more functional the design, and the easier it is to work on it.

If the workbench is single-seater, then its dimensions must correspond to the following parameters: height 0.8-0.9 m, width 0.7-0.8 m, length 1.2-1.5 m. The design and adjustable height 50 will be more convenient -250 mm. If the workbench is double/multiple, it is increased in length.

The workbench will serve as a good assistant to any craftsman, and the garage where it is located can already be considered a real workshop.

How to make a wooden workbench

An alternative to inexpensive and easy-to-use equipment is a wooden workbench table, made in the garage with your own hands. To make it, you will need:

- board with a treated surface, 40-50 mm long;

- rectangular box made of timber;

- self-tapping screws, nails, screws.

Tool:

- screwdriver or screwdriver;

- saw (hand or circular);

- hacksaw;

- roulette.

Cutting and assembling material for a wooden workbench will not be difficult for one person. The basic rule is to follow the sequence during the assembly stages:

- The first step is to make the vertical legs of the future design.

- The next stage is the assembly of two spatial devices. To do this, we connect the base of the table surface and the frame. The resulting design is a finished frame.

- We install the countertop in the selected location in the garage. We fix it with a beam on the back side for a stable position and rigidity. Attach carefully - be careful not to get into the transition points of the crossbars into the frames.

- Finally, we put a shelf at the bottom. The board can be taken with a small thickness.

- We treat the entire wooden surface with a special fire-retardant compound and water-based varnish.

Workbench for the garage: its purpose and types

Initially, the workbench was used exclusively for woodworking , and its main task was to secure the workpiece to support the use of tools. To do this, they cut out holes of various shapes along the edge of the tabletop, hammered in wedges, and inserted combs and blocks for support or as guides. This workbench is called classic .

The simplest workbench design looks like this:

- supporting frame with legs;

- thick table top with a powerful surface;

- additional shelf under the tabletop for storing tools and accessories;

- shelves or drawers that increase storage space.

Improvements in tools and the advent of electrical equipment affected the modification of the workbench . And manual processing of a new material - metal - created a completely new type of workbench for metalwork. This is how by purpose today:

DIY garage table - photo options:

A work desk in a garage can be designed for a different number of workers, or zoning locations.

In this case, workbenches are distinguished:

The addition of the capabilities of a specialized workplace has given rise to the following varieties:

- folding;

- mobile (on wheels);

- wall-mounted folding workbench;

- workbench cabinet (with sections for storing tools).

Based on the material from which the work table for processing materials is made, there are:

- wooden (made of durable wood);

- metal (welded structures);

- combined (the wooden base is reinforced with a metal sheet on the tabletop, supplemented with metal combs, threaded screws; the metal body is equipped with wooden shelves and drawers).

Design Features

A workbench is a multifunctional table on which various work is carried out on the manufacture and repair of any metal, wood or other products. It is complemented by various drawers and shelves for power tools, spare parts, small parts, fastening and construction items. The universal table is useful for both welders and motorists, and thanks to its simple design it is quite easy to assemble.

You can make a workbench with your own hands in other sizes, taking into account your individual characteristics. Making a workbench is not difficult; materials that can be found in any hardware store, in the country house or in the garage are suitable for this. You can set up a work area in an apartment on a balcony or loggia, in a private house in the basement (if there is no garage or separate workshop) or under a canopy (outdoor option). The unpretentiousness of the design allows you to install workbenches not only for the home, but also in a home car service.

You need to choose not only a suitable workbench model, you also need to take into account its location in the room. The table should be located near a window or other source of lighting and be equipped with additional lighting. The drawing must be drawn up taking into account whether you are right-handed or left-handed.

You need to think through the design down to the smallest detail: what the base materials will be, whether the table will be roll-out or stationary, the number of sockets that may be needed, and much more. The more detailed you are about your ideal workplace, the easier it will be to bring your idea to life. There is no need to use industrial workbenches as a basis; it is labor-intensive and requires a lot of financial investment.

Locksmith table for garage

In order to correctly make the frame of the structure, you must first obtain a drawing or plan of the table. With the help of a clear model, you will be able to correctly imagine the finished result and carry out all the work step by step. If you need not only carpentry in the garage, but also a place for processing steel objects, then you can go according to the following plan:

- To give the frame rigidity, it is necessary to use an iron corner (the thickness of the corner is 5 mm, and the edge must be at least 35 mm),

- As a tabletop, you can use a 2 mm sheet of steel,

- We straighten the metal sheet and fix it either on a 50 mm board or weld it to a frame from a corner,

- For pull-out shelves there is no need to use thick boards - simple plywood will do,

- In the form of corners for drawers, you can use a 3 mm corner,

- If you do not need a portable or folding table for the garage, then you can make a stationary frame secured with anchor bolts,

- We weld the metal tabletop along the contour to the corner and clean the drops until smooth.

A metal garage table is a versatile option for any room. By making a wooden work table for the garage with your own hands, you can create a convenient place for processing any products. Next to such a workbench, you also need to make your own chair for the garage.

Design options

The functionality of a garage workbench depends on its design. For convenience, it is equipped with additional elements. Depending on the type of occupation, a workplace in the garage includes:

- Frame with legs. Serves as a supporting element on which the remaining parts are supported.

- Tabletop. The surface chosen is powerful, capable of withstanding hammer blows and the weight of placed objects. It can be made from a thick board or sheet metal; a combined design is relevant.

- Nightstand. Equip one or two compartments along the edges of the workbench. The internal content may consist of shelves and drawers designed for storing small tools in the garage.

- Additional shelf. Located on the wall in front of the workbench, its function is also to store available tools.

For work, it is better to choose a table or wall lamp with the ability to adjust the direction of light. There must be an outlet near the desktop, which is designed not only to provide lighting, but also to operate all power tools.

The idea of making a folding workbench in the garage with your own hands is not very practical. The main purpose of the folding structure on two legs is to save free space in the garage. In this case, the tabletop will be attached to the wall and will be in a raised state when it is not needed. But the essence of a workbench is a well-equipped workplace, when everything you need is at hand. And with a folding tabletop, the space under it should be free; there can be no talk of any bedside tables or shelves. This option is acceptable for garage owners who have limited space and who rarely need a workbench.

Mechanic's workbench

This device is distinguished by its functionality and durability.

On the working surface of the bench, you can fix workpieces intended for processing, and the pull-out shelves are very practical for storing technical equipment.

Mechanic's workbench

The height of the structure is adjustable.

The main elements of a workbench of this type include the bench (its base) and the lid (working surface).

Components of a carpentry workbench

The benchtop of a bench is usually made from hardwood. However, pine is used for the underlayment.

The thickness of the cover measures approximately 60–80 mm and 500 mm in width. The parameters of the workbench depend on the main purposes of making the workbench.

The understand can be collapsible or stationary. Since the device is easy to assemble and disassemble, it is convenient to use during transportation.

Collapsible workbench

If the workbench base is made of metal, then planks are additionally attached to its base to protect it from various defects. For this purpose, the tabletop is covered with linoleum. This method will prevent small elements from falling into the cracks on the desktop.

It is recommended to install high sides on the workbench lid so that small parts being processed do not roll off the surface. A protective partition will isolate the workplace and prevent chips from flying out during metalworking.

The sides will prevent small parts from rolling off

A workbench for your home requires at least several shelves and drawers.

You can fill the space under the countertop of the device with a variety of cabinets in which it will be convenient to store building materials.

For the convenience of working at the workbench, you will need to install sockets, especially if you frequently use power tools.

In large production, it is better to use roller workbenches. This will allow you to freely move them to the desired place.

Workbench on wheels

Construction of an inspection pit

Of course, you should take care of the presence of an inspection hole at the construction stage of the structure itself, strengthening the foundation and constructing the base. But no one forbids adding it to the garage when it has already been built.

Of course, when there is no particular desire to completely immerse yourself in the nuances of construction work, you can turn to qualified specialists for help, who will help you complete the garage with such a plinth for a monetary reward.

The inspection hole, in addition to its main purpose, can also be used as a cellar. This, by the way, is a very interesting idea. In addition, entering the cellar through an inspection hole, especially when it is equipped with a stepped entrance, is much more practical than in the case of a free-standing basement with a vertical iron staircase.

When constructing a viewing hole, you should adhere to the following basic principles:

- The inspection pit is concreted and waterproofed along the entire perimeter: walls, floor. This will prevent further penetration of moisture during rising groundwater, precipitation and melting snow. Also, concrete walls crumble, thereby not endangering the motorist who is under the car while it is being serviced.

- As was previously the case, in order to comfortably descend into the inspection hole, it is better to equip it with a convenient ladder.

- It is advisable to equip the inspection hole with a drain hole. This will allow water and other liquids that accidentally fall on the floor to drain away. This hole is equipped with a grate.

- Don’t forget to think about opening/closing the inspection hole. Keeping it open all the time is unsafe. The optimal solution would be a sliding deck equipped with small handles.

- Also, at the stage of constructing an inspection pit, it is worth thinking about organizing work directly in it. Everything necessary for carrying out repair work should be at hand. You can make shelves and niches in the walls where the owner stores tools.

- And yes, it is definitely worthwhile to provide lighting in the inspection hole. Having good lighting makes working much easier.

Safety requirements for a homemade workbench design

Any design must first be safe, and then functional and practical.

Drawing of a workbench for garage work.

Working on a workbench carries potential danger, so it must meet the following requirements:

The workbench must be securely fixed to the floor and not wobble during work. A table covered with sheet steel must be equipped with a protective mesh at least 1 meter high, running along the entire length of the workbench. The workplace should be designed conveniently and ergonomically: everything is at hand and nothing interferes with the work process. The corners of the tabletop should not have sharp edges. The wedges in the holes should be attached firmly, but not so tightly that the edges do not chip. The holes are made the same size. The screws are well lubricated to ensure smooth movement of the workbench running parts. They are made of metal, less often wooden

At the end of the work, they should be loosened slightly and kept loose. The surface of the tabletop is sanded; it is important to achieve smoothness and absence of defects. The working surface must be constantly cleaned of chips and oil. Keep the floor near the workbench clean, otherwise injury may occur. The jaws of the vice must have soft gaskets to ensure reliable fixation of the workpieces. When using multiple vises, they should be spaced at least one meter apart. It is necessary to use vibration-damping rubber pads when working with power tools. You should not place hot things on the workbench, spill water on them, or place heating appliances near it. When drilling, sawing and other work that can damage the surface of the tabletop, you should place a protective board under the workpiece. A properly designed workbench can withstand a load of about 200 kilograms.

Important! The master must also remember about his safety. The workplace should be well lit, the tools should be in good working order, the vice should be equipped with an unworked notch and the parts should be firmly secured

You should work in special safety glasses.

More advanced requirements for work tables are described in GOST 20400 and GOST 22046. The workbench must meet all safety requirements and only after all conditions have been met should you start working.

Assembly steps

First you need to prepare the previously measured workpieces. To do this, use a grinder to cut off all the required metal and wooden parts, after which you can begin assembling the equipment.

- The first step is to weld the main frame elements. To do this, two parts of the frame are connected: lower and upper, after which the body of the workbench is assembled, and four legs are welded to it. The height of the legs, which are made from pipe blanks, should not be higher than one meter. The main part of the structure is ready.

- To give the structure strength, it should be strengthened. To do this, it will be necessary to weld additional stiffeners, which consist of corners and steel strips.

- Next, you should make a protective screen from a steel sheet. To do this, you need to weld racks of corners at the corners of the tabletop, and then cover them on top with a horizontal corner over the entire surface. To strengthen the structure, additional stiffeners can be welded. After this, the screen is sheathed with a sheet of durable plywood.

- Drawers and shelves are made from plywood. They are assembled using small corners. After this, the guide elements should be installed and the handles secured, treated with impregnation and painted.

- The selected material is installed on top of the tabletop - it can be a sheet of plywood, several boards or DSP. Then the tabletop is fixed to the frame using self-tapping screws.

- A steel sheet is again attached to the top of the installed and secured work surface, cut around the perimeter of the table and painted over.

- After this, all that remains is to insert the previously prepared drawers and shelves, as well as all the fixing elements on the screen for attaching various tools.

- At the end, plumbing tools are installed and fastened on top of the tabletop: a vice, sharpening, and so on. Garage equipment is laid out on the shelves, and tools are hung on the screen.

Upon completion of all work, the structural elements must be degreased and painted over. It is best to choose hammer paint, since it is resistant to many external influences and mechanical damage.

Drawings and dimensions of workbenches

The workbench can be assembled of any size, but for ease of work it is better to stick to the optimal dimensions. Therefore, first you need to prepare drawings and diagrams where all the exact parameters of the table will be displayed.

The main indicators include:

- length. The parameter is determined by what work will be done on the table, as well as the free space in the room. On average, the length chosen is about 2 m;

- width. The workbench is installed, as a rule, along the wall, and it should be possible to reach the tools located on the shelf or in the bedside table. It is recommended to make the width no more than 60 cm when placing the workbench next to the wall;

- height. This parameter depends on the person’s height. The standard value is 0.8-1 m.

The structure of a universal workbench

A workbench, like any other specialized furniture, has several options that differ in shape, size, type of construction and purpose. But traditionally, the workbench model has several components:

- The tabletop is the right size.

- An underframe with compartments for storing tools and drawers.

Directly on the tabletop itself there are vices (clamps), carpentry tools, planes, and wood processing machines.

Other types of tools can be installed on the surface of the workbench, depending on the purpose of the structure and the professional occupation of the owner of the workshop or garage.

Step-by-step instructions for making a workbench for a garage

Assembling the support frame

Let's consider an approximate procedure for assembling a metal workbench. The following operations must be performed:

According to the assembly drawing, parts of the appropriate length are cut to assemble the support frame. A rectangular pipe, angle steel or other types of rolled products selected for this purpose are used. The frame is being welded. First, the support platform for the tabletop is welded, then it is turned over and the supports and frame of the cabinet are welded. Drawer guides are installed and side panels are attached. Weld seams are cleaned using a grinder, burrs and sharp edges formed during metal cutting are removed. The workbench is turned over and installed in a pre-selected place. The required number of boards to cover the table top is cut from sheet material or cut to length. The surface is installed and finished. Depending on the type of construction, a back wall is attached to the rear edge of the tabletop, which prevents tools or parts from rolling off and falling behind the workbench.

In a garage, this is very important, since it will be extremely difficult to find a rolled small screw. The instrument panel is assembled and hung on the wall. Typically a sheet of plywood is used with rows of holes into which rods are inserted to hang the tool. The racks are assembled in a similar way: welding the frame, installing the planes and hanging them on the walls or installing them with fixation to them

All edges are carefully processed and cleaned, sharp corners are rounded. The finished structure is painted, after the paint has dried, lighting is installed, tools are placed, a vice, emery and other necessary equipment are attached.

The listed operations refer to the basic, most necessary actions. Depending on the type of structure and the presence of additional elements, other assembly steps may be required. In order to avoid mistakes, it is recommended to think through the order of work when creating a working drawing. It is necessary to follow the points of the plan to increase the speed of work and eliminate confusion in assembling the structure.

DIY garage compressor

A compressor is needed in any garage. And, by the way, this is not the most difficult homemade product for the garage. A low-power compressor for the garage for inflating tires and other small jobs can be made with your own hands from auxiliary materials. For example, from a compressor from a refrigerator. For this you will need:

- refrigerator compressor;

- a sealed cylinder with thick walls (you can use a fire extinguisher flask or a small gas cylinder);

- safety valve 8 atm;

- pressure gauge;

- fitting;

- oxygen hoses with couplings (select the length based on the size of your spare parts);

- base for the compressor - a thick board or piece of plywood will do.

In order not to pump any nasty stuff into the tires, it is advisable to also install a filter to separate oils, dust and other contaminants. The diagram of a homemade compressor is shown in the photo.

Homemade compressor diagram

The compressor must have a starting device. We plug it into the network, see which tube the air is sucked into, and mark it. You can put a car filter on it - clean air will be pumped in.

We assemble an oil separator receiver from a cylinder and a safety valve. To do this, we cut two fittings into the cylinder - for air inlet and outlet. We place a safety valve on the inlet hole and connect the compressor outlet to it using an oxygen hose.

Homemade compressor for the garage based on a compressor from a refrigerator

We install another automobile oil filter at the outlet of the oil separator receiver to completely remove the oil. We connect the filter to the pressure gauge, and from it comes a hose, which is connected to the tire through the appropriate adapter.

Assembly is complete. But in order to carry this device comfortably, everything needs to be secured in some way. You can weld the frame to size, attach wheels and a handle for easy transportation. One of the compressor options for inflating wheels is described in the video. There is no receiver, but its functions are performed by an oil filter. You can do it this way, but with a receiver the design is more reliable.

Since the compressor in the refrigerator is low-power, it may take a long time to inflate the tires. You can make it more powerful by installing two compressors that will start simultaneously. Accordingly, the pressure will build up twice as fast. But such an installation requires a more robust security group. Such homemade products require a little more equipment, since the circuit is still more complicated.

Requirements for a workbench in the garage: dimensions of the structure

In order not to lose sight of anything important, you must make a preliminary plan for the manufacture and assembly of a workbench with your own hands; a drawing with dimensions is one of its main points. This takes into account the area of the garage and the size of the vehicle.

On average, the length of a workbench in a garage is about 1.5-2 m.

The length of the table depends on the amount of free space in the garage, as well as on the intended types of work. On average, this figure is about 1.5-2 m. When choosing the width for a future workbench, you need to take into account the nature of the placement of tools and other objects around the table. Shelves on the wall must be freely accessible. For this reason, it is undesirable to make a tabletop more than 60 cm wide, otherwise you will not be able to reach the necessary tools with your hand. If the workbench is located in the center of the room, then the width of its working surface can be increased.

The height of the bench is selected individually. The dimensions of a desktop differ significantly from the dimensions of a dining table. They are calculated taking into account the height of the master, as well as the position in which he is used to working. The standard figure is 80 cm. However, working at such a table in a standing position will be inconvenient. To prevent your back from getting tired, it is recommended to increase the height to 100 cm.

There is an effective way to accurately determine the optimal height of the workbench. To do this, you need to take a position in which it will be comfortable to rest your elbows on the table while standing. All that remains is to measure the distance from the elbows to the floor.

On a note! If the design of the workbench is designed for work in a standing position, it is necessary to provide a wooden stand for the chair in case you want to sit at the table.

The standard height of a table in a garage is 80 cm.

On one side of the workbench a power tool is installed. This edge of the tabletop should protrude beyond the frame by about 20-30 cm. If the work surface is made of wood, it should be protected with a metal sheet. Stainless steel with a thickness of 1.5-2 mm is best suited for these purposes. Although a regular steel sheet 1.5 mm thick will be cheaper.

Installation location

When choosing a location for a workbench, there are several nuances to consider that can make the installation process easier.

- You need to choose a part of the garage that is very well lit and has access to sockets. It is best if natural light falls either directly or from the left side.

- The length of the working surface should be such that large parts can be placed without problems.

- The width should not exceed 60 centimeters - in order to easily reach the opposite side of the tabletop.

- The height of the stand should be such that it is as comfortable as possible to work at the workbench.

- The workbench should be located in such a way as not to impede the entry of the car into the garage and ensure the free opening of the door.

- It is necessary to design the placement of equipment so that you can safely work on it without driving the car out of the garage.

Preparatory work

Creating a drawing of a workbench is an obligatory part of the preparatory stage

Preparation for assembling a workbench consists of determining the design features, choosing the dimensions and installation location of the structure. In order to ensure that not a single moment escapes attention or is forgotten, it is recommended to create a working drawing of the workbench, made to scale with reference to the size of the garage

Particular attention should be paid to the height of the tabletop - it differs significantly from the height of a regular dining table. The optimal option is the height from the floor to the bend of the elbows of a person standing straight

Considering the difference in height between different people, assembling the optimal workbench for yourself can be a very useful exercise.

In addition, we must remember that the width of the tabletop should not be too large. The size of the garage is relatively small; you often have to work next to a car parked inside.

You will need space for a person to pass through, so the optimal width is considered to be 50 cm. You also need to decide on the size of the shield for the tools that are needed most often.

Features of the workbench design

A workbench for a garage is often compared to a desk because it provides convenience for a variety of tasks and makes it possible to keep all the necessary tools at hand. Thus, in addition to the tabletop, it has a large number of shelves and drawers. The design of the workbench consists of the following elements:

- The supporting element is a frame with legs. Everything else rests on it.

- Tabletop. Presented as a thick and powerful surface that can withstand hammer blows. Made from sheet metal or thick board.

- Nightstand. There may be one or two and they are located at the edges of the tabletop. They are equipped with shelves, drawers, or both. They usually store small tools or spare parts.

- Additional shelf. It is mounted under the countertop and is most often used for storing various fixtures, tools and other necessary things that may be needed during repair work.

The workbench must be well lit. To do this, install a stationary rotating lamp, which is plugged into an outlet. It can be installed on the wall, near the workbench, but it is much more practical to build electrical equipment directly into it. In this case, there will be no problems with electrification if you need to install the table in a new place.

Workbenches for garage

Purpose

A workbench is a craftsman’s workplace used for repairing building materials.

Home workbenches are designed for carpentry, metalworking and carpentry work.

A carpenter's workbench is a small table (1×6 m), which has stops for processing workpieces.

Carpenter's workbench

Workbenches are made of wood or metal.

It is preferable for an auto mechanic to choose a workbench made of metal, and for a mechanic to choose one made of wood.

The structures are easy to assemble and disassemble, so there are practically no difficulties when transporting them.

Metal bench

The use of the design is quite common in various fields of activity. Workbenches are widely used both in utility rooms and in large-scale production enterprises.

Additional accessories that can be equipped with a workbench provide convenience when processing building materials.

A workbench for home intensifies the work process

That is why, when manufacturing it, it is important to take into account the scope of production and the layout of the room in which it will be located.

Compact workbench for small spaces

When there is not enough space to install a workbench of standard sizes, you can build a workbench consisting of one bedside table and place it on the loggia.

Technology for creating a carpentry workbench with your own hands: drawings, dimensions and procedure

The most convenient option for a private home or garage is a design with a hinged lid. Unlike a folding workbench, its working surface rotates rather than unfolds. This design option has a completely different structure, although it is no less functional and compact.

Drawing of a wooden carpentry workbench with dimensions.

Mobility is achieved due to the presence of wheels installed on the bottom. To prevent arbitrary movement of the structure, it is advisable to use rollers with a locking function. As a last resort, you can install a wedge under the wheels, but this option is not so convenient and practical.

On the right side of the design there are pull-out drawers for convenient storage of small items. If the table will be used by a left-handed master, they should be placed on the other side so that everything you need is at hand. In addition, the workbench is equipped with a special holder. It is made of perforated plywood and mounted on the back of the cabinet. Thus, it becomes possible to make maximum use of the surface of the workbench and organize additional space for storing small tools for carpentry.

On the left or right (for left-handers) there is an open compartment in the design. It is suitable for placing narrow, tall equipment such as a drilling machine. Thanks to the roller mounted on the edge of the tabletop, the process of processing long lumber is greatly simplified, and due to the multi-socket outlet, you can simultaneously connect several tools to the network.

Racks and tool boxes

If you type the phrase into a search engine: “how best to place tools in a garage or workshop,” the Internet will return dozens of options and hundreds of photos. Often, these are beautiful and expensive devices from foreign sites. We need something of our own - native, and preferably cheap or even free. And we have it! Let's turn to the personal experience of FORUMHOUSE users.

Vreeon

Tell us how you place the tool in the workshop so that it is out of the way and always at hand? Especially if there is a lot of it.

Andrey 203Administrator FORUMHOUSE

I try to buy power tools in cases. If there is no case, then I store the tools in the original box.

vreeon

What to do if there are no cases or boxes?

OlegychModerator FORUMHOUSE

I cut strips from 5 to 25 cm wide from plywood 1 cm thick. I run them through a woodworking machine with a saw blade. It turns out to be a groove. Then I assemble boxes with a sliding lid from these strips. Box size for a specific tool. If you need to store small items, I make an additional compartment.

A description is, of course, good, but when it comes to storing tools, it is better to see once than to hear a hundred times. See what portal users offer.

Qzmich-NN

I refused to buy ready-made “organizers” for the tool. I made a drawer. I drilled holes in the laminated chipboard cover for a specific tool. Now you can’t put a flat-head screwdriver in place of a Phillips head.

And these are life hacks from Ivanrin. All tools are laid out in their places on the shelves.

To maintain order in the workshop, immediately, and not later, put the tool back where you got it from.

Ivanrin

I was lucky, I was able to buy used metal shelving from a store on the cheap. I took 7 pcs. The width of the shelves is 500 mm. Now my instrument has room to roam.

The shelves can withstand loads of up to 50 kg.

This “storage” looks neat and there is enough space for everything.

Experience shows that the optimal depth of shelves is no more than 40-50 cm. If it is deeper, then you will have to climb far to get the tool. It is not comfortable. True, there is a nuance: storing various small things in jars and containers is more convenient on shallow shelves, 15-20 cm wide.

Convenient containers for small items, made from plastic meat or salad trays.

Ivanrin's workshop after putting things in order.

And this is a homemade plywood box for storing a jigsaw, which was made by ShmulikShleperson.

Comfortable. Practical. Mobile.

Making your own compressor

An air compressor is a useful craft that can spray paint. To make it yourself, you will need a car accessory used to inflate wheels. The compressor must be powerful - quickly create pressure up to six atmospheres, without loading the engine, and also productive - release compressed air quickly, giving a strong flow. To combine both performance and power, you need a high-speed engine equipped with a positive displacement piston system. The device can overheat, which will inevitably lead to stops during operation, so you will have to organize sufficient cooling for the cylinders. To reduce the cost of the design, a receiver is used - a storage tank, which is a steel cylinder. To make a small compressor, take an electric motor from a toy or a device that supplies water to an aquarium with fish.