“Iron casting” has been known to mankind since time immemorial. Nowadays, it is widely used in many areas of the national economy and is called cast iron. And while the average person may not know about crankshafts, gear housings, wheel hubs, fittings, everyone knows about frying pans, cast iron pots, radiators, bathtubs, grates and other cast iron products.

The metallurgical industry produces various simple and special types of cast iron, each of which has its own scope of application.

Classification of cast irons

Cast iron smelted in blast furnaces can differ in its physical and chemical nature depending on the iron ore being processed.

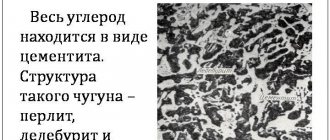

Practice has shown that if iron ore has a high manganese content in its composition, then cast iron with a cementite structure is obtained. This cast iron is called white . White cast iron is the main raw material in steel production. In this regard, it received the name pig iron.

If cast iron has the structure of pearlite + ledeburite or ledeburite + cementite, then such cast iron is called half-cast iron .

If iron ore with a low manganese content but high silicon content is smelted, then the cast iron smelted in blast furnaces will have a ferrite + pearlite structure. Such cast irons are called foundry gray cast irons.

White pig iron is processed into steel in converters, arc and induction furnaces, as well as open-hearth furnaces. Malleable cast iron is obtained from half cast iron by long annealing . High-strength and special cast irons are produced by introducing modifiers in the molten state into cast gray cast iron. Foundry gray cast iron is used mainly in the production of castings for mechanical engineering and machine tools.

In addition to the indicated groups of cast irons, in the last decade of the 20th century. In Russia (JSC Tulachermet), the production of cast iron with increased purity in terms of the content of harmful impurities and other chemical elements has been mastered. This cast iron is called nodular cast iron (for example, PVK-N - high-quality nodular cast iron).

Advantages and disadvantages

The first discovered rough cast iron castings date back to the mid-14th century. Since then, technology has changed significantly, and the use of cast iron has expanded. Objectively assessing this product of ferrous metallurgy, one must name both its positive and negative sides.

Undeniable advantages

First of all, it is environmentally friendly and excellent hygienic qualities. The same cast iron cookware does not break down in acid-base solutions, washes well and warms up, retaining the accumulated heat for a long time. It should be noted the durability and wide range of assortments, cost-effectiveness and relatively simple process of production of cast iron products.

By varying the state of carbon in the alloy, white or gray cast iron can be obtained. The wide range of applications is explained by easy processing (forging), high heat transfer and strength.

Disadvantages of cast iron as a material

The weakest aspects of alloys are considered to be brittleness and susceptibility to rust even after short-term interaction with water. In addition, cast iron products are distinguished by their heavy weight and a specific set of physical and mechanical characteristics, which require special conditions for their transportation, assembly and maintenance.

How is cast iron made?

The alloy is smelted in blast furnaces and cupola furnaces. The main source of iron is iron ore - a product of ore enrichment. The fuel used is coke (a product of special processing of coal), natural gas, and pulverized coal fuel. High-temperature technology for melting cast iron in a shaft furnace makes it possible to launch reduction chemical processes and separate iron from oxides.

As a result of blast furnace smelting, an alloy of iron and carbon is obtained - cast iron, as well as slag containing unreduced oxides, flux residues, fuel ash, etc.

White cast iron

White cast iron is obtained by processing iron ores with a high manganese content. When fractured, this cast iron has a fine-grained or needle-like structure with a matte white color. All carbon, usually with a mass fraction of 6.67%, is in a chemically bound state in the form of cementite in the surface layers of the casting.

White cast iron is very brittle, practically impossible to cut, its hardness reaches 700 ... 800 HB. Due to its high hardness and brittleness, white cast iron has no direct use as a structural material. In some cases, the properties of high hardness and wear resistance of the structure of white cast iron (cementite) are created artificially in the surface layers of parts. This operation is called surface bleaching of parts and castings. The bleaching operation is achieved by a high cooling rate. For example, in order to obtain high hardness, the surface of rolling mill rolls, plowshares, mill balls, diesel crankshafts and other parts are bleached to a depth of up to 5 mm.

The structure of white cast iron is unstable. At high temperatures, cementite decomposes into austenite and free carbon (graphite). The melting point of white cast iron is 1,600 °C.

White cast iron is produced in the form of pigs weighing 40 kg, which are used for steel production in open-hearth and other furnaces, or in a liquid state (in this case, the cast iron is stored in special containers (mixers), from which it is then supplied to converters for steel production).

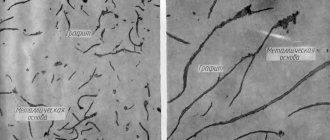

Half cast iron is a low-grade white cast iron in which part of the carbon is in a chemically bound state in the form of cementite, and part is in the form of free carbon (graphite) or mechanical mixtures, depending on the mass fraction of carbon (Fig. 1). Thus, cast iron with a mass fraction of carbon equal to 4.3% is eutectic and has the structure of ledeburite (a mechanical mixture of cementite and ferrite). Hypereutectic cast iron (more than 4.3% carbon) has the structure of pearlite + cementite + graphite. Hypoeutectic cast iron (less than 4.3% carbon) has the structure of pearlite + ledeburite + graphite.

Half cast iron has very high mechanical properties, but is brittle, so this cast iron is not directly used in foundries.

Rice. 1. Microstructure of half-cast iron: 1 - perlite; 2 - cementite; 3 - ledeburite

Due to the presence of free carbon in the structure, as well as the unstable structures of ledeburite and cementite, half cast iron is a raw material for the production of malleable and special cast irons.

Suitability of cast iron for welding work

Connecting cast iron parts by welding is more relevant than ever and requires a serious approach. In the technological aspect, the suitability of the metal is low. There are a number of reasons for this, and the main one is the very high content of carbon and impurities. In addition, it is difficult to form a weld due to the fluidity of the material. Possible lack of penetration is the result of the formation of refractory oxides during the oxidation of silicon and other alloy components. Intense gas release leads to the formation of pores in the weld.

The use of cast iron for welding with metals that differ in cooling/heating rates leads to cracking in the weld and its brittleness. Therefore, for welding they resort to the use of coated or carbon electrodes, flux-cored wire, and gas welding installations. Preliminary heating of the parts being welded and the correct choice of welding mode help to avoid the formation of hardened areas.

Foundry gray cast iron

Foundry gray cast iron got its name due to its high casting properties (fluidity and low shrinkage), as well as due to its dark gray color. At the fracture it has a coarse-grained structure. Soft, easy to cut. The hardness of cast gray cast iron is 140 ... 260 HB. Tensile strength σв 100…450 MPa (10…45 kgf/mm2). Relative elongation δ 0.2 ... 0.5%. In the domestic mechanical engineering industry, up to 74% of all critical castings are produced from foundry gray cast iron. Based on their microstructure, gray cast irons are divided into ferrite-graphite, ferrite-pearlite and pearlite (Fig. 2). The carbon in these cast irons is in a free state in the form of graphite. The greater the mass fraction of carbon, the greater the graphite structure in gray cast iron and the lower its mechanical properties, therefore the maximum carbon content is limited to its hypoeutectic limits, i.e., no more than 4%, but practically up to 3.7%.

Reducing the carbon content reduces its castability. In this regard, a lower limit on the mass fraction of carbon is set. It is approximately 2.2%. The lower limit is accepted for thick-walled castings, the upper limit for thin-walled ones.

Blast furnace shops produce gray cast iron in the form of pigs, which are supplied to the foundries of machine-building plants.

Cast gray iron consists of iron, carbon, and other chemical elements, and therefore is not a two-component alloy. In addition to carbon, it contains silicon, manganese, sulfur and phosphorus. Silicon and manganese influence the graphitization process, microstructure formation, and mechanical and technological properties of gray iron castings.

Carbon affects the properties of cast iron depending on the form of the connection with iron, i.e., on the structure that is formed in the alloy. The formation of structures is collectively influenced by the melting and cooling conditions, as well as the presence of accompanying chemical elements: manganese, silicon and, slightly, sulfur and phosphorus. Silicon with a mass fraction of 3 ... 5% in gray cast iron promotes the release of carbon in the form of graphite. By changing the mass fraction of silicon, it is possible to obtain castings with different structures, and with changes in the structure, the mechanical properties of cast iron also change. For example, cast iron with a structure in the form of lamellar graphite has a relative elongation δ = 0.2 ... 1.1%, and cast iron with a flake-shaped graphite structure has a relative elongation δ = 5 ... 10%. Silicon promotes the formation of the microstructure of graphite, gives cast iron a number of valuable mechanical, technological and operational properties, and improves machinability. In addition, graphite inclusions (porous, soft) quickly dampen vibrations and vibrations and disperse shock loads throughout the mass of load-bearing parts. Cast iron parts are insensitive to mechanical damage. Due to the graphite structure, gray cast iron has high anti-friction properties. In this case, the graphite acts as a lubricant. Due to the listed properties, silicon is a constant and essential element in foundry gray cast irons.

Rice. 2. Microstructures of cast gray cast irons: a - ferritic-graphite; b - ferrite-pearlite; c - pearlitic

Manganese prevents the graphitization of cast iron, whitens it, promotes the formation of a crushed perlite structure (ferrite + cementite), improving mechanical properties. The mass fraction of manganese in gray cast iron ranges from 0.2 ... 1.1%, while strength, wear resistance and hardness increase. With a higher manganese content, the structure of pearlite and ferrite decreases, the structure of cementite increases, and cast iron becomes hard but brittle.

Sulfur is a harmful impurity. It has a negative effect on the mechanical and casting properties of gray cast iron, reduces fluidity, increases shrinkage, and promotes the formation of cracks. The mass fraction of sulfur for small castings is 0.08%, for large castings, which do not require increased fluidity, 0.10 ... 0.12%.

Phosphorus in foundry cast iron is a useful admixture, as it increases fluidity. In addition, phosphorus promotes the formation of a structure that increases the overall hardness and wear resistance of castings. A high phosphorus content (up to 0.7%) increases the cold resistance of cast iron, therefore, in castings operating under loads, the mass fraction of phosphorus can reach 0.3%, and in castings operating without loads (art and household castings) - 0.7 %.

Phosphorus has no effect on the formation of microstructure and graphitization. In practice, using structural diagrams, depending on the mass fraction of carbon and silicon in cast iron, its approximate microstructure in castings with a wall thickness of 50 mm is determined.

According to GOST 1412-87, there are the following grades of gray cast iron: SCh10, SCh15, SCh18, SCh20, SCh21, SCh24, SCh25, SCh30, SCh35, SCh40 and SCh45, where the letters SCh mean foundry gray cast iron, and the numbers indicate tensile strength. For example, cast iron grade SCh15 has a tensile strength of 150 MPa (15 kgf/mm2).

Thus, casting gray cast irons have high mechanical properties (σв - up to 450 MPa (45 kgf/mm2) and also high technological properties (casting properties, machinability, etc.). In addition, as already noted, casting gray cast iron has the ability dampen and dissipate vibrations and loads. This property is called the damping property. It is widely used in machine tool construction. From gray cast iron, which has a damping property, the beds of machine tools, machines and other supporting structures are cast, which allow creating the accuracy and rigidity of the machine-device-tool system - detail (AIDS).

The main technological properties are high fluidity and machinability. Gray cast iron castings lend themselves well to processing on various metal-cutting machines: turning, milling, planing, drilling, grinding and scraping. Due to the wide range of mechanical properties (strength and hardness), this cast iron is used in various sectors of the economy. For example, low-grade gray cast iron is used for the manufacture of castings that operate without loads (household and artistic castings, weights, stands, covers, plugs, plates, flanges, etc.). Cast gray cast iron with a tensile strength of 200 MPa or more is used for castings of parts operating under medium loads (pipes, frames, brackets, gearbox housings, etc.). Cast iron with a tensile strength of 300 MPa or more is used for parts operating under high loads (bearing housings, pulleys, gear and worm pairs, cylinder blocks, block heads, pistons, clutch discs, pump housings, steam turbine cylinders, crankshafts, sprockets, brake drums, etc.).

Main characteristics of the metal

The key parameters of cast iron are determined by the amount of carbon, which has the form of graphite, and the presence of silicon. Pearlitic malleable cast iron alloy contains two more constituent elements - chromium and manganese.

Characteristics of Ductile Iron

The difference in the structure of malleable cast iron is also reflected in the final properties of products obtained from it. For example, workpieces made from ferritic cast iron have lower hardness than those made from pearlitic material, but at the same time the former have increased ductility. Graphite in the form of flakes provides high strength parameters to finished parts with relatively good ductility. Products made of KCh cast iron can be deformed at room temperature and humidity. It was this property that determined the name of this material – malleable. In fact, this is a conditional name and does not mean that finished parts are obtained from it using forging equipment. Casting is used to produce products. The main property of this material is that there is no stress in it.

Microstructure of ductile iron

The mechanical properties of ductile cast iron are between gray cast iron and steel. That is, cast iron of this type has high fluidity, resistance to wear, corrosion, and aggressive substances. In addition, this material has high strength properties. Thus, a part with a wall thickness of 7–8 mm can withstand working pressure of up to 40 atm. This allows it to be used for the manufacture of pipeline fittings for gas and water.

We must not forget that at low temperatures, cast iron becomes very brittle and is very susceptible to impact.

Malleable iron

Malleable cast iron is called cast iron obtained from white (half) cast iron by prolonged annealing (simmering). The scheme for producing malleable cast iron is shown in Fig. 3.

Rice. 3. Scheme for producing malleable cast iron by annealing (simmering) half-cast iron: 1 - curve for producing malleable ferritic cast iron; 2 - curve for producing malleable pearlitic cast iron; t—temperature; τ — time; Ac1 - critical temperature (eutectoid)

The process of producing malleable cast iron is as follows. In cupola furnaces or electric furnaces, low-grade (half-grade) white cast iron is melted, then poured into earthen or metal molds. Once cooled, the castings are removed from the molds and placed in boxes containing crushed iron ore or scale. The boxes are heated in ovens to a temperature of 900 ... 1,000 ° C and kept for 6-10 days. During this thermal operation (simmering), carbon from cementite diffuses to the surface of the part, turning into free carbon in the form of graphite (annealing carbon), and part of it burns out.

Currently, the technology of accelerated annealing of white cast iron castings onto malleable cast iron has been introduced. The essence of this technology is to carry out preliminary heat treatment of castings: normalization or hardening and tempering. These operations make it possible to obtain a larger number of crystallization centers, which leads to faster decomposition of cementite into annealing carbon and significantly reduces the duration of the process of producing malleable cast iron.

Quenching is carried out at a temperature of 820 ... 950 ° C and cooled in mineral, spindle or transformer oil. Tempering is carried out at a temperature of 400 °C. During the second stage of final annealing at a temperature of 950 °C, the duration is reduced to 5 hours.

In practice, stepwise annealing is also used: castings are cooled from 950 to 760 °C for 2 ... 3 hours, from 760 to 680 °C for 8 ... 10 hours, then cooled in air.

Modern accelerated production of malleable cast iron is carried out in two stages. The first stage is heating of castings in salt baths or molten metals at 1,050 ... 1,100 ° C and holding for 1 ... 2 hours; the second is heating to 700 °C and holding for 4 hours. The whole process also lasts 5 ... 7 hours. As a result of annealing in the castings, the structure of ledeburite and cementite transforms into the structure of flake-shaped graphite (annealing carbon). Compared to the original cast iron, the hardness of malleable cast iron castings is reduced, brittleness is eliminated, strength is increased, and the castings acquire high ductility (up to 12%) and impact strength. Due to its high ductility, this cast iron is called malleable cast iron, but this cast iron is not subject to forging, especially it cannot be forged (deformed) in a hot state, since cast iron becomes brittle along the grain boundaries in a hot state, and microcracks appear. After forging, castings become brittle. Ductile iron castings undergo slight deformation in a cold state, bend, stretch, and straighten.

The structure of malleable cast iron in the form of flake graphite has higher hardness, strength and ductility compared to gray cast iron. As practice has shown, half-cast iron castings subjected to annealing for malleable cast iron should have a diameter of no more than 40 ... 50 mm. With a cross section of more than 50 mm, a very hard and brittle structure of lamellar graphite is formed in the core.

Ductile iron castings have the following impurity content: carbon - 2.4 ... 2.9%, silicon - 1.0 ... 1.6%, manganese - 0.2 ... 1.0%, sulfur - up to 0.2% and phosphorus - up to 0.18%.

The structure of malleable iron castings, depending on the annealing conditions, can be ferritic or ferritic-pearlite (Fig. 4). The ferrite and carbon annealing structure is obtained by step annealing. Castings obtained by stepwise annealing have ductility up to 12%.

Rice. 4. Microstructures of malleable cast iron: a - ferritic (black-core); b - ferrite-pearlite (light-heart)

Malleable pearlitic iron castings are produced by prolonged annealing at a temperature of approximately 1,000 °C. After the first stage of graphitization, slow continuous cooling is carried out to normal temperature. After cooling, the castings develop a pearlite and annealed carbon structure. The structure of pearlite determines higher mechanical properties of parts, strength and hardness. During annealing, casting stresses are relieved in castings.

According to GOST 1215-79**, the following grades of malleable cast iron are produced: KCh 30-6, KCh 30-8, KCh 35-10, KCh 37-12, KCh 45-7, KCh 50-3, KCh 50-4, KCh 60 -3, KCh 65-3, KCh 70-2, KCh 80-1.5, where KCh is malleable cast iron; the first numbers indicate tensile strength, the numbers after the hyphen indicate elongation.

Malleable cast irons are used for the manufacture of parts with small cross-sections that operate under severe conditions: abrasive wear, shock and alternating loads, in the automotive, tractor and textile engineering, boiler, carriage and diesel industries.

The high strength and density of ductile iron castings makes it possible to widely use them as water supply and gas installations and equipment.

The disadvantage of malleable cast iron is the high cost of castings due to long annealing and metallurgical units with special equipment.

To change the microstructure of ductile iron castings after machining, they are subjected to various types of heat treatment: normalization, hardening and subsequent tempering. During the heat treatment process, the metal base of the castings changes, after which the hardness, wear resistance, strength and impact strength increase.

Ductile iron

Domestic science and practice have developed a technology for producing castings from gray cast iron with a structure in the form of nodular graphite. This cast iron, compared to conventional gray cast iron, has high mechanical properties, combining the properties of steel and cast iron. The structural material used for casting parts and products with a spheroidal graphite structure is called high-strength cast iron. The technology for producing high-strength cast iron is as follows. Before pouring into a mold, magnesium additives are introduced into the liquid cast iron in the casting ladle in the range of 0.03 ... 0.07% of the total mass of the melt. This process is called modification. Modification with pure magnesium causes a flash, so magnesium is introduced into the evaporator (metal or graphite boxes with holes) in the form of a master alloy - alloys of magnesium with silicon or nickel. In the process of modifying cast gray cast iron in the molten state, the microstructure changes when the castings are cooled (Fig. 5).

Rice. 5. Microstructure of cast iron before modification - pearlite (a) and after modification - nodular graphite (b)

The resulting spheroidal graphite microstructure does not weaken the metal substrates of the casting. After modification, the hardness, strength and impact strength of cast iron castings increases several times compared to the original material.

According to GOST 26358-84, the following grades of high-strength cast iron are produced: VCh 38-17, VCh 42-12, VCh 45-5, VCh 50-2, VCh 50-7, VCh 60-2, VCh 70-2, VCh 80-2 , HF 100-2, HF 120-2. The letters HF mean high-strength cast iron, the numbers after the letters indicate tensile strength, and the hyphen indicates elongation. For example, HF 50-2 cast iron has a tensile strength σв = 500 MPa (50 kgf/mm2), and a relative elongation δ = 2%.

Certain grades of high-strength cast iron have a hardness of up to 370 HB, tensile strength σв = 1,200 MPa (120 kgf/mm2).

The state standard sets requirements for the mechanical properties of castings made of high-strength cast iron, depending on the grade, according to the following characteristics: tensile strength, yield strength and relative elongation.

To improve the mechanical properties, castings made of high-strength cast iron are subjected to various types of heat treatment: hardening followed by tempering, annealing and normalization. Castings made of high-strength cast iron have high machinability.

The mass fraction of chemical elements in high-strength cast iron is as follows: carbon - 2.7 ... 3.6%, silicon - 1.5 ... 3.8%, manganese - 0.3 ... 0.7%, sulfur - 0.01 ... 0, 02%, phosphorus - 0.1%. The mass fraction of these elements varies depending on the cross-section of the castings.

| Table 1. Application of ductile iron castings | ||

| Application area | Machine parts cast from high-strength cast iron | |

| Automotive engineering | Crankshafts, piston rings, brake pads, brake drums, etc. | |

| Machine tool industry | Calipers, tool holders, heavy faceplates, spindles, levers, etc. | |

| Rolling and forging equipment | Rolling rolls, beds of rolling mills and forging hammers, bolts, cross beams, descaling plates, brake housings, etc. | |

| Handling equipment | Large crankshafts of excavators, drums, hoists, winch bodies, hook chains, etc. | |

| Stone crushing equipment | Crusher eccentric shafts, hubs, housings, balls, etc. | |

By structure, high-strength cast irons are ferritic (ferrite + nodular graphite), ferritic-pearlitic (ferrite + pearlite + nodular graphite) and pearlitic (perlite + nodular graphite). In Fig. 5, a shows the microstructure of gray cast iron grade SCh30 (σв = 300 MPa (30 kgf/mm2), hardness - 181 ... 255 HB) before modification, in Fig. 5, b - microstructure of the casting obtained after modifying gray cast iron grade SCh30 - high-strength cast iron grade VCh 70 (σв = 700 MPa (70 kgf/mm2), hardness - 229 ... 300 HB). As you can see, modifying gray cast iron during the casting process dramatically improves the mechanical characteristics of the castings.

High-strength cast irons have high casting properties: the fluidity of almost all grades of high-strength cast irons is up to 600 mm, and shrinkage in castings is up to 1 mm. There is practically no segregation in these cast irons. In addition, castings made of high-strength cast iron have high machinability by cutting (turning, milling, grinding, etc.), high hardening and hardenability. In order to change (correct) the structure of castings made of high-strength cast iron, they are subjected to various types of heat treatment.

An important operational property of parts made from high-strength cast iron is their wearability in friction and pressure units (press cross-beam, forging hammer head, etc.). In the turbine industry, high-strength cast iron is used to make the casings of steam turbines, guide vane blades, and in the tractor and diesel industry - crankshafts, pistons, etc. For example, the crankshaft of the Volga passenger car is cast from high-strength cast iron of the HF 70-2 grade. When modified with magnesium, ferrosilicon is added to this cast iron, which gives the part the properties of steel and cast iron.

High-strength cast irons are widely used in automotive engineering, in the production of rolling, forging, lifting and transport and stone crushing equipment instead of large-sized steel castings, forgings and stampings weighing up to 48 tons (Table 1).