Ballast rheostat RB-306

Operation of the RB-302 model revealed a number of limitations.

Rapid failure of resistors due to overheating and insufficient accuracy of current regulation. In particular, during long duration periods the rheostat overheats greatly, which forces the use of a similar device connected in parallel to the main one. The RB-306 model is free of these shortcomings. The body of the device is made with an increased number of blinds, which improve the airflow of the elements of the resistor boards, and fechral springs with a diameter of 3 mm are used as the wire material. The first branch - 6 A - is assembled in the form of a tubular electric heater.

The modular arrangement of resistance elements facilitates their diagnosis and replacement. As a result of these design changes, with the same size and weight of the unit, it was possible to expand the control range of welding currents and increase the accuracy of adjustment.

On the basis of RB-306, blocks of ballast rheostats (marked BBR) are assembled, which are used for electric arc cutting of metals. BBRs are effective in the case of multi-station welding; they are also used to control the welding current from the rectifiers of automatic welding machines.

When using ballast rheostats, the following operating rules should be followed:

- Operate under the conditions specified in the device passport (climatic design of all types of ballast rheostats - from -40 to +45ºС);

- Operation in an atmosphere contaminated with dust and near sources of gas and steam, which contribute to the destruction of electrical insulation, is prohibited;

- The ballast rheostat used must undergo periodic verification in a specialized electrical laboratory. The timing and content of such verification are determined by the provisions of RD 03-614-03.

source

Ballast rheostat - what is it? Principle of operation

Taking into account the purpose and principle of operation, we can briefly say that a ballast rheostat is a simple installation for increasing resistance during welding. It is characterized by the simplicity of the device and is therefore often built into advanced models of welding machines. In addition, the rheostat can be purchased separately at retail.

According to the principle of operation, the device is a certain point of obstacle in the path of movement of electric current from the source to the cable of the welding machine. An obstacle point is nothing more than an area of high resistance connected to an electrical circuit. Visually it looks like a thick spring. It is equipped with a moving contact. Its movement along the spring allows you to change the length of the path through which the electric current passes. Due to this, the resistance in the circuit changes.

It cannot be said that the different device models on the market have any significant differences. They are equipped almost identically, with the exception of some nuances:

- spring sizes. Some welding machines are equipped with a long spring, and some with a small spring. The dependence here is simple: the longer the ballast, the greater the resistance that can be set during operation;

- the spring can be made of different grades of metal, which also affects the resistance of the unit;

- the thickness of the metal from which the spring is made. This is another important factor affecting resistance.

What is the role of the ballast rheostat? If it were not there, then the output current would be 250A. If you add a ballast to the electrical circuit, then with its help this indicator can be reduced to 10A. Any value in this corridor can be set depending on the type of welding work, consumables and materials used.

Purposes of application

Welding equipment is a modern installation with which it is possible to join various steels or non-ferrous metals. Using it at the intended welding site, it is possible to melt the parts and connect them together, forming a seam, which is subsequently filled with welding wire or a metal electrode.

Features of choice

You need to choose welding equipment on our official website depending on what tasks you have to cope with

It is worth paying attention to several important criteria:

- Material. The equipment is selected at the rate of 30-50A for every 1 mm of material thickness. The SVAR-GAZ company presents only reliable welding equipment from the world's best manufacturers; it allows you to weld both ordinary or stainless steel and non-ferrous metals.

- Place of application. Depending on the amount of power, the unit is used for various purposes. Household ones are used in private workshops or in the country, their power is 200A. Semi-professional and professional devices with power from 300 to 500A are purchased for large enterprises.

- Weight. If the device needs to be moved around the site, lightweight structures are chosen. Powerful and large-sized units are used for permanent installation.

On the official website of SVAR-GAZ you can buy manual, semi-automatic or automatic welding equipment, with stepwise or smooth adjustment at an affordable price.

Why us

- large range of products;

- cooperation with the world's best manufacturers;

- convenient payment methods;

- fast delivery in Moscow.

Our company employs only employees with extensive experience. If you require detailed information regarding quality or selection of suitable equipment, you can obtain it by calling us.

CALL

What is the correct name for a grinder tool?

First, let's figure out what a “grinder” is. The name “grinder” is very strongly attached to this instrument. In professional language, this tool is called an angle grinder (angle grinder). But historically, this tool was first assembled in Bulgaria, which is why the name “grinder” was attached to the angle grinder.

Why do you need a grinder?

A grinder or angle grinder performs a simple function - grinding. But many craftsmen use angle grinders not only for grinding, but also for working on concrete, metal and even wood. But this tool was originally created only for grinding, however, a modern grinder can easily cut, polish and clean materials.

At the same time, grinding and cleaning can be done with almost any material that comes to hand. To do this, use various nozzles, each suitable for its own type of material. Angle grinders can process: cement, concrete, slate, brick, glass, porcelain, wood and even plastic.

The main advantage of this tool is that it is almost universal; you only need to change the attachments.

The first criterion is the size of the disk used

The most important and first criterion that you need to decide on when buying an angle grinder is the size of the disc used. At the moment, the minimum size of a cutting disc is 0 115 mm, and the maximum possible size is 230 mm.

Just note that not the entire part has the ability to cut, but only the one protruding beyond the body of the angle grinder. This means that if the case is at least 55mm wide, then about half of a 115mm disc (even less) can cut something. Simply put, a 115 mm grinder can cut a board no thicker than 30 mm (and in practice, a maximum of 25 mm). At the same time, all disks tend to wear down, that is, in a minute of operation this figure can be halved. Based on this, you can already think about the size of the disk.

After all, for cutting metal pipes with a diameter of 20 millimeters or more, a 115 mm grinder will no longer be appropriate due to low wear resistance. And if you buy an angle grinder for cutting pipes, then at least 180 mm. And this is only for cutting, but what if you need a tool for grinding? There is no need to take more here; it will be enough to choose a tool for 125 mm, which is the norm for most grinding attachments.

As you noticed, choosing is not so easy; you first need to think about what the tool is needed for, and only then start selecting it.

Let us characterize the types of angle grinders based on size so that we can more easily understand what will suit us best.

Angle grinder 115 mm

This is the smallest saw blade size that can be purchased. It is suitable for the simplest work, and often, wheels of this diameter are used exclusively for grinding, since the smaller the size, the less the weight. This is the best option for small jobs.

Angle grinder 125 mm

This is the next largest type and at the moment it is the most popular among our population

Grinders of this size are not heavy, but very comfortable and have decent power characteristics, and, importantly, still have a low cost. This grinder can both grind material and cut

Of course, such an angle grinder will not be able to handle parts that are too thick, since the depth of penetration of the blade is much less than the radius, but for household work this grinder is just right.

Angle grinder 150 mm

This type of grinder is not very popular in everyday life, but is sometimes in demand. This grinder is somewhat more powerful than the previous ones and allows you to perform more voluminous work.

Angle grinder 230 mm

This is the maximum you can buy based on the diameter of the circle. The most important advantage of such an angle grinder, of course, is in a large circle. With this tool you can cut bricks, tiles, boards and even pipes without much effort, but it is better not to use such a grinder for grinding. Firstly, it has a very large weight, which is extremely inconvenient when grinding material, and secondly, a large circle will prevent you from getting to narrow grinding spots. You should buy such an angle grinder only if you are planning a major renovation or large-scale construction. This grinder is not suitable for small jobs

Ballast rheostat settings

The main thing in a high-quality welding process is stable performance of the electric arc, or rather, its current-voltage characteristics. Modern inverters cope well with this requirement.

This is done by converting the current into two stages and switching the inverter itself. All other welding machines cannot boast of such characteristics. Therefore, a ballast rheostat must be present next to them.

It is designed for stepwise control of arc operation and compensation of the current component during recharge from the transformer. Nichrome wire in a parallel connection circuit is the main component

It is important that each section of the rheostat is connected to the network independently, using a switch

Such a rheostat has only two working functions:

- Current regulation in a discrete manner.

- Compensation of the direct current component formed during the feeding of the welding element using a transformer.

The performance and overall efficiency of a ballast rheostat directly depend on the number of turns or sections of the spiral. After all, each of them is an element of a chain that is broken using a switch.

The circuit is serial, and the connection of sections is parallel. This combination gives an excellent result: periodically connecting each of the elements to the work in order to regulate the voltage in the welding machine.

The connection of the rheostat to the welding circuit must be in series with the power source.

Control buttons are always located on the outer wall of the protective metal case. The most advanced rheostatic models have internal fans that cool the device’s elements while operating at high current levels.

If there are no fans, you must ensure that several rheostats are switched on in series.

The most popular line of ballast rheostats on the market under the abbreviation RB: there are only five options for different current values - its range - minimum and maximum values.

We offer an easy walk through the most popular models to get acquainted with their technical characteristics in more detail:

RB-302

Ballast RB-302.

An excellent device as a companion to welding units for adjusting the current strength in semi-automatic or manual welding processes. Works in parallel with welding rectifiers and generators.

This version is designed for a power supply range of 27 - 30 V with a maximum maximum of 70 A and a minimum drop of 30 A.

The rheostat is equipped with an air cooling system. It has a good PV indicator - the on-time is 60%. This means that the welding duration should not exceed 10 minutes. Otherwise, the PV must be reduced.

In this device, the welding current adjustment is represented by six steps, which are cyclically turned on and off.

The structural elements are made of the most modern materials: the insulation, for example, is made of ceramic profiled plates, and the plateau is formed from special heat-resistant fechral wires.

RB-302U2

This model is a type of mother rheostat for operation in conditions of high humidity or harsh ultraviolet radiation. As a result, you can work with it outdoors in conditions unfavorable for conventional equipment.

RB-306

This model is more serious: it does not overheat and is much more accurate in regulating the welding power supply than the RB-302. The rheostat is equipped with an improved cooling system: there are more blind holes in the body, so the blowing of the resistors is intense and efficient.

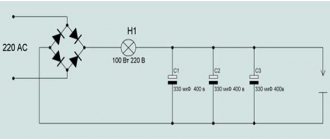

Electrical circuit of the ballast.

All resistance elements are arranged in a modular system. This arrangement makes diagnosing and replacing elements much easier and more accurate. The range of current values is much wider, and the indicators can be adjusted with much greater accuracy.

BBR

These are special Ballast Rheostat Blocks. They are assembled from RB-306 elements for cutting metals using the electric arc method. This is an excellent solution for controlling the welding current from the rectifier in automatic machines.

How it works?

At its core, it is a ballast rheostat - a special device for generating increased resistance for welding electricity. This rheostat is distinguished by its simplicity. It is built into many advanced and expensive models of welding machines, and can also be purchased separately.

In addition, you can build a ballast yourself without any problems. It should be noted that every self-respecting welding master has such a device in his storage room.

According to the principle of its operation, the welding ballast is a point of obstacle in the path of the movement of electric current; it is a “point” of high resistance. From an external point of view, it looks like a complex thick spring.

Why do you need a ballast?

This spring is always equipped with a movable contact, which, when moving along the spring, changes the length of the path that the current passes through the ballast.

This device cannot boast of a particular variety of models.

There are some differences, they are determined by the following criteria:

- Dimensions of the spring: the longer it is, the longer the path of electrons through all turns of the rheostat, the greater the resistance reduces the current strength.

- The nature of the metal with certain resistance coefficients.

- The thickness of the spring is also directly proportional to the resistance force. The thickness is related to the length of the rheostat.

In fact, it turns out as follows: without a ballast rheostat, the current would have a force of 250 A. If you connect a ballast to this circuit, the electric flow will begin to lose strength and would have only 10 A at the output.

Of course, the regulator can change the length of the spiral path along which the flow passes. The losses in this case would be different.

How to make it yourself

It is easier to make your own ballast rheostat in the form of a spiral. Use soft (annealed) wire. You will need a cylindrical object for winding. You can use a piece of metal or plastic pipe. For a mobile contact, a wire from a welding holder is suitable.

It’s not enough to make a ballast yourself; you need to test it. You need to connect the contacts to an ammeter. All that remains is to wind the wire piece around the form and secure it to an electrically insulating stand. The end of the twisted wire is connected to a power source. The holder is attached to the moving current-carrying element.

After measuring the current strength with an ammeter in different positions of the holder, you can put a scale with current parameters on the supply. A homemade ballast rheostat is inferior in accuracy to a factory one. Open model cools naturally

Use the device carefully

rheostat for a homemade welder

I made myself a crane resistance in the form of a convenient ballast with a copper knife (nichrome “spring”). I made a neat stand from a strip 1.5-2 mm thick and 25-30 mm wide. The width of the stand should be such that the mounting holes for the crane the resistances lay on the jumpers of the stand and it could be screwed on. The height of the stand should be such that the spring was no less than five centimeters from the floor. Along the edges of the stand from the same strip, I welded ears with holes so that they were higher than the spring. I took a rod with a diameter of 8 mm, cut a thread along the edges, and then pulled a cambric over it along the entire length, without covering the thread, so that the “knife” with which it will be necessary to regulate the welding current was isolated from the stand. Making a “knife.” I took a strip from which I made a stand, twenty centimeters long, riveted the same strip to it, but copper. Then I drilled two holes at the edges of 10 - an insulated rod of 8 is inserted into one hole, along which it moves “ knife" (the rod is attached in the ears), secondly, a 10mm bolt is inserted from the side of the metal plate and welded (bolt length 40mm). The electrode holder cable terminal is then put on the bolt and screwed. Then I took this metal-copper plate and the same width, but four centimeters larger than the diameter of the copper spring, I placed one next to the other and drilled holes in them at 6" for a bolt at 6". We insert bolts at “6”, about 40 mm long, put springs on them, washers on top of the springs and fasten them with nuts. But so that then the “knife” sits tightly on the coil of the spring. Usually the springs have copper ears soldered with brass. To one We attach a 50cm cable from the ears (clamps on both ends), the second end is then attached to the bolt on the welder. That's all. ...Yeah, I almost forgot. So as not to fasten the cables and ballast with nuts, constantly carrying a wrench with me, I also made wings. And I took the wings from the KRAZovsky engine - there are some (sorry, I’m not a driver, so I don’t know how to express myself correctly, but I think you will understand what we are talking about). The threads in them are fine by 10. Therefore, I took a drill, carefully clamped it in a vice, since the plastic is fragile and can crack, I drilled it deeper, but so that the drill did not come out. This was done so that there would be enough stroke for the tap at “10”. I cut the thread for the bolt, and I got comfortable wings. You need three of them. That’s all now.

Ballast rheostat

Ballast rheostat is a device that is used to regulate the current level when performing welding work. Its device is a set of several resistance elements. They are made of special constantan wire. This allows you to achieve maximum ohmic resistance. This unit is connected to the welding circuit using special switches.

Ballast rheostat

Its connection should be made in series in a circuit, while the resistance level is adjusted by turning the working sections on and off. Welding work with a rheostat connected can be performed with current in steps of 5-10A.

Device

The design of the ballast rheostat is quite simple: it consists of working sections placed in the body of the device. A resistance switch is installed on each section, with which you can turn the sections on and off. The device also includes terminals for connecting to the welding circuit.

Each section is a tape made of a special metal, for which constantan or nichrome wire is usually used. Also, most machines are equipped with a switching unit that allows you to adjust the welding range to the required level.

All controls, including the power unit and toggle switches, are usually located on one panel of the device.

It should be noted that most modern rheostat models are equipped with a cooler system for cooling the device, represented by built-in fans. This system helps to avoid overheating during prolonged operation of the device. This allows you to operate at high currents without the need to connect an additional rheostat.

Ballast rheostat circuit

It should be noted that when overloaded, this device is characterized by significant heating, which occurs at a current strength of 225 A. Therefore, it is recommended, in order to avoid embarrassment and malfunctions, to include two rheostats in the circuit.

Purpose

The purpose of the ballast rheostat is quite simple, but in some cases it is impossible to perform welding work without its function. This device is necessary to regulate the current strength in the required range using toggle switches and compensation of the constant component. This effect occurs in cases where welding work is performed from a transformer.

The efficiency and cost of the rheostat depends on the number of sections, with the help of each of which you can adjust the resistance level in a certain way. The switch allows you to mechanically break the chain.

Parallel connection of sections allows you to optimally combine the work of each, which is very important for the welding machine that performs the corresponding work. The current adjustment step is usually in the range from 5 to 10 A

Radio beginners

Rice. 114. Homemade filament rheostat.

The simplest rheostat can be easily made by every radio amateur.

To make it, you will need a wire with high resistivity, such as constantan or nichrome. If the rheostat is designed for a small resistance - up to 10 ohms, then they usually take a constantan with a diameter of 0.3-0.4 mm (you can take it from a spiral to an electric stove).

When making rheostats with high resistance (up to 50 ohms), it is better to use nichrome wire with a diameter of 0.2-0.25 mm. You can also use wire from old heating devices, such as electric irons.

How such a rheostat is designed is shown in Figure 114. The frame for the winding can be a wooden or ebonite stick 40-45 mm long. A porcelain tube from a conventional constant resistance (often the so-called Kaminsky type) is also quite suitable for the frame.

For a rheostat, a wire can be used either with or without insulation. If the wire is taken without insulation, then it must first be heated with current to a dark crimson color. A thin layer of scale forms on the surface of this wire. This layer will serve as insulation and protect the winding turns from short circuits. The wire is wound in one layer, turn to turn, its ends are soldered to the output contacts.

Along the entire length of the rheostat winding, a narrow path 5-6 mm wide is sanded, along which the slider will slide. The frame with wound wire is fixed on plywood.

The slider is made of tin or brass. Its axis is a copper rod, which is secured with nuts to the same plywood as the frame.

The slider should slide well along the rheostat winding, giving reliable contact. Two leads are made from the rheostat using a flexible wire: one from one of the ends of the wound wire, and the other from the slider with the rod. These terminals turn on the rheostat when installing the radio structure.

An electrical voltage regulator is needed so that the voltage can be stabilized. It ensures reliable operation and longevity of the device.

The regulator consists of several mechanisms.

- How should the wires be connected?

a) Terminals 1 and 2 – power, 3 and 4 – load

b) Terminals 1 and 3 – load, 2 and 4 – power

- Do I need to install a radiator?

Answers:

Option 1. The resistor resistance is 10 kOhm - this is the standard for installing the regulator, the wires in the circuit are connected according to the principle: 1 and 2 terminals for power, 3 and 4 for load - the current will be distributed correctly to the required poles, a radiator must be installed - to protect against overheating, The transistor used is KT 815 - this will always do. In this embodiment, the constructed circuit will work, the regulator will begin to work.

Option 2. Resistance 500 kOhm - too high, the smoothness of the sound in operation will be disrupted, or it may not work at all, terminals 1 and 3 are the load, 2 and 4 are power, a radiator is needed, in the circuit where there was a minus there will be a plus, any transistor - You can really use whatever you want. The regulator will not work because the circuit is assembled incorrectly.

Option 3. Resistance 10 kOhm, wires - 1 and 2 for load, 3 and 4 for power, resistor has a resistance of 2 kOhm, transistor KT 815. The device will not be able to work, since it will overheat greatly without a radiator.

Rheostat for interior heating stove

You can understand that the rheostat of the interior heating stove is faulty by the following signs:

- the interior does not warm up, despite the fact that the engine temperature has reached nominal;

- the stove does not turn on in one or more modes;

- When tested with a multimeter, the rheostat block shows values close to a short circuit or open circuit.

Electric rheostats are widely used in industry, technology and automobiles. Resistors are used to start electric motors, in radio engineering, and as an active load. The failure of a resistor can render the entire circuit in which it is included inoperable.

Ballast rheostats (RB) - are used together with multi-station welding rectifiers VDM and DC generators to regulate the welding current. The ballast rheostat is a set of resistors that allows you to stepwise change the slope of the external characteristic of the welding rectifier and stepwise change the welding current of each station. They differ in adjustment step, rated current, material of the working parts of the switches and climatic design.

Rheostat RB-302 (ESVA) - used to change the welding current when working in conjunction with unregulated multi-station welding rectifiers such as VDM-1202S, VDM-1205. The rheostat RB is connected to the welding circuit in series. It has seven levels of adjustment, which can be switched using contact knives and toggle switches.

Ballast rheostat RB-306 (ESVA) - used to adjust the welding current of multi-station welding rectifiers VDM-1201, VDM-1202S and similar ones for manual metal arc welding (MMA). The ballast rheostat is connected in series to the welding circuit. In the manufacture of RB-306, load elements of three diameters are used, compared to RB-302, this guarantees reliable operation at high currents under harsh operating conditions. There are seven steps for adjustment, which can be switched using contact knives and toggle switches located on the front panel of the rheostat.

Ballast rheostat RB-302T (ESVA) - has a tropical design, designed to regulate the current during manual arc welding in multi-station welding rectifiers, with an operating voltage of no more than 70V. It consists of seven stages, which can be activated using copper contact knives and toggle switches located on the front panel of the rheostat. RB-302T is connected to the welding circuit in series. In the manufacture of RB-302T, load elements of three diameters are used, like the RB-306, but in addition they are equipped with copper contact switches (knives) that have a long service life.

The block of ballast rheostats BBR 4x315 U2 is a module assembled from 4 pieces of rheostats RB-302. By combining four rheostats into one complex, the total supplied load increases to 1200A. Combining all RBs into one frame complex significantly optimizes the work of current regulation and provides mobility when transporting the entire load module. The main technical characteristics of the BBR-4x315 are determined by the characteristics of the RB-302 ballast rheostats.

POSSIBLE MALFUNCTIONS AND WAYS TO DO THEM

Table 3 Name Probable cause Method of troubleshooting When the device is operating, no Loosening Tighten the contacts is provided by the contacts for regulating the current at 6 and 10 A toggle switch terminals.

When the rheostat is operating, Loosening Tighten the threaded connections are unsatisfactorily threaded connections in the places where the currents are regulated in the connections in the places of contacts in the stages of the contacts

9. SERVICE LIFE AND STORAGE.

9.1 The service life of the rheostat is 5 years, subject to compliance with the rules of operation and storage.

9.2. Packaged rheostats can be transported by any type of transport, provided that the rheostat is protected from unacceptable climatic and mechanical influences.

9.3. The rheostat should be stored in a dry, ventilated room at a temperature from -200C to +450C and a relative humidity of no more than 80% at 200C. It is strictly forbidden to store materials in the same room with the rheostat, the vapors of which can cause metal corrosion and destruction of insulation (acids, alkalis, etc.).

9.4. The shelf life in the warehouses of trading enterprises is no more than 24 months from the date of release, after which it is necessary to remove the rheostat casing and inspect it.

10. ACCEPTANCE CERTIFICATE Ballast rheostat RB – 302/306 U2 serial number __________________ complies with the technical specifications TU 3441-008-24154334-2008 and is recognized as suitable for operation.

Release date: _________________________________2011

Quality control stamp ______________

Signature of the person responsible for acceptance: ______________________

11. WARRANTY

11.1. The manufacturer guarantees that the product meets the requirements of the technical specifications, subject to the conditions of transportation, storage and operation rules established by the technical specifications and this passport.

11.2. The warranty period for the product is 12 (twelve) months.

11.3. The warranty does not apply to products with:

a) mechanical damage or unauthorized design changes;

b) traces of outside interference or a repair attempt was made at an unauthorized service center.

c) damage caused by foreign objects, substances, liquids, insects getting inside the product;

d) damage caused by elements, fire, household factors;

e) malfunctions resulting from overloading of the product, resulting in failure of components and parts.

Unconditional signs of product overload include, but are not limited to: changes in appearance, deformation or melting of parts of product components, darkening or charring of wire insulation under the influence of high temperature.

Attention: Before putting the product into operation, carefully read the instructions. Violation of operating rules entails termination of warranty obligations to the buyer. If a malfunction of the product occurs during the warranty period, the buyer must contact the trading organization where the product was purchased or the manufacturer.

If a malfunction of the product occurs during the warranty period, the buyer must contact the trading organization where the product was purchased or the manufacturer.

Manufacturer's address:

Manufactured by Modern Welding Equipment LLC specifically for PKP Plazer LLC

344064, Rostov-on-Don, st. Vavilova, 69.

Ballast resistance for DIY welding

After all, what is a conductor? This is a material with minimal resistance so that electric current passes through them with the same minimal losses. This is common practice. The exception is cases with tasks “on the contrary”: when resistance needs to be increased.

This need arises when the current readings are too high and need to be regulated. It is for such purposes that a welding ballast exists. It makes welding easier and faster.

How to make a ballast for a welding machine with your own hands

The parameter of least resistance is extremely important, since the current passes almost unhindered and does not lose energy. For this reason, almost all conductors are made from materials with the lowest resistance.

But sometimes it is necessary to artificially simulate a situation of increased resistance, when the current indicator is too high and requires adjustment. For these purposes, there is a ballast for the welding machine.

With it you can carry out welding work easier and faster.

A ballast rheostat for welding or simply a ballast is a structural element or a separate device that creates increased resistance to current and thereby regulates its strength. This device is simple and reliable.

The ballast is found in many expensive welding machines, but it can also be purchased separately, which is not cheap. We suggest you make a ballast with your own hands.

The design of the ballast is simple and clear, so every welder can make it himself.

Operating principle and design

So how does a ballast work? In simple terms, the current that flows unhindered through the circuit encounters high resistance at a certain point, due to which it loses its magnitude. The “culprit” of high resistance is precisely the ballast connected to the circuit.

Visually, the ballast for a welding machine is a large spring with many thick turns. This spring creates ballast resistance.

A regulator is connected to the spring, with which you can change the resistance value to more or less, and therefore change the current strength.

The regulator is a movable contact that is moved along and thereby reduces or increases the length of current flow through the ballast. Ballasts are an integral part of any experienced welder's arsenal.

CLASSIFICATION

Ballasts are almost the same in their operating principle or design, but may have a number of features. The range of values that we can choose to set the desired resistance will depend on them. So, ballasts differ in the following parameters:

- Spring length. Everything is simple here - the longer the spring, the longer it takes for the current to pass through all the turns.

- Metal. Ballasts are made of various metals, each of which has its own resistance coefficient. The more powerful and serious the welding machine, the more carefully the ballast material is selected.

- Thickness. Both individual turns and the entire spring as a whole. This determines how strong the resistance indicator will be. The thickness indicator is closely related to the length indicator.

DIY ballast

To make a ballast we need thick metal wire. We used copper wire in our work. You also need a cylindrical shape (it can be pre-welded from any thick metal or take a small-diameter pipe), materials for the movable contact (we used a wire from the welding machine holder) and an ammeter.

We wind the wire around a pre-made cylindrical shape, placing the turns at a distance of no more than a centimeter from each other. We connect one end of such a spring to the current-carrying part.

To this design we attach our wire from the holder, which will be used as a mobile contact.

Before you make a ballast rheostat for welding with your own hands, please note that a home-made device may work less accurately than a factory-made device. Also follow safety precautions, because homemade ballasts are not hidden in a metal case and may not be fastened securely enough, which can lead to dire consequences

Ballast for welding machine

As you know, current always follows the path of least resistance, since the greater the value of this parameter it encounters, the greater the losses. Almost always, they try to make conductors from materials with the least resistance, but sometimes, for the operation of various mechanisms, artificial nodes are created where this parameter is specially overestimated. The ballast for a welding machine is a clear example of this. This part is intended to regulate the output current. Among all the available methods, this is the simplest and most reliable. It is used in many modern devices.

Ballast for welding machine

The operating principle of this device is based on the elementary laws of electrical engineering. The current passes through the circuit until it reaches a certain area where there is high resistance, then its value begins to drop significantly. When considering what a welding machine ballast is, you should imagine a thick, tightly compressed spring with many turns.

This is the main part of the resistance, which creates the so-called ballast. A regulator is installed on it that will change this parameter. It is presented in the form of a movable contact, which is attached to one part of the surface of the ballast.

This contact moves along the surface of the resistance, providing a faster outlet for current than if it were to flow through the entire device.

In a practical example, everything looks like this. If there were no ballast in the circuit, then the current would have no losses and its strength would be 200 A. If there is a ballast, large losses are obtained and the output current reaches 10 A. Thanks to the presence of a regulator, it is possible to reduce the length of current passage through the ballast, providing more quick exit. Due to the fact that the current follows the path of least resistance, it goes to the line of the regulator, which has a significantly lower number of Ohms than the device in question. This helps set the output current in the range from 10 to 200 A.