A beam crane is a bridge-type lifting mechanism that moves along crane tracks installed on building floors or special supports. It consists of three main elements: a span bridge, end beams with running wheels, a manual or electric hoist (hoist), which lifts and moves loads. By design it can be suspended or supported. A support crane is considered more reliable and durable; moreover, with the same parameters (load capacity and bridge length), it is cheaper than a suspended one.

It is used in small and large manufacturing enterprises, warehouses, construction sites, workshops, service centers - anywhere where it is not possible (or necessary) to install a large bridge forklift. Used during loading and unloading operations, during installation, lifting and moving loads from 1 to 10 tons.

General device

A beam crane differs from an overhead crane in that it has only one main beam part. It consists of:

- lifting device;

- span beam - the trajectory of its movement;

- end beams.

The work cycle consists of several operations:

- lifting the load to a given height;

- its horizontal movement to the place of installation work or laying;

- unloading materials;

- returning to the starting position.

This design is convenient:

- compactness - it can be used in small spaces;

- ease of installation;

- ease of maintenance;

- sufficient load capacity;

- affordable price.

Beam crane design

Features and characteristics of the overhead crane

Suspended crane beams differ only in that they are attached not from above, but from below the cargo tracks. They are divided into single-span and double-span. The design of the former includes two end beams, and the latter - three.

With this arrangement, the main load falls on the lower part of the crane runway, which negatively affects the lifting capacity. However, there is a significant advantage that must be taken into account if you are going to make the most of your warehouse space.

Suspended models do not require support columns, so they can easily be moved along areas along the walls, and not just under the ceiling. The described device has no “dead” zones, and if the production does not involve lifting loads of more than 10 tons, a suspended beam crane is a more suitable option, although it is more expensive.

Comparative characteristics:

| Support mechanism | Hanging mechanism |

| Load-bearing structures - supports located under the ceiling, the crane beam is mounted on top of them | Serves the entire workshop area, including vertical surfaces. |

| Increased load capacity | It is possible to operate two devices simultaneously. |

| Ability to change speeds | Limited load capacity |

| Due to the need to install columns and crane tracks, the movement area is limited. | Supporting structures are the vulnerable part of the device. |

Despite some differences, suspended and support crane beams have common characteristics that have ensured their widespread use:

- ease of installation, management, operation;

- compactness (some models are suitable for small spaces)

- low maintenance requirements;

- load capacity (depending on the specific model);

- affordability.

In addition, the market offers an impressive variety of device configurations, from which you can always choose the one that suits you. Often, a manufacturing plant produces a product tailored to specific customer requirements, which also makes beam cranes popular.

Types of equipment

Today, the crane beam market offers two types of such equipment, which have minor differences:

- support crane beam;

- suspended crane beam.

In the first type of model, special rails are used to move the end beams along the crane runway, along which their running wheels move. The support crane can be controlled manually or electrically. They are typically used for warehouse handling or industrial workshops.

Construction of a support crane beam

In a suspended structure, crane tracks do not require additional supports; they are installed in the ceiling, which saves installation time. Suspended crane beams are moved using a control panel. They are convenient for servicing large materials and industrial equipment. Their main advantage is the expanded work space. In addition, with the same load capacity, they are much lighter.

Installation of a suspended crane beam

For large working areas, a successful design solution was the use of suspended two-span crane beams. They differ from standard ones only in the length of the bridge. By increasing its length, the service area is significantly expanded. To reduce the excess load on the bridge and prevent its deformation, another I-beam track is mounted to the floors as an additional supporting element.

Characteristics

The parameters of the cargo device are completely determined by its design and purpose, incl. the mass of cargo that is supposed to be moved with its help. The characteristics of a crane beam almost always indicate the lifting capacity: when they say a crane beam is 5 tons or 10 tons, they mean that this crane can move loads weighing 5 tons (or 10 tons, respectively). And the dead weight of the crane beam (with a lifting capacity of 10 tons) can be from 4 to 5 tons or more (depending on the length of the span beam).

The height of the crane beam must be distinguished from the height of the load. The lifting height is determined by the distance from the lowest point (zero mark, i.e. the floor of the working area) to the highest point of the maximum possible lifting of the load. It is limited only by the size of the cargo drum and the length of the stored cable (i.e., the type and model of the cargo hoist). The height of the lifting device itself matters when calculating the position of the crane tracks - for example, their distance from the ceiling or floor beams of the room. It is defined as the distance from the bottom of the rim of the running wheels to the top plane of the bridge girder (or in the case of a double girder crane with a load trolley moving along the upper tier of the bridge - to the most protruding part of the equipment mounted on the load trolley) - and can be, for example, about 900 mm – for a support crane with a lifting capacity of 10 tons.

The length of the crane beam is determined by the length of the bridge, and in turn, depends on the estimated length of the span in which the lift will be installed. For typical commercially produced models of beam cranes, this parameter usually does not exceed:

- 22.5 m for support cranes,

- 15 m for suspended single-span crane beams,

- 24 m for suspended two-span crane beams.

But when manufacturing a cargo lift according to special customer requirements, the length of the crane beam can be increased to 32 m (and in some cases more).

Crane devices with telescopic boom

When unloading covered cars at railway stations, it is most convenient to use beam cranes with a telescopic boom. They consist of:

- from a crane bridge;

- telescopic beam;

- support rollers;

- devices for extending the telescopic boom;

- hook, which is mounted on hinges capable of rotating in all planes.

Very compact jib cranes

To ensure that the extension of the boom does not disturb its support base, the drive with rollers is mounted on an intermediate beam. It is known that telescopic forklifts with inclined crane beams are indispensable in warehouses, railway stations, and ports. Telescopic crane beams, capable of changing the angle of inclination in the range of 0-30 degrees, have become especially popular.

Telescopic loaders are presented on the market in three modifications. They can simultaneously combine three beam cranes. Telescopic forklifts are equipped with a comfortable cabin and a safety system. Some models are capable of lifting loads to a height of up to 18 m. Telescopic loaders are multifunctional; they can be equipped with various attachments - buckets, loading platforms.

Does it make sense to purchase a used crane beam?

In general, purchasing used equipment in some cases allows you to seriously save on the costs of equipping or re-equipping production. This is why sometimes people decide to buy a used beam crane. But not all used equipment can be considered a successful acquisition. For example, a purchased old crane beam can become a source of serious problems.

Let's look at the root of the problem: why do people sell beam cranes in the first place? All the many reasons can be reduced to two main ones:

1) bankruptcy of the company with the sale of its property, and

2) an attempt to get rid of a low-quality (or, possibly, exhausted) crane beam.

And if in the first case there is a chance of acquiring very decent lifting equipment, then in the second case it is much more likely to get additional worries on your head.

How to determine the quality of a purchased used crane beam?

Regardless of the price and terms offered, the entire used overhead crane should be inspected very carefully. Everything should be carefully studied - from the bridge to the gear motor and power supply system.

The bridge beam must be level and straight in all planes, and there must be no serious damage or signs of repair. It is also necessary to assess the degree of wear of the shelves on which the hoist moved - it should not exceed 3 mm.

The next point will be to inspect the wheels of the cargo mechanism. Their condition clearly shows in what mode the crane was operated and for how long. Excessive wear indicates heavy duty work. And this, in turn, leads to the conclusion that the crane beam may have exhausted its resource. If the wheel flanges are worn on one side, this indicates a misalignment and the impossibility of using the loading device without replacing the wheels.

Another important component is the gearbox. If the gears of its drive are worn out, the teeth are ground off, then most likely the drive units will need to be replaced. It is imperative to check the gear motor and assess its condition and the possibility of replacement. It often happens that this engine model has long been discontinued, and the new one is incompatible with other components and the gearbox will have to be replaced completely.

The dangers of operating a worn-out tap

In some cases, a visual inspection may not reveal all defects. For example, crane beams may have microcracks, which during operation will sooner or later lead to the destruction of the bridge or end beams. Such an accident can have the most severe consequences, so the visual inspection must be supplemented with thorough flaw detection using special equipment.

Even if the span beam is in perfect order and will withstand several more years of operation, the running mechanism may require modernization. Bringing the forklift into working condition will require additional costs. As a result, the savings will be negligible, and the increased risk of breakdowns leading to downtime and additional repair costs will eat up the remaining benefits.

Ultimately, it may turn out that the total cost of buying a used crane beam and upgrading it will exceed the cost of a new beam. In any case, the decision is up to you. If you decide to repair or modernize a used crane beam, contact our specialists.

Mobile crane racks

Instead of ceiling trusses, special overpasses can be installed for suspended modifications. Such structures are more often used in open areas. Mobile crane racks are made of metal structures and mounted on the concrete surface of the working site.

The columns are interconnected and do not require attachment to fixed structures or walls. The size of the overpass is calculated depending on the technical specifications and the required load capacity. The mobile structure consists of:

- several types of beams, among them - load-bearing, span I-beams and others;

- running carriage;

- lifting telpher;

- remote control.

Installation and operation

The installation of a crane beam involves differences depending on the characteristics of the equipment and the type of machine - whether a suspended or a support crane beam is installed. The support crane requires special crane tracks, which are mounted on special supports. Suspended allows the use of conventional I-beams, which can be attached directly to the floors of the building.

The sequence of installation work depends on the size and weight of the cargo lift and the possibility of using special equipment - for example, a self-propelled jib crane. In this case, the crane beam assembled on the floor is lifted and installed on the assembled crane tracks. If this is not possible, use large-block or element-by-element installation of the mechanism on crane tracks.

Before connecting the crane beam to the power supply system, you must carefully check the fastening of all structural elements and the reliability of the equipment. After connection, the operation of the load device is checked at idle and only after that static and dynamic tests are carried out.

Successful operation of a beam crane is based on careful and correct installation in compliance with all construction and technological standards. And in order for the crane beam to work effectively throughout the entire design period of use, it is necessary to operate it in accordance with its characteristics - load capacity, design operating mode, climatic conditions.

It is important to regularly inspect and maintain the cargo lift - inspect the crane tracks, clean and lubricate the moving parts of the mechanisms, monitor the condition of the power supply system and all electrical equipment installed on the crane beam.

Types of drives

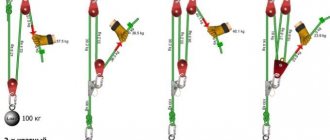

The crane design uses two types of drives.

Manual overhead crane - device diagram

Manual is cheaper and easier to operate. It is usually installed when lifting small masses and dimensions, and provides a low speed of movement of the hoist compared to an electric one.

The manual mechanism is used less and less; it gives low productivity, as it is driven by the worker’s muscle power. It operates using a shaft connected to running wheels and is more often used in small repair shops or artisanal workshops and warehouses. Manually driven beam cranes have the following characteristics: lifting capacity – up to 10 tons; span – 20 t.

Undoubtedly, the electric drive has higher performance characteristics; it also has the greatest application. The movement of cargo in it is ensured by an electric motor, a gearbox and a transmission shaft, which transmits rotation via gears to the wheels of the cargo trolley. The electric drive is designed for high performance:

- significant carrying capacity;

- intensive use of crane equipment;

- high labor productivity.

At the same time, the electric drive significantly increases the weight of the lifting mechanism and the entire structure as a whole.

The electric motor can be controlled:

- from the operator's cabin located at the level of the crane beam;

- using a wired remote control;

- via radio control is the most convenient option.

Electrically driven overhead cranes

Features and characteristics of the support crane beam

The design of this type includes: a load-bearing beam, end beams, and a control system. May be electric or manual depending on the specific configuration. Such a crane beam rests on a specially equipped crane track, moving along rails from above. It is safe, highly effective, and versatile in terms of use.

When using the described option, there is no need to limit the length of the rail tracks, and the overpass itself becomes independent. Plus, a load of much larger tonnage is captured and lifted than that of suspended structures with identical parameters.

It is controlled in two ways: by manual drive, when human physical strength is used, or by electricity. The first option is less productive because it requires more labor, plus it is unprofitable when working with heavy loads. Electric overhead cranes easily cope with tasks corresponding to their technical characteristics and do not require human effort. Most often found in premises with relatively small areas: production workshops, warehouses, hangars, ports.

Other options

At the same time, other important characteristics of the beam are taken into account, among which the following can be distinguished.

The span size or area of the crane's working area is its possible range of 3-28.5 m. For single-span cranes it is 3-15 m, for double-span cranes it is from 7.5 to 12 m.

Crane beam - installation diagram and characteristics

Lifting height . For suspended modifications, this figure reaches from 6 to 36 m, for a support version – from 6 to 18 m, but a model with a lifting height of up to 36 m can be custom-made.

Electrical voltage . To operate the devices, a three-phase current with a voltage of 380 V and a frequency of 50 hertz is supplied using a flexible cable.

Speed of cargo movement. For supporting devices - 24-60 m/min, for suspended devices - no more than 30 m/min.

Temperature conditions . Most modern models can operate in the temperature range from -20 to +40 degrees, and low-temperature modifications can operate even in 40-degree frosts.

Power and Control

Crane beams are controlled in two ways:

1. Manual - suitable if high speed of movement and lifting is not required. Suitable for workshops, assembly shops, service centers.

2. Using a push-button wired remote control or radio remote control is the most convenient and safe option, which is used in most manufacturing plants where heavy loads must be lifted and carried frequently.

The crane control panel usually has from 4 to 6 buttons, and allows you to raise/lower the load, move the hoist (along the bridge) and the crane (along the crane tracks). The remote control system for a crane-beam radio control often contains 8-9 buttons, or even more, depending on the installed systems (several speeds, etc.).

The crane beams are connected to the electrical network using trolleys, a ring current lead and a flexible cable. Electric drives use three-phase current with a voltage of 380 V. All parts of the crane beam that are not part of the electrical circuit must be grounded.

If lifting equipment is used in rooms with high air temperatures, electric drives are insulated, and all electrical equipment is placed in special cabinets or equipment cabins.

Metal faucet components

The supporting structures of the crane - span and end beams - have the highest metal consumption, which affects its weight. The main beam is usually rectangular in shape, welded from steel parts or lattice trusses to increase load resistance.

Features of the crane beam configuration

To ensure strength, diaphragms with stiffeners are inserted inside the beam. The main beam and end beams are connected by welding or using bolts. The second method eliminates the possibility of deformation and guarantees quick and accurate installation of the crane.

The weight of the outer, auxiliary wall of the bridge is reduced due to cutouts in the metal sheets, without reducing its load-bearing characteristics. The main beam may experience bending deformations from constantly moving loads. To prevent its deformation, the beams are given a construction lift in advance, that is, when cutting the steel sheets, they are slightly bent upward.

The end beams, which have a rectangular shape, have limiters. If the crane is used in an open area, additional anti-theft devices are installed to protect against wind.

Load-handling devices

Various types of load-handling devices are used for beam cranes:

- crane hooks,

- pins,

- cargo forks,

- pincer grips,

- magnetic,

- vacuum, etc.

The simplest and most common type of load-handling device is a hook. It can be one-horned or two-horned.

Less commonly used are magnetic devices - for lifting flat and round objects, and vacuum devices - driven by compressed air or using fan-type vacuum electric pumps, used in textile and paper production.

Necessary conditions for installing a crane

Before you begin installing the crane beam, you should make sure that the building can withstand the loads that arise during operation. The assembly process is carried out in several stages:

- delivery of all mechanisms to the assembly site;

- installation of the unit on crane tracks;

- lifting and installation of the bridge;

- final installation steps.

Before installing the crane, the following preliminary work should be done:

Design of the crane runway of the support crane beam

- complete the installation of metal structures for at least 5-6 spans;

- install and check crane tracks;

- make sure there is a railway track on the site;

- calculate the length of the installation area - it should be twice as long as the bridge.

After receiving the certificate of completion of the preparatory work, installation of the installation can begin.

Affordable prices, ease of assembly, and good performance indicators have ensured that the beam crane is highly popular among customers. They often act as the only possible option for carrying out lifting work in hard-to-reach places.