Today, not a single large construction project that uses concrete can do without reinforcement. After all, the latter, despite its high strength, is easily damaged when working in bending and tension. Thanks to metal rods, this drawback is eliminated, and the material that has gained sufficient strength is able to withstand significant loads of all types without harm to itself. But for each construction project, different materials and, accordingly, different classes of reinforcement will be the appropriate choice. In one case, it is worth giving preference to thin reinforcement of one grade of steel, capable of working in an aggressive environment for years without harm. And in another you will need thick reinforcement from a different grade of steel. Let's talk about it.

What classes are the fittings divided into?

Reinforcing bars are manufactured and marked in accordance with industry state standards. It is marked with a combination of letters and numbers.

It is divided into three main classes:

- A – rod reinforcement intended to form the main frame;

- Вр – wire reinforcement used to connect the main elements together;

- K – rope reinforcement, which is the most important part of factory-made prestressed reinforced concrete parts and structures. It is rarely used in individual construction.

The digital index following the letters can have a value from 1 to 6. The higher it is, the stronger the product. Currently, there is a gradual shift away from the Soviet marking system, so often the same material can be designated in two ways. Table No. 1 is intended to help correlate old and new names.

Table 1. Types of fittings and their names

| Type of fittings | Reinforcement class | |

| Designation | ||

| Old | New | |

| Hot rolled rod (GOST 5781-82*): | ||

| smooth | A-I | A-I(A-240) |

| periodic profile | A-II | A-II(A-300) |

| Ac-II | Ac-II(Ac300) | |

| A-III | A-III(A-400) | |

| A-IV | A-IV(A-600) | |

| A-V | А-V(А-800) | |

| A-VI | A-VI(A-1000) | |

| Thermally strengthened reinforcing steel for reinforced concrete structures Technical specifications GOST 10884-94 | At-IV | At 400s |

| At 500s | ||

| At 600 | ||

| At 600s | ||

| At 600k | ||

| At 800k | ||

| At 1000 | ||

| At 1000k | ||

| Ordinary reinforcing wire: | ||

| smooth | B-I | — |

| periodic profile | Vr-I | — |

The type of reinforcement is determined at the design stage of a reinforced concrete product. In this case, the method of connecting individual elements into a single frame is determined. In practice, electric welding or tying with steel wire intended for this purpose is used for this.

Rod reinforcement – class A

Hot-rolled rod reinforcement is the most popular in monolithic construction. It is divided into classes marked A400, A600 and beyond. When constructing foundations that experience maximum loads, the rods are not subjected to electric welding, but are tied together with wire. In this case, due to some mobility, it is possible to avoid increased local stresses.

Let's consider the main brands of fittings of this class:

AI (A240) – smooth rods with a cross-section from 6 to 40 mm. They are characterized by high plasticity and frost resistance of the resulting monoliths. They can be welded together or tied with wire.

A II (A300) – corrugated rods with a diameter of 10 to 80 mm. They are used as part of prestressed reinforced concrete products. Parts with them as a frame rarely crack even after prolonged use.

A III (A400) - the most common type of reinforcement for high-rise and individual construction has the form of smooth or corrugated rods with a diameter of 6 to 40 mm. Products with the letter “C” in the marking are suitable for welding.

A IV (A600) – used for the frame of prestressed concrete structures. Consist of two steel alloys. They have the form of rods with a cross section of 10-32 mm.

AV (A800) – a class of corrugated rods made of high-carbon steel with a diameter of 6 to 36 mm, used in the manufacture of long-length reinforced concrete products.

A VI (A1000) – rods made of low-alloy steel with a thickness of 6-32 mm, used in the construction of stressed monolithic structures.

Bar reinforcement is made mainly of carbon steel, which is a commonly used structural material. Sometimes a small amount of alloying additives is added to it. Even at minimal concentrations, they have a beneficial effect on improving performance characteristics:

- mechanical strength;

- plasticity;

- corrosion resistance in a slightly alkaline environment of concrete solutions.

A reinforcing frame made of alloy steel performs well in areas with increased seismic hazard and in cold climates. It is included in the most critical objects and structures operating under conditions of alternating dynamic loads.

To increase the strength of carbon steel rods, heat treatment processes (quenching and tempering) are used. Reinforcement strengthened in this way is designated as:

At.

Reinforcement resistant to alkali cracking - letter:

TO.

Products that can be welded are marked with an additional letter:

WITH.

You should pay attention to the most popular types of fittings intended for assembly using welding:

- A400S fittings are produced using hot rolling technology. The thickness of the products can reach 40 mm. A characteristic design feature is the presence of a pair of longitudinal ribs. Such reinforcement has found application in low-rise construction.

- A500C reinforcement is a common type of reinforcement reinforced by heat treatment. It is used in the production of serial reinforced concrete products not intended for use under dynamic loads.

- A600C reinforcement is a corrosion-resistant version of rods made from a carbon steel alloy with a small addition of vanadium and molybdenum. The material has found wide application in areas prone to earthquakes.

Wire reinforcement – class VR

In the manufacture of most reinforced concrete products, cold-drawn wire of ordinary quality can be used. In the case of prestressed reinforcement, special grades of high-strength wire are required.

Wire reinforcement.

Reinforcement in the form of a rope - class K

Rope reinforcement is best suited for the most heavily loaded reinforced concrete structures. It is poured with concrete in a pre-stressed state. It is better than others capable of compensating for soil movements, taking on the main bending moment acting on the foundation. To increase the service life of ropes, they are impregnated with lubricants or placed in a protective sheath of a polymer nature.

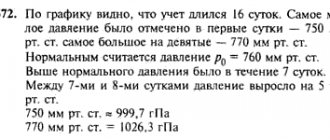

The main technical characteristics of classes and brands of building reinforcement are presented in Table No. 2.

Table 2. Standard indicators of construction reinforcement

| Reinforcement class | Nominal diameter of fittings, mm | Normal value of tensile resistance Rsn and calculated value of tensile resistance for limit states of the second group | Calculated values of reinforcement resistance for limit states of the first group | ||||

| MPa | kgf/cm2 | tensile strength, Rs | compression, Rsc | ||||

| MPa | kgf/cm2 | MPa | kgf/cm2 | ||||

| A240 | 6-40 | 240 | 2450 | 215 | 2190 | 215 | 2190 |

| A300 | 10-40 | 300 | 3060 | 270 | 2750 | 270 | 2750 |

| A400 | 6-40 | 400 | 4080 | 355 | 3620 | 355 | 3620 |

| A500 | 6-40 | 500 | 5100 | 435 | 4440 | 400 | 4080 |

| A600 | 10-40 | 600 | 6120 | 520 | 5300 | 400 | 4080 |

| A800 | 10-10 | 800 | 8160 | 695 | 7090 | — | — |

| A1000 | 10-40 | 1000 | 10200 | 830 | 8470 | — | — |

| B500 | 3-12 | 500 | 5100 | 415 | 4230 | 360 | 3670 |

| VR1200 | 8 | 1200 | 12240 | 1000 | 10200 | 400 | 4080 |

| VR1300 | 7 | 1300 | 13260 | 1070 | 10910 | — | — |

| VR1400 | 4;5;6 | 1400 | 14280 | 1170 | 11930 | — | — |

| VR1500 | 3 | 1500 | 15300 | 1250 | 12750 | — | — |

| K1400 (K-7) | 15 | 1400 | 14280 | 1170 | 11930 | — | — |

| K1500 (K-7) | 6;9;12;14 | 1500 | 15300 | 1250 | 12750 | — | — |

Color marking

Symbols of fittings can also be distinguished by the color of the ends - this is applied at the manufacturer when batches are shipped to consumers. For such designations there is also a classification table in which the marking of the reinforcement can be represented by the column “end color”; there is also a column corresponding to it and the steel grade “the number of transverse ribs between the markings”:

| Bar class | Colored (painted) marking of rod ends | Number of transverse edges between markings |

| A III | — | 3 |

| At III | White | 3 |

| A 500s | White and blue | 1 |

| A-IV | Red | 4 |

| At-IV | Yellow | 4 |

| At-IVc | Yellow and white | 4 |

| At-IVk | Yellow and red | 4 |

| A-V | Red and green | 5 |

| At-V | Green | 5 |

| At-Vk | Green and red | 5 |

| A-VI | Red and blue | 6 |

| At-VI | Blue | 6 |

| At-VIk | Blue and red | 6 |

| At-VII | Black | 7 |

As an additional column in the tables, a parameter such as “cold bending test” can also be entered.

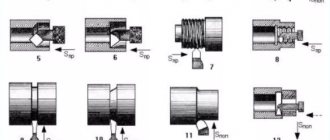

Rod reinforcement by profile type

In monolithic construction and in the manufacture of standard reinforced concrete products, reinforcement with a smooth or textured surface is used.

Smooth reinforcement

Reinforcement with an absolutely smooth surface is not capable of providing the most reliable adhesion to the concrete mixture. It is used to strengthen elements that are not subject to extremely high loads. Round bars are installed in the brickwork of load-bearing walls, in the sand-cement screed of floors and platforms, and under paving slabs.

Smooth reinforcement.

Corrugated fittings

Corrugated reinforcement has a developed outer surface, due to which it is firmly held inside the concrete layer.

There are three types of corrugation:

- ring-shaped;

- sickle-shaped;

- mixed.

Circular corrugation

Such reinforcement has good adhesion to concrete, but when used under conditions of increased loads, the rod may break in the area of the smallest cross-section.

Circular corrugation of reinforcement.

Crescent checkering

Crescent profile rods do not have pronounced weak zones, but have worse adhesion to concrete.

Crescent corrugation of reinforcement.

Mixed corrugation

Products of mixed type do not have the listed disadvantages, but require more complex manufacturing technology, and therefore are expensive.

Mixed corrugation of reinforcement.

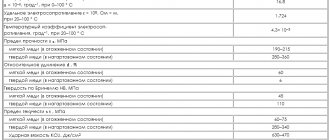

The manufacturing material and geometric features of smooth and periodic profile reinforcement according to GOST 5781-82 are collected in table No. 3.

Table 3. Requirements for fittings of various classes

| Profile type | Class | Diameter, mm | steel grade |

| Smooth profile | A1 (A240) | 6-40 | St3kp, St3ps, St3sp |

| Periodic profile | A2 (A300) | 10-40, 40-80 | St5sp, St5ps, 18G2S |

| Periodic profile | A3 (A400) | 6-40, 6-22 | 35GS, 25G2S, 32G2Rps |

| Periodic profile | A4 (A600) | 10-18 (6-8), 10-32 (36-40) | 80С, 20ХГ2Ц |

| Periodic profile | A5 (A800) | 10-32 (6-8), (36-40) | 23Х2Г2Т |

| Periodic profile | A6 (A1000) | 10-22 | 22Х2Г2АУ, 22Х2Г2Р |

What to demand and expect?

According to current standards, reinforcing steel must be:

- easy to weld;

- plastic;

- durable.

Strength is usually understood as the ability of reinforcement to withstand destructive loads of the external environment. External influences can stretch and bend metal, twist and compress, and cut. For each type of load, separate strength indicators are identified. Reinforcement is more often used in conditions where tensile loads are high, so it is this value that you should pay attention to first. To assess how much reinforcement can resist tension, you need to evaluate:

- fluid limit;

- breaking resistance.

Plasticity is a parameter that reflects the adaptability of a material to external loads that try to change the shape of the product, its cross-section. If the reinforcement under such conditions retains its initial parameters, then after removing the load it can return to its original state or retain the changes obtained. Plasticity is expressed in elongation at break, bend angle, and the number of bends remaining after cooling of the metal.

Weldability is an indicator that reflects the ability to qualitatively connect with other materials when using a particular welding method. This parameter is defined:

- metal composition;

- smelting method;

- the size of the rods in section;

- connecting features;

- plasticity.

Fittings by manufacturing method

Reinforcement for construction work is obtained in various ways.

Hot rolled rebar

This common type of rolled rod is made from rectangular steel bars, which have the specific name “bloom”. The bloom is heated until plasticity appears, after which it is driven through a rolling mill through a series of rolls, which transform the billet into a rod of a predetermined cross-section. The reinforcement obtained by this method is characterized by high strength and is suitable for the manufacture of parts subject to maximum loads.

Cold-worked reinforcement

Reinforcement of this type is produced by mechanical methods without preheating the workpiece. Its surface is clean and has a characteristic metallic luster. It is easy to weld and has good corrosion resistance. Such reinforcement can be used as a frame for reinforced concrete products, but it is more appropriate to use it when creating architectural forms with maximum aesthetic requirements.

Cold-deformed reinforcement.

What else is important?

When creating unstressed reinforced concrete structures, you should choose classes from first to third, and higher ones are useful if the structure has undergone prestressing.

If you have to work at low temperatures, and the object will continue to be operated in extreme conditions, then a brand of fittings that has a lower percentage of carbon is more suitable. As an alternative, you can choose raw materials that have undergone additional high-temperature processing.

But if it was decided to use wire as a reinforcing material, then it is better to give preference to one in which carbon is either completely absent or its content does not exceed 0.8%. This material is characterized by increased strength - up to 180 kgf/mm2 inclusive. The following parameters are provided:

- high temperature treatment;

- hardening

Reinforcement depending on the metal used

Based on the component composition of the alloy used, two main groups of reinforcing bars are distinguished.

Carbon Steel Rebar

Reinforcement in this category is made from an alloy containing only two chemical elements in significant quantities: iron and carbon. When the relative proportion of carbon increases to a certain limit, the strength and hardness of the material increases, but brittleness to fracture appears and welding capabilities deteriorate.

Alloy steel fittings

Alloy steel contains small amounts of chromium, manganese, titanium, molybdenum, tungsten and other elements. A wide variety of combinations are possible, which have different effects on the performance characteristics of the resulting alloy. Manganese increases the strength and wear resistance of the material, and silicon makes it more elastic and fluid.

How to improve?

In order for the reinforcing steel to have better quality, additional components can be added to the alloy. It is customary to use the following alloying components:

- tungsten;

- vanadium;

- chromium;

- nickel.

Some alloys add only one or two additional components, while others add a mixture of 5-6 metals. This allows you to obtain high-quality alloy steel with high performance:

- strength;

- hardness;

- corrosion resistance.

To obtain alloy steel, you can include silicon and manganese in the raw materials. Depending on how many additives are contained in a substance, it is customary to say that the material belongs to one of the following classes:

- low-alloy reinforcing steel containing no more than five percent inclusions;

- medium alloyed, in which the amount of additives varies between 5-10%;

- highly alloyed, one tenth or more consisting of additional components.

Fittings according to purpose

When creating a reinforcing frame, reinforcing bars occupy a strictly defined place. There are types of fittings that differ in their position and purpose.

Working fittings

Working reinforcement is laid along the longest structural elements. For strip foundations, floor slabs and load-bearing beams it occupies a horizontal position, and in piles and columns it occupies a vertical position. In this case, it is able to take on tensile loads, thereby increasing the strength and durability of the entire part. Rods of this class always have a variable cross-section. They form the basis of the frame.

Distribution

Distribution fittings are considered auxiliary. It is responsible for connecting the main rods into a common frame with a spatial structure. In this case, the loads are optimally distributed between several elements, which reduces the risk of damage to any of them. Such rods can occupy horizontal and vertical positions. The optimal shape for them is corrugated, although in the least critical parts it is allowed to use smooth rods or pieces of pipes.

Assembly

The task of mounting reinforcement is to ensure that the shape of the reinforcing frame remains unchanged during transportation, placement in formwork and pouring with mortar. For these purposes, rods with any surface structure are used.

1. Working.

2. Distribution.

3. Assembly room.

How and why?

The A240 grade of reinforcing steel is necessary in construction and other areas where reinforced concrete structures are used, as it is used for their reinforcement. Some experts call this category of materials “loop”, since it is customary to use reinforcement to form loop-shaped elements that strengthen reinforced concrete products. This is most relevant when the element stands out from the main plane of the structure. Hot rolled reinforcing steel A1 is suitable for creating elements that simplify loading of finished blocks, transportation and unloading. In addition, it is easier to connect different elements directly on the construction site.

The AI grade of reinforcement, like round reinforcement, is necessary for a wide range of structures. When using it, they make:

- fencing;

- furniture;

- railing

The circle and metal fittings A1, if they are manufactured in accordance with specialized standards, are used as raw materials: wire can be drawn from them. It is allowed to produce profiles:

- periodic;

- smooth.

If the reinforcement plant has the appropriate equipment, then A1 steel can be used for the manufacture of various products on lathes or milling machines. The material is processed mechanically.

Composite reinforcement

Composite reinforcement is a modern alternative to steel analogues, which have long been used in monolithic construction. Its development began back in the 60s of the last century. In Russia it is produced in accordance with the requirements of GOST 31938-2012. In other countries, the international standard ISO 10406-1:2008 is used as a basis.

Classification of composite reinforcement

The starting materials for the production of composite reinforcement are carbon, glass, and fibers based on natural minerals. They form a strong rod, which is given a ribbed shape in various ways. Parts acquire strength and hardness as a result of high-temperature treatment.

Based on material design, non-metallic fittings are divided into several categories:

1. Fiberglass composite reinforcement (FFR) is a product of a combination of fiberglass (glass roving) with special resins. The fibers are obtained by drawing a molten aluminoborsilicate mixture to a thickness of about 10-20 microns. They are used to form rods of larger diameter using adhesive impregnations and resins.

ASK fittings.

2. Basalt-composite reinforcement (BCR) is obtained from molten mountain mineral - basalt. It is brought to a molten state, stretched to the state of the finest fibers. They are woven in the presence of organic resins into fairly thick rods that, when hardened, can withstand extreme loads.

ABK fittings.

3. Combined composite reinforcement (AKK) consists of fiberglass rods coated on the outside with basalt-plastic winding. It is somewhat inferior in strength characteristics to basalt rods, although it is often passed off as them by unscrupulous suppliers.

ACC fittings.

4. Carbon composite reinforcement (ACF) is made from carbon fibers 3-15 microns thick, laid parallel to each other. This material has very high tensile strength, but is more expensive than other composite analogues.

5. Aramidocomposite rods (AAC) are durable and chemically resistant parts made from polyamide molecular chains. The hydrogen bonds that arise between them during the molding process give the products special reliability and durability.

Dimensions of composite reinforcement

Composite reinforcement, even with a small thickness, can take on enormous loads. The most popular diameters of such rods are presented in Table No. 4.

Table 4. Nominal diameters of composite reinforcement

| Nominal diameter according to GOST 31938-2012 Composite polymer reinforcement for reinforcing concrete structures. General technical conditions (as amended), mm | ||||||||||||

| 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 |

The standard allows the production of composite reinforcement with other sizes. The rods usually arrive from the manufacturer in a strictly defined cut. Their length ranges from 0.5 to 12.0 meters. Maximum deviations in the length of single copies cannot exceed the values specified in table No. 5.

Table 5. Requirements for the manufacturing accuracy of composite rods

| Rod length | Maximum deviations along the length, mm |

| up to 6 meters inclusive | +/- 25 |

| over 6 to 12 meters | +/- 35 |

| more than 12 meters | +/- 50 |

Some types of composite rebar come in the form of coils or wound on rigid drums.

Coil of composite reinforcement.

Mechanics and reliability

The above parameters allow us to talk about how good the mechanical parameters of steel are. It is on their basis that technical characteristics and indicators are distinguished.

An important feature of reinforcement is its temporary resistance. To determine it, as well as to determine how large the fluid limit is, how large the elongation of steel can be relative to the initial value, special tests are carried out in production: tensile testing machines designed for this task are used.

The work is carried out as follows: when starting the machine, the load on the placed sample gradually increases. In this case, the reinforcement is located in a rigid fastening system that does not allow the specimen to “slip away.” The mechanisms try to lengthen the rod longitudinally, deforming it. The indicators taken from the reinforcement make it possible to form a tension diagram (the scale is set arbitrarily).

Corrosion

The surface of a concrete structure must be looked after and any cracks that appear must be eliminated in a timely manner.

Due to the ability of iron to react with oxygen, steel products are inherently sensitive to the atmosphere. The interaction between it and oxygen in the air causes an oxidation process, more often called rust or corrosion.

Surface rust of the reinforcement that is located inside the structure does not affect its properties. The alkaline environment prevents this. It can even increase the bond between the bar and the concrete. However, a long process of surface oxidation (with access to air) can eventually lead to internal corrosion, which will inevitably weaken the steel bar.

The resistance of reinforcement to corrosion is determined by the chemical composition of the steel, the production method, and is designated by the letter K. In this case, the reinforcement is made of stainless steel. In private construction, it is irrational to use such rods.

It's not just about cost. Damage to the surface by metal slings or friction against the steel of the body creates pockets of corrosion.

Ferrous reinforcing metal is protected by hot-dip galvanizing or coating with epoxy resins.

Parameters and scope

Reinforcement with high strength values is usually more expensive than low-quality material. At the same time, practice shows that the use of such material allows one to achieve significant savings, since the reinforcement of reinforced concrete structures requires more economical consumption of metal.

Pay attention to the plasticity of the reinforcement: there are certain limits beyond which it is extremely undesirable. When this parameter decreases below a certain level, it is impossible to use rolled products at full strength. A structure made using such consumable raw materials becomes fragile and can unpredictably collapse under the influence of external factors. There is another risk associated with a decrease in the ductility of the metal: the likelihood of brittle fracture increases already at the stage of reinforcing reinforced concrete structures.

The most popular - what is it?

Traditionally, the most in demand in the metal market is reinforcement 8 mm in diameter. It belongs to the third class and is produced in coils, skeins, and rods. 8 mm is the parameter for the average diameter of the building material. The production of such fittings must comply with GOST 30136-95. The reinforcement produced in coils is called “wire rod” by specialists.

8mm reinforcement is made from low carbon steel. Brands ST0, ST3 are used. During the manufacturing process there are two (sometimes one) cooling stages, which makes it possible to achieve high reliability of the material. Wire rod in coils is wire.

A3 reinforcement is steel with a circular cross-section. It is necessary for the subsequent production of wire and springs. Raw materials are also indispensable in the production process of cold-drawn construction reinforcement.

Functionality

For reinforcement of precast concrete, reinforcement up to class A600 is used. Classes above this are built into prestressed reinforced concrete structures.

Types of fittings by purpose.

- Working (longitudinal and transverse): accepts the main types of loads in a reinforced concrete product, the diameter is determined by calculations.

- Assembly (distribution and structural): for the formation of three-dimensional frames and meshes.

- Distribution: ensures the correct location of the working rods.

- Structural: not calculated; installed in places that may be subject to random loads.

- Anchor: for the formation of embedded elements, including gripping loops.

The consumption of reinforcement of all types in reinforced concrete structures ranges from 50 to 80 kg per cubic meter of concrete, but not less than 8 kg. The calculation of the required quantity for a strip foundation is given below.

Production and sales

8 mm reinforcement is usually made on wire-section machines from raw materials that comply with GOST 380. This is a standard technology that involves the presence of bar steel processed by a shaft system. On machines, the material is rolled and drawn, heated and cooled. Depending on the characteristics of a particular product, it will be cooled naturally or forcibly.

This product is available for sale both by linear meters and in large skeins (for wholesale buyers).

Delivery status

An area where the private developer almost always faces unpleasant discoveries.

The reinforcement is supplied in coils (up to 22 mm thick) and rods. The skein should consist of one, maximum two segments.

Length of rods: 6 - 18 m. Rods according to standard 34028-16 come in measured length (MD), measured with unmeasured (MD1), unmeasured (ND, 6 - 12 m). In the supply of MD1, no more than 3% of unmeasured rods with a length of at least 2 m are allowed.

Rods of irregular length are cheaper. But the probability of deception here is quite high. If it is not possible to count and measure each rod, you will pay more. Please also take into account that due to the overlap of individual rods, the consumption of reinforcement will increase.

The skeins should unwind freely, and the overlap of the turns should not interfere with unwinding.

Why is this necessary?

8 mm reinforcement is indispensable in the construction of reinforced concrete and metal structures. The wire rod is quite thin, so it is used in the manufacture of meshes, frames, and ropes. The reinforcement is effective as a base for staples. It is used to strengthen building structures. A specific option is selected by analyzing the operating conditions of the building, on the basis of which a decision is made in favor of one brand or another.

Reinforcement is more often used as a raw material for the manufacture of other construction products, and not as an independent material. If wire rod is needed to produce nails or cables, then you need to control the evenness of the products: rough surfaces are unacceptable, this will significantly reduce the strength of the finished product. When manufacturing thick reinforcement and staples, the requirements for surface smoothness are not so significant. The reinforcement used to construct load-bearing walls cannot contain air-filled cavities or cracks. If 8 mm diameter reinforcement is purchased in rods, quality control involves tracking the identity of the products.