Copper is a ductile golden-pink metal with a characteristic metallic luster.

In the periodic system of D.I. Mendeleev, this chemical element is designated as Cu (Cuprum) and is located under serial number 29 in group I (side subgroup), in the 4th period. The Latin name Cuprum comes from the name of the island of Cyprus. There are known facts that in Cyprus back in the 3rd century BC there were copper mines and local craftsmen smelted copper. You can buy copper from the KUPRUM company.

According to historians, society has been familiar with copper for about nine thousand years. The most ancient copper products were found during archaeological excavations in the area of modern Turkey. Archaeologists have discovered small copper beads and plates used to decorate clothing. The finds date back to the turn of the 8th-7th millennium BC. In ancient times, copper was used to make jewelry, expensive dishes, and various tools with thin blades.

A great achievement of ancient metallurgists can be called the production of an alloy with a copper base - bronze.

What is

Copper is a pinkish metal with a golden-metallic luster. Element No. 29 of the Mendeleev periodic table. International designation: Cu (Cuprum).

Pure metal is soft, so it is often used with impurities. Plastic: stretches to micron diameters.

In air it becomes covered with a film, acquiring a yellowish-red tint. Thin plates are greenish-blue when exposed to light.

According to the official classification, it is classified as a heavy non-ferrous metal. This group also includes lead, zinc, tin, and nickel.

Basic properties of copper

Physical properties.

In air, copper acquires a bright yellowish-red hue due to the formation of an oxide film. Thin plates have a greenish-blue color when examined through them. In its pure form, copper is quite soft, malleable and easily rolled and drawn. Impurities can increase its hardness.

The high electrical conductivity of copper can be called the main property that determines its predominant use. Copper also has very high thermal conductivity. Impurities such as iron, phosphorus, tin, antimony and arsenic affect the basic properties and reduce electrical and thermal conductivity. According to these indicators, copper is second only to silver.

Copper has high densities, melting points and boiling points. An important property is also good resistance to corrosion. For example, at high humidity, iron oxidizes much faster.

Copper lends itself well to processing: it is rolled into copper sheets and copper rods, and drawn into copper wire with a thickness brought to thousandths of a millimeter. This metal is diamagnetic, that is, it is magnetized against the direction of the external magnetic field.

Chemical properties.

Copper is a relatively low-active metal. Under normal conditions in dry air, its oxidation does not occur. It reacts easily with halogens, selenium and sulfur. Acids without oxidizing properties have no effect on copper. There are no chemical reactions with hydrogen, carbon and nitrogen. In humid air, oxidation occurs to form copper (II) carbonate, the top layer of platinum. Copper is amphoteric, meaning it forms cations and anions in the earth's crust. Depending on the conditions, copper compounds exhibit acidic or basic properties.

Story

Copper is one of the first metals that humanity dealt with. This was facilitated by the advantages: high prevalence, availability, relatively low melting point.

People appreciated the benefits of copper eight thousand years ago.

The Copper Age began immediately after the Stone Age:

- Copper artifacts dug up in the territory of modern Turkey are recognized as the oldest. These are beads and decorative overlays.

- Cutting tools and utensils were made from metal.

- The history of the discovery of copper mines in Rus' begins in the Urals two thousand years before the new era. Then there were the Caucasus, Altai, Siberia.

- Industrial processing using bronze began in the 14th century. Cannons and bells were cast from the alloy.

The Tsar Bell and the Tsar Cannon were cast from bronze.

It is assumed that the metal is named after the island of Cyprus. Copper deposits were discovered here back in the 3rd century BC, and the population mastered copper smelting.

M. Vasmer’s “Etymological Dictionary of the Russian Language” links the origin of the Russian term copper with the ancient German root smid – blacksmith, metal.

Reserves, production

Global quantities of copper ore are estimated at one billion tonnes (explored). The presence of half is confirmed. Scientists believe that the earth's crust hides another three billion tons of copper ore.

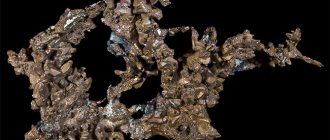

Native copper

Countries on all continents have rich reserves:

- America – Chile, Canada, USA.

- Asia – Kazakhstan, Iran.

- Africa – South Africa, Zambia, Zaire.

Russia accounts for 3% of world reserves. The deposits are concentrated in the Urals. The main producer is the Norilsk Nickel concern.

Ore is mined by open or closed methods, depending on the depth of occurrence.

The annual global ore production is 15-20 million tons.

Physico-chemical parameters

Copper is a metal with typical external characteristics (brilliance, smoothness) and crystal lattice structure. Endowed with high electrical and thermal conductivity. According to these physical properties, it is second only to silver.

| Name, symbol, number | Copper/Cuprum (Cu), 29 |

| Atomic mass (molar mass) | 63.546(3)a. e.m. (g/mol) |

| Electronic configuration | [Ar] 3d10 4s1 |

| Atomic radius | 128 pm |

| Chemical properties | |

| Covalent radius | 117 pm |

| Ion radius | (+2e) 73 (+1e) 77 (K=6) rm |

| Electronegativity | 1.90 (Pauling scale) |

| Electrode potential | +0.337 V/ +0.521 V |

| Oxidation states | 3, 2, 1, 0 |

| Ionization energy (first electron) | 745.0 (7.72) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Density (at normal conditions) | 8.92 g/cm³ |

| Melting temperature | 1356.55 K (1083.4 °C) |

| Boiling temperature | 2567 °C |

| Ud. heat of fusion | 13.01 kJ/mol |

| Ud. heat of vaporization | 304.6 kJ/mol |

| Molar heat capacity | 24.44 J/(K mol) |

| Molar volume | 7.1 cm³/mol |

| Crystal lattice of a simple substance | |

| Lattice structure | cubic face-centered |

| Lattice parameters | 3.615 Å |

| Debye temperature | 315 K |

| Other characteristics | |

| Thermal conductivity | (300 K) 401 W/(m K) |

| CAS number | 7440-50-8 |

The main chemical property of metal assessed by humans is zero corrosion. Copper is chemically inactive and does not oxidize under standard conditions.

Copper in nature

In nature, two manifestations of the element have been identified - nuggets and components of compounds with other elements.

Copper nugget

Most often these are compounds: oxides, sulfides, bicarbonates. The most common raw material is copper pyrite.

Copper gives deep blue, cyan, greenish shades to malachite, turquoise, chrysocolla, and other minerals of the jewelry and decorative segment.

Methods of obtaining

The metal content in ores does not exceed 2%. Therefore, they are enriched before smelting. There are two ways to obtain copper: pyro- and hydrometallurgical.

Pyrometallurgical

A multi-level process that includes the following steps:

- Enrichment. Ores are enriched by flotation. Copper particles suspended in water “cling” to air bubbles, which carry them to the surface. The output is a concentrated powder with 12-36% copper.

- Burning. The procedure is indicated for poor (9-24% copper) copper ores and con sulfur. When calcined with oxygen, the proportion of sulfur drops by half.

- Fuse. Shaft or reverberatory type furnaces are loaded with pieces of ore or powder concentrate at 1452°C. Copper matte is obtained.

- Purge. In converters it is exposed to compressed air. Sulfides and iron are oxidized, almost pure (98.51 - 99.51%) blister copper plus iron and other valuable components in trace quantities are formed.

- Refining. The rough product is sent for refining - with flame, then with electrolyte. Impurities are removed with gases. After the first stage, the metal is purified to 99.51%, after the final stage – to 99.96%.

The method is applied to 9/10 of the extracted raw materials.

Hydrometallurgical

It consists of treating raw materials with low concentration dissolved sulfuric acid and isolating the copper metal product.

The method is optimal for ores with a minimum percentage of copper. Removal of other components is not provided.

Reactions with copper sulfate, compounds

Copper sulfate hydrolyzes well, forming an electrolytic solution with an acidic environment:

CuSO4 → Cu 2+ + SO42-

This produces a fairly strong electrolyte. Electrolysis proceeds with the release of free oxygen, copper and sulfuric acid:

2CuSO4 + 2H2O →2Cu + 2H2SO4 + O2

The compound interacts with metals:

CuSO4 + Zn→ZnSO4 +Cu

A substitution reaction is characteristic, during which pure copper precipitates.

Copper sulfate is characterized by interactions between ion exchange and various precipitation. Most often, copper sulfate reacts in this way with other salts:

3CuSO4 + 2Na3PO4 – Cu3(PO4)2 ↓+3Na2SO4

As a result, greenish crystals of copper orthophosphate fall out. Sometimes the exchange reaction occurs with a change in oxidation states, then we are talking about redox reactions:

2CuSO4 + 4NaI → 2CuI + I2 + 2Na2SO4

Cedi sulfate reacts with sodium iodide, free iodine is released.

Copper sulfate can be reduced with hydrogen when heated:

CuSO4 + H2 → Cu + H2SO4

It often forms complex salts, such as ammonia:

CuSO4 + 4NH4 → [Cu(NH3)4]SO4

The reaction produces a bright purple solution and tetraamine copper sulfate is formed.

Alloys

The range of copper alloys with other components includes dozens of items.

Copper alloys and their applications

They are used more often than pure metal because they reduce the disadvantages inherent in pure metal. That is, they make the product stronger, more stable, and cheaper.

Copper connections are divided into two groups:

- Bronze - with tin.

- Brass – with zinc.

In addition to these main alloying components, the compound contains aluminum, nickel, bismuth, titanium, silver, gold, and non-metallic elements.

Solubility in cast iron

In the structure of malleable pearlitic cast iron, in addition to the main components, there is an additional element in the form of ordinary copper. It is this that increases the graphitization of carbon atoms and helps to increase the fluidity, strength and hardness of alloys. The metal has a positive effect on the level of perlite in the final product. The solubility of copper in cast iron is used to alloy the original composition. The main purpose of this process is to obtain a malleable alloy. It will have increased mechanical and corrosion properties, but reduced embrittlement.

If the copper content in cast iron is about 1%, then the tensile strength is equal to 40%, and the yield strength increases to 50%. This significantly changes the characteristics of the alloy. Increasing the amount of metal alloying to 2% leads to a change in strength to 65%, and the fluidity rate becomes 70%. With a higher copper content in cast iron, spheroidal graphite is more difficult to form. The introduction of an alloying element into the structure does not change the technology for forming a viscous and soft alloy. The time allotted for annealing coincides with the duration of such a reaction in the production of cast iron without copper admixture. It is about 10 hours.

The use of copper for the production of cast iron with a high silicon concentration is not able to completely eliminate the so-called ferruginization of the mixture during annealing. The result is a product with low elasticity.

Areas of application

The properties of the metal determine its use in various fields. The main consumer is the industrial complex.

Industry

Metal and alloys are used by the following industries:

- Electrical engineering, radio electronics. Cables (power, others), wires. Winding in transformers. Heat exchange devices (heating radiators, air conditioners, computer coolers, laptop heat pipes).

- Instrumentation, mechanical engineering. Parts and machine components are made from alloys of copper with zinc, tin, and aluminum. Without it, it is impossible to create galvanic cells and batteries.

- Pipes. For transporting steam, water, gas. In the energy sector, shipbuilding, for domestic needs.

Copper heat pipe cooling system in a laptop

In Japan, copper pipelines are recognized as earthquake-resistant, which is vital for this country.

Copper pipes

Construction

Roofs made of copper sheets are environmentally friendly; they do not need to be painted, since moisture and weather disasters are not scary. Service life – up to 100 years.

Medicine

The characteristics of the metal as an antiseptic and astringent are in demand in medicine.

It is a component of eye drops and mixtures for the treatment of burns.

Copper door handles and other surfaces are an attribute of medical institutions.

Copper compounds suppress the swine flu virus.

Jewelry

Jewelers use copper-based alloys.

Copper ring

Red or rose gold is a conglomerate of the noble metal with copper.

Its amount in the composition determines the final shade:

- 25% – pink;

- 50% – red.

These types of gold are the most beloved by jewelers. Copper makes products stronger, while simultaneously reducing the cost.

The second popular jewelry alloy is cupronickel (copper + nickel).

Other industries

- Copper oxide is the basis of cuprate, used in superconductors.

- Brass is used to make cartridges for rifles and artillery.

- Nickel silver is used to mint coins, create interior decorations, and cutlery.

- Copper is involved in the synthesis of chlorophyll. It is always added to mineral fertilizers for plants.

Copper

(Cu from Latin Cuprum) is an element of the eleventh group of the fourth period (a side subgroup of the first group) of the periodic system of chemical elements of D. I. Mendeleev, with atomic number 29. The simple substance copper is a plastic transition metal of golden-pink color (pink color when absence of oxide film). It has been widely used by humans for a long time. Copper coin (photo)

History

Copper is one of the first metals well mastered by man due to its availability from ore and low melting point. This metal is found in nature in native form more often than gold, silver and iron. Some of the most ancient copper products, as well as slag - evidence of its smelting from ores - were found in Turkey, during excavations of the settlement of Çatalhöyük. The Copper Age, when copper objects became widespread, follows the Stone Age in world history. Experimental studies by S. A. Semenov and his colleagues showed that, despite the softness of copper, copper tools, compared to stone ones, provide a significant advantage in the speed of cutting, planing, drilling and sawing wood, and processing bone takes approximately the same time as for stone tools

In ancient times, copper was also used in the form of an alloy with tin - bronze - for the manufacture of weapons, etc., the Bronze Age replaced the Copper Age. An alloy of copper and tin (bronze) was produced for the first time in 3000 BC. e. in the Middle East. Bronze attracted people because of its strength and good malleability, which made it suitable for making labor and hunting tools, dishes, and jewelry. All these items are found in archaeological excavations. The Bronze Age regarding tools was replaced by the Iron Age.

Copper was originally mined from malachite ore rather than sulfide ore, as it does not require pre-roasting. To do this, a mixture of ore and coal was placed in a clay vessel, the vessel was placed in a small pit, and the mixture was set on fire. The released carbon monoxide reduced malachite to free copper:

In Cyprus, already in the 3rd millennium BC there were copper mines and copper smelting was carried out.

Copper mines appeared on the territory of Russia and neighboring countries two millennia BC. e. Their remains are found in the Urals (the most famous deposit is Kargaly), in Transcaucasia, in Siberia, Altai, and in Ukraine.

In the XIII-XIV centuries. mastered industrial copper smelting. In Moscow in the 15th century. The Cannon Yard was founded, where guns of various calibers were cast from bronze. A lot of copper was used to make bells. Such works of casting art as the Tsar Cannon (1586), the Tsar Bell (1735), the Bronze Horseman (1782) were cast from bronze, and a statue of the Big Buddha was cast in Japan (Todai-ji Temple) ( 752).

With the discovery of electricity in the 18th-19th centuries. large volumes of copper began to be used for the production of wires and other related products. And although in the 20th century. wires often began to be made of aluminum; copper has not lost its importance in electrical engineering.

Origin of the name copper

The Latin name for copper Cuprum (ancient Aes cuprium, Aes cyprium) comes from the name of the island of Cyprus, where there was a rich deposit.

Strabo calls copper chalkos, from the name of the city of Chalkis on Euboea. From this word came many ancient Greek names for copper and bronze objects, blacksmithing, blacksmithing and casting. The second Latin name for copper Aes (Sanskrit ayas, Gothic aiz, German erz, English ore) means ore or mine.

The words copper and copper are found in the most ancient Russian literary monuments. Slavic *mědь “copper” does not have a clear etymology, perhaps an original word. V.I. Abaev assumed the origin of the word from the name of the country Media: *Copper from Ir. Māda - through the Greek. Μηδία[8]. According to the etymology of M. Vasmer, the word “copper” is related to ancient German. smid “blacksmith”, smîda “metal”.

Copper was designated by the alchemical symbol “♀” - “mirror of Venus”, and sometimes copper itself was also called “Venus” by alchemists. This is due to the fact that the goddess of beauty, Venus (Aphrodite), was the goddess of Cyprus, and mirrors were made from copper. This symbol of Venus was also depicted on the brand of the Polevsky copper smelter, it was used to brand Polevsky copper from 1735 to 1759, and is depicted on the modern coat of arms of the city of Polevskoy. Polevsky’s Gumeshevsky mine, the largest copper ore deposit of the Russian Empire in the Middle Urals in the 18th-19th centuries, is associated with a famous character in P. P. Bazhov’s fairy tales - the Mistress of the Copper Mountain, the patroness of the mining of malachite and copper. According to one hypothesis, she is the image of the goddess Venus refracted by the popular consciousness.

Copper in nature

The average copper content in the earth's crust (clarke) is (4.7-5.5) 10−3% (by mass). In sea and river water the copper content is much lower: 3·10−7% and 10−7% (by weight), respectively.

Copper occurs in nature both in compounds and in native form. Of industrial importance are chalcopyrite CuFeS2, also known as copper pyrite, chalcocite Cu2S and bornite Cu5FeS4. Together with them, other copper minerals are also found: covellite CuS, cuprite Cu2O, azurite Cu3(CO3)2(OH)2, malachite Cu2CO3(OH)2. Sometimes copper is found in native form; the mass of individual clusters can reach 400 tons. Copper sulfides are formed mainly in medium-temperature hydrothermal veins. Copper deposits are also often found in sedimentary rocks - cuprous sandstones and shales. The most famous deposits of this type are Udokan in the Trans-Baikal Territory, Zhezkazgan in Kazakhstan, the copper belt of Central Africa and Mansfeld in Germany. The other richest copper deposits are in Chile (Escondida and Colhausi) and the USA (Morenci).

Most copper ore is mined by open pit mining. The copper content in the ore ranges from 0.3 to 1.0%.

Physical properties of copper

Copper is a golden-pink ductile metal; in air it quickly becomes covered with an oxide film, which gives it a characteristic intense yellowish-red hue. Thin films of copper have a greenish-blue color when exposed to light.

Along with osmium, cesium and gold, copper is one of the four metals that have a distinct coloration that is different from the gray or silver of other metals. This color tint is explained by the presence of electronic transitions between the filled third and half-empty fourth atomic orbitals: the energy difference between them corresponds to the wavelength of orange light. The same mechanism is responsible for the characteristic color of gold.

Copper forms a cubic face-centered lattice, space group F m3m, a = 0.36150 nm, Z = 4.

Copper has high thermal and electrical conductivity (it ranks second in electrical conductivity among metals after silver). Specific electrical conductivity at 20 °C: 55.5-58 MS/m. Copper has a relatively large temperature coefficient of resistance: 0.4%/°C and is weakly dependent on temperature over a wide temperature range. Copper is diamagnetic.

There are a number of copper alloys: brass - with zinc, bronze - with tin and other elements, cupronickel - with nickel and others.

Atomic density of copper (N0) = 8.52 * 10 28 (atom/m³).

Application of copper

in electrical engineering

Due to its low resistivity (second only to silver, resistivity at 20 °C: 0.01724-0.0180 μOhm m/), copper is widely used in electrical engineering for the manufacture of power and other cables, wires or other conductors, for example, in printed circuit wiring. Copper wires, in turn, are also used in the windings of electric drives (household: electric motors) and power transformers. For these purposes, the metal must be very pure: impurities sharply reduce electrical conductivity. For example, the presence of 0.02% aluminum in copper reduces its electrical conductivity by almost 10%.

Heat exchange

Cooling system made of copper on heat pipes in a laptop Another useful quality of copper is its high thermal conductivity. This allows it to be used in various heat sink devices, heat exchangers, which include well-known cooling, air conditioning and heating radiators, computer coolers, and heat pipes.

For pipe production

Due to their high mechanical strength and suitability for machining, copper seamless round pipes are widely used for transporting liquids and gases: in internal water supply systems, heating systems, gas supply systems, air conditioning systems and refrigeration units. In a number of countries, copper pipes are the main material used for these purposes: in France, Great Britain and Australia for gas supply to buildings, in Great Britain, USA, Sweden and Hong Kong for water supply, in Great Britain and Sweden for heating.

Copper rods (photo)

Copper pipes (photo)

In Russia, the production of water and gas pipes from copper is standardized by the national standard GOST R 52318-2005, and the application in this capacity by the federal Code of Rules SP 40-108-2004. In addition, pipelines made of copper and copper alloys are widely used in the shipbuilding and energy industries to transport liquids and steam.

Copper alloys

Alloys using copper are widely used in various fields of technology, the most widespread of which are the above-mentioned bronze and brass. Both alloys are general names for a whole family of materials, which, in addition to tin and zinc, may include nickel, bismuth and other metals. For example, the composition of gun bronze, used for the manufacture of artillery pieces until the 19th century, includes all three main metals - copper, tin, zinc; the recipe changed depending on the time and place of manufacture of the weapon. A large amount of brass is used for the manufacture of artillery ammunition casings and weapon casings, due to its manufacturability and high ductility. For machine parts, alloys of copper with zinc, tin, aluminum, silicon, etc. (rather than pure copper) are used because of their greater strength: 30-40 kgf/mm² for alloys and 25-29 kgf/mm² for technically pure copper. Copper alloys (except beryllium bronze and some aluminum bronzes) do not change their mechanical properties during heat treatment, and their mechanical properties and wear resistance are determined only by the chemical composition and its effect on the structure. Modulus of elasticity of copper alloys (900-12000 kgf/mm², lower than that of steel). The main advantage of copper alloys is their low coefficient of friction (which makes them especially rational for use in sliding pairs), combined for many alloys with high ductility and good resistance to corrosion in a number of aggressive environments (copper-nickel alloys and aluminum bronzes) and good electrical conductivity. The magnitude of the coefficient of friction is almost the same for all copper alloys, while the mechanical properties and wear resistance, as well as behavior under corrosion conditions, depend on the composition of the alloys, and therefore on the structure. Strength is higher in two-phase alloys, and ductility is higher in single-phase alloys. Copper-nickel alloy (cupronickel) is used for minting small change coins. Copper-nickel alloys, including the so-called “Admiralty” alloy, are widely used in shipbuilding (turbine exhaust steam condenser tubes cooled by sea water) and applications related to the possibility of aggressive action of sea water due to their high corrosion resistance. Copper is an important component of hard solders - alloys with a melting point of 590-880 ° C, which have good adhesion to most metals, and are used for durable connections of a variety of metal parts, especially dissimilar metals, from pipeline fittings to liquid rocket engines.

Alloys in which copper is significant

A duralumin part of the Hindenburg airship (LZ 129) damaged by fire. Dural (duralumin) is defined as an alloy of aluminum and copper (copper in duralumin is 4.4%).

Jewelry alloys

In jewelry, alloys of copper and gold are often used to increase the resistance of products to deformation and abrasion, since pure gold is a very soft metal and is not resistant to mechanical stress.

Copper connections

Copper oxides are used to produce yttrium-barium-copper oxide (cuprate) YBa2Cu3O7-δ, which is the basis for the production of high-temperature superconductors. Copper is used to produce copper oxide galvanic cells and batteries.

Other Applications

Copper is the most widely used acetylene polymerization catalyst. Due to the fact that copper is a catalyst for the polymerization of acetylene (forms compounds of copper with acetylene), copper pipelines for transporting acetylene can only be used if the copper content in the alloy of the pipe material is no more than 64%.

Copper is widely used in architecture. Roofs and facades made of thin sheet copper, due to the auto-attenuation of the corrosion process of the copper sheet, serve trouble-free for 100-150 years. In Russia, the use of copper sheets for roofs and facades is regulated by the federal Code of Rules SP 31-116-2006.

The predicted new mass use of copper promises to be its use as bactericidal surfaces in medical institutions to reduce intra-hospital bacterial transfer: doors, handles, water stop valves, railings, bed rails, table tops - all surfaces touched by the human hand.

Copper vapor is used as a working fluid in copper vapor lasers at lasing wavelengths of 510 and 578 nm.

Copper production and mining.

World copper production in 2000 was about 15 million tons, and in 2004 - about 14 million tons. World reserves in 2000 were, according to experts, 954 million tons, of which 687 million tons were proven reserves; Russia accounted for 3.2% of total and 3.1% of confirmed world reserves. Thus, at the current rate of consumption, copper reserves will last approximately 60 years.

Production of refined copper in Russia in 2006 amounted to 881.2 thousand tons, consumption - 591.4 thousand tons. The main copper producers in Russia were:

Company thousand tons % Norilsk Nickel 425 45% Uralelectromed 351 37% Russian Copper Company 166 18%

In 2009, Metalloinvest Holding joined these copper producers in Russia, purchasing the rights to develop the new Udokanskoye copper deposit. World copper production in 2007 was 15.4 million tons, and in 2008 - 15.7 million tons.

The leaders in production were:

Chile (5.560 million tons in 2007 and 5.600 million tons in 2008), USA (1.170/1.310), Peru (1.190/1.220), China (0.946/1.000), Australia (0.870/0.850), Russia (0.740 /0.750), Indonesia (0.797/0.650), Canada (0.589/0.590), Zambia (0.520/0.560), Kazakhstan (0.407/0.460), Poland (0.452/0.430), Mexico (0.347/0.270). In terms of global production and consumption, copper ranks third after iron and aluminum.

The world's explored copper reserves at the end of 2008 amounted to 1 billion tons, of which 550 million tons were confirmed. Moreover, it is estimated that the global world reserves on land amount to 3 billion tons, and deep-sea resources are estimated at 700 million tons.

Copper powder (photo)

Modern mining methods

More than 170 minerals containing copper are now known, but only 14-15 of them are of industrial importance. This is chalcopyrite (also known as copper pyrite), malachite, and native copper is also found. Copper ores often contain molybdenum, nickel, lead, cobalt as impurities, and less commonly gold and silver. Typically, copper ores are beneficiated in factories before being sent to copper smelters. Kazakhstan, the USA, Chile, Canada, and African countries are rich in copper - Zaire, Zambia, South Africa. Escondida is the world's largest copper ore quarry (located in Chile). Depending on the depth of occurrence, ore is mined using open or closed methods.

90% of primary copper is obtained by pyrometallurgical method, 10% by hydrometallurgical method. The hydrometallurgical method is the production of copper by dissolving it in a weak solution of sulfuric acid and subsequent separation of metallic (blister) copper from the solution. The pyrometallurgical method consists of several stages: enrichment, roasting, smelting for matte, purging in a converter, refining.

To enrich copper ores, the flotation method is used (based on the use of different wettability of copper-containing particles and waste rock), which allows one to obtain copper concentrate containing from 10 to 35% copper.

Copper ores and concentrates with high sulfur content are subjected to oxidative roasting. In the process of heating the concentrate or ore to 700-800 °C in the presence of atmospheric oxygen, sulfides are oxidized and the sulfur content is reduced by almost half of the original. Only poor concentrates (with a copper content of 8 to 25%) are fired, and rich concentrates (from 25 to 35% copper) are melted without firing.

After roasting, the ore and copper concentrate are smelted into matte, which is an alloy containing copper and iron sulfides. Matte contains from 30 to 50% copper, 20-40% iron, 22-25% sulfur, in addition, matte contains impurities of nickel, zinc, lead, gold, and silver. Most often, smelting is carried out in fiery reverberatory furnaces. The temperature in the melting zone is 1450 °C.

In order to oxidize sulfides and iron, the resulting copper matte is subjected to blowing with compressed air in horizontal converters with side blast. The resulting oxides are converted into slag. The temperature in the converter is 1200–1300 °C. Interestingly, heat is released in the converter due to chemical reactions, without fuel supply. Thus, the converter produces blister copper containing 98.4–99.4% copper, 0.01–0.04% iron, 0.02–0.1% sulfur and a small amount of nickel, tin, antimony, silver, gold. This copper is poured into a ladle and poured into steel molds or a casting machine.

Next, to remove harmful impurities, blister copper is refined (fire refining and then electrolytic refining are carried out). The essence of fire refining of blister copper is the oxidation of impurities, removing them with gases and converting them into slag. After fire refining, copper with a purity of 99.0–99.7% is obtained. It is poured into molds and ingots are obtained for further smelting of alloys (bronze and brass) or ingots for electrolytic refining.

Electrolytic refining is carried out to obtain pure copper (99.95%). Electrolysis is carried out in baths where the anode is made of fire-refined copper, and the cathode is made of thin sheets of pure copper. The electrolyte is a solution of sulfuric acid with copper sulfate. During electrolysis, the concentration of sulfuric acid increases. When a direct current is passed, the anode dissolves, the copper goes into solution, and, cleaned of impurities, is deposited on the cathodes. Impurities settle to the bottom of the bath in the form of sludge, which is processed to extract valuable metals. When receiving 1000 tons of electrolytic copper, you can get up to 3 kg of silver and 200 g of gold. The cathodes are unloaded after 5-12 days, when their weight reaches 60 to 90 kg. They are thoroughly washed and then melted in electric furnaces.

Copper granules (photo)

Meaning for humans

Copper is inherent in the human body initially:

- Participates in the formation of red blood cells, collagen, elastin.

- Activates the endocrine system, slows down the aging of the body.

- Its deficiency is fraught with a slowdown in protein metabolism. This leads to pathologies in the development of the skeleton and blood composition.

It is found in many foods. Beef liver, oysters, sesame seeds, cocoa powder, black pepper, and buckwheat are rich in copper. And also nuts (hazelnuts, walnuts, cashews, peanuts, almonds).

Effect on the human body, pharmacological action

With the right dosage and course of treatment, copper sulfate does not have a negative effect on health. Pharmacological action consists of disinfection, wound healing, adaptogenicity. This is a valuable medicine that must be used wisely to achieve the best therapeutic effect. Therefore, treatment with copper sulfate should be supervised by a doctor.

Acceptable norms for taking copper sulfate

The toxic dose of copper sulfate when taken orally is 0.5 g per 1 kg of weight. At this concentration, the first symptoms of poisoning begin to appear. The maximum permissible consumption rate must necessarily be less than this value. Fatal poisoning occurs with simultaneous administration of 45-125 g.

Benefits of copper sulfate

Copper sulfate is valued in many fields of activity. Due to its strong antiseptic properties, it is able to suppress the development of bacterial infections of various origins, and can be used to treat diseases of the oral cavity (gingivitis, stomatitis, inflammation of the tonsils), as well as gynecological inflammations. Copper sulfate effectively destroys pathogens; solutions, powders and ointments based on this substance are used.

Copper salt of sulfuric acid is necessary in industry. It is distinguished by its high reactivity and low toxicity, which is why it can be used for treating residential premises, water and for direct work with metal products. Due to its high hygroscopicity, anhydrous copper sulfate powder is capable of retaining moisture for a long time and is a component of air humidifiers.

Harm of copper sulfate

Copper sulfate is harmless when used correctly. When contacting it, it is important to follow safety measures and not neglect hygiene procedures. There is no E519 in domestically produced food products, so a negative impact on humans through food is excluded.

Copper sulfate can be toxic to fish, aquatic plants and invertebrates in high doses. Therefore, before use, you need to read the instructions and consult a veterinarian.

When disinfecting premises, inhaling copper sulfate aerosol can lead to burns to the respiratory tract and severe poisoning.

Warning

The metal contains isotopes: two stable ones plus two dozen unstable ones. Although the half-life of the “long-liver” is less than 2.5 days, the material is toxic.

Therefore, the use of copper is controlled.

In Russia at the federal level (national standard, federal Code of Rules) the following is regulated:

- Production and use of copper water, steam and gas pipes.

- Amount of copper in drinking water.

1 liter of drinking water should not contain more than 1 mg of copper.

Excess copper components cause poisoning of the body. Copper utensils are not suitable for cooking.

A quarry in which copper ore was extracted by open pit mining becomes a source of toxic compounds.

Dissolution in ammonia

The process often occurs by passing NH3 in gaseous form over hot metal. The result is the dissolution of copper in ammonia, the release of Cu3N. This compound is called monovalent nitride.

Its salts are exposed to ammonia solution. The addition of such a reagent to copper chloride leads to the formation of a precipitate in the form of hydroxide:

Excess ammonia promotes the formation of a complex type compound that is dark blue in color:

This process is used to determine cupric ions.

Prices

The world price of copper is set on the London Metal Exchange. It depends on demand, determined by the state of the economy.

And fluctuates accordingly:

- By the beginning of 2008, the psychological mark of $8,000 per ton was overcome.

- Six months later it was already $+940, which became a record in the entire history of the exchange.

- At the beginning of 2011, the level was set at $10,000.

Then there was a recession. For 2022, a ton of copper is trading at $8,057. The economic slowdown due to the coronavirus pandemic has had an impact.