Copper is a ductile golden-pink metal with a characteristic metallic luster.

In the periodic system of D.I. Mendeleev, this chemical element is designated as Cu (Cuprum) and is located under serial number 29 in group I (side subgroup), in the 4th period. The Latin name Cuprum comes from the name of the island of Cyprus. There are known facts that in Cyprus back in the 3rd century BC there were copper mines and local craftsmen smelted copper. You can buy copper from the KUPRUM company.

According to historians, society has been familiar with copper for about nine thousand years. The most ancient copper products were found during archaeological excavations in the area of modern Turkey. Archaeologists have discovered small copper beads and plates used to decorate clothing. The finds date back to the turn of the 8th-7th millennium BC. In ancient times, copper was used to make jewelry, expensive dishes, and various tools with thin blades.

A great achievement of ancient metallurgists can be called the production of an alloy with a copper base - bronze.

Basic properties of copper

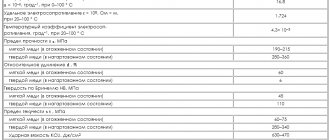

Physical properties.

In air, copper acquires a bright yellowish-red hue due to the formation of an oxide film. Thin plates have a greenish-blue color when examined through them. In its pure form, copper is quite soft, malleable and easily rolled and drawn. Impurities can increase its hardness.

The high electrical conductivity of copper can be called the main property that determines its predominant use. Copper also has very high thermal conductivity. Impurities such as iron, phosphorus, tin, antimony and arsenic affect the basic properties and reduce electrical and thermal conductivity. According to these indicators, copper is second only to silver.

Copper has high densities, melting points and boiling points. An important property is also good resistance to corrosion. For example, at high humidity, iron oxidizes much faster.

Copper lends itself well to processing: it is rolled into copper sheets and copper rods, and drawn into copper wire with a thickness brought to thousandths of a millimeter. This metal is diamagnetic, that is, it is magnetized against the direction of the external magnetic field.

Chemical properties.

Copper is a relatively low-active metal. Under normal conditions in dry air, its oxidation does not occur. It reacts easily with halogens, selenium and sulfur. Acids without oxidizing properties have no effect on copper. There are no chemical reactions with hydrogen, carbon and nitrogen. In humid air, oxidation occurs to form copper (II) carbonate, the top layer of platinum. Copper is amphoteric, meaning it forms cations and anions in the earth's crust. Depending on the conditions, copper compounds exhibit acidic or basic properties.

Copper-nickel alloys

| Cupro-nickel alloys are copper-based alloys in which the main alloying component is nickel. According to their purpose, they are divided into structural and electrical alloys. Kunial (copper-nickel-aluminium) contains 6-13% nickel, 1.5-3% aluminum, the rest is copper. Kunials are subjected to heat treatment (hardening-aging). Kunials are used for the manufacture of high-strength parts, springs and a number of electrical products. Nickel silver (copper-nickel-zinc) contains 15% nickel, 20% zinc, the rest copper. Nickel silvers have a pleasant white color, close to the color of silver. They resist atmospheric corrosion well; used in instrument making and watch production. Cupronickel (copper-nickel and small additions of iron and manganese up to 1%) have high corrosion resistance, particularly in sea water. They are used for the manufacture of heat exchangers, stamped and embossed products. Kopel (copper-nickel 43%-manganese 0.5%) is a special thermoelectrode alloy for the manufacture of thermocouples. Manganin (copper-nickel 3%-manganese 12%) is a special alloy with high electrical resistivity, used in electrical engineering for the manufacture of electric heating elements. Constantan (copper-nickel 40% manganese 1.5%) has the same purpose as manganin. |

Information sources:

| ©Gukov Konstantin Mikhailovich 2006 - 2013 Mail: |

Methods for obtaining copper

In nature, copper exists in compounds and in the form of nuggets. The compounds are represented by oxides, bicarbonates, sulfur and carbon dioxide complexes, as well as sulfide ores. The most common ores are copper pyrite and copper luster. The copper content in them is 1-2%. 90% of primary copper is mined using the pyrometallurgical method and 10% using the hydrometallurgical method.

1. The pyrometallurgical method includes the following processes: enrichment and roasting, smelting for matte, purging in a converter, electrolytic refining. Copper ores are enriched by flotation and oxidative roasting. The essence of the flotation method is as follows: copper particles suspended in an aqueous medium adhere to the surface of air bubbles and rise to the surface. The method allows you to obtain copper powder concentrate, which contains 10-35% copper.

Copper ores and concentrates with a significant sulfur content are subject to oxidative roasting. When heated in the presence of oxygen, sulfides are oxidized, and the amount of sulfur is reduced by almost half. Poor concentrates containing 8-25% copper are roasted. Rich concentrates containing 25-35% copper are melted without resorting to roasting.

The next stage of the pyrometallurgical method for producing copper is smelting for matte. If lump copper ore with a large amount of sulfur is used as a raw material, then smelting is carried out in shaft furnaces. And for powdered flotation concentrate, reverberatory furnaces are used. Melting occurs at a temperature of 1450 °C.

In horizontal converters with side blowing, the copper matte is blown with compressed air in order for the oxidation of sulfides and ferrum to occur. Next, the resulting oxides are converted into slag, and sulfur into oxide. The converter produces blister copper, which contains 98.4-99.4% copper, iron, sulfur, as well as small amounts of nickel, tin, silver and gold.

Blister copper is subject to fire and then electrolytic refining. Impurities are removed with gases and converted into slag. As a result of fire refining, copper is formed with a purity of up to 99.5%. And after electrolytic refining, the purity is 99.95%.

2. The hydrometallurgical method involves leaching copper with a weak solution of sulfuric acid, and then separating copper metal directly from the solution. This method is used for processing low-grade ores and does not allow for the associated extraction of precious metals along with copper.

Mechanical properties of copper

The mechanical properties of different grades of copper during standard static tensile tests at a temperature of 20°C differ slightly from each other.

The mechanical properties of oxygen-free copper M16 during standard static tensile tests are given in Table. 1.

Table 1. Mechanical properties of oxygen-free copper grade M1b

| Properties | State | |

| deformed | annealed | |

| Tensile strength σb, MPa | 340…450 | 220…250 |

| Yield strength σ0.2, MPa | 280-420 | 60-75 |

| Relative elongation δ, % | 4…6 | 40…50 |

| Relative narrowing ψ, % | 35…45 | 70…80 |

| Brinell hardness, HB | 90…110 | 45 |

| Endurance limit σ-1, MPa, (T=108 cycles; kσ*=1) | 100…120 | 70…80 |

| Impact strength KCU, MJ/m2 | 1,0 | 1,70 |

*kσ—stress concentration factor

The influence of the degree of cold deformation and annealing temperature on the mechanical properties of copper is shown in Fig. 1 and 2.

Rice. 1 Influence of the degree of cold deformation (%) on the mechanical properties of copper: 1 - oxygen-containing; 2 - deoxidized by phosphorus, with a high residual phosphorus content

Rice. 2. Effect of annealing temperature (within an hour) on the mechanical properties of oxygen-containing copper M1

The oxygen content in copper affects impact strength and technological ductility.

For example, the impact strength of hot-rolled copper strips (99.9% Cu) with different oxygen contents is:

O2, % 0.026 0.030 0.034 0.042

KCU,kJ/m2 860 560 510 270

The effect of oxygen on technological plasticity using the example of copper wire with a diameter of 2.6 mm in the solid state and with a copper content of 99.90% is as follows:

| Method of obtaining | Number of bends with a radius of 5 mm | Number of bend twists, at a length of 152 mm |

| Oxygen-free | 12 | 92 |

| Oxygen-free | 7 | 45 |

Copper and many of its alloys have zones of reduced ductility (“plasticity failure”). At the same time, oxygen-containing copper has a clearly defined zone of reduced plasticity at temperatures of 300...500°C; Copper deoxidized by phosphorus and with a high residual content (0.04%) also exhibits reduced ductility in this temperature range. As the purity of copper increases, the zone of reduced ductility decreases, and in oxygen-free copper of high purity (99.99%) this zone is practically absent. There is also no zone of reduced ductility in copper deoxidized with boron (0.01% B).

At negative temperatures, copper has higher strength and ductility than at a temperature of 20°C.

The mechanical properties of copper, using the example of resistance welding electrodes used at high temperatures, are given in Table. 2.

| Table 2. Mechanical properties of copper at high temperatures | |||||||

| Properties | Temperature, °C | ||||||

| 20 | 200 | 300 | 400 | 500 | 600 | 700 | |

| Tensile strength σb, MPa | 220 | 200 | 150 | 110 | 70 | 50 | 30 |

| Yield strength σ0.2, MPa | 60 | 50 | 50 | 40 | 30 | 20 | 10 |

| Relative elongation δ, % | 45 | 45 | 40 | 38 | 47 | 57 | 71 |

| Relative narrowing ψ, % | 90 | 88 | 77 | 73 | 86 | 100 | 100 |

| Vickers hardness, HV | 50 | 40 | 38 | 35 | 19 | 1 | 9 |

| Impact strength KCU, MJ/m2 | 1,7 | 1,5 | 1,4 | 1,4 | 1,2 | 0,9 | 0,8 |

| Long-term hardness HV (within 1 hour) | — | — | — | 25 | 10 | 6 | 5 |

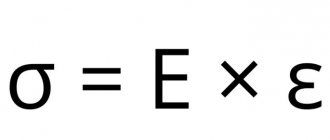

Elasticity characteristics. The elastic properties of an isotropic material are characterized by the modulus of normal elasticity E (Young's modulus), shear modulus G and volumetric compression Ecz, as well as Poisson's ratio (µ). The values of moduli E and G in the temperature range 300... 1300K decrease according to a linear law. Only in the region of low temperatures is a deviation from a uniform change in modules observed (Table 3).

| Table 3. Elasticity and shear moduli of copper at different temperatures | |||||||||

| Modules, GPa | Temperature, K | ||||||||

| 4,2 | 100 | 200 | 300 | 500 | 700 | 900 | 1100 | 1300 | |

| E | 141 | 139 | 134 | 128 | 115 | 103 | 89,7 | 76,8 | 63,7 |

| G | 50 | 49,5 | 47,3 | 44,7 | 37,8 | 31 | 24,1 | 18,5 | 11,5 |

The regulated mechanical properties of copper products for various manufacturing methods, delivery conditions and sizes are given in Table. 4 - 7.

As a rule, on tapes with a thickness of less than 0.5 mm, as well as on tapes with a thickness of 0.5 ... 1.5 mm in a soft state, used for stamping, the tensile strength and relative elongation are not determined, but tests are carried out for extrusion of the hole according to Eriksen ( see table 5).

| Table 4. Flat rolled copper. Dimensions and mechanical properties | ||||||

| Product, standard or specification | Brand | Manufacturer | Comp. fast. | Thickness, mm | Tensile strength σb, MPa | Relative elongation δ10, % |

| no less | ||||||

| Plates made of deoxidized copper, TU 48-21-517-85 | M1p | GK | — | 75…11О | 180 | 20 |

| General purpose sheets, GOST 1173-2006 | M1, M1p, M1f, M2, M2r, M3, MZr | GK | — | 3…25 | 200 | 30 |

| HC | M | 0,05… 12 | 200…260 | 36 | ||

| PT | 240…310 | 12 | ||||

| TV | 290 | 3 | ||||

| High quality sheets and strips TU 48-21-664-79 | M1 | LHC | M | 3…8 | 200 | 36 |

| LGC | — | 8…10 | 200 | 30 | ||

| PHC | M | 3…6 | 200 | 36 | ||

| Tires for electrical purposes, GOST 434-78 | M1 | HC | M | St. 7 | — | 35 |

| General purpose tapes, GOST 1173-2006 | M1, M1p, M1f, M2, M2p, M3, MZr | HC | M | 0,1…6 | 200…260 | 36 |

| PT | 240…310 | 12 | ||||

| TV | 290 | 3 | ||||

| Tapes for coaxial trunk cables, GOST 16358-79 | M1 | hk | M | 0,16…0,3 | 210 | δ5≥25 |

| Tapes for capsules, GOST 1018-77 | M1, M1p, M2, M2p | HC | M | 0,35…1,86 | 200 | 36 |

| Tapes for electrical purposes, TU 48-21-854-88 | M1, M2 | HC | M | up to 0.2 | — | — |

| 0,2…2,5 | — | 36 | ||||

| 2,5—3,53 | — | 36 | ||||

| 3,55…5,5 | — | 36 | ||||

| TV | up to 0.2 | 310 | — | |||

| 0,2…2.5 | 310 | — | ||||

| 2,5…3,53 | 284 | |||||

| 3,55…5,5 | 284 | — | ||||

| Rolled foil for technical purposes, GOST 5638-75 | M1, M2 | HC | TV | 0,015…0,05 | 290 | — |

| Legend: | ||||||

| GK - hot rolled; ХК - cold rolled; LCC cold-rolled sheets; L GK - hot-rolled sheets; PHC - cold rolled strips; M - soft; PT - semi-solid; TV is solid. | ||||||

| Table 5. Characteristics of cold-rolled strips when tested according to Eriksen (punch radius 10 mm) | ||||

| Ribbons | Brand | State | Thickness, mm | Hole depth, mm, not less |

| General purpose, GOST 1173-2006 | M1, M1p, M1p, M2, M2p, M3, MZr | soft | 0,1…0,14 | 7 |

| 0,14…0,16 | 7 | |||

| 0,16…0,28 | 8 | |||

| 0,28…0,55 | 8,5 | |||

| 0,55…0,6 | 9 | |||

| 0,6…1,1 | 9,5 | |||

| 1,1…1,5 | 10 | |||

| Radiator, GOST 20707-80 | M1, M2, M3 | soft | 0,06…0,07 | 4,5…9.0 |

| 0,08…0,09 | 6,0…9,0 | |||

| 0,1 | 7,5 | |||

| 0,12…0,15 | 7,5 | |||

| 0,17…0,25 | 8 | |||

| hard | 0,1 | 1,5…3,5 | ||

| 0,12…0,15 | 1,5…3,5 | |||

| For electrical purposes, TU 48-21-854-88 | M1 | soft | 0,1…0,15 | 7,5 |

| 0,2…0,25 | 8 | |||

| 0,3…0,5 | 8,2 | |||

| 0,6…1 | 9,5 | |||

| Table 6. Pipes and tubes made of copper. Dimensions and mechanical properties | ||||||

| Product, standard or specification | Brand | Manufacturer | Comp. fast. | Diameter, mm / Wall thickness, mm | Tensile strength σb, MPa | Relative elongation δ10, % |

| no less | ||||||

| General purpose pipes, GOST 617-2006 | M1, M1p, M1f, M2r, MZr, M2, M3 | HD | M | 3…360 / 0,8…10 | 200 | 35 |

| PT | 240 | 8 | ||||

| TV | 280 | |||||

| Etc | — | up to 200 / 5…30 | 190 | 30 | ||

| >200 / 5…30 | 180 | 30 | ||||

| Square and rectangular pipes with a round hole, TU48-21-497-81 | M1, M1p, M1f, M2r, MZr, M2, M3 | T, P | M | b; h; d | 200 | 35 |

| 15…20,5; | ||||||

| 13.5…14; | ||||||

| 6…12,5 | ||||||

| Etc | b; h; d | 190 | 30 | |||

| 36…120; | ||||||

| 16…36; | ||||||

| 11…28 | ||||||

| Copper pipes, TU 48-21-482-85 | M1, M1p, M1f, M2r, MZr, M2, M3 | Etc | — | 30 / 9 | 190 | 30 |

| Thin-walled copper tubes, TU 48-21-161-85 | M1, M2 | T | M | 0,8…2 / 0,15…0,5 | 210 | 35 |

| TV | — | 4 | ||||

| Thin-walled copper tubes. GOST 11383-75 | M1, M2, M3 | T | M | 1,5…28 / 0,15…0,7 | 210 | 35 |

| TV | 340 | 2 | ||||

| Round copper pipes for water and gas GOST 52318-2005 | M1p, M1f | T | M | 6…22 / 0,5…1.5 | 220 | δ10≥40 |

| PT | 6…54 / 0,5…2 | 250 | δ10≥20 | |||

| TV | 6…267 / 0,5…3 | 290 | δ10≥3 | |||

| Legend: | ||||||

| HD - cold-deformed; Pr - pressed; T stretched; | ||||||

| P - rolled: M - soft; PT - semi-solid; TV - solid; h, h,d - width, height, diameter of the hole. | ||||||

| Table 7. Rods, rods and wire made of copper. Dimensions and mechanical properties | ||||||

| Product, standard or specification | Brand | Manufacturer | Comp. fast. | Dimensions, mm | Tensile strength σb, MPa | Relative elongation δ10, % |

| no less | ||||||

| Square bars, TU 48-21-97-72 | M2 | Etc | — | 42…94 | 200 | 30 |

| Rods, IOCT 1535-2006 | M1, M1p, Мф, М2р, МЗр, М2, М3 | T | M | 3…50 | 200 | 35 |

| PT | 240 | 10 | ||||

| TV | 270 | 5 | ||||

| Etc | — | 20…50 | 190 | 30 | ||

| Oxygen-free copper profiles, TU 48-21-637-79 | M0b | T | M | bxh 11.4 x 8 | 200 | 38 |

| Wire for rivets, TU 48-21-456-2006 | M1, M2 | T | TV | d 1…2 | 240 | 8 |

| d 2…10.7 | 240 | 15 | ||||

| Oxygen-free copper wire, TU 48-21-158-72 | M0b | T | M | d 3.5;4.2 | 200 | 30 |

| Chopping wire, GOST 4752-79 | M0b | HD | TV | d 3…10 | 320… | — |

| 360 | ||||||

| Wire for electrical purposes, GOST 434-78 | M0, M1 | T | M | d up to 2.5 | — | 35 |

| d 2,5…7 | — | 35 | ||||

| d 7…10 | — | 35 | ||||

| d St. 10 | — | 35 | ||||

| TV | d up to 2.5 | 310 | — | |||

| d 2.5…7 | 290 | — | ||||

| d 7…10 | 270 | — | ||||

| d St. 10 | 270 | — | ||||

| Copper wire rod, TU 16705.491-2001 | not lower than M1 | NL | — | d 8…23 | 160 | 35 |

| Legend: | ||||||

| Pr - pressed; T - pulled; HD - cold-deformed; NL - continuous casting and rolling; | ||||||

| M - soft; PT - semi-solid; TV - solid; b—width; h—height; d—diameter. | ||||||

Copper Applications

Due to their valuable qualities, copper and copper alloys are used in the electrical and electrical engineering industries, in radio electronics and instrument making. There are alloys of copper with metals such as zinc, tin, aluminum, nickel, titanium, silver, and gold. Less commonly used are alloys with non-metals: phosphorus, sulfur, oxygen. There are two groups of copper alloys: brass (alloys with zinc) and bronze (alloys with other elements).

Copper is highly environmentally friendly, which allows its use in the construction of residential buildings. For example, a copper roof, due to its anti-corrosion properties, can last more than a hundred years without special care or painting.

Copper in alloys with gold is used in jewelry. This alloy increases the strength of the product, increases resistance to deformation and abrasion.

Copper compounds are characterized by high biological activity. In plants, copper takes part in the synthesis of chlorophyll. Therefore, it can be seen in the composition of mineral fertilizers. A lack of copper in the human body can cause deterioration in blood composition. It is found in many food products. For example, this metal is found in milk. However, it is important to remember that excess copper compounds can cause poisoning. This is why you should not cook food in copper cookware. During boiling, large amounts of copper can leach into food. If the dishes inside are covered with a layer of tin, then there is no danger of poisoning.

In medicine, copper is used as an antiseptic and astringent. It is a component of eye drops for conjunctivitis and solutions for burns.

Brass

Brass is a copper-based alloy, where the main alloying element is zinc (from 5 to 45%). The brass grade is made up of the letter “L”, indicating the type of alloy - brass, and a two-digit number characterizing the average copper content. For example, grade L80 is brass containing 80% Cu and 20% Zn. Brass is divided into double and multi-component. Double copper-zinc alloys - simple or double brass, multi-component - special brass. Double brass containing 88 - 97% copper is called tombak

, and containing 79 - 80% copper -

semi-tompak

.

Also, the names of brass may contain additional designations characterizing the content of other additives (except copper and zinc). For example, LAZHMts66-6-3-2 stands for: brass, which contains 66% Cu, 6% Al, 3% Fe and 2% Mn. It contains 100-(66+6+3+2)=23% zinc. Such brasses are called multicomponent. Additional additives impart certain properties to brass: Manganese

- increases strength and corrosion resistance, especially in combination with aluminum, tin and iron;

Tin

- Increases strength and greatly improves resistance to seawater corrosion.

Brasses containing tin are often called marine brasses; Nickel

- increases strength and corrosion resistance in various environments;

Lead

- worsens mechanical properties, but improves machinability.

Typically, such brass is used for processing on automatic machines and is called automatic; Silicon

- worsens hardness and strength, but improves the anti-friction properties of brass.

Brasses have relatively high mechanical properties and satisfactory corrosion resistance and, being the cheapest of copper alloys, are widely used in many branches of mechanical engineering. Double wrought brasses

| Brand | Melting point °C | Purpose |

| L60 | Thick-walled pipes, nuts, machine parts | |

| L62 | 905 | Nuts, bolts, car parts, condenser pipes |

| L68 | 938 | Stamped products |

| L70 | 950 | Chemical equipment sleeves |

| L80 | 1099 | Parts of machines, thermal and chemical equipment, coils, bellows, etc. |

| L85 | 1025 | Parts of machines, thermal and chemical equipment, coils, bellows, etc. |

| L90 | 1045 | Parts of machines, thermal and chemical equipment, coils, bellows, etc. |

| L96 | 1070 | Radiator and capillary tubes |

Multi-component wrought brasses

| Brand | Electrical resistivity Ohm * mm2/m | Elastic modulus kg/mm2 | Purpose |

| LA77-2 | 0,075 | Marine condenser pipes | |

| LAZ60-1-1 | 0,09 | 10500 | Marine parts |

| LAN59-3-2 | 0,078 | 10000 | Parts of chemical equipment, electrical machines, marine vessels |

| LZhMa59-1-1 | 0,093 | 10600 | Bearing shells, aircraft and marine parts |

| LN65-5 | 0,146 | 11200 | Gauge and condenser tubes |

| LMts58-2 | 0,118 | 10000 | Nuts, bolts, fittings, machine parts |

| LMtsA57-3-1 | Details of sea and river vessels | ||

| L090-1 | 0,054 | 10500 | Condenser pipes of heating equipment |

| L070-1 | 0,072 | 10600 | Condenser pipes of heating equipment |

| L062-1 | 0,072 | 10000 | Condenser pipes of heating equipment |

| L060-1 | 0,07 | 10500 | Condenser pipes of heating equipment |

| LS63-3 | 0,066 | 10500 | Watch parts, bushings |

| LS74-3 | 0,078 | 10500 | Watch parts, bushings |

| LS64-2 | 0,066 | 10500 | Printing matrices |

| LS60-1 | 0,07 | 10500 | Nuts, bolts, gears, bushings |

| LS59-1V | 0,68 | 10500 | Nuts, bolts, gears, bushings |

| LZhS58-1-1 | Parts made by cutting | ||

| LK80-3 | 0,2 | 9800 | Corrosion-resistant machine parts |

| LMsh68-0.05 | Condenser pipes | ||

| LAMsh77-2-0.05 | Condenser pipes | ||

| LOMsh70-1-0.05 | Condenser pipes | ||

| LANKMts75-2-2.5-0.5-0.5 | Springs, pressure tubes |

Foundry brasses

| Brand | Purpose |

| LTs16K4 | Reinforcement parts |

| LTs23A6ZhZMts2 | Solid worm screws, compression screw nuts |

| LCZOAZ | Corrosion-resistant parts |

| LTs40S | Cast fittings, bushings, cages, bearings |

| LTs40MtsZZH | Critical parts operating at temperatures up to 300°C |

| LTs25S2 | Car hydraulic system fittings |

Physical and mechanical properties

Deoxidized copper M1 effectively resists corrosion, including under standard atmospheric conditions, under the influence of sea and fresh water, and aggressive environments. Therefore, M1 copper pipe is often used for structures, units and mechanisms operating in difficult conditions. The material is weakly stable only in ammonia and sulfur dioxide gases.

Pure copper has low electrical resistance (0.018 μOhm), toughness, strength and ductility. It is easily processed by pressure and soldering, but has low casting properties and is difficult to cut and weld. It is also used to produce wear-resistant alloys with improved mechanical characteristics.

Material M1 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells M1 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, M1 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Composition and characteristics

Other elements in total should be no more than 0.1%. Impurities may contain the following elements, not more than (GOST 859-2001):

- iron – 0.005%;

- nickel – 0.002%;

- sulfur – 0.004%;

- arsenic – 0.002%;

- lead – 0.005%;

- zinc – 0.004%;

- oxygen – 0.05%;

- antimony – 0.002%;

- bismuth – 0.001%;

- tin – 0.002%.

Copper alloy M1 has excellent physical characteristics: high electrical conductivity and low (0.018 μΩ) electrical resistivity, which after heat treatment by annealing decreases by another 2.8%. The plastic properties of the alloy make it possible to use it for the manufacture of parts used in fixed joints with operating temperatures up to 250°C

Due to the very low impurity content, the cost of M1 copper is 20% higher than the other popular brand, M2. Various types of rolled copper made from M1 alloy are widely used in cryogenic industries. Due to its thermal stability, its viscosity, strength and plastic properties do not change under extreme temperatures.

Characteristics of alloy M1

Copper alloy M1 complies with GOST 859 - 2001, can be hard and soft (M1t and M1m), and can be easily processed by pressure and soldering.

Casting properties are low, so cutting and welding are difficult. The influence of impurities in the alloy on the properties of copper M1 (their percentage is indicated in brackets):

- nickel (0.002%), zinc (0.004%), iron (0.005%) and other elements that form solid solutions - reduce thermal and electrical conductivity, the presence of antimony makes hot working more difficult;

- insoluble components, such as bismuth (0.001%), lead (0.005%) - have almost no effect, but make pressure processing difficult;

- inclusions of sulfur (0.004%) and oxygen (0.05%) reduce strength and electrical conductivity.

Under normal conditions, as well as in fresh and sea water, the alloy has anti-corrosion resistance, but deteriorates in ammonia and sulfur environments. M1 copper has a melting point of 1083°C, casting temperature range is 1150-1250°C.

Copper m1 m2 m3 difference - Metalist's Handbook

- 1 Copper M1 - prices in Moscow. Hard, soft, pressed, annealed copper

- 2 Copper sheet grades M1, M1R, M2, M2R, M3, M3R. GOST 495-92

- 3 Copper pipe (tube)

- 4 Copper

- 5 Article about the types and differences of copper scrap, and the services of the Phoenix-C company

sells bushings, round bars, strips, wire rods, sheets, pipes, hexagons, foil, tires and wire from copper alloy M1 at the lowest prices in the assortment.

All types of products are manufactured in accordance with the relevant GOSTs. If necessary, we sell in pieces/blanks. We also provide related services for metalworking, packaging, storage and delivery of goods to various regions of Russia.

We will provide you with a comfortable full-cycle service. Flexible system of discounts. Your own fleet of vehicles - free delivery within Moscow within 1 day. Delivery to the regions in 2-3 days (free delivery to the transport company terminal).

Copper alloy M1 is produced in accordance with GOST 859-2001. This material contains 99.9% copper, as well as other substances: iron, arsenic, nickel, zinc, sulfur, lead, oxygen, bismuth, tin and antimony. This is a highly plastic material with good corrosion resistance. It is highly processed and is part of the manufacturing process for many other metals.

The key alloying elements here are nickel and phosphorus. Copper alloy M1 can be oxygen-free, cathodic, deoxidized with phosphorus or oxygen. At the same time, according to technical parameters, hard and soft copper are distinguished. This alloy is used primarily in the automotive and aircraft industries, as well as in instrument making.

| Copper pipe M1T | Check availability, sizes and prices in the catalogue. |

| Copper pipe M1M (MM) | Check availability, sizes and prices in the catalogue. |

| Copper busbar М1М (ШММ) | Check availability, sizes and prices in the catalogue. |

| Copper bus M1T (SHMT) | Check availability, sizes and prices in the catalogue. |

| Copper wire M1M | Check availability, sizes and prices in the catalogue. |

| Copper wire M1T (MT) | Check availability, sizes and prices in the catalogue. |

| Copper strip (bus) M1 | Check availability, sizes and prices in the catalogue. |

| Copper tape M1 | Check availability, sizes and prices in the catalogue. |

| Copper tape M1M | Check availability, sizes and prices in the catalogue. |

| Copper tape M1T | Check availability, sizes and prices in the catalogue. |

You can get more information on the current range of M1 copper products we offer from our managers.

Moscow, sh. Enthusiastov, 56, building 44

This material has a number of analogues abroad:

- American alloy C11000;

- English composition C106;

- Italian copper Cu-DHP;

- European copper Cu-ETP;

- German alloy 2.0090.

They have similar technical characteristics and can be used for the same tasks as the M1 brand.

Areas of application

M1 alloy is used for the manufacture of conductive parts and various rolled semi-finished products. The alloy is also used for the production of tin-free bronze compounds. It is popular in the production of cryogenic equipment, and the wire is often used to make rods intended for welding.

Features of production and application

Copper of a chemical composition similar to the domestic M1 grade is produced in many countries with a developed metallurgical industry:

- Japan (JIS standard), USA – C1100, C1220.

- European Union (EN standard) – Cu-ETP.

- England (BS standard) – C106.

- France (AFNOR standard) – Cu-B.

- Italy (UNI standard) – Cu-DHP.

The undoubted leader in the production of various oxygen-free copper alloys - analogues of the domestic M1 grade is the German metallurgical industry. In accordance with DIN and WNR standards, non-ferrous metallurgy plants produce three types of alloys - Ecu57, ECu58, SF-Cu.

The coefficient of friction of metal with lubricant is 0.011, without lubricant - 0.043. There are two categories of alloys according to GOST 1173-2006 in terms of Brinell hardness:

| solid | HB 10 -1 95MPa |

| soft | HB 10 -1 55MPa |

During the casting process, it must be remembered that the linear shrinkage of M1 is 2.1%. Copper melts at a temperature of 1083°C, casting is carried out in the temperature range of 1150-1250°C.

M1 is produced in the form of cast (horizontal casting ingots, GOST 193-79) or deformed (wire rod, TU 1844-01003292517-2004; strip, GOST 1173-2006; annealed and pressed rod, GOST 1535-2006; pipe, GOST R 52318- 2005) semi-finished products. Rolled sheets must be subjected to bending tests. According to the standard, tape up to 5 mm thick must withstand bending until the sides touch. Thicker sheets (6-12 mm) are checked until the sides are parallel.

Semi-finished products produced by cold rolling are tested for bending at temperatures up to 90°C. Cold-deformed copper pipes (soft, semi-hard, hard) are produced using technology that does not affect further performance. They do not defrost and are resistant to rupture when liquid media freeze. Large cross-section pipes are manufactured using pressing technology.

Alloy M1 is used in cryogenic production. It is used to make current conductors, wire, rods and electrodes for automatic welding and gas welding of non-critical joints of cast iron and copper parts. M1 is the main alloy for the production of high quality bronze.

Source