Published: 08/04/2012 Category: Tools and devices

Drill attachment - Malco Turboshear TSNS1 scissors. Can handle both slate and slate.

Did you know that a regular drill can do much more than just drill? Its capabilities are significantly expanded by special attachments, attachments and various devices.

Surely not every owner of a drill knows that it can not only drill holes, but also saw, mill, and even turn into a lathe or a pump for pumping liquids. An ordinary electric drill owes such an enviable versatility to the abundance of a wide variety of attachments, attachments and accessories. It is hardly possible to find another power tool for which there are as many attachments as for an electric drill.

Of course, the multifunctionality of the drill created by the attachments is in no way capable of replacing a fleet of special professional tools (in terms of cleanliness of processing, accuracy and productivity). But at the household level, all the additional functions acquired by the drill will fully satisfy the needs of the home craftsman.

The SC 165 quick clamp ensures quick fixation of the workpiece when drilling. The drill holder allows you to quickly secure the drill and perform stationary work. Can be rotated 360 degrees, just like vertically. The same goes horizontally.

The most widely available are drill stops . The simplest stop, installed on the auxiliary handle of the drill (attachment set: auxiliary handle and stop with a metric scale), allows you to drill holes to the desired depth. With it, you will never accidentally drill through a workpiece or a thin partition.

The parallel stop is more advanced, since it controls not only the depth of the hole, but also its verticality relative to the surface being machined. This type of attachment is produced both for construction (drilling in walls and ceilings) and carpentry (furniture) work. The attachment for construction purposes is professional and is a single unit with an additional handle mounted on a powerful drill. Some models have a built-in dust extractor connected to the vacuum cleaner.

| The simplest stop for a drill is an additional handle. It has an adjustable drill depth stop (metric) | The professional stop is more reliable and has a convenient metric depth limiter scale. |

| The parallel stop, in addition to the depth of the hole, sets its perpendicularity. Model for working on vertical surfaces. | A dust removal attachment is also necessary for a drill. They are equipped with certain models of professional stops. Connects to a vacuum cleaner. |

Attachments for carpentry work are structurally similar to the racks of hand-held milling cutters, but are made less precisely and are intended only for small-scale household work. And more is not required here: a drill is a low-speed tool (relative to an electric milling machine) and does not provide high precision when machining a surface. The drill is clamped in a basket, which easily moves along two vertical guides.

Devices and attachments for drilling at an angle will allow you to drill a hole where it is simply impossible to approach with a conventional drill. Depending on the design and manufacturer, the drilling angle may be different. The most common attachments allow drilling at an angle of 90º.

This attachment allows you to limit the drilling depth , ensures strict verticality of the hole and allows you to perform (with appropriate attachments) some milling work. This is especially important when making furniture at home: inserting furniture hinges, holes for assembly fasteners and dowels, or cutting grooves. The stop can be equipped with various inserts for side drilling in round parts or with complex profiles. Some models of stops have a dust extraction device connected to the vacuum cleaner. But a professional will prefer a manual milling machine (the same operational capabilities, but high surface quality and accuracy).

Of course, holes in parts can be made most accurately and quickly on a drilling machine. But a drill equipped with a drill stand - a guide attachment - shows excellent results. As a rule, such a stand is equipped with a convenient clamping vice (for the workpiece). The vice can be moved along the stand frame to the desired position.

A drill (almost any) is easily and quickly clamped into the “basket” of the stand and the drilling machine is ready for work. The compact dimensions of this attachment, smooth feed and accurate metric scale make it a valuable acquisition for a small workshop.

| A home craftsman can get by with the simplest parallel stop: made of plastic, the dust is localized within itself. | Parallel fence for carpentry work: guide groove and inserts for side drilling of bars and round parts. | Removing dust and sawdust in this attachment is necessary. With it, the drill can already work like a simple hand-held milling machine. |

There are additional functional holes on the platform of the console, with which you can install a side stop. In this case, the drill is capable of performing all the operations of a manual milling cutter, for example, selecting a groove exactly (with the appropriate attachment). | ||

The attachment to the drill, which turns it into a wood lathe, cannot but arouse interest . The attachment is easily attached to the table and the machine is ready. Available in several design options. As a rule, a certain set of accessories and cutting tools is offered for it. This type of attachment does not pretend to be a professional tool, but many parts for individual furniture or a country house can be made quite well using it. But if you start mass production of turned table legs or balusters using this attachment, it will quickly break, and the drill will not withstand such violence. Our photographs give a clear idea of the design and operating principle of this attachment.

| Compact wood lathe from a drill | Compact wood lathe from a drill |

| A compact wood lathe is the dream of any home craftsman. There are several types of turning attachments for drills. They differ not only in their design, but also in the set of cutting tools offered for them. | |

The most famous and widespread are attachments that turn a drill into an electric sharpener . Here we will introduce you to only two specialized attachments of this type: one for sharpening circular saw blades and the other for sharpening drills, chisels and plane knives. The value of attachments lies in the fact that they allow you to avoid the expensive services of professional sharpeners of such tools. With them you will not have problems with either the sharpening angle or the perfect cutting edge (even if you have never done this before). Installing such attachments on a drill does not cause any difficulties.

| A drill stand plus a drill is a convenient drilling machine. The design of the frame allows you to mount a clamping vice on it to fix the workpiece. | Vises for racks come in different modifications. But their mounting holes must correspond to the grooves in the rack frame. |

| The vice on the bed can be moved. There are options with the vise rotating around an axis and even with a changing angle of the stand. | A drill mounted in a stand plus an abrasive attachment allows you to create high-quality concave surfaces. |

Noteworthy is an easy-to-use and compact attachment for milling grooves in the ends of cabinet furniture parts or joinery (for corner joints). It is very simple to work with it: there is no need to clamp the workpiece on a workbench, the quality and accuracy of processing is high, the depth of the groove and its level can be set by simple adjustment. This attachment will completely satisfy a professional furniture maker.

For those craftsmen whose work is very diverse, a long flexible or angled drive for a drill . They are simply installed in the drill chuck and have their own clamping chuck, suitable for any attachments (drills, grinding stones, bits, etc.). These attachments allow you to work with a drill in the most difficult to reach places. It certainly wouldn’t occur to anyone to use a drill to pump liquids.

| Attachment - water pump for Bosch drill | The nozzle is a water pump. Capacity up to 2500 l/h. |

But this is quite realistic and not unreasonable if you use a pump attachment installed in the drill chuck . Of course, it is not intended for long-term continuous operation and has a low productivity, but it can and is quite convenient to pump out (viscous) paint from a barrel or dirty water from a basement. By changing the speed of the drill, you change the speed of pumping out liquid. As a rule, the entire body of such a set-top box is made of plastic: the service life is short, but the price is low.

| The attachment for sharpening disc blades allows you to do it yourself, without resorting to the expensive service of a professional. | The grooves for corner joints can also be selected using a drill, equipped with a special attachment. It has a dust extraction device. | A long flexible drive with a chuck is another great addition to a drill. It works with any attachments. |

| A small attachment to the drill will help you sharpen a drill, chisel or plane knife to high-quality sharpening. The sharpening angle is adjustable. | The drill can be used as a screwdriver, suitable for working even in hard-to-reach and inconvenient places. | The drill can work as a pump. Nozzles come in different capacities (suitable for paint and even dirty water). |

| Professional template: durable, reduces the labor intensity of marking and drilling standard holes for furniture assembly. | The furniture template for drilling holes has standard dimensions: holes, distances between them and from the edge of the part. | This template ensures that the hole is vertical and centered. A plastic template is enough for a home craftsman. |

It is generally accepted that templates significantly speed up many operations and increase the accuracy of processing parts and their assembly. This can be confirmed by the abundance of existing drill templates . We show only the most common patterns that are most often in demand when working with a drill. Among them there are both professional ones (durable and maintain the accuracy of their dimensions) and for home craftsmen (made of plastic).

Drilling template | Drilling template |

Template (jig) for drilling precise holes for dowels.

But regardless of this, they contain all the basic standard sizes of furniture holes: for inserting hinges and locks, for furniture ties and dowels, as well as the distances between them and from the edges of parts. Some templates allow you to dispense with the rip fence.

Sometimes you can’t do without a good dust removal and garbage collection system when working independently. The DeWALT DWA500DC dust collector will help with vertical drilling in the ceiling.

Drill Guide Features

The drill stand has several important characteristics:

- Vertical stroke (how far the tool can be moved vertically).

- The diameter of the fixing flange (determines what size tool can be clamped).

- Material.

- Size and weight of the device.

Drilling stands can be mobile or stationary. The stationary guides are very reminiscent of a small drill press, they look like a tripod for a drill. Mobile guides are attachments for drilling tools. Their main advantage is their very high mobility.

An important property of the rack is the method of fastening. The most reliable option is a magnetic mount. There is also a simpler option - this is a vacuum mount.

Mobile devices fit comfortably in your hands and absorb vibration when drilling. Most people choose mobile guides. All thanks to their excellent characteristics. They are very reliable, compact and have a low price.

Top 3. WolfCraft 5027000

Rating (2021): 3.96

21 reviews taken into account from resources: Yandex.Market, All Tools

The most reliable design The model is made of durable cast iron that can withstand significant loads. The high-alloy steel support makes the stand even more reliable and durable. The manufacturer does not use silumin and other brittle alloys.

- Characteristics

Average price: 12,700 rub.

- Country: Germany

- Height (mm): 305

- Drill socket diameter (mm): 45

- Working stroke (mm): 130

- Base size (mm): 203×307

- Weight (kg): 8.07

This drill stand belongs to the professional category. This is evidenced not only by its price, but also by some design features. In particular, there is a completely closed carriage, which prevents chips from getting into the pressing mechanism. For more precise work, there is a ruler, as well as a limiter that prevents the drill from falling below the set level. There are also very comfortable handles, consisting of three modules, and not one, as is most often the case. Of course, you won’t be able to wrap the steering wheel completely; the travel depth is only 130 millimeters, but it is very convenient when working. And of course, only durable materials are used - cast iron and alloy steel. No silumin or cheap plastic.

Advantages and disadvantages

- Triple lever

- Closed carriage

- Ruler and depth gauge

- High price

See also:

- 12 Best Cordless Drills

The rating of the best models is represented by the following tools:

Tecmobit Wolfcraft

“Caliber 96302“. An excellent budget model. It has good quality and low price. The attachment consists of two chromed metal rods and a plastic base. The device also has a special device for fixing the tool. The caliber has proven itself to be an inexpensive and reliable tool.

Caliber 96302

The Chinese model “KWB 7784“ has long been a leader. The design of this device is similar to the Russian Caliber. Consumer opinion about it is mixed. Some consumers comment on the short service life of the device and its breakdowns. The height of the device is small, only 213 mm. It has a vertical stroke of 160 mm and a tool hole diameter of 43 mm. The weight of the device is a little more than a kilogram.

KWB brand products

Stand DIOLD SMS-43. It consists of a base, a column and a clamp for attaching an electric drill. The base has grooves for a vice. It has a height of 500 mm and a drill hole diameter of 43 mm.

Please note the following manufacturers:

- Dremel is a company that produces machines for drills. With their help you can drill at an angle, polish and grind materials.

- Sparta – Stationary racks. Important advantages are the high quality and smooth movement of the drill.

- Skrab – Often used at home and small workshops. An excellent device for its very modest price.

And these are only the most basic vertical devices for drills; besides them, there are many more well-known and not so well-known ones.

Electric drills with templates

Electric drills are often used simultaneously with special templates, which not only increase the reliability of drilling and subsequent installation, but also significantly stimulate processing. The drill guide attachment is made of metal and retains its own geometric qualities for a long period of time. For home use, you can purchase an affordable plastic sample, which, although not as strong as their metal counterpart, guarantees the highest accuracy of processing.

Required Parts

Any drill stand, regardless of its dimensions and taking into account the purpose of such devices, has basic structural elements, each of which performs its own functions and must meet certain requirements.

- The bed is one of the main components of the described equipment, which is its base (stand) and ensures the stability of the entire structure. In addition, a vice is located on the bed for fixing the workpieces being processed. The weight and dimensions of this element depend on the power of the tool used and the list of tasks performed.

- A guide post, which is positioned strictly vertically in relation to the base. Even with a slight deviation, the workpiece being processed can be damaged and the drill or cutter can be broken. Depending on the design features of a particular model, this part can be made of different materials.

- Movement mechanism. There are no strict requirements for the design of this node; templates are not applied. Its main task is to ensure smooth movement, secured with brackets or clamps of the drilling tool along the tripod. There are many variations of such mechanisms.

- Holder for equipment (drill, hammer drill, screwdriver). Clamps, blocks and other mounting elements are used as effective fastening.

Stops

This type of device is the most widely represented and has many interpretations.

- Drilling limiter. On the auxiliary handle for an electric drill there is a metal rod with metric divisions - this is a limiter that rests against a wall or workpiece and prevents the drill from penetrating to a greater depth.

- Parallel exposure. This device is more advanced - it can control the depth of the future hole and the correct location of the tool, and is used for perpendicular drilling during construction. There are models where dust is simultaneously removed using a connected vacuum cleaner. The attachment can be made in conjunction with an additional handle, which is installed on impact drills intended for long-term use in construction.

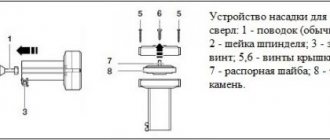

Mechanism for moving the drill in the vertical direction

A homemade drilling machine must be equipped with a mechanism that will ensure the movement of the drill in the vertical direction. The structural elements of such a unit are:

- a handle with which the carriage with a drill attached to it is brought to the surface of the workpiece;

- a spring necessary to return the carriage with the drill to its original position.

Spring mechanism for moving the drill

You can make such a mechanism using two design schemes:

- the spring is connected directly to the handle of the machine;

- the springs are located at the bottom of the carriage - in special grooves.

According to the first option, the design is carried out according to the following scheme:

- two metal plates are fixed on the machine stand using screws, between which an axis is installed, where the installation handle will be placed;

- on the other side of the rack, plates and an axis are also installed, on which one end of the spring is fixed, and its second end is connected to the handle;

- the pin with which the handle is connected to the installation carriage is placed in a longitudinal groove made in it.

The basis was an old stand from a Crocus photo enlarger made in Poland

If the springs are located at the bottom of the return mechanism, then the handle of the device is also fixed using two plates and an axis that ensures its movement. With this design, the springs are located in the lower part of the guide grooves, which are modified using metal corners that limit their movement.

The principle of operation of a drilling machine, in which the springs are located at the bottom of the carriage, is quite simple: moving down during the drilling process, the carriage with the drill attached to it presses on the springs, compressing them; after the mechanical impact on the springs stops, they unclench, lifting the carriage and drill to their original position.

Racks

To accurately drill the necessary holes in various materials, special stands or guide attachments are used, which can be purchased in stores - they ensure vertical movement of the drill clamped in a special basket. Their compactness, smooth operation and accurate metric scale make them attractive for equipping a small workshop, where a home craftsman can accurately drill any holes, even in round objects.

A small vice with a clamped workpiece can be installed anywhere on the bed and secured tightly, thanks to the grooves cut into the base.

Features of self-production

When designing a conductor for confirmation, it is necessary to correctly calculate what functions it will have to perform in the future. It should be done for the most commonly used fasteners in the house. If such a device is required by furniture makers for constant work, then it is better to buy a factory model, which is distinguished by great precision. In addition, manufacturers often include additional fasteners, stops and templates in the kit.

The price of such a device for professional use ranges from 400 to 1100 rubles. It depends on the immediate capabilities of a particular unit, the number of holes made, their length, etc. Many people are interested in how to make a furniture jig with their own hands. Drawings with dimensions are a must for novice craftsmen, as they allow you to make a high-quality design on the first try. Similar diagrams can be found on the Internet.

Basically, the conductor has the following elements:

- The basis of the product. It is directly applied to the plane of the furniture, on which the holes will be drilled.

- Guide bushings. A drill goes through them.

- Surface clamping parts. As a rule, they are located at the end of the conductor.

Next you need to take care of the correct direction of the sleeve. It can be made from stainless pipe. The length of the sleeve should be at least twice as long as the hole in which it will be located on the angle. The bushing should fit tightly in the hole. The simplest and most common option is a shaft-type landing. A corresponding hole is drilled in the corner to fit the already known diameter of the bushing, and then the fit is made. It is recommended to use a low interference fit.

There are cases when the jig needs to be made for drilling deep holes. Then the bushing is made with a collar. The number of possible holes, their length and the distance between them is selected to suit the specific needs of each master.

Several options can be used to attach the device:

- Spring support. The conductor will adhere to the material being processed using spring force. For these purposes, you can use any flat spring with the required force.

- Fastening to wood using self-tapping screws. Using this method, the jig is pressed and held on the working surface due to friction. This fastening method allows you to use the resulting marks for subsequent centering of the part. When working with chipboard, you need to use this method with great care.

- Clamps with rubber gaskets. This method is dangerous due to possible displacement of the bushing axis. This happens because the weight of the jig increases and the bushings become bent. Therefore, you must first attach the jig to the surface, mark the future hole, and then start drilling.

Top 9. SPARTA 934055

Rating (2021): 3.36

23 reviews taken into account from resources: Yandex.Market, All Tools, Ozone

- Characteristics

Average price: 2,000 rub.

- Country: China

- Height (mm): 470

- Drill socket diameter (mm): 43

- Working stroke (mm): 72

- Base size (mm): 226×226

- Weight (kg): 2.55

At first glance at this tool, you may get the impression that it has a professional purpose. Confidence-inspiring large closed carriage, high platform with diagonal slots. Even a vice is included, which is quite rare. At the same time, the price is only 2 thousand rubles, and the thought of some kind of catch involuntarily creeps in. He really is. Silumin is used in almost all parts. Metal is fragile and short-lived. It should not be subjected to high loads. It turns out that what we have in front of us is a very ordinary household counter. But already with a vice and ready to work. A good option for your money if you only use it occasionally.

Advantages and disadvantages

- The set includes a vice

- Wide platform

- Quite fragile design

Making a machine tripod

The machine will consist of the following parts:

- Bottom part;

- metal vertical guides;

- upper part with cartridge.

Bottom part

It is a board or thick plywood in which we drill two holes for the guides. These holes should be slightly larger in diameter than the guides so that in the future they can be set exactly at 90 degrees.

Metal vertical guides

They are two rods of the same size. They are attached to the bottom of the product using cold welding or epoxy resin.

In order to set them straight at an angle of 90 degrees, you can use a regular wooden block, in which the cuts on both sides should also be straight.

After the glue has completely dried, we make the upper part.

Upper part with chuck

It is made from a bar as follows. We accurately measure three holes on the block, two at the edges, they will be through and one in the center. In the central hole, the depth on both sides will be equal to the width of the bearings, which will be glued with the same glue to the axis of the chuck and the central hole of the upper part of the machine.

We install bushings in the side holes that will move freely along the metal guides, but there should be no play. The bushings must be selected exactly according to the diameter of the guides.

We also glue these bushings so that they are tightly secured and do not fly out.

We take the cartridge and glue the guide to its axis.

We put the guide on the cartridge axis and remove excess glue. The guide should also fit tightly onto the chuck axis. We get the following.

We install a bearing of a pre-selected size on the cartridge tube.

We coat it with glue and install it in the central hole of the upper part of the machine.

On the other side we do the same thing, install the second bearing.

As you can see, the tube is clamped in the cartridge. Instead, you can clamp a drill. It is needed in order to subsequently install the cartridge at an angle of 90 degrees relative to the bottom of the product.

After installing the cartridge and the glue has dried, remove the upper part of the product from the guides and place springs and washers on the metal rods.

Springs can be purchased at any hardware store. Then we put on the top.

You can install plugs on the vertical rods. We cut a hole in the bottom of the product for ease of drilling.

It turns out like this.

Checking the product for accuracy and quality of work

Installs a drill, drills a hole

insert a metal rod or drill of a suitable diameter into it.

We measure with a corner to make a right angle after drilling.

Our expectations and efforts were justified. The machine works accurately. Can be used when performing work.

Result of work

If you liked my article, give it a thumbs up. I hope you find it useful.

Good luck.

An attachment for a drill that allows you to quickly make holes for planting plants.

Spring is a busy time for gardeners and gardeners. And many are already thinking about how to make their work easier and more productive. Perhaps the most important of the upcoming events is planting, which requires some effort.

A new device called MAXBIT will help to significantly facilitate and speed up this process. It is an attachment to a drill, with which you can quickly dig holes of the ideal size and shape. The device is simply inserted into any cordless drill instead of a drill, immersed in the ground, and after pressing the “start” button, it begins to rotate, creating a neat hole.

The new product has specially curved blades that push out the soil and throw it to the sides, leaving a round hole in the ground with a flat bottom, ready for planting.

MAXBIT is available in two sizes - with a diameter of 10 and 15 cm. The device comes with a kind of extension (63 cm), which is inserted between the drill and the attachment and allows you to work without squatting or bending.

The new product is made of durable steel and has a special coating that protects the metal from rust and damage and thus increases the service life of the product. The attachment is suitable for all drills, but the manufacturer recommends using a tool with a voltage of 18 to 24 V.

Price: Ø 10 cm – $40, Ø 15 cm – $50.

10

Brands

The described equipment is a comfortable and useful addition that provides quick and reliable fixation of drilling tools for performing stationary work with high precision. Taking into account the demand, many manufacturing companies have started producing such devices. All models presented in this market segment differ from each other in design, functions, equipment and cost.

One of the popular brands is Anchor. The company offers consumers high-quality devices for working with tools that have different characteristics (power, weight and body neck diameter).

Sparky brand products are no less in demand

In reviews, owners of this equipment draw attention to the increased stability provided by the presence of a high-quality base plate cast from cast iron

Also, today there are other models of racks in the popularity rating.

- “Caliber” is a reliable and versatile design that transforms a hand-held drilling tool into a compact, stationary machine.

- Dremel is a device characterized by functionality, long service life and affordable cost. These models allow for vertical drilling, drilling holes at an angle, polishing and grinding materials in a horizontal plane.

- Sparta – stands that turn both drills and screwdrivers into stationary devices. The main advantages include the presence of a high-quality mechanism responsible for the smooth and uniform feeding of the fixed tool.

- Skrab is a rotary modification that has become a rational option for use in small workshops, garages and home environments. The design combines strength, durability and affordable cost.

In addition to all of the above, users highlight the Diolod and Artu models. The former are used with equal efficiency in domestic and industrial conditions. Depending on the modification, the diameter of the neck of the tool body, which can be fixed in the holder, varies.

Top 7. DIOLD SMS-43

Rating (2021): 3.51

35 reviews from resources were taken into account: Yandex.Market, All Tools, 220 Volt, Ozone

Extended equipment Included with the stand you also receive spare bolts, a set of keys for repair and adjustment, as well as a cast iron vice. This is the richest package at a low total cost of the product.

- Characteristics

Average price: 1,800 rub.

- Country: Russia (manufactured in China)

- Height (mm): 550

- Drill socket diameter (mm): 43

- Working stroke (mm): 65

- Base size (mm): 245×245

- Weight (kg): 2.37

Studying the reviews left under this product by real customers, you can find a lot of negativity. It concerns not the most durable structure, but also balancing. Apparently, the heavy carriage is a little overweight, and the stand must be firmly screwed to the workbench. But all these shortcomings are covered by the product package. In addition to the rack itself, you also receive a set of keys with different tips, three spare bolts for each module and a vice. The biggest rarity on the market. And all this costs less than 2 thousand rubles. Otherwise, it’s an ordinary vertical stand, hardly suitable for professional use.

Advantages and disadvantages

- Maximum configuration

- Own vice

- Failed balancing

- There are brittle metals in the structure

How to make a drilling device with your own hands

Before proceeding directly to the manufacture of the device, it is necessary to determine for what purposes it will be used, and then select the optimal design.

Conductors differ in functionality and type of execution. The following types of devices are most in demand:

- Invoices. The devices are placed on the part to be processed and secured to it using mechanisms or manually. Used for drilling holes in flat products.

- Rotary. The tool is used when it is necessary to make holes in products with a cylindrical cross-section. They have vertical and horizontal rotating axes, allowing drilling at the desired angle.

- Universal. Suitable for small-scale production, allowing for changeover in the shortest possible time.

- Tiltable. They are used in cases where technology requires drilling holes in several planes.

- Sliding. No mounting is required for these devices. The device is simply applied to the desired area of the workpiece.

- Pinned. They are easy to use, but are limited in movement across the surface of the product.

By making your own drilling jig, you can save a fair amount of money for more important needs.

For construction you will need:

- Bulgarian;

- welding machine;

- drill;

- locksmith tools.

The manufacture of the device is carried out in the following sequence:

- A piece of reinforcement with a square section of 10x10 mm is selected.

- A piece of the required length is cut, the edges and edges are cleaned.

- Markings are made for template holes. Their center should be located at least 8 mm from the edge. A distance of at least 32 mm is maintained between the centers of the nearest holes.

- A hole with a diameter of 5 mm is drilled in pre-marked centers.

- To create a stop, you will need a metal plate 1 mm thick and 2.5 mm wide, bent at a right angle.

- A thread is cut in the plate and in the fittings for attaching the clamp.

- Both parts are connected into a single structure.

Having certain skills in handling a simple tool, making a drilling device is not so difficult. For infrequent use in the household, such a device is quite sufficient. If all else fails, then the easiest option is to purchase the device in specialized or construction hypermarkets.

Attachment for shaped cutting of metal and plastic products

The Australian company Canibble offers to use its original development for cutting sheet metal - nibblers, which are an attachment to a drill.

The new product is attached to any standard drill installed in a drill chuck and converts its rotational movements into reciprocating ones, allowing you to cut steel, copper, brass, PVC and aluminum, polycarbonate and other sheet materials with a thickness of no more than 2 mm.

Due to its maneuverability and minimal turning radius (8 mm), the nozzle makes it possible to make not only straight, but also curved, round and even ornate cuts in products of various shapes and configurations. It leaves no burrs or sharp edges at the work site, ensuring the cleanest possible cut.

The cutting speed with nibblers directly depends on the speed of the drill used, however, it is not recommended to use a tool with a productivity of more than 3000 rpm.

In addition to the attachment, the manufacturer offers special clamps that allow you to comfortably hold the drill in your hands while cutting materials, or permanently mount it on the work table.

6