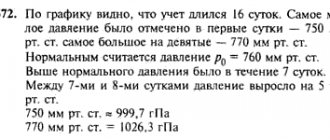

Liquid pressure gauge

The open liquid manometer device is a two-legged glass tube filled with liquid. Since only atmospheric pressure acts on the surface of the liquid, the liquid is established at the same level.

A rubber tube is attached to one end of the glass tube and connected to a flat box covered with rubber film. What happens if we press our finger on the film? Figure 2 shows that the liquid level in the pressure gauge elbow, which is connected to the rubber tube, will decrease.

Figure 2. Open liquid pressure gauge.

Let's remember Pascal's law: the pressure exerted on a liquid or gas is transmitted to any point without changes in all directions. This means that when we pressed the film, we increased the air pressure in the box.

Since the box is connected to the elbow of the glass tube, pressure is transferred to the liquid in this elbow (let’s call it “first”), that is, the pressure in the first elbow will be greater than the pressure in the other, because only atmospheric air pressure acts on that elbow.

The liquid will come to equilibrium and stop when the excess pressure in the first bend equals the pressure of the excess liquid column in the other.

The pressure exerted on the film will depend on the force of pressing: the harder we press, the higher the excess column of liquid will be. This means that the change in pressure can be associated with the height of this excess column.

With the help of a liquid pressure gauge we can measure pressure in liquids. Pay attention to Figure 3.

Figure 3. Measuring fluid pressure using a fluid pressure gauge.

The design of the pressure gauge has not been changed, but we can immerse a box covered with film in a container of water. From experience it is clear that the deeper the box is, the greater the difference in height of the liquid in the pressure gauge elbows becomes . We can say that the more pressure the liquid produces in the container.

What if we turn the box in different directions at the same depth? And again, Pascal’s law will help us answer this question: the pressure gauge readings will not change, because the pressure in all directions at the same depth/height is the same.

Take a look at Figure 4. This is what a liquid pressure gauge looks like in real life.

Figure 4. Realistic image of a liquid pressure gauge.

Strain gauge transducers

The principle of operation of strain gauge transducers is based on the dependence of the electrical resistance of the metal. Strain gauges are placed on the elastic sensing element of the pressure gauge. The change in their resistance is converted into an electrical signal and transmitted to secondary devices. To measure high and ultra-high pressures in laboratory practice, deadweight pressure gauges are used. You can purchase industrial equipment in the online store "Industrial Automation"

.

Sales department employees will help you navigate a large assortment of products, tell you about the features of the equipment and answer your questions by calling toll-free number 8

or at

Metal pressure gauge

You have already seen the appearance of a metal pressure gauge in Figure 1. Let us now consider its internal structure, which comes in two main types. The first is shown in Figure 5.

Figure 5. Design of metal pressure gauge No. 1.

A curved hollow tube 1, sealed at one end, is connected on the other side to a tap 4, which communicates with the vessel in which the pressure needs to be measured.

As the pressure increases, tube 1 begins to unbend, and with the help of lever mechanism 5 and gears 3 transmits movement to pointer 2, which moves along the scale of the device.

Tube 1 is elastic, and when the pressure decreases, it returns to its original position, and the pointer returns to the zero scale division.

Figure 6 shows a slightly different type of metal pressure gauge.

Figure 6. Design of metal pressure gauge No. 2.

The difference in structure is only that the tube is sealed on both sides, but has an outlet for connection to the vessel in which the pressure needs to be measured. There are also two rods (levers) 2.

Note that, despite slight differences in the device (Figures 4 and 6), the principle of operation of metal pressure gauges remains the same.

The actual appearance of the metal pressure gauge is shown in Figure 7.

Figure 7. Realistic image of a metal pressure gauge.

Why is there poor pressure in the water supply in the apartment?

There are 3 main causes of low blood pressure:

- Large blockages in pipes and wastewater treatment plants. Heavy rainfall, river pollution - all this leads to the accumulation of garbage in the water supply. To combat this, comprehensive measures are used, which involve specialists and special equipment.

- Pipeline damage. Lack of measures to update supply systems leads to wear and subsequent breakdowns.

- Mistakes in developing a water supply plan. A large number of height differences, bends, and connections of several lines into one lead to a slowdown in the speed of water flow, which directly affects the pressure.

It is almost impossible to correct this on your own, but you can artificially increase it in an apartment or house using pumping equipment.

How to increase it?

The easiest way to increase the pressure is to install a pump. In stores you can find:

- flow-through;

- stationary (pumping station).

To ensure a guaranteed result, it is better to install several of these devices. This can be done without asking permission from housing and communal services.

Simultaneous operation of several pumps can reduce the pressure of other residents . In this case, the court may order the removal of additional equipment from the water supply.

It is worth choosing equipment with a capacity of 3.5 m3 per hour and automatic adjustment. It is highly undesirable for the noise level to exceed 40 dB, otherwise additional sound insulation will be required. Flow pumps are connected to the pipes with two hoses.

For pumping stations you will have to install a separate circuit. Installation and sales are carried out by special companies. Installing such a device guarantees a stable water supply for many years.

A pumping station is a complex system that includes:

- small tank;

- pressure meter;

- pump.

This design allows the system to be protected from even small pressure fluctuations. It analyzes the pressure value in real time, increases or decreases it depending on the specified parameters. This is necessary in the private sector, when several neighbors simultaneously begin watering their plots.

Atmosphere pressure

The atmosphere is a gas, or more precisely, a mixture of gases, which is held near the Earth due to gravity. The atmosphere passes into interplanetary space gradually, and its height is approximately 100 kilometers.

How do we understand the expression “atmospheric pressure”? Above every square meter of the earth's surface there is a hundred-kilometer column of gas. Of course, the air is clear and pleasant, but it has a mass that presses on the surface of the earth. This is atmospheric pressure.

Normal atmospheric pressure is considered to be 101325 Pa. This is the pressure at sea level at 0 degrees Celsius. 766 high exerts the same pressure at the same temperature on its base .

The higher the altitude, the lower the atmospheric pressure. For example, at the top of Mount Chomolungma it is only one-fourth of normal atmospheric pressure.

Everest. At its top the pressure is 4 times less than at the foot

Application of all devices

A liquid pressure gauge is used in blood pressure measuring instruments. To demonstrate experiments at schools and universities. A metal pressure gauge is used to measure pressure at thermal stations. In steam heating systems, gas cylinders, car tires. Water pumps are used to supply water to homes. Hydraulic press is used to produce various types of oils. For the manufacture of plastic utensils. Presses cardboard, plywood. In agriculture, hay is baled. The hydraulic press is used as a lifting device.

Purpose of pressure measuring devices

Pressure gauges are used in gas, vapor and liquid circulation systems, that is, wherever there is a need to control or regulate the pressure of flows. The scope of application of pressure meters is extensive, but such devices are most in demand in the heat power industry, food industry, and petrochemical enterprises.

The main purpose of the pressure gauge is to constantly display the internal stress in the pipeline, thereby preventing emergency situations and destruction of the hydraulic network. No less dangerous is insufficient pressure, which can lead to the formation of air bubbles (cavitation) inside the pipe system and the occurrence of water hammer. Examples of using pressure gauges in everyday life:

- heating systems in public utilities;

- monitoring the state of the atmosphere using barometers;

- monitoring the health of the human heart and blood vessels with a tonometer.

The types of pressure gauges can be explained through the concept of pressure. Its unit of measurement is kg/cm²: the ratio of force to the surface area on which the load is applied. The manifestation of this value can be different:

- atmospheric pressure - the pressure of the Earth's air shell;

- absolute - its count starts from zero and includes the weight of the air column;

- excess - the difference between total and atmospheric exposure;

- discharged or vacuum pressure - the difference between the absolute load and the value of the air column;

- differential - the difference between two measured characteristics.

In accordance with the listed types of pressure, pressure gauge designs have been developed. The devices can be found in heating boilers, compressors, cylinders, and autoclaves. Measuring the load on any surface is not the only purpose of these devices. Liquid level sensors and flow meters are also based on the operating principle of barometers.

Design and operation of a liquid pump (water supply)

Plumbing installation:

- Cylinder.

- Two valves.

- Lever arm.

- Outlet pipe.

Actions of the water supply. At the initial moment, using a lever, we create the conditions for the formation of airless space. Between the top valve and the cylinder. Then we press the lever under atmospheric pressure and the piston rises to the top. The bottom valve opens and water fills the entire space of the cylinder. Next, pressing the lever lowers the piston. Closing the bottom valve. The compressed water exits through the outlet pipe. Then all processes are repeated.