When and why to adjust

The procedure for adjusting the carburetor is usually carried out quite rarely. The highest quality and best option is factory settings. But if necessary, it can be done by adjusting the corresponding screws. A carburetor in a chainsaw is necessary to prepare an air-gasoline mixture, which must have a certain ratio of ingredients. If the balance is not maintained, then malfunctions will begin to occur in the engine.

A mixture that does not meet specifications may be oversaturated or lean. In the first case, the amount of fuel relative to air is increased, in the second there is more air than needed, and less fuel. The article will discuss carburetor adjustment using the Husqvarna 142 chainsaw as an example.

Chainsaw delivery set

When ordering the Husqvarna 142 model, the buyer receives absolutely everything necessary to start using and further maintain the garden tool. The model kit includes:

- branded tire and chain;

- plastic tire cover;

- hand tools for assembly and maintenance;

- user manual.

For an additional fee, the manufacturer supplies the chainsaw with a bag for transportation, branded oil for 2-stroke engines and additional spark plugs.

Signs of poor performance

Some signs may indicate a carburetor malfunction. For example, if the engine stalls quickly or is difficult to start, a lean mixture could be a possible cause. Excessive fuel consumption also becomes a problem. You should also be wary of intense exhaust emissions. The cause is an oversaturated mixture.

Sometimes it happens that the engine does not want to work at all. There can be 2 reasons for this: there is no spark or gasoline. In the second case, the problem is expressed in a clogged fuel nozzle; in the first, the problem is a faulty spark plug or failure of the electronic unit.

Settings can go wrong quite rarely, but the reasons are:

- wear of the piston group;

- violation of the fastenings of the adjusting screws;

- carburetor contamination.

In the first case, adjustment will not help much; you need to think about replacing the saw or repairing the engine. As for fastening failures, the cause may lie in a careless touch or strong external vibration. Sometimes an attempt at rough adjustment leads to a violation.

Carrying out the adjustment

The Husqvarna 142 carburetor must be adjusted using a tachometer. You must be able to work with it. If experience allows, manipulations can be carried out by ear, determining the maximum speed by sound. In other cases, a positive result may not be achieved. The Husqvarna 142 carburetor is adjusted with one, two or three screws. You can distinguish them by their designations.

Idle speed is adjusted with a screw under the letter T. You can adjust the minimum speed with screw L. While screw H is intended for maximum speed. You will see one idle screw and two others that will be hidden behind the cover. This version of the carburetor is explained by the fact that the manufacturer recommends that the operator adjust only one idle speed screw, since otherwise the optimal settings are already set at the factory. But for some extreme conditions you can make adjustments.

How does a chainsaw carburetor work, on what principle does it work?

Modern car engines are no longer equipped with a carburetor. Meanwhile, previously, virtually every driver knew how to adjust it. Now chainsaws with injection engines have already begun to appear on sale, but carburetor models will hold the palm for a long time, because their price is 5-15 times lower than that of the modern version.

The carburetor consists of several main parts:

- duralumin body;

- diffuser and air damper at the inlet;

- jets (valves for regulating fuel supply);

- atomizer (it provides injection);

- fuel (float) chamber.

The mechanism of operation of a chainsaw carburetor is quite simple. Fuel is supplied continuously, and its quantity is regulated by jets. Air enters through the air damper due to the vacuum of air created by the piston. In the diffuser, fuel and air are mixed. This same fuel-air mixture enters the cylinder, causing the engine to work.

How to adjust the carburetor of a chainsaw if it doesn’t start at all

A fairly common discrepancy occurs in cases where a “master” from the “I know everything” series tries to get into an option with hands that do not rise from the shoulders. In a similar case, there are standard screw positions from which you can “dance” further. First you need to tighten both screws completely (don't be too zealous). Then turn it out:

- screw L – one turn;

- screw H – one and a half turns.

As for the idle speed screw, at first the damper should be completely closed (screw T will be unscrewed). After which you need to turn it one and a half turns clockwise and try to start the engine. If it doesn’t work, add a quarter turn at a time until starting. When the engine starts running, the position of the idle screw is adjusted so that the internal combustion engine does not stall, but the chain remains in place.

Related article:

A machine for sharpening chainsaw chains: aspects of choice, design features, technical and operational properties of the equipment, the mechanism of operation of manual and automatic devices, a review of the favorite models of sharpening units.

Work methodology

The Husqvarna carburetor is adjusted using screws L and H if gasoline is used that differs from that recommended by the supplier. If the octane number is low, to increase it, turn the screw using the unscrewing method. This will increase speed and power. But with an increased octane number, to lower it, you must turn the screw in the opposite direction, tightening it. This will help reduce engine speed.

When adjusting the Husqvarna carburetor, the screws must be used in the following order: L – H – T. By maintaining precise angles of rotation, you will follow the requirements that will allow you to maintain the best operating parameters of the engine. There is no universal way of adjustment. The procedures may differ from one another. But the process is usually divided into two stages. The first is basic, the 2nd is final. The basic stage is performed with the engine turned off, while the final stage involves warming up the engine for 10 minutes.

Husqvarna 142 Carburetor Tuning

Auto Private

Content

How to adjust the carburetor on a Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main components, which at times require maintenance and adjustment. In this article we will talk about how to adjust the carburetor on a Husqvarna chainsaw.

Fundamentally. An experienced electrician leaked the secret of how to pay half as much for electricity, a legal method. Read more

In what cases does the carburetor of a Husqvarna chainsaw require adjustment?

There are quite a few problems that can be solved by adjusting the carburetor. Adjusting the carburetor of the Husqvarna chainsaw is necessary when defects such as:

- high idle speed;

- strong smoke when operating the tool;

- Difficulty starting a cool or hot engine;

- lack of traction and low maximum speed.

This is by no means a complete list of problems that can be solved by tuning the Husqvarna carburetor. In a number of different cases, adjusting the properties and amount of fuel consistency is carried out after a half-year engine repair or during scheduled maintenance of the chainsaw.

The manufacturer Husqvarna AB recommends adjusting the carburetor before and after break-in.

The design and principle of operation of the Husqvarna carburetor

To successfully install the Husqvarna chainsaw carburetor option, you should know its structure and understand how it works. In fact, everything is not as difficult as it seems at first glance.

The saw carburetor has an integrated fuel pump, which is responsible for transporting the mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work allows the fuel supply to be dosed into the main chamber and two dampers.

One of the dampers is designed to regulate the flow of fuel into the cylinder when you press the gas, it is called the throttle, the second is responsible for limiting the flow of air from the air filter to facilitate starting a cool Husqvarna chainsaw. At the moment when the operator shuts off the air supply to the carburetor using the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than in this case, when a cool start is carried out in normal mode.

The operation of the Husqvarna carburetor involves a valve-nozzle, which sprays fuel and ensures the flow of air into the main chamber. Often, problems when operating a saw can be caused by shortcomings of this particular element. For example, if the chainsaw is stored incorrectly, the valve may stick, the fuel supply will end, which will make the engine impossible to operate. Setting up the carburetor factory settings Husqvarna I give on. Also, malfunctions in the operation of the nozzle can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation; it will be necessary to carry out repairs or replace the unit.

Three adjusting screws installed in the carburetor body are responsible for setting the properties and amount of consistency, as well as the number of crankshaft revolutions in idle mode:

- screw (L) – regulates the amount of fuel in low and medium speed modes;

- (H) – responsible for traction at high speeds and their number;

- (T) – changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the tool’s motor in idle mode.

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Incorrect adjustment of the properties and amount of fuel consistency can lead to the engine not working or working incorrectly, which will lead to rapid wear or even jamming.

Tools required for work

Before you start setting up the Husqvarna carburetor, you need to make sure you have all the tools you might need. To carry out this type of work without the help of others, it will be useful:

- a screwdriver for adjusting screws (H) and (L), it can be purchased at specialized stores;

- an electric tachometer for determining crankshaft speed readings (with some experience, you can make adjustments by ear);

- Phillips screwdriver for adjusting screw (T);

- compressor with a blow gun for cleaning the saw before work.

A regular slotted screwdriver will not work for adjustment, since the adjusting screws on Husqvarna chainsaws can have a different cross-section. You will have to purchase a special one, this is a feature of repairing Husqvarna chainsaws; they have created everything so that the saw can be repaired exclusively in a special Husqvarna service center.

Algorithm and description of Husqvarna carburetor settings

The Husqvarna carburetor is adjusted in the same way as carburetors on chainsaws from other manufacturers are adjusted.

Specifically, before making adjustments, you need to conduct a full diagnosis of the saw and make sure that there is no difficulty in supplying fuel or air leaks into the crankcase of the chainsaw. You also need to make sure that the air filter is clean and, if necessary, replace it with a new one.

The order of work is as follows:

- The factory options for the Husqvarna carburetor are installed on the muffled saw.

- The engine is started and the saw is warmed up for several minutes.

- By rotating the screw (L) clockwise, you find the position at which the engine develops the highest speed, after which the screw must be turned back 1⁄4. If the chainsaw chain is spinning, then you need to reduce the idle speed by adjusting the position of the screw (T).

- The next step is to adjust the power of Husqvarna at the highest speeds and adjust their number. To do this, the tachometer is connected to a running chainsaw, the throttle is squeezed to full, after which the tachometer readings are checked. If the maximum speed value differs from the maximum number recommended by the manufacturer, then by adjusting the position of the screw (H) the tachometer readings are returned to normal.

READ Adjusting the Carburetor of the Champion 142 Chainsaw with Your Own Hands

Nuances of adjustment

After the adjustment, the chainsaw should simply pick up and drop speed, work steadily at low and high speeds. If the saw chain spins at idle after adjusting the carburetor control screws, this is a sign that the adjustment was carried out incorrectly and the position of the screw (T) needs to be adjusted.

Also, when adjusting the Husqvarna carburetor, it is worth taking into account the response time of the chainsaw to the rotation of the screws. Options do not change immediately, but within 5, 10 seconds.

One of the characteristics of an incorrectly carried out adjustment is strong smoking when the saw is operating, which indicates a large amount of fuel entering the combustion chamber. If such a situation occurs, it is necessary to adjust the position of the screw (L).

Factory settings

The standard factory options for the Husqvarna carburetor are the position of the screws (H) and (L), in which a working chainsaw should be guaranteed to start. For Husqvarna instruments, this is one and a half turns from fully tightened screws (H) and (L). During the adjustment process, you must first set the screws to the standard position, then start the chainsaw and make precise adjustments to the power, the number of maximum revolutions and idle speed.

DIY carburetor repair

If, during a full diagnosis of the Husqvarna , carburetor defects were discovered, then some of them can be removed without calling the Husqvarna AB service center. Adjusting the Husqvarna carburetor 137, 14, 435 and other models. Do-it-yourself husqvarna chainsaw carburetor adjustment. For example, without the help of others you can:

- change the gaskets under the covers of the main chamber and fuel pump;

- clean or change the mesh filter;

- change the diaphragm or needle valve of the main chamber;

- remove faults in the fuel pump diaphragm.

Gaskets, diaphragms and a needle valve with a rocker arm can be found in the repair kit, which is available for each model of Husqvarna chainsaw carburetors.

Also, if you have some experience, you can try to return the faulty injector valve, but you cannot guarantee a good result when trying to restore the injector; if it malfunctions, manufacturers advise replacing the carburetor one hundred percent.

The first thing you need to do before removing the carburetor from the Husqvarna is to clean the saw with a compressor, since dirt can interfere with high-quality repairs. Next, you need to open the top cover of the chainsaw, remove the air filter, disconnect the rods from the air and throttle valve control levers. Then unscrew the carburetor mounting screws.

Disassembling the carburetor body for repairs is quite easy. The main chamber cover is held in place by 4 screws, which can be removed using an ordinary screwdriver; the fuel pump cover is secured with 1 wide screw.

Below is a video, after watching which it will become clear how exactly you can repair a carburetor without calling a Husqvarna service center.

Conclusion

The work of adjusting or repairing the carburetor on Husqvarna chainsaws can be done without any specific experience. In order to do everything right, you need to follow the method and have a small set of tools. It is also worth assessing your strengths in advance and not taking risks if you are completely unaware of the technique. Believe me, from time to time it is better to pay a small amount to the master than to damage the instrument by adjusting it yourself.

Chainsaw Husqvarna 142. Features of operation and maintenance

The Husqvarna 142 chainsaw is used for work in the garden and at the dacha; it is an excellent option both for felling trees and for collecting firewood. The Husqvarna 142 chainsaw has technical properties that ensure the highest performance and safety. The engine speed reaches nine thousand units per minute. The cylinder size is nominally 40.2 cm³. The fuel tank capacity is 410 ml and the oil tank is 200 ml. It is worth considering that the noise level is 118 dB. The mass of the unit is 4.6 kilograms. The length of the tire is from 33 to 38 cm, the chain pitch is 0.83 centimeters.

How to properly adjust the carburetor on a Husqvarna chainsaw

How to tune the carburetor

on a chainsaw

Husqvarna

Adjusting

the carburetor

on a chainsaw using 3 THL screws.

Carburetor adjustment!!!Husqvarna 137-142 AntiReg!

Hare to feed the Chinese and rednecks!!! Disassemble and clean the carburetor

, change dry diaphragms, twist and

Advantages of the model

- The relatively light weight of the Husqvarna 142 chainsaw and the ergonomic design combined with a curved front handle make the operation of the equipment very comfortable.

- The anti-vibration system allows you not to feel lethargic for a long time.

- A guard and chain brake are provided to ensure the safety of users.

- The power of the Husqvarna 142 chainsaw is increased by a forged crankshaft consisting of 3 sections.

Possible malfunctions of the Husqvarna 142 chainsaw

Like any other devices, the operation of which is associated with intense loads and complex criteria, Husqvarna 142 chainsaws can fail, and the reasons for the problems can be divided into two groups:

- Damage to the motor or piston group. Problems with the fuel, exhaust or ignition systems.

- Problems that have arisen in mechanical components - tires, clutch, brake or lubrication systems.

Engine

Motor breakdown is one of the most common and labor-intensive. This problem is manifested by the following factors:

- Unbalanced idle speed.

- Does not start.

- There is not enough power, or the Husqvarna 142 chainsaw starts and stalls as it begins to gain momentum.

Before you begin repairing the Husqvarna 142 chainsaw, it is recommended to conduct a full diagnosis of the equipment to clearly determine the circumstances of the problems.

The reason why the Husqvarna 142 chainsaw does not start

If the Husqvarna 142 chainsaw does not start, there may be several circumstances. The most common ones include the following:

- Damage to spark plugs - to determine whether a spark plug is working properly, you need to unscrew it and inspect it. In this case, if the porcelain insulator has cracked, you see a burnt or warped electrode, you should immediately change the spark plug. In addition, after working for several seasons, the Husqvarna 142 chainsaw requires inspection of spare parts. Spark plugs also develop their own resource, and to ensure the safety of the saw, replace them with new ones.

- Carburetor clogged - during operation, fuel vapors evenly settle on the internal walls, forming a sticky consistency that can clog the carburetor, preventing the engine from starting. You will need to clean it with a special detergent. When repairing a Husqvarna 142 chainsaw, carburetor adjustment is always carried out with a warm engine and cleaned systems.

- Malfunction of the ignition coil - before you decide to replace this part, make sure that the spark plugs meet the required technical condition.

READ Board Saw

How to adjust the carburetor of a Husqvarna 142 chainsaw

Adjusting the carburetor of the Husqvarna 142 chainsaw should be done when the engine is warm. Pay attention to the condition of the air filter, which will need to be cleaned as necessary and make sure that it is not clogged. Do-it-yourself adjustment of the carburetor of the Husqvarna 142 chainsaw is done using 3 screws:

- L – for low engine speeds.

- H – for high engine speeds.

- T – for idle speed.

By turning the low and high speed control screws clockwise, move them to the maximum, and after the peak is reached, turn them in the opposite direction, one and a half turns. When idling, the chain for the Husqvarna 142 chainsaw must be motionless. Inspect at maximum speed.

You can avoid most defects and costly repairs by following the manufacturer's instructions and advice, and also using unique spare parts for the Husqvarna 142 chainsaw.

Related Posts

How to properly adjust the carburetor on a chainsaw with your own hands

“A carburetor is a device responsible for the mixture and supply of fuel to the combustion chamber of an internal combustion engine.”

I am glad to welcome all lovers of “interesting and suitable men’s toys.”

Correct carburetor adjustment ensures reliable operation of the chainsaw in all modes, and with economical fuel consumption. In general, if we remove the word “chainsaws”, then this applies to all internal combustion engines.

Now let's talk about how to adjust the carburetor on a chainsaw. Tuning a Husqvarna 137 carburetor usually does not cause any problems. In general, such a procedure is carried out from time to time. Factory setting is the best and highest quality option. But, as needed, it is made a means of adjusting special screws. Let's figure out how to rebuild it yourself:

The principle of operation of the saw carburetor (generally):

This device prepares an air-gasoline mixture in a certain ratio. If this balance is not maintained, then malfunctions occur in the operation of the internal combustion engine (gasoline engine). A mixture that does not meet the standard can be either oversaturated (when the amount of fuel relative to air increases) or lean (when there is more air than required and less fuel).

- The air flow moves through a special channel, and the damper regulates its speed;

- Opening the damper regulates the amount of fuel and air supplied;

- Gasoline and air, flying through the diffuser, are mixed and atomized;

- The resulting mixture flows through the intake manifold into the combustion chamber (cylinder).

Signs and causes of poor unstable performance

Signs of malfunctioning chainsaw carburetor:

- The engine starts poorly and stalls quickly. Probable cause: lean mixture.

- Excessive (more than normal) fuel consumption. In addition, rich (more than usual) exhausts. Probable cause: oversaturated mixture.

- The engine does not want to work at all. There are two prerequisites: there is no gasoline (the fuel nozzle is clogged) or there is no spark (the spark plug is faulty, the high-voltage wire is broken, or the electrical unit is faulty).

The failure of options itself occurs occasionally and the prerequisites are usually the following:

- Damage to the fastenings of the control screws due to a faulty (damaged) coating of the protective casing. Probable cause: careless touch, attempt at rough adjustment, or strong external vibrations.

- Wear of the piston group. Naturally, adjusting the carburetor will not help much here. Think about repairing the internal combustion engine or replacing the saw.

- Carburetor contamination. Possible reason: breakdown or unsatisfactory condition of the air filter, introduction of bad fuel, ingress of scale, small sawdust, etc. into the fuel channels. In such cases, the entire fuel system is first flushed, and then adjustment is made.

Do-it-yourself carburetor adjustment

“According to the mind,” it is recommended to carry it out with the use of a tachometer (and the ability to work with it), or if experience allows, by ear (i.e., determining the maximum speed by sound).

In other cases, it is unlikely to guarantee a good result. The chainsaw carburetor is adjusted with one, 2 or 3 screws. Everything depends on the brand of saw.

Let's look at the adjustment option on the popular Husqvarna chainsaw. This carburetor has three adjustment screws labeled:

- T – idle speed control;

- L – low speed regulation;

- H – regulation of maximum speed;

In the first case, there is one “visible” idle screw (T), and the other two (L and H), usually hidden behind the casing. This is not easy. The consumer should make adjustments only with the idle speed screw, since otherwise rational factory options are installed. But for some extreme modes there remains the possibility of adjustment.

The idle speed screw may be designated by different symbols from different manufacturers. For example, Husqvarna and Partner are designated by the Latin letter “T”, and another recognizable manufacturer, Stihl, uses the letters “LA”.

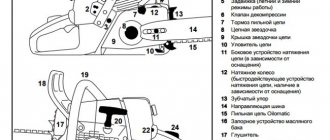

Here is a clear picture of the carburetor of the Husqvarna 137 chainsaw:

Hidden lower screws (L and H) serve to adjust the operation of the carburetor in cases where gasoline different from that recommended by the manufacturer is used.

If the octane number is low, then to increase it, turn the screw from right to left (unscrew it). Recommendations for adjusting the carburetor of the Husqvarna chainsaw 137. adjustment from 142 not. This way you can increase power and speed.

If the octane number is increased, then to reduce it, turn the screw in the opposite direction (tighten it). This will allow you to reduce engine speed.

The screws are adjusted in this order: L – H – T.

Make an annotation for a specific chainsaw! It indicates clear angles of rotation of the screws. This is an indispensable requirement for maintaining the best performance characteristics of the internal combustion engine.

How to make the adjustment correctly? There is no universal method. This procedure is slightly different for everyone. But the process of adjusting any chainsaw can be roughly divided into 2 steps.

- Basic (carried out with the engine turned off);

- Final (carried out with the working engine warmed up for more than 10 minutes).

READ Carburetor Adjustment Husqvarna Scythe 235 RUR

Wrench (screwdriver) for adjusting carburetor screws

Many manufacturers use branded keys. Use them, don't lose them. Finding such special tools on sale is not easy. For example, like the one in the photo on the right.

Be sure to follow the safety rules specified in the instructions for the chainsaw.

Candles

Use unique ones and change them on time. This should be done at least once a year. Although, if you look more broadly, then everything depends on the volume of work performed. Some work almost every day, while others work once during the summer season.

Air filter condition

His condition is definitely checked, as he experiences enormous stress during intense work. Fine wood dust is everywhere. At the end of the working cycle, it is recommended to remove it and clean it (wash it).

If it is a polymer (nylon) mesh, then a neutral soap (not foamed) solution is used. Husqvarna 125r carburetor adjustment without. Washing is done under running water and dried in the open air (only at “plus” temperatures).

If the “air vent” is made of foam rubber, you can really wash it with kerosene, squeeze it out very well and dry it (although the kerosene will not evaporate one hundred percent). There are filters made of material similar to velvet mesh. This filter is rinsed in ordinary warm water without using detergents. Then they dry it.

The new absorbent element (aka filter) must be the same as the used one.

Fuel mixture

You should use oil recommended by the manufacturer and in the required proportions. Otherwise, there is a risk of losing the warranty in advance. In the latter case, take into account the degree of engine boost (i.e. the ratio of power and engine volume, and indirectly the highest number of revolutions). Remember that too little or too much oil in the consistency will lead to premature wear of the internal combustion engine.

As a result, I will say the following: if the chainsaw carburetor adjustment is carried out correctly, then:

- When idling, the chain should be motionless (with the brake released);

- When you press the gas, from idle to maximum, the engine quickly, quickly and easily picks up speed. If the chain is sharpened perfectly, then the chainsaw won’t care about any log;

- The sound of the running engine is measured, without howls or spontaneous accelerations. I really want to create, like in the photo.

A funny story on the topic: Suddenly from my mother’s bedroom, covered in blood, with one leg,

Mom's lover runs out. And a father with a chainsaw.

That's all. I will be glad if the information was useful. Subscribe to the blog for updates, it will be more interesting!

Good luck in all matters and trouble-free operation of your chainsaw, especially since the season is just around the corner! Bye!

Wisdom Quote: No one is rich enough to buy their own past (Oscar Wheels).

Are common. Factory Instructions for Adjusting the Carburetor of the Husqvarna Saw 142

About setting up the carburetor of the Shtil 180 chainsaw, read Abstract and details for the husqvarna 137 chainsaw Oregon chain 20bpx - years old, in the summer I changed the piston and cylinder from 142 not original. I sawed it in the summer.

The factory setting must be maintained for the first hours of operation of the chainsaw. Screw. T at Partner and Husqvarna (at Shtil LA) - adjusting the idle speed of the chainsaw Adjusting screws for the carburetor of the STIHL chainsaw Download annotations and drawings for Husqvarna chainsaws.

Adjusting the carburetor of a chainsaw ensures efficient operation. Adjusting the carburetor of a chainsaw is divided into two steps - basic (factory).

The carburetors of most chainsaws have three screws for adjustment: L – jet screw for adjusting low speeds H – jet screw for adjusting high speeds Screw. T at Partner and Husqvarna (at Shtil LA) - adjusting the idle speed of the chainsaw. Screws H and L regulate the ratio of the consistency of gasoline and air, determined by the opening of the carburetor throttle valve.

Video; Gallery; Abstract Adjusting the carburetor of a husqvarna chainsaw Husqvarna 142 carburetor adjustment . When using a new chainsaw, it is recommended to leave the carburetor settings at the factory settings.

Adjusting the chainsaw carburetor. I would not recommend changing the factory settings right away. And if BU, then even more so. cause.

The best advice I can give you is to consult a specialist! Believe me, for very little money, specialists will adjust the carburetor and check the general condition of the saw. But if you still need to adjust the carburetor on the Husqvarna 137 saw yourself, then I will try to describe this process in detail. Also at the end of the post I added a video on how to adjust the carburetor of a chainsaw at idle speed. Read about setting up the carburetor of the Shtil 180 chainsaw here: Carburetor Sthil MS180 (Shtil 180). Adjustment - no, I haven’t heard... In the picture above you can see three screws for adjustment. Each of them has its own purpose: Screw T is necessary to adjust the idle speed. Screw L is used to adjust low speed. Screw H regulates high speed. Adjustment procedure: First, using screw L (rotating it), we look for the highest idle speed. After we have found them, we need to turn this screw a quarter turn counterclockwise. Adjusting the Husqvarna 137 carburetor. In the correct operation of the Husqvarna 137 chainsaw, high-quality carburetor adjustment and tension are important. If in this position the chain continues to rotate, then by rotating the screw T we achieve its stop. Then we warm up the engine at full speed for about 10-15 seconds and turn screw H a quarter counterclockwise. We wait 10 seconds and listen - the engine should sound like a 4-stroke. If a squeal is heard, then the mixture is lean (unscrew the screw), if it smokes, then the mixture is rich (tighten the screw). After adjusting the low and high speeds, we set the idle with screw T. This is done as follows: 1. The engine should be running 2. Rotate screw T clockwise until the chain begins to rotate. 3. Rotate the screw in the other direction until the chain stops. With a correctly adjusted carburetor, your chainsaw quickly picks up speed and sounds similar to a 4-stroke engine.

Source

Specifications

In order to ensure long-term operation of the described equipment, you need to know how to adjust the Husqvarna 142 carburetor with your own hands. This was discussed above. However, this is not the only thing that the future owner of such a device should know. Before purchasing such equipment, it is important to inquire about the technical characteristics. For example, evaluate whether the weight, which is 4.6 kg, suits you. By the way, it is well balanced, so the saw fits comfortably in your hands.

The shape of the handles is ergonomic, which guarantees a reliable grip during complex work. There is a vibration protection system inside, and operation is not accompanied by too high a noise level. All this contributes to high labor productivity and the preservation of human performance during large-scale work.

Adjusting the Husqvarna 142 carburetor with your own hands is quite simple if you read the instructions. From it you can find out that the power of the device is 2.6 liters. s., or 1.9 kW. The chain pitch is 0.325 inches. The number of links is 64.

The kit comes with a chain whose thickness is 1.3 mm. The engine capacity is 40.2 cm3. The length of the tire is 38 cm or 15 inches. The oil and fuel tanks hold 0.2 and 0.41 liters, respectively.

Headset

This unit consists of a 15" removable guide bar, cutting chain with 0.325" pitch. The kit also includes a drive sprocket and tensioner. Other smaller kits are likely to be installed, generally meeting the requirements of the intended purpose.

Lubricating the chain prevents overheating and accelerated wear. The system includes an oil pump with adjustable capacity, into which the working fluid is supplied from a built-in tank with a capacity of 200 ml.

Sources:

https://morflot.su/nastrojka-karbjuratora-benzopily-huskvarna-142/ https://smotri-dtp.ru/obsluzhivanie/regulirovka-karbjuratora-huskvarna-142.html

Consumer Reviews

You can adjust the Husqvarna 142 chainsaw yourself. Consumers consider this feature a plus, as well as the fact that the crankshaft in the design is made of forged steel. Another advantage is the relatively easy access to the air filter. The ignition system is durable and simple. The piston group has two compressor rings, which have an increased working life. The manufacturer emphasizes that they will be ready to last up to 5 years.

Consumers also like the fact that the cylinder liners have a wear-resistant chrome coating. You may not have to adjust the Husqvarna carburetor, because, according to the manufacturer, it is the best in its class. The design is also good because it has a built-in primer. It is a pump that provides the engine with a quick start. This feature is independent of ambient temperature.

Operating instructions and repair features

From the instructions you can find out that the carburetor of the Husqvarna 142 chainsaw is adjusted after running in the machine. It is important to know that the maximum speed is 12,500 per minute. Idle speed reaches 2500 per minute. If your saw starts to behave differently at startup, at high speeds, and when accelerating after switching to a different fuel type, fine adjustments may be required. Before this, the air filter is cleaned and the cylinder cover is replaced. If adjustments are made with a dirty air filter, this may result in a lean mixture, which will cause engine damage.

As for the repair of Husqvarna 142, there are several main breakdowns and ways to fix them. You should know the approximate reasons that lead to a malfunction. Among others, problems with the engine should be highlighted. If it runs non-stop, won't start, or starts but stalls frequently, you need to inspect the spark plugs. When starting equipment in cold weather, it may happen that the combustion chamber is filled with a fuel mixture. In this case, the spark plug is unscrewed, and the combustion chamber is dried by idle. The spark plug must be cleaned and the saw must be started again.

Don't underestimate muffler failure. If it fails, the saw may not start or lose power. When disassembling this part of the chainsaw, you will be able to inspect and get rid of carbon deposits. It may contain carcinogens that are hazardous to health, so dry cleaning should be avoided as it may cause inhalation of harmful substances.

After the muffler is removed, the engine exhaust hole should be plugged with a clean rag. The muffler becomes clogged for several reasons. The first of these is the use of the wrong fuel mixture. The second reason is using the wrong oil.

Chainsaw malfunctions and how to fix them

Owners of the Husqvarna 142 model often encounter typical breakdowns caused by improper use of garden tools or simple wear of its parts.

These malfunctions include:

- the chainsaw does not start - the cause of this breakdown lies in the spark plug being flooded. To be able to start the saw motor, you need to remove, wash and dry the spark plug. After this, you need to blow out the cylinder by sharply pulling the starter cable several times with the spark plug turned out. After this, you need to screw in the spark plug and start the engine of the garden tool;

- increased vibration during operation of the saw - repair of this breakdown is carried out by cleaning or replacing the muffler. You will also need to inspect the springs of the anti-vibration system. If necessary, sagging parts must be replaced;

- shooting sounds - if loud popping noises are heard during operation of the Husqvarna model, then the causes of the breakdown should be sought in the carburetor or muffler. The operator will first need to adjust the carburetor. After this, you need to remove and wash the muffler;

- leakage of oil to lubricate the chain - to eliminate this breakdown, you need to check the condition of the oil pump and pipes. The faulty part will need to be replaced.

To avoid further breakdowns of the Husqvarna 142 chainsaw, you need to use high-quality gasoline and oil to refuel it. This will help prevent increased wear of parts and protect model components from overheating.