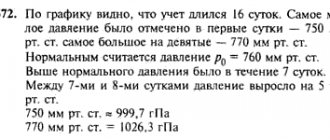

What causes the sharp increase

An increase in pressure in the heating circuit can be caused by the formation of air pockets. Traffic jams can occur due to incorrect wiring of the circuit, which does not take into account its kinks and slopes, as well as due to leaks or damage (poor sealing of joints, coolant leaks).

The reason for the formation of plugs can also be low coolant pressure, which creates voids filled with air, as well as improper filling of the coolant circuit at the start-up stage.

The absence or ineffective operation of air intake devices or air release valves allows air pockets to accumulate especially quickly.

Air plugs form areas that are difficult for water to pass through, blocking its movement in individual structural units, thereby increasing water pressure.

An obstacle to movement can be coarse filters (mud filters), usually installed in several sections of the heating circuit. Untimely cleaning of mud pits (less than once a year) can also create conditions for the occurrence of these situations.

How to properly configure the unit?

Usually, the settings set by the manufacturer are sufficient for normal operation of the system. For example, the factory settings of the RDM-5 Gilex model are 1.4-2.8

If for some reason they need to be changed, all manipulations should be carried out very carefully so as not to damage the device by inept handling

Before setting up the relay you must:

- Turn off the power supply to the pump.

- Drain all water from the system (the pressure gauge needle reaches zero).

- Turn on the pump and fill the system with water.

- Wait for the pump to automatically turn off and record the shutdown pressure.

- Drain the water, wait for the pump to turn on automatically and record the start pressure.

To adjust the water pressure sensor, two springs are used - large and small. Using a large spring, the maximum water pressure in the system is set. To do this, the spring is twisted. The small spring does not regulate the minimum pressure value, but the difference between the minimum and maximum. If the preset value seems too small, this spring should also be tightened until a suitable value is reached. It is not the spring itself that is tightened, but the nut that holds it. When you tighten this nut, the spring contracts, and when you unscrew it, it straightens.

To increase the pump activation pressure, a large spring must be tightened. Check the obtained settings by draining water from the system. Manipulations with the large spring are repeated until the switching pressure reaches the required level. To increase the pump shut-off pressure, tighten the small spring. This spring is more sensitive than a large one, so you should act more carefully. If the on-off performance needs to be reduced, the spring nuts are not tightened, but unscrewed.

No one thinks about the water pressure in the water supply until it reminds you of itself: water flows from the tap, and it seems to be flowing well, but after a couple of minutes the flow already resembles a thin thread. Then the alarmed residents of high-rise buildings begin to find out from each other what happened to the water pressure and what it should be like under normal conditions.

Thermal manometer

thermomanometer in 3d

We had places where we needed local instruments for measuring temperature and pressure; in order to save space, it was decided to install a thermomanometer instead of a thermometer and pressure gauge. The thermomanometer is supplied with a valve so that it can be removed without depressurizing the system.

The price of a pressure gauge and thermometer at the same ROSMA is 350+685 = 1035 rubles, the price of a thermomanometer = 1110 rubles. Considering that you will need twice as many fittings, I see no reason to install a separate thermometer and pressure gauge.

Were ordered:

- Thermal manometer ROSMA TMBR - 31Р2(0-140°C)(0-0.25MPa)G1/2

- Boss No. 2 BP-BT-30-G½ (for BT thermometer)

Which fire extinguishers have a pressure gauge installed?

Types of fire extinguishers based on pressure:

- low, up to 2.5 MPa:

- high, from 2.5 MPa:

The principle of operation of a fire extinguisher is the displacement of fire extinguishing agent by the pressure created inside the cylinder. The color of the indicator scale sector and the digital indicator of the arrow position are the main indicators of serviceability.

For some models, checking with a pressure gauge is possible only after activating the cold gas source. Options:

| View | Peculiarities |

| Downloads | The gas inside the cylinder is directly from the OTV. The procedure is carried out at any time. |

| With a separate cold gas source (IGC) |

The internal source is not checked independently; this is done only with special equipment, since it is without a fitting and is disposable. |

The pressure indicator is built-in or can be inserted/pulled out. The sensor is not formally required, but without it, maintenance and monitoring of the condition of the fire extinguisher is impossible. Fire inspection services are not fined for the absence of a pressure gauge.

Types of devices

Pressure gauges are now very diverse and everyone chooses exactly the one that is most convenient for him. Here are the types you can find in car stores:

Mechanical option. This is the most common type of device, which has been used for quite a long time and has a number of advantages and disadvantages.

The main advantage of such a tire pressure gauge is its low price; in addition, it is very convenient to use.

- Brush with scraper - how to choose the best models and what a brush with scraper should be like (85 photos + video)

- Gasoline canister - features of choice and the best models of canisters. How to choose the best canister (85 photos + video)

- Spare wheel cover - how to choose and make it yourself. 135 photos of the best models of 2022

Rack pressure gauge. This option is similar to a ballpoint pen. It is more accurate in definition than the previous version. Mechanical ones are found on sale a little less often. But this type is very fragile and often inconvenient to use.

Electronic pressure gauge. It is quite accurate and has a lot of functions in its arsenal. However, its use is not the most convenient due to its constant dependence on battery power.

It can run out at the most inopportune time and is very expensive. It may look like a tire gun with a tire pressure gauge, or it may just be a mechanical one.

How to choose the right calibration service provider?

We buy testing equipment to perform certain measurements, on the basis of which a decision is made about the suitability or unsuitability of products. For these decisions to be correct, the equipment must be properly calibrated regularly.

We've covered some important aspects of calibration. When choosing a calibration service provider, you should ask the following questions:

- How were the procedures he used developed?

- what equipment does he use as standards?

- What reports does it provide to confirm the work completed?

- what measurement errors will it provide for the devices being tested?

- Is it accredited to measure the parameters necessary to test devices?

- Does it provide metrological traceability of calibration?

It is very common to find that laboratories differ in these parameters.

Once you have gained clarity on the technical aspects of calibration, you can explore other factors that are also important when providing calibration services. When choosing a calibration service provider, make sure that they:

What do the colored areas mean?

For the convenience of checking the working pressure of the cylinders, the pressure gauge display is divided into 3 color zones: yellow, red and green.

To make it easier to remember what the arrow readings mean in each zone, I suggest comparing the color display of the device with a traffic light.

We all know that green is a good color. If the arrow of the device is frozen in the green sector, then the cylinder is in working condition and its pressure is normal.

Everything is clear with red too. Red color indicates that the cylinder is faulty. Its pressure is not enough to extinguish the fire and it must be urgently sent for inspection and refueling.

But what does the yellow zone mean?

This is the intermediate sector, as in a traffic light, which indicates: “Attention!” That is, if the arrow points to the yellow zone, then pay attention to this

Check that the cylinder is positioned correctly. It may be exposed to direct sunlight, heating the balloon.

The most universal and common models with pressure gauges are powder cylinders designed to localize class A and B fires. They easily and effectively cope with extinguishing fires of solids and flammable liquids and gases. They can also be used to extinguish electrical installations if the voltage does not exceed 1000 V.

A pressure gauge is installed on the head of the powder devices, which indicates the operating pressure of the cylinder. Small hand-held fire extinguishers are mainly used by motorists. It is easy to check the pressure using the device, determining its performance.

Requirements for instruments for measuring pressure and their classification

Modern science and technology place a wide variety of demands on pressure measuring instruments. This is primarily due to the wide range of measured pressure values, from micropascals (µPa) to gigapascals (GPa). Requirements for measurement accuracy are increasing, research objects are becoming more complex, which impose additional conditions on the design of instruments. For example, instruments used to measure steady-state pressures are unsuitable for measuring pressure pulsations, and in real processes frequencies up to megahertz (MHz) are encountered.

The variety of requirements has given rise to a large number of devices, different in operating principle, measurement accuracy and design.

Conventionally, all devices for measuring pressure can be classified according to the following criteria:

a) by the type of quantity being measured;

b) principle of operation;

The established accuracy classes for pressure instruments correspond to the following series: 0.005; 0.02; 0.05; 0.1; 0.2; 0.5; 1.0; 1.5; 2.5; 4.0.

Classification according to the type of quantity being measured. Depending on the type of pressure measured (excess pizb

or absolute

pabs

) there are several types of devices:

a) pressure gauges – devices for measuring positive excess pressure;

b) vacuum gauges – devices for measuring negative excess pressure;

c) pressure and vacuum gauges - devices that allow you to measure both positive excess pressure and negative;

d) differential pressure gauges - devices for measuring the pressure difference at two points;

e) barometers - instruments for measuring absolute pressure equal to atmospheric pressure. To measure absolute pressure greater than atmospheric pressure, two instruments are used - a barometer and a manometer; less atmospheric - barometer and vacuum gauge.

Classification by principle of action. Instruments for measuring pressure are divided into the following types:

a) liquid - based on the hydrostatic principle of operation, i.e. the measured pressure is balanced by the pressure of a liquid column, the height of which is determined directly or by calculation.

The idea of measuring pressure by the size of a liquid column was first proposed by the Italian scientist E. Torricelli in 1640, and implemented by the Italian mechanic Viviani in 1642 and the French scientist B. Pascal in 1646. Liquid instruments have not lost their importance to the present day. This is explained by the fact that the operating principle of these devices is very simple. They are not difficult to manufacture, accurate and reliable;

b) mechanical - the operating principle of which is that under the influence of pressure, deformation of some elastic element occurs, and the magnitude of this deformation serves as a measure of the measured pressure;

c) deadweight - pressure gauges in which the measured pressure, acting on one side of the piston, is balanced by an external force applied on the opposite side of the piston. Weights are used as a balancing force. The weight of the load divided by the area of the piston determines the amount of pressure measured;

d) electrical - the principle of operation is based on a change in the electrical properties of certain materials or a change in any electrical parameters under the influence of pressure;

e) combined – the principle of action of which is mixed.

Classification by accuracy class. According to the accuracy of readings, all commercially produced devices are divided into classes. The accuracy class of a device is the main maximum permissible reduced error.

The established accuracy classes for pressure instruments correspond to the following series: 0.005; 0.02; 0.05; 0.1; 0.2; 0.5; 1.0; 1.5; 2.5; 4.0.

Mechanical devices are also divided into technical and exemplary. Exemplary ones are used for verification purposes, since they are compared with standard instruments. Technical ones are used directly to measure pressure.

Date added: 2014-12-30 ; ; Copyright infringement

Source

Seasonal car tire pressure

As a general rule, it is recommended to check your tire pressure every month, or even more often. This is necessary primarily for the safety of the driver, as well as to prevent premature tire wear.

A decrease in tire pressure in a car usually directly depends on the wear of the tires, air mixture, nipple, or rubber tubeless valve. It could also be an ordinary small “leak” of air that comes out through microscopic cracks between the rubber molecules of the tires.

Tire pressure under standard conditions drops by 0.2 bar every month. But the normal tire pressure for all passenger cars is considered to be from 2.0 to 2.5 bar, which depends directly on the air temperature.

In practice, very often there are car enthusiasts who believe that it is necessary to adhere to a single rule, namely, the pressure in the tires of the front wheels should be 2.2 atmospheres, and in the front wheels - 2.0. And when the car is loaded, its pressure in the rear tires reaches 2.4 atmospheres.

For normal and safe driving, it is imperative to adhere to all standards specified by the manufacturer. You should take into account the fact that when the temperature changes by 10 degrees, the tire pressure changes by 0.1 bar.

According to physics theory, air is a gas that expands when it is heated, or vice versa. During severe frosts and cold weather, you should always add 0.2 bar to the car manufacturer’s figure.

Also, many car enthusiasts argue that during icy conditions, the tire pressure should be lowered. It is then that the chain properties of car tires will increase. This is, of course, a lie. And in case it is a hot summer season, then the pressure in the tires of the car must be checked every 300-400 km of the trip. Because the temperature in them increases significantly due to the ambient temperature.

The vehicle's load, road surface and speed have a significant impact on tire pressure changes. To prevent the air from quickly escaping from the tires, it is recommended to fill them with nitrogen. This will avoid large temperature fluctuations, and the pressure will linger longer.

Since the car still has a “fifth wheel,” that is, a spare wheel, it also needs to be monitored for normal tire pressure readings. And anyway, who said that simply tapping your foot on the tires of a car is already a completed pressure check? Do not forget about your safety, ignoring all the rules.

Reduced tire pressure

When, during frequent checks of the pressure in the tires of a car, it is low, and this is after it has been normalized, then this is the first sign that either the rim or the tire itself is damaged. If this was not noticed by the driver in time, then the rubber of the wheel will begin to gradually deteriorate during operation of the car.

In case the tire pressure is less than 1.9 bar, then some troubles begin to arise because of this. For example, this can lead to a change in the angle of a car wheel by wearing off the tires and making them flat. If they gain a higher temperature, then this is fraught with their explosion.

Also, the tire bead can easily become damaged due to its separation from the wheel. If the pressure is low, then the tire sides bend, and fuel consumption also increases, since the area between the wheel and the road surface increases significantly.

Analog and digital

Digital inspection instruments can be either digital or analog. The former are considered more convenient. In them, indicators of force, voltage or current are converted into numbers and then displayed on the screen.

But at the same time, inside each such device there is an analog converter. It is often a sensor that takes and sends readings to convert them into a digital code.

Although analog instruments are less accurate, they are simpler and have better reliability. There are also varieties of analog instruments and devices that include amplifiers and value converters. For a number of reasons, they are preferable to mechanical devices.

Operating principle

In a deformation (spring) pressure gauge, water enters a curved tube made of copper alloy. The water pressure causes the tube connected to the mechanism to deform, which causes the needle to turn.

Pressure gauges with a single-turn spring are designed for pressures up to 100 atm. To measure higher pressures, springs with several turns twisted into a spiral or screw are used.

There are devices in which a thin two-plate membrane is installed instead of a tube. They are suitable for viscous or contaminated solutions, withstand strong vibrations, but are sensitive to temperature fluctuations.