The type of lift drive is essential. The cost here directly depends on the configuration and functionality. A simpler option is the electromechanical model. The design is simple, which ensures ease of operation. It is necessary to monitor the connections so that the equipment does not wear out. We will indicate the most important points.

- Electromechanical lifts do not have stoppers. This slightly reduces the level of security, but increases the speed and efficiency of work.

- You can make equipment more durable if you lubricate it regularly.

- Single motor models have chain and belt drives which make the lift less reliable. A more modern version has a transmission shaft that transmits force to the second column. This increases the level of security.

- If there are two engines, they are synchronized by a special electronic program. It is extremely important that the control system is of high quality and reliable, since the effectiveness of work and safety depend on it.

- The electro-hydraulic drive ensures smooth, quiet, high-speed work. At the same time, significant energy savings are guaranteed.

- Among the different types of lifts, two-post and single-post lifts are in the greatest steady demand. They save space, are simple in design and reliable.

- It is extremely important to consider the height of the ceiling when choosing a specific type of lift. Unfortunately, most garages have fairly low ceilings, making it difficult to accommodate large lifting equipment. Sometimes, if possible, it is worth building an additional garage height.

The speed and height of lifting, the level of load capacity, as well as design characteristics must be taken into account. Remember that this is important equipment, so you should trust only manufacturers with a good reputation and experience.

Article on the topic: How to install a vice in the garage

Reliable installation is a prerequisite for successful and safe operation

Many people are interested in how to install a lift in a garage. It is important to make a solid foundation, reinforce and fill it well, and securely fasten the structure. Otherwise, even high-quality equipment can become dangerous and ineffective.

Minimum paw lowering height

The lower point of descent is of great importance. This is why they choose a garage with a lift. The plane at the bottom point should be flat. The minimum lowering height of the lamps differs among different manufacturers. However, there is a standard: a maximum of 110 mm and a minimum of 95.

Determining the height of the ceiling

It is necessary to correctly calculate the height of the ceiling along with the lift. In this case, the raised trunk is not taken into account. The type of equipment also matters. When the model has retractable legs, you need to subtract the height between the bottom of the car and the floor from the final figure, this is approximately 300 mm. If the lift is overpass, the height of the machine is added to the formula.

Pay attention to the approximate parameters. Overpass lifts are 440 cm for an SUV, and 3990 cm for a passenger car. The model with retractable legs for an SUV has a height of 410 cm, and for a passenger car - 360 cm.

What will the job require?

Before you start creating a lift, you need to decide on the design of the future device. To do this, it is recommended to pay attention to those items that are already offered on the market, find out their structure and understand what materials will be needed to create the equipment.

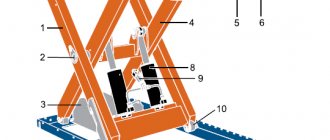

Garage lift diagram.

To make a lift, you need the following tools and materials:

- steel corners measuring 7.5*7.5*0.8 cm;

- worm-type gearbox, with a load capacity of 300 kg and a gear ratio of 60 kg;

- steel plate 1 cm thick;

- bolts;

- 2 dense iron chains with a diameter of 2-3 cm;

- hook;

- steel rope;

- 2 keys with different diameters in the shape of an asterisk.

When preparing a drawing and project for a future car lift, you must, first of all, remember about work safety. It is recommended to choose materials and design with reserve so that the device is durable and the user can operate it safely.

Under no circumstances should you make a garage lift out of wood, as the material can age, which can lead to accidents. It is important to firmly secure the tipper to the floor and make a good connection to the vehicle.

Consider the load capacity and the number of people who will take part in turning the car over when creating the drawing. When choosing a lifting angle, it is more practical to do it with a larger degree. It is also important to regularly inspect the mechanism during operation.

Article on the topic: How to make a garage in Minecraft without mods

Step-by-step installation of a lift with your own hands

Having chosen the right car lift, you do not get a guarantee that it will work properly. For comfortable operation, the device must be installed. The main condition for successful installation is the high reliability of the garage foundation.

Installation of a solid base

The area of the garage in which the car lift will be installed using fastenings must have a thickness of concrete material of at least ten centimeters. In addition, when pouring concrete, the layer of material is additionally reinforced. Without reinforcement, the foundation may be pushed through. In such a situation, it will be necessary to dismantle the car lift and re-fill the foundation.

Calculation of the minimum height of paw lowering

When installing the lift, you need to determine the minimum height for lowering the legs. The plane below should be level. The minimum height to which the arms of the equipment can be lowered depends on the specific model of the device.

However, there is a standard: the maximum height is 11 centimeters, the minimum is 9.5.

Assembly of the structure

The equipment must be positioned according to the length of the machine. On average, the bumper of all cars protrudes about two meters from the center of the lift holders.

At the next stage of installing the car lift, it is necessary to install its frame and fix it. Next, the solution is poured. Before pouring, you need to check whether the frame is symmetrical. After the solution has hardened, you need to tighten the bolted connections. This will allow the frame to be securely fastened.

The bolts are installed in the grooves of the risers. The minimum length of bolts is 22 centimeters. After tightening the bolts, tighten the nuts. Attaching the stands to the frame is carried out in accordance with the instructions supplied with the equipment.

Preliminary height adjustment is necessary for screw car lifts. If the lift operates hydraulically, the cable must be pulled. Then all the chains are installed, and the quality of tightening of bolted connections on the frame floors is checked.

If, when tightening bolted connections, the frame is displaced and the symmetry of the racks is disturbed, metal plates are placed under them. Metal plates are usually supplied with the car lift.

Article on the topic: How to issue a deed of gift for a garage in Belarus

Electrical connection

After assembling the structure, electrical cables are connected and emergency switches are installed. To do this, it is advisable to call an experienced electrician who will carry out the procedures according to the wiring diagram. If you know how to build electrical circuits, you can do it all yourself. Whether the lift drives will work properly depends on how correctly the electrics are connected.

Checking operational readiness

Hydraulic lifts must be filled with oil. After this, you need to check the equipment. To do this, lowering and raising are performed several times.

Make sure there are no grease leaks anywhere. It is recommended to check the condition of the equipment at least once every six months.

see also

Comments 71

In St. Petersburg the price is from 8tr + oil and anchors from the official companies. From leftists and individual entrepreneurs it is possible for 5 + oil and + anchors

I installed an Italian two-post at work, with lower synchronization. According to the passport, it is provided to cast a slab 1.5 X 4 meters in level. Thickness 0.3m. The fittings are 12 mm, the spatial grating is 15 cm apart. The grating is welded. About the composition of concrete it is written M250. In fact, they were cast 0.5 m thick. Then, according to the markings, we drilled holes for M16 studs. Strength class of studs is 8. The thickness of the washers is 6mm, sharpened from Steel 65G and normalized. Double height nuts with skirt, strength class 8. The studs were placed on chemical anchors. Three days after polymerization, the lifts were installed and the nuts were tightened. All.

The store told me two separate pillows 1m*1m*0.5m, reinforcement from level -0.5 to -0.2, at level -0.2 to put a road mesh, but they didn’t indicate the thickness of the reinforcement

These are the requirements of the factory passport. 3 ton lift. Synchronization from below with shaft. The passport also included a version of the lift itself with a standard frame. Those. the columns were mounted on a factory transverse frame, and the synchronization shaft was hidden in it. The frame contained longitudinal channels No. 14, rolled 1.5 m forward and 2 m backward. Under this frame, at the location of the mounting holes, casting anchors 0.5x0.5m were provided. Depth 0.8 m. 4 on the right and 4 on the left: along longitudinal channels. M16 studs. Those. All the loads were taken by the frame.

At the top, the distance between the posts should be 1-1.5 cm greater than at the bottom, well, the anchors are normal and everything will be fine)

Article on the topic: How to remove the smell of diesel fuel in the garage

There were two people with a child. easily . about 3 business hours. If you know how to do it. The main thing is to align the racks vertically. and normal anchors.

You guys are not turning your attention to the right place. Look at the design of the locking mechanism when purchasing a Chinese product.

Why complicate things by tying traverses to the walls? I poured half a cube of concrete under each rack 400 1x1 and 0.5 deep, anchors for 200 and it doesn’t move

I stretched it in the corners with chains, everything became very rigid. Cars do not rock at all during repairs. I recommend.

chains limit travel only in one direction (stretching) maybe better than pipes?

So, when lifting the machine, the columns of the lift rush towards each other and fold, and the chains in the walls hold them.

It’s true, the weight of the car pulls them inward, the chains don’t let them, but they won’t let the racks with the car swing in just one direction. therefore, with pipes the rigidity would be higher. I had a Chinese lift that was completely damaged to death. I had to make a truss between the posts, and two pipes per post to support the wall (triangle). it turned out pretty tough. for the crazy Chinese shit

So I have chains on all 4 corners. That's why the car doesn't rock

But I realized that I thought that there were two chains per rack and they prevented the rack from tilting only inward. If they are stretched in all directions then yes. It becomes noticeable that the rigidity of the structure has become higher. In fact, the design is becoming more rigid.

I agree, especially when you lift a heavy jeep, the chains are like strings)))))

Why complicate things by tying traverses to the walls? I poured half a cube of concrete under each rack 400 1x1 and 0.5 deep, anchors for 200 and it doesn’t move

There is no reason to question here. If the lift swings from the foundation, then it is not the foundation. The lift stand, although a thick piece of iron, can bend back and forth on its own. The more it bends and sways, the more the geometry is disrupted. even a simple force connection at the top significantly increases the bending rigidity of the structure (and a raised car tries to bend the racks inward. Pull a tape measure between your racks, secure it and lift the heavier car under the sky. You’ll immediately see the centimeters by which the racks are bent. But with a spacer you can’t It will be, but if you attach triangles to the walls, then the car will sit very rigidly.

Article on the topic: How to make a closet for a garage

The design of the lift does not provide for any other attachment other than to the floor, the racks most likely play under load, but so what, but it never occurred to me to measure with a tape measure, and I couldn’t even measure through a car. I haven’t lifted light cars, only minibuses and SUVs like the Prado 120 -150,

Well, yes, the stand plays under the weight. good lifts have less, crap lifts have plus or minus half a meter

Do not forget about the minimum lowering point - it should always be level. It may differ for different models, but all correspond to the same standard: from 95 to 110 mm.

Calculate the height of the lift with its arms raised as high as possible and compare it with the height of the ceiling. If the equipment has retractable arms, these must also be taken into account. For an overpass lift, you also need to add the height of the machine.

Do-it-yourself garage door finishing from the outside

Making racks and shelves for the garage with your own hands

Garage interior decoration

Exterior decoration of the garage

DIY garage interior design

Types of lifting devices

Today, manufacturers offer a wide range of lifting equipment for garages and car repair shops.

- Depending on the installation method, devices for servicing vehicles can be stationary, mobile or portable.

- Floor and pit lifts are available.

- Based on the type of drive, the units are classified into several categories: mechanical, pneumohydraulic, hydraulic.

The most affordable are electromechanical devices, which are easy to operate and maintain.

For those who want to have equipment in their garage that runs smoothly and quietly, you should pay attention to models with an electro-hydraulic drive. Their installation is not much more complicated than their analogues, but their operation is much more pleasant. In addition, the speed of work significantly increases.

Important! If the unit is equipped with two motors, it is recommended to pay attention to the synchronization program. If the software fails, the effectiveness of such technology will drop sharply. And equipment safety too.

Depending on the type of racks, there are several types of lifts.

Article on the topic: How to make a garage out of Lego

Single column units

The main part of the design of such a device is a single supporting rack, which is equipped with powerful brackets for lifting loads. It does not require a large space to install. In some cases, this is the determining factor for acquisition.

Lifts can be mobile or permanently fixed. They are usually designed to lift equipment weighing up to 2.5 tons.

Two-rack devices

It is no longer possible to move such equipment. It is fixed to the floor surface using anchor bolts. Two racks allow vehicles weighing typically up to five tons to be lifted for maintenance.

Four post lifts

These units are a platform mounted on four supporting posts. They are designed to lift any equipment, even heavy ones.

Scissor equipment

Lifts have both mechanical hinges and hydraulic cylinders, which are designed to raise and lower the platform.

Most often, such models are built into the floor. Scissor lifts are characterized by reliability and their operation is quiet.

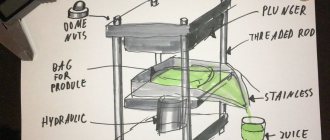

Plunger

This hydraulic design is equipped with plunger cylinders that can be recessed into the base or located on the surface.

- Plunger lifts are great for saving space in the garage (when folded) and provide access to the car from all sides. The number of plungers can be different - from one to four. When operating multi-plunger technology, synchronization circuits are used.

- For personal use, one- or two-rack units are usually purchased, most often of the electromechanical type. The characteristics of such equipment are quite sufficient for the repair of passenger vehicles. It is not difficult to maintain, and a small garage box with a ceiling height of 3 m is sufficient for installation.

- Units of a higher category are usually installed at service stations.

- An interesting option for a private garage, characterized by its simplicity of design and affordable cost, is a mobile lift-lift. Such models are adapted to work with most types of passenger vehicles and even minibuses. This device is of the mechanical type. It is driven by a drill or hammer drill.

- Such a device for lifting vehicles is very convenient and does not take up much storage space. There are no requirements for the dimensions of the garage when placing such equipment, including the height of the ceilings. It takes a couple of minutes to install the lift under the car and raise it.

Article on the topic: What kind of foundation for a garage is made of expanded clay concrete blocks

Of course, the scope of application of such a device is quite limited. With its help, you can perform only part of the maintenance work on the iron horse.

Four-post design type

This type of lift consists of 4 columns with a lifting platform in the middle. Thanks to the hydraulic lifting system, the equipment operates quietly and neatly. This type of car lift can be used to service many cars, including sports cars with low ground clearance.

Lifting platforms on this type of structure can be of three types:

- Smooth;

- Long smooth;

- For wheel alignment.

On such lifts, sliding plates are placed under the rear wheels, which provides a slight lift of the car being repaired at an angle. Micro-lifts installed on individual models also help with the work. The four-post lift design is used in the maintenance of special equipment and trucks in all types of car repair shops.

Tips for choosing a garage lift

For an ordinary garage, the best option is to install a one- or two-post electromechanical lift, since such a unit is reliable and has a load capacity sufficient for repairing a passenger car. In addition, this type of equipment is compact (small room height is suitable and there are fewer requirements for the size of the garage box) and does not require special knowledge for maintenance. The small size of this equipment allows it to be installed even in small rooms with a ceiling height of 2 meters.

A higher-class lift is rarely used for private needs; its place is in a car repair shop, not in a garage.

Also be sure to take the height of the room into account. The small height of the garage for a lift simply technically does not allow the installation of powerful equipment, and it is not necessary for a private owner.

When choosing a lift, pay attention to:

- Load capacity,

- Load lifting speed,

- Design features (size, weight and configuration).

Don't want to make a fatal mistake and purchase low-level equipment? Do not trust unknown manufacturers - we advise you to choose NORDBERG and Trommelberg brands.

Optimal dimensions and height

Not every garage will be able to install a car lift. For example, if you are the owner of a minibus, which almost touches the ceiling when entering the garage, there is no question of any single/two-post lift. The garage space must have appropriate dimensions.

Next, you can familiarize yourself with the minimum garage dimensions required for a certain type of car. Add to the height of the garage the value of the height to which you plan to raise the car. This way you will determine what minimum height the garage ceiling must have to install a car lift.

For passenger cars

The length of the garage should be three meters greater than the length of the car, and the width should be the same. The optimal height is three meters.

For jeep

The length, width, and height of the garage space for a jeep or other SUV should be eight, five, three meters, respectively.

For minibus

If you own a minibus, the garage should be large. The optimal length is seven and a half meters, width is five meters. The minimum garage height for a minibus is three and a half meters.

If you have a Gazelle cargo truck with an extended platform, the length of the garage space should be ten meters. The minimum height here increases to four meters.

How to install a car lift in a garage

In order to install a lift in the garage, you must perform the following steps:

- Prepare the surface for installation of equipment. The thickness of the concrete platform must be at least 10 cm. It is not recommended to install the device on a freshly poured concrete floor; at least 25 days must pass from the moment of pouring.

- It is prohibited to install the lift near the storage area of flammable materials and substances, as well as near the painting and washing area.

- The area around the equipment must be sufficiently illuminated.

- Before installation, it is necessary to provide for the direction of entry of the vehicle, and also correctly calculate the height of the mechanism so that it does not rest against the ceiling.

- Align the frame to the height of the equipment and secure it with fasteners.

- Insert mounting bolts into the riser holes and tighten the nuts. The length of the bolts must be at least 22 cm.

- Attach the posts to the lifting device support frame.

- Before installing the screw lift, you need to align the height of the posts.

- Before installing hydraulic equipment, it is necessary to stretch a special cable, put on all the chains and check their tension.

- After installing the frame, connect the electrical equipment and install emergency switches. To do this, you need to fill the oil fluid to the required level and test the auto-lifting device.

- Raise and lower the loading platform several times. In this case, it is necessary to check whether there is any leakage of working fluid.

- To connect the hydraulic system, raise the loading platform to half its maximum height, open the front of the control panel, route the hydraulic hoses and connect them to the fittings. All elements must be well fixed and tightened.

- The pneumatic system is connected using special hoses. They need to be attached to the air valve, which is located in the system control unit, connect the compressed air mechanism and check the functionality of all parts.

- At the very end, it is recommended to do several test lifts of the platform.

Article on the topic: How to make a garage entrance with your own hands

Garage lift: what is it and what is its purpose?

A garage lift is one of the most popular and necessary types of equipment intended for use in a garage for the purpose of not only maintenance, but also repair of various car models.

Thanks to its use, you can

easily raise the car to a height that will allow you to carry out an inspection, perform the necessary operations, carry out plumbing work, which involves diagnosing the functioning and repairing the transmission, hanging the wheels and repairing the exhaust system.

Quite often in the garage, lifts turn out to be simply indispensable for carrying out tasks with engines or electrical wiring.

In addition, this is much more convenient and practical, because by lifting the car, all components and individual parts are well exposed. Therefore, even without additional lighting, it is possible to carry out both detailed diagnostics and repairs .

Today, there are also several alternatives to the use of lifts - these are overpasses and special inspection pits .

An overpass is an engineering structure that has an elongated shape and is constructed from a number of spans and supports of the same type. It is intended to facilitate inspection of the engine and other components of the vehicle by raising the vehicle to a certain height.

The inspection hole is a recess that is made in the central area of the garage. The main advantage of such a device is that it can be used to effortlessly repair car parts located in very hard-to-reach places in its lower part.

There are stationary and mobile car lifts for garages. However, they can also be distributed according to the list of technical characteristics: the speed and height of the vehicle, the number of racks, as well as the power of the electric motor of this equipment.

Stationary lifts come in scissor , single-post , two-post , and four-post types . Recently, two-post scissor lifts, which can be either passenger or cargo . Mini garage lifts are also gaining popularity.

Related article: How to fix a metal garage roof

Look at the photo - a mini garage lift :

Single-post car lifts A single-post car lift is equipped with one post that lifts the car from one side. It has a small carrying capacity compared to other types of this equipment. The mobile version is convenient for use in confined spaces.

Four post car lifts

When using a four-post lift, the machine is installed directly on the wheels . Such lifts are characterized by the presence of an electro-hydraulic drive, as well as a special platform. They are installed, as a rule, at posts for the purpose of checking gatherings. For carrying out entrance control of vehicles, they are quite inconvenient because they are not travel cards.

Two post car lifts

Perhaps this is the most convenient and most popular garage lift . It is quite easy to install and has a simple technical structure. The carrying capacity of different equipment models is about five tons . In most cases, they are used to service the chassis and wheel drive. This type of lift is not equipped with a platform , so the machine is suspended.

The main advantage of this lift is that there is no need to perform preliminary preparation of the vehicle.

It is easy to work with cars, small buses, jeeps and other car models. This is the most versatile and necessary equipment for fairly quick tire fitting.

Such lifts are divided into three types - electrohydraulic , pneumatic , and electromechanical . Pneumatic devices lift cars using compressed air .

Electromechanical equipment has a simpler structure, which is much more convenient to use. Electro-hydraulic car lifts operate using hydraulics, it is safer to operate and durable.

Scissor car lifts

Today, scissor lifts for garages are very popular. They are characterized by compactness, which makes it possible to save enough useful space. The structure of the device is the simplest: it consists of a platform - special scissors with an electro-hydraulic drive.

Related article: How to fix a metal garage roof

There are two types of scissor lifts: low-profile and floor-mounted car lifts They are highly reliable and also heavy-duty.

Plunger car lifts

Plunger lifts are one of the latest development options for car repair shops. The equipment is considered quite progressive . Its price is high , but all modern automobile workshops prefer this model for their business.

The design of such a device is not complicated - it consists of lifting beams placed on plungers (hydraulic cylinders). The latter are installed directly into the garage floor.

In case of absence of work, this lift can be easily hidden in the floor, as a result of which they will be practically invisible. Attention can only be paid to the grabs. If the device needs to be activated, the plungers will rise from the floor at the operator’s command in just a few seconds.

a homemade car lift for a garage looks like :

Which foundation to choose?

It is important to remember that all these measurements will be useless if you do not first take care of the foundation strength necessary for this very installation. The primary requirements for it are, of course, external integrity, density, the absence of any irregularities or differences, etc.

It is recommended to take this issue as seriously as possible - after all, even if installing a lift on a crooked or cracked foundation is successful, there is no guarantee that everything will not go awry when lifting the first load. So negligence and neglect are almost guaranteed to lead not to additional savings, but, on the contrary, to even greater expenses:

Foundation for the lift

It is prohibited to install lifts (as well as other massive structures) on a recently poured foundation. The optimal time required for compaction and hardening of concrete is about 30 days. To further strengthen and seal microscopic (and other) holes on its surfaces, polymer and paint coatings, silicone, rubber and ceramic tiles are used, which also contribute to less friction and abrasive wear of the floor.

Types of lifts

Do-it-yourself lifts can be:

- screw;

- hydraulic;

- chain

Screw platform lift

In this case, it is recommended to give preference to the screw type in the form of a platform. To make a lift for a car of this type, the structure is made in the form of rolled elements placed parallel to each other with the ribs down. They are attached to a drive mechanism that ensures the platform is raised.

In these types of lifts, the requirements for shafts are significantly lower. This is explained by the presence of four of them (not two). The main disadvantage of such lifts is the need to use a jack to repair the suspension. This is explained by the fact that the wheels of the car do not hang in the air, but are on the surface of the channels.

Screw car lift - operating principle

Other popular types of lifts

Very often, forklifts and platform lifts for cars are made with a chain drive. In terms of their performance characteristics, they are not inferior to screw ones. But it is quite difficult to make such a design on your own. This is explained by the need to ensure coordinated operation of engines and braking devices.

Chain car lift - diagram

The scissor type of lifting mechanisms most often operates using a hydraulic drive. But many craftsmen decide to equip them with a screw or chain mechanism, which they most often do with their own hands.

Scissor car lifts

These systems are intended for maintenance or adjustments. Among the advantages is the possibility of installation flush with the floor surface. Due to the design features that allow the system to be folded, the unit is quite compact.

In most cases, lifting a machine on a lift of this type is carried out using a hydraulic drive. Due to this, silent operation, smooth running, and high durability are achieved. There are stationary or mobile models. Portable versions are used for quick maintenance outside the workshop. As for the main characteristics, the load capacity is only up to 5 tons. The main disadvantage of these designs is the high price.